Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Reduce processing preparation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

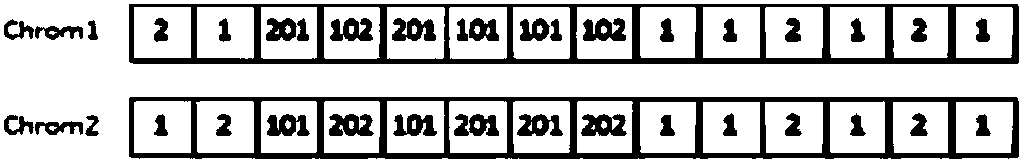

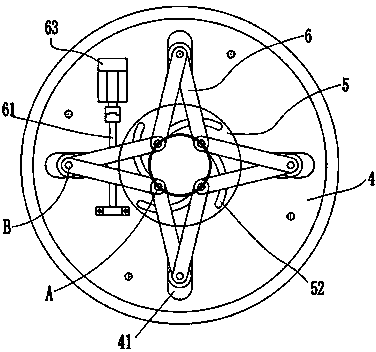

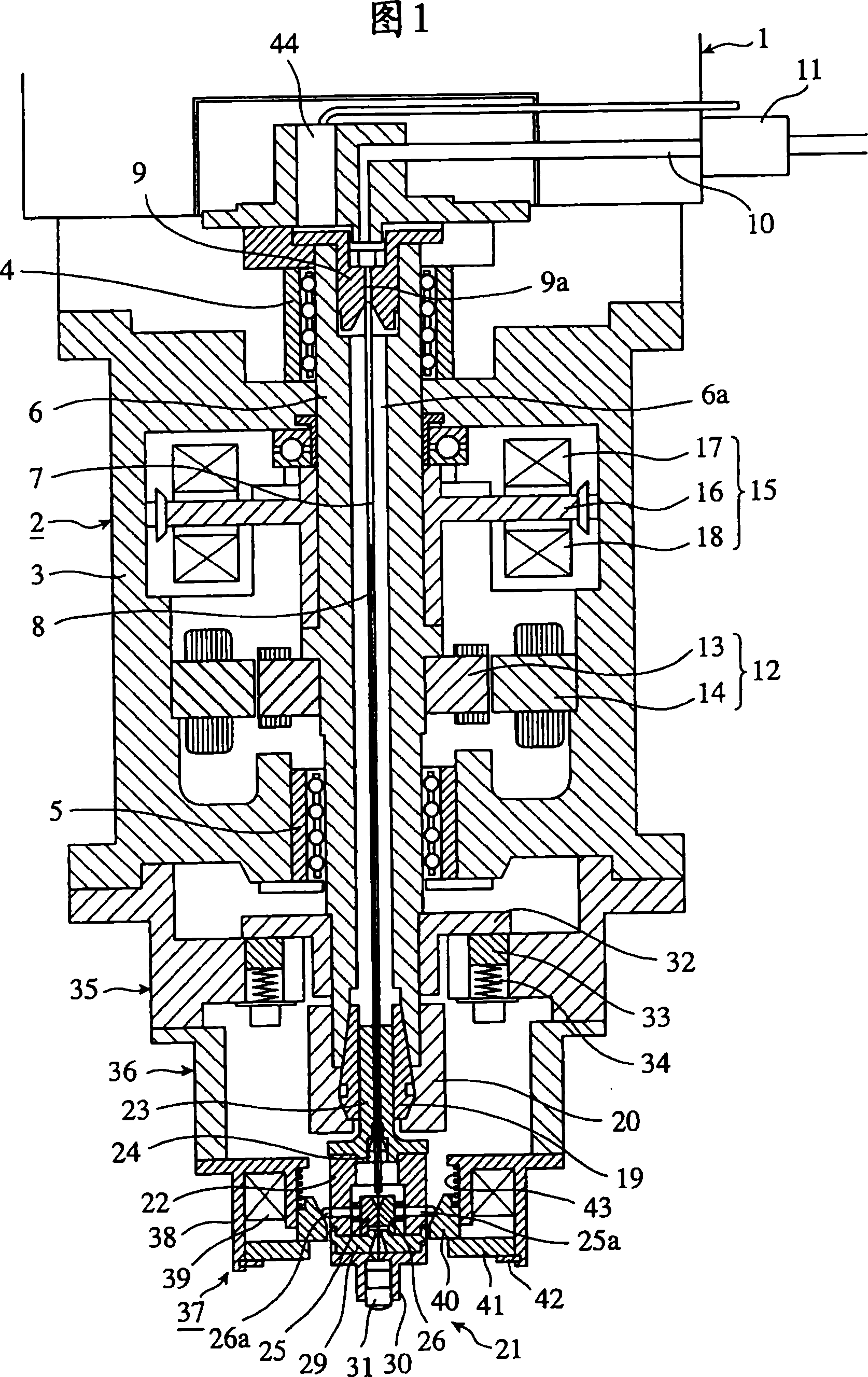

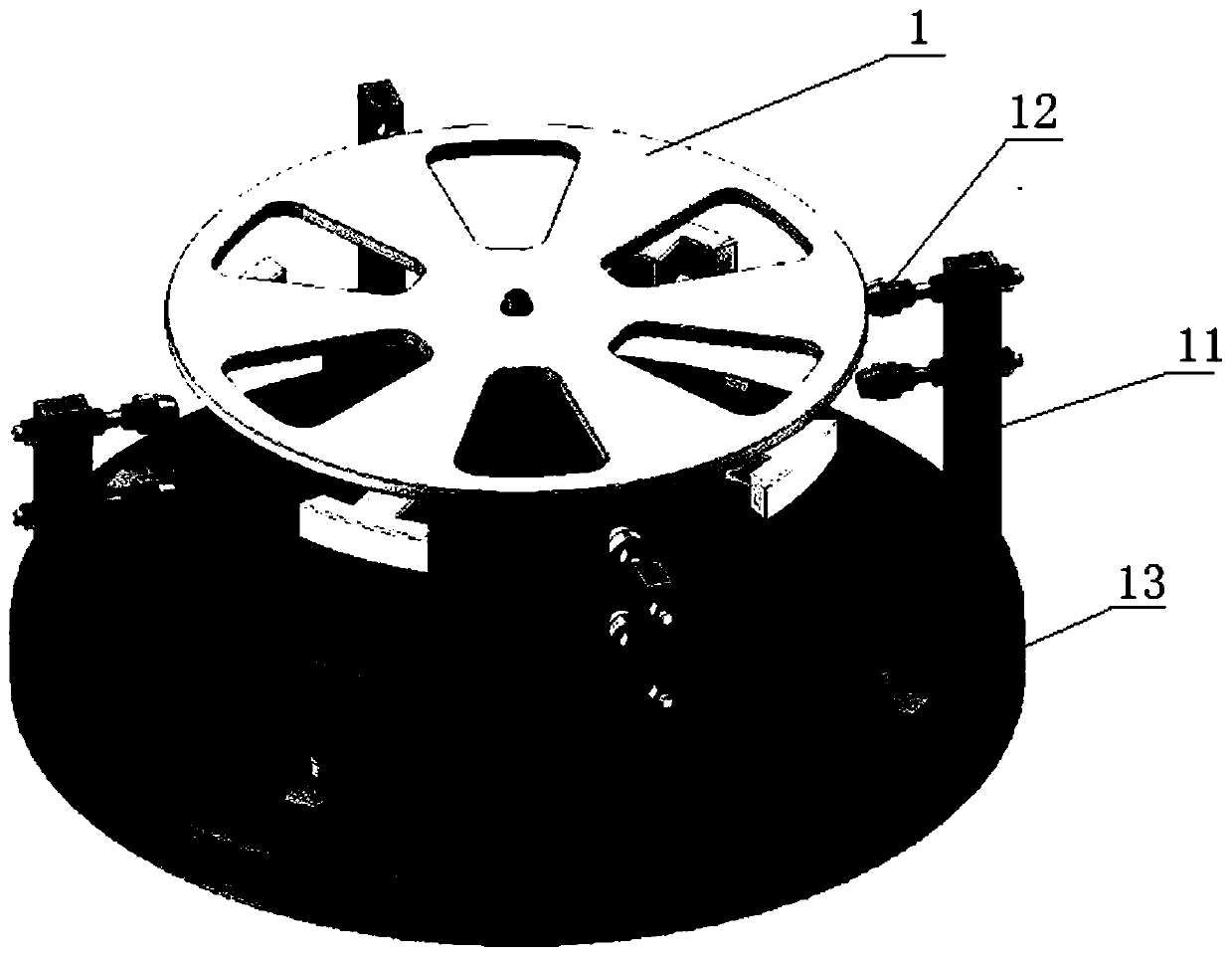

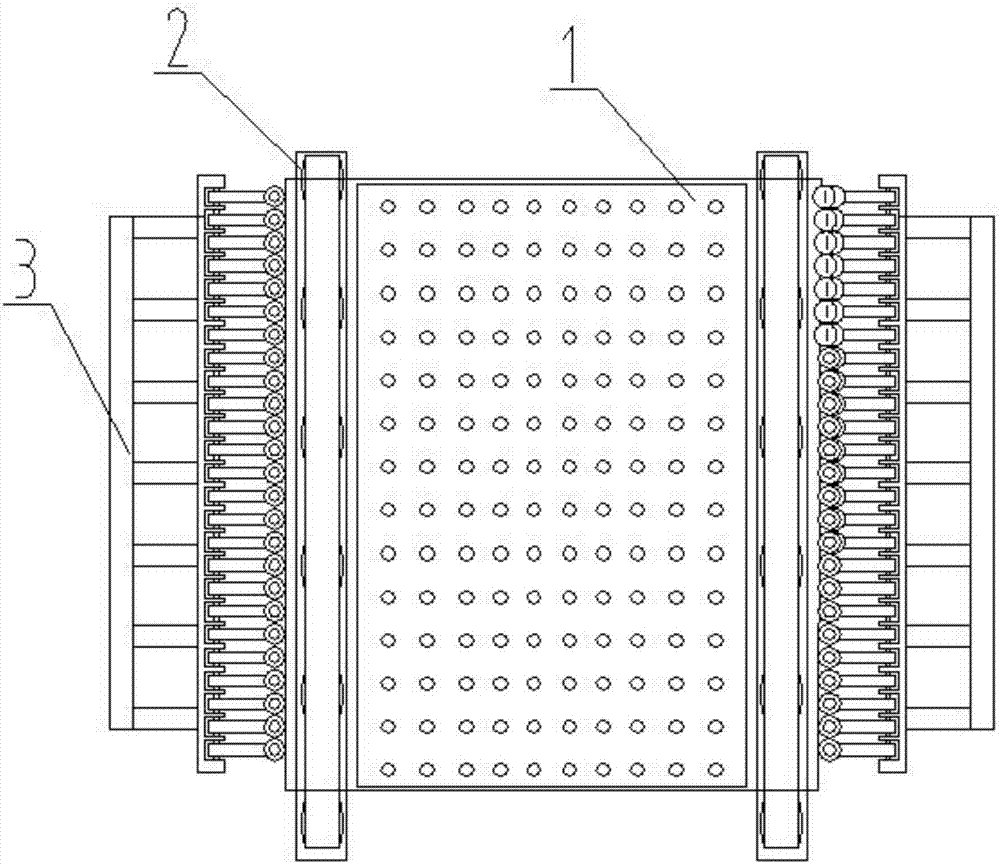

Self-centering clamping device of drill press workpiece

ActiveCN103801959AImprove processing efficiencyEasy to operateWork clamping meansFeeding apparatusLathe faceplateEngineering

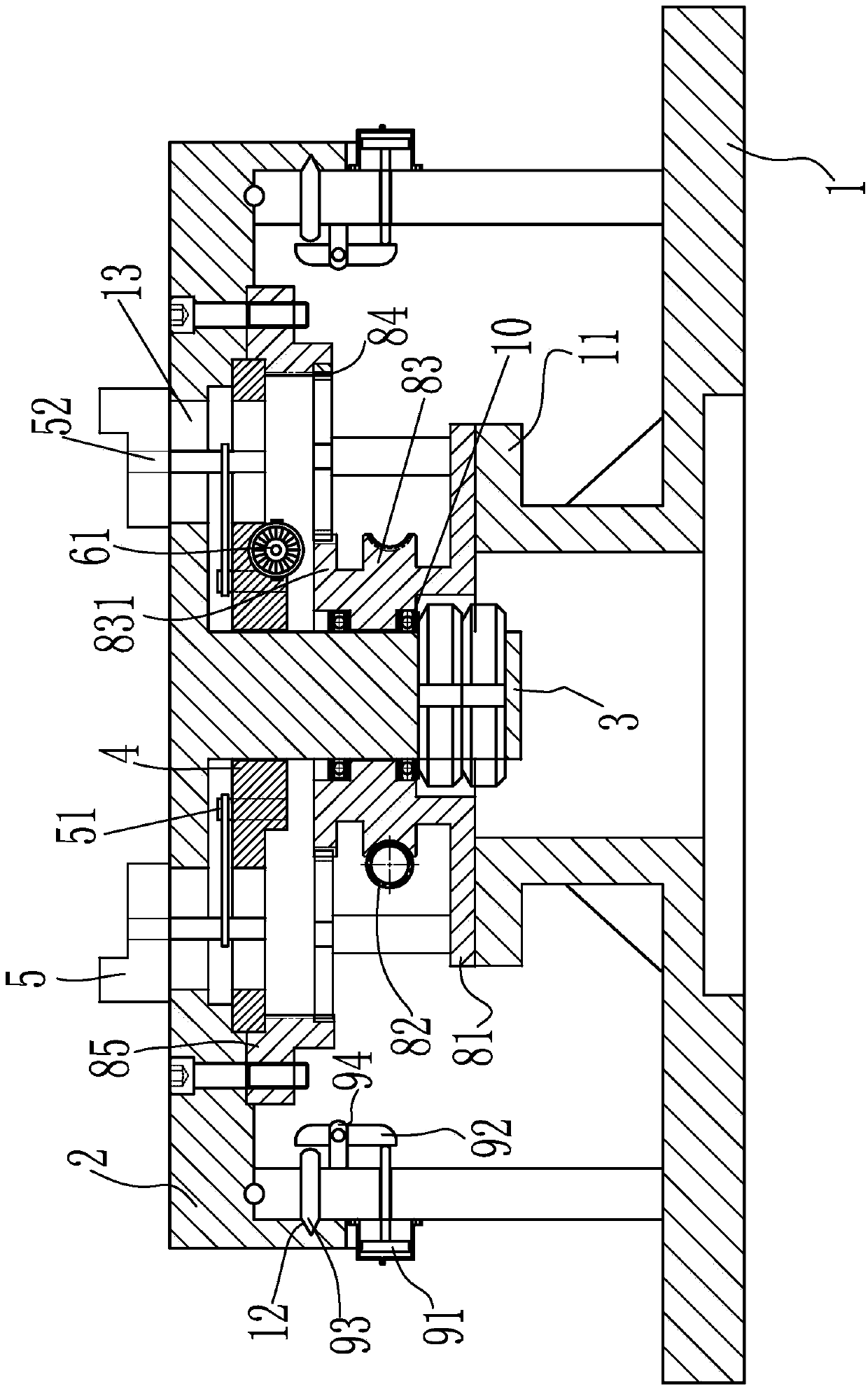

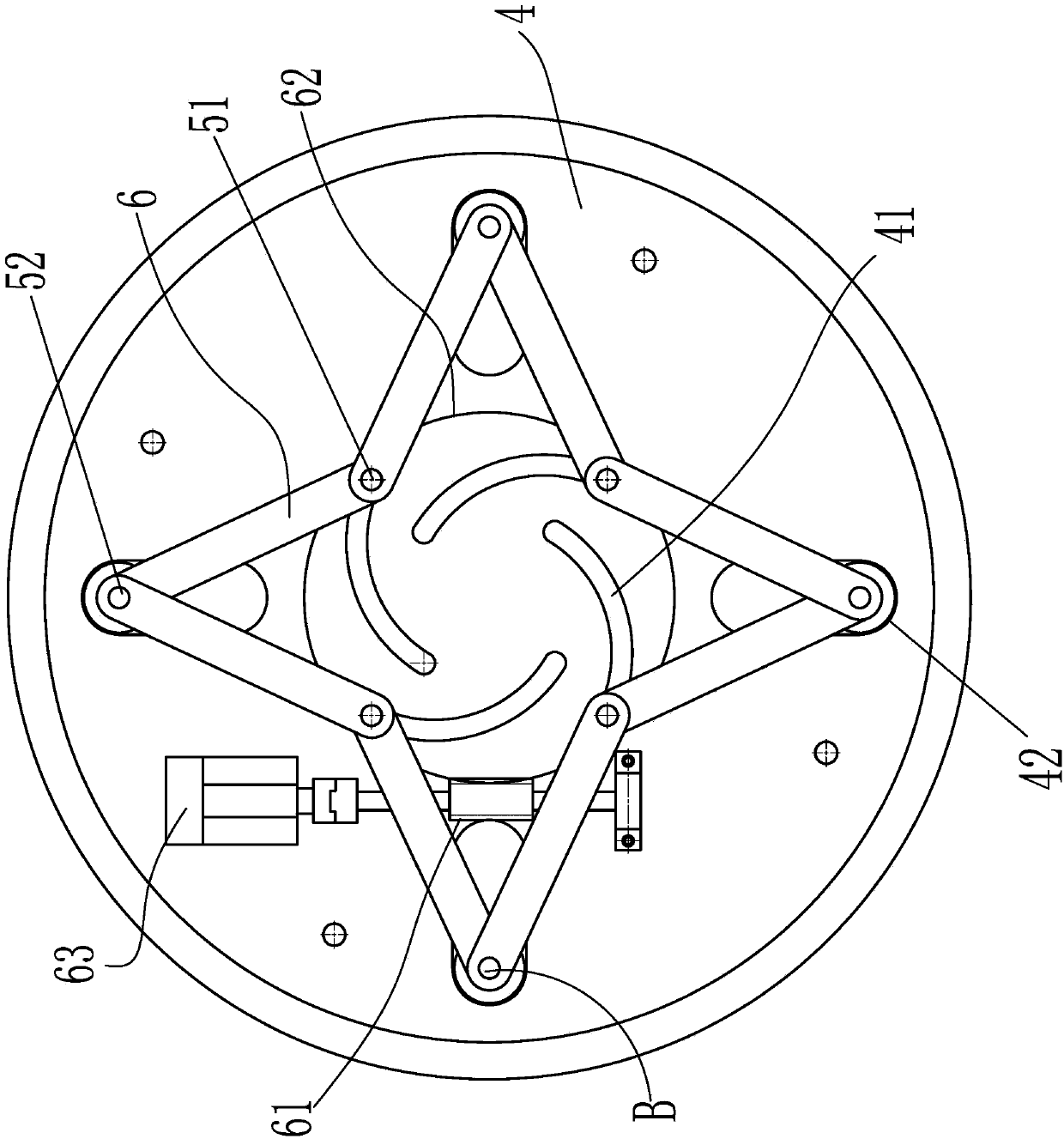

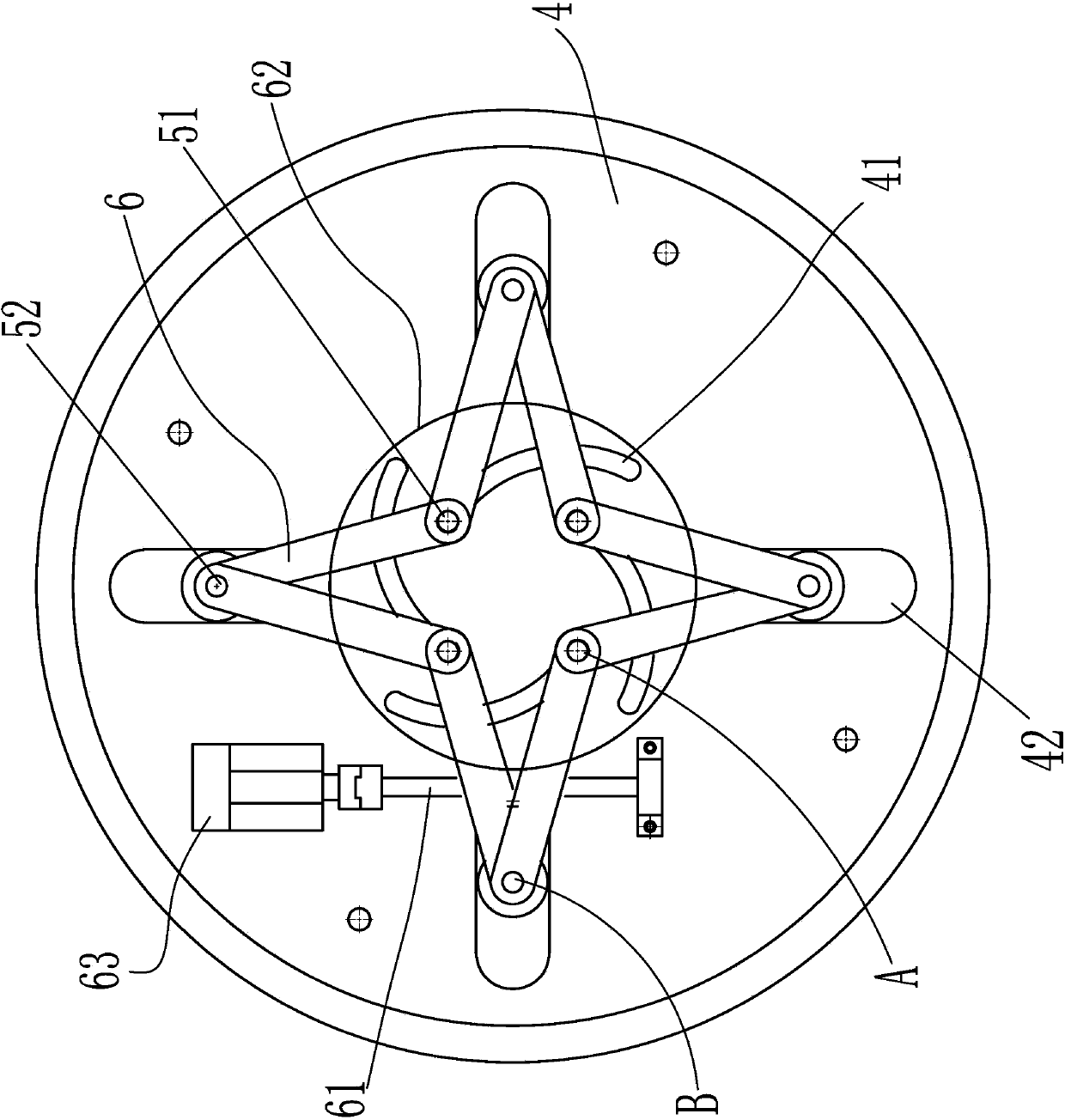

The invention provides a self-centering clamping device of a drill press workpiece. The device can realize the self-centering function for a workpiece. The device comprises a connecting base, a workbench rotary disc, a main shaft, a parabola self-centering flower disc, a plurality of connecting rods and a plurality of positioning pawls, wherein the workbench rotary disc can be arranged above the connecting base in a rotary way, the main shaft is fixedly arranged below the middle part of the workbench rotary disc, the parabola self-centering flower disc can be arranged below the workbench rotary disc on the main shaft by a transmission mechanism in a rotary way, arc-shaped gradually slotting grooves are uniformly formed in the parabola self-centering flower disc in the radial direction, the head of one connecting rod is hinged to the end of the other connecting rod, both ends of each of the connecting rods are respectively a first hinging end and a second hinging end, the first hinging ends are respectively hinged to the arc-shaped gradually slotting grooves on the parabola self-centering flower disc, long hinging grooves corresponding to the positions of the peripheral sides of the arc-shaped gradually slotting grooves are respectively formed in the parabola self-centering flower disc, the second hinging ends are respectively hinged to the long hinging grooves in a hinge way, and the positioning pawls are respectively arranged above the second hinging ends of the connecting rods.

Owner:HUHANG TECH GRP CO LTD

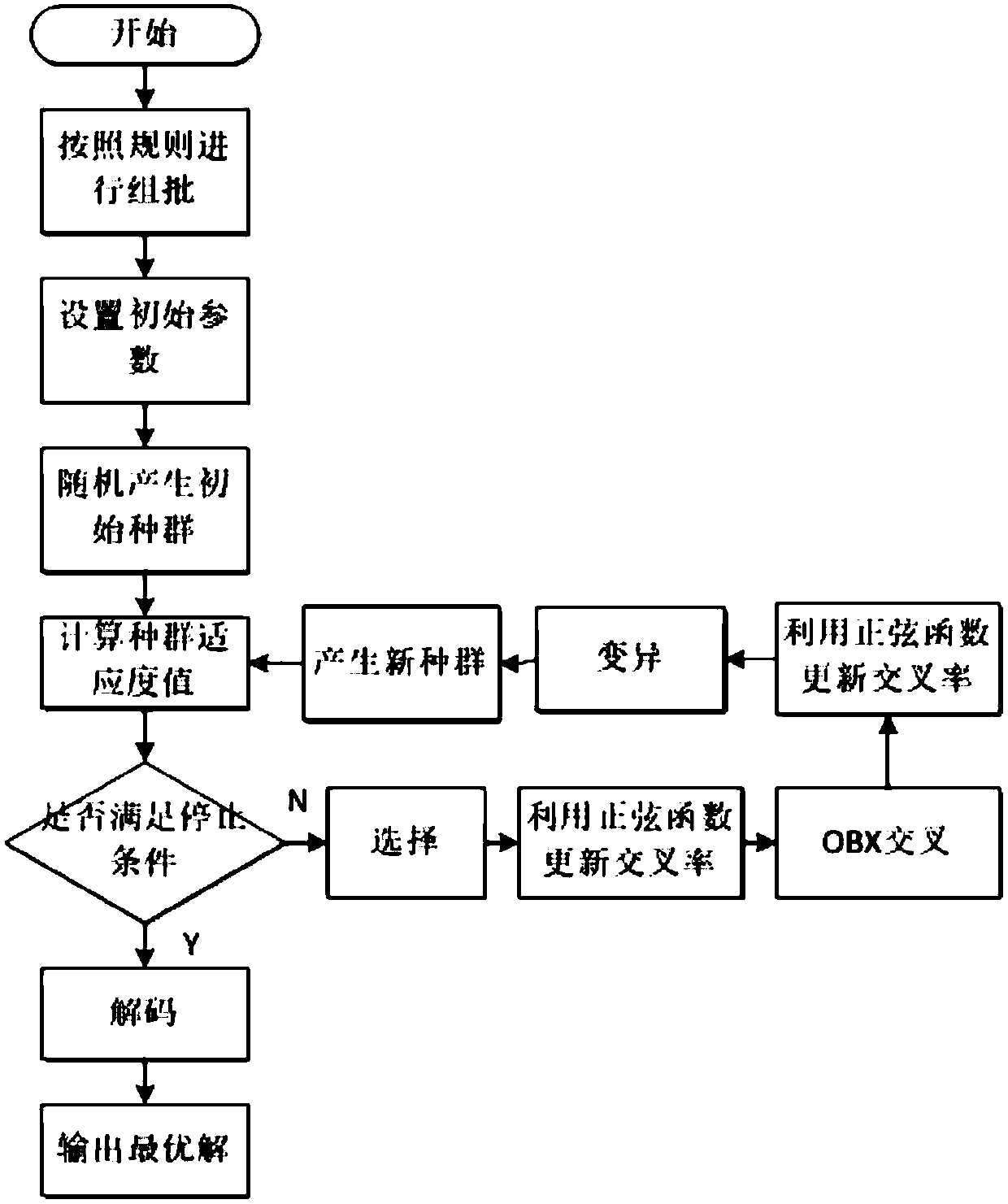

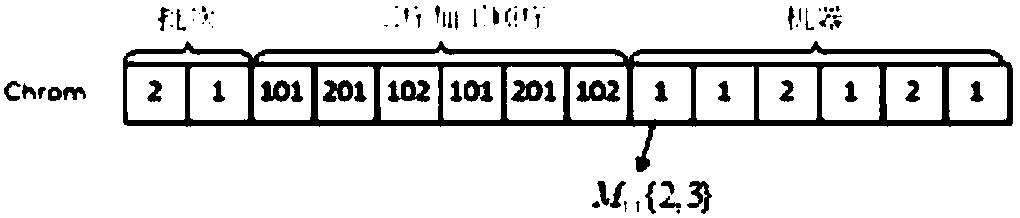

Large-scale flexible work workshop scheduling optimization method

The invention provides a large-scale flexible work workshop scheduling optimization method. A large-scale production task is reorganized to be downscaled and then solving and optimization are performed by using the adaptive improved genetic algorithm. The method comprises the following concrete steps that (1) the workpieces of which the processing technology is similar, the workpiece dimension iswithin the same range and the blank material is the same are clustered and grouped for batching so as to reduce the problem solving scale; and (2) the initial parameter of the algorithm is set, the three-layer gene coding technology, the OBX crossover mode and the certain variation strategy are adopted, the crossover length is selected through combination of the simulation experiment and optimization and solving are performed by using the adaptive improved genetic algorithm. According to the method, the problem solving scale can be reduced and the solving speed can be improved; and the workpiece completion time and delay time can be reduced.

Owner:SOUTHWEST JIAOTONG UNIV

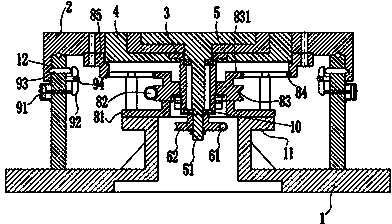

Workpiece automatic clamping device

ActiveCN103817553AAchieve self-centering functionImprove processing efficiencyWork clamping meansPositioning apparatusEngineeringMechanical engineering

The invention provides a workpiece automatic clamping device, which is convenient to operate, and the workpiece automatic centering function is realized. The workpiece automatic clamping device comprises a connecting base, a worktable turntable, a main shaft sleeve, an automatic centering disc chuck, a parabolic disc chuck, a plurality of connecting rods and a plurality of positioning claws, wherein the worktable turntable is rotationally arranged above the connecting base; the main shaft sleeve is fixedly arranged below the worktable turntable; the parabolic disc chuck is rotationally arranged on the worktable turntable; the automatic centering disc chuck is fixedly arranged on the worktable turntable; the parabolic disc chuck is provided with arc-shaped involute grooves from the inside to the outside in the radial direction; the connecting rods are hinged to each other end to end; two ends of each connecting rod are respectively a first hinge end and a second hinge end; the first hinge ends are respectively hinged to the involute grooves on the parabolic disc chuck; the automatic centering disc chuck is uniformly provided with long hinge grooves corresponding to the arc-shaped involute grooves in quantity; the second hinge ends are respectively hinged to the long hinge grooves; the positioning claws are respectively arranged above the connected first hinge ends.

Owner:南通棉锦纺织品有限公司

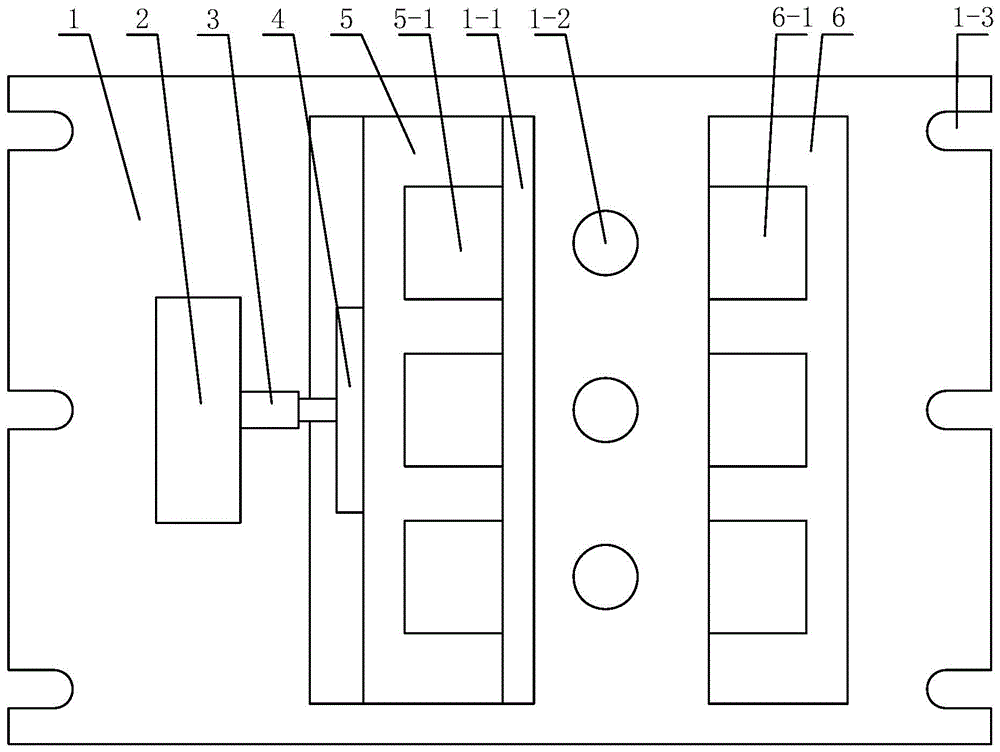

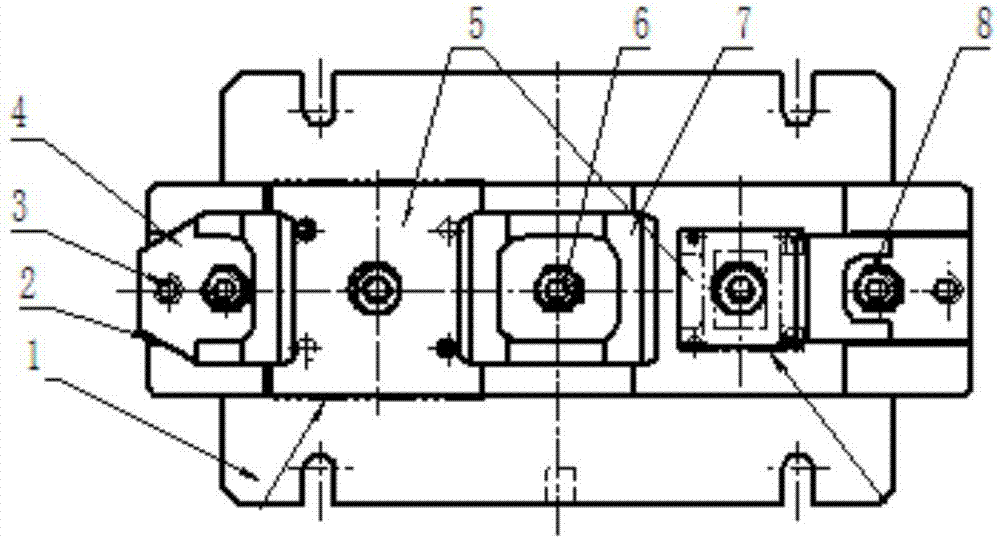

Hydraulic driving type multi-station milling fixture

InactiveCN104440288AReasonable designSimple structureWork clamping meansPositioning apparatusPulp and paper industryEngineering

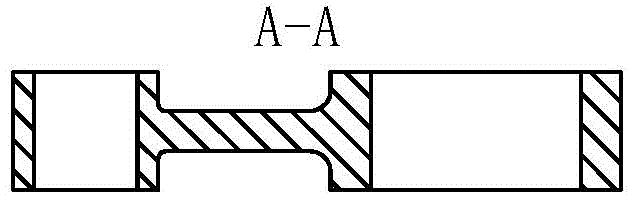

The invention discloses a hydraulic driving type multi-station milling fixture. The hydraulic driving type multi-station milling fixture comprises a rectangular base, a hydraulic oil cylinder and a positioning compressing sliding block; a mounting frame is fixedly arranged on one side of the rectangular base, and the hydraulic oil cylinder is fixedly arranged on the mounting frame; a pushing plate is fixedly arranged at the end of a piston rod of the hydraulic oil cylinder; the pushing plate is fixedly connected with the positioning compressing sliding block arranged in a sliding groove in a sliding manner, and at least two first positioning grooves are formed in the upper side of the positioning compressing sliding block; a positioning fixed block is fixedly arranged on the other side of the rectangular base; second positioning grooves which are matched with the first positioning grooves to be used for positioning a T-shaped workpiece to be machined are formed in the upper side of the positioning fixed block; and positioning holes are formed in the position, between the first positioning grooves and the second positioning grooves, of the middle of the rectangular base. The hydraulic driving type multi-station milling fixture has the advantages of being reasonable in design, simple in structure, capable of carrying out multi-station clamping at one time, high in working efficiency, convenient to operate, low in labor intensity, high in automation degree, low in production cost and convenient to use and popularize.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

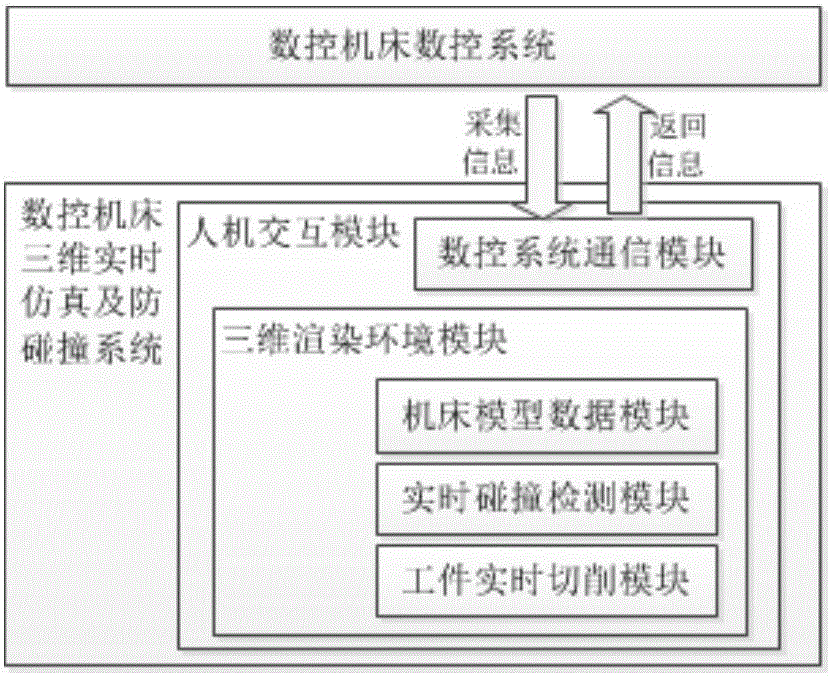

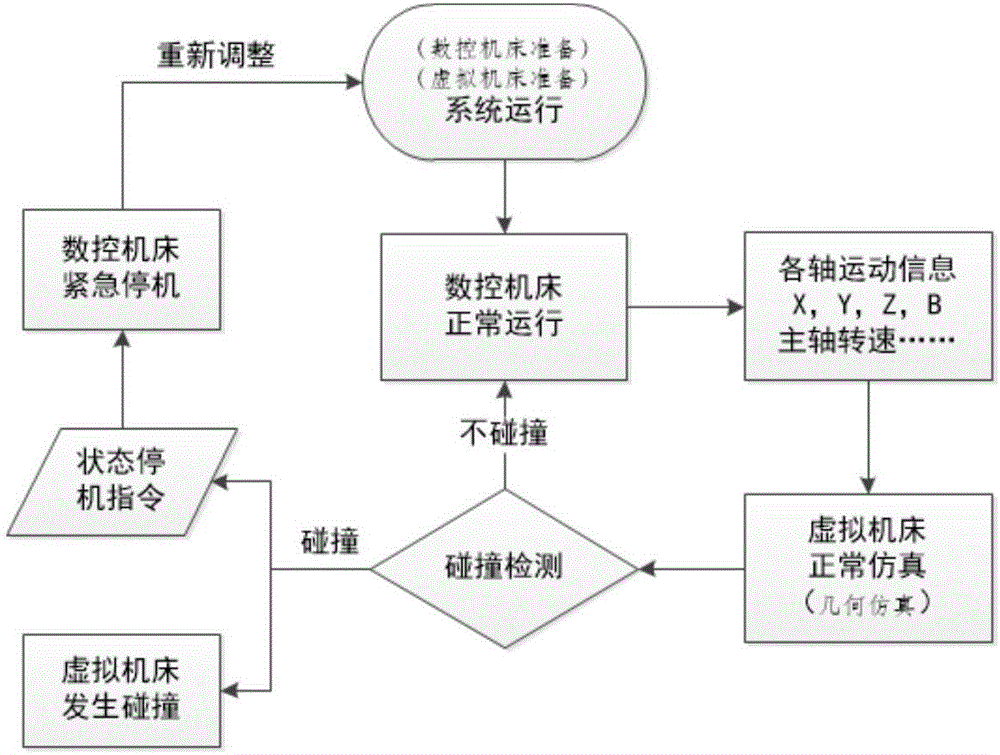

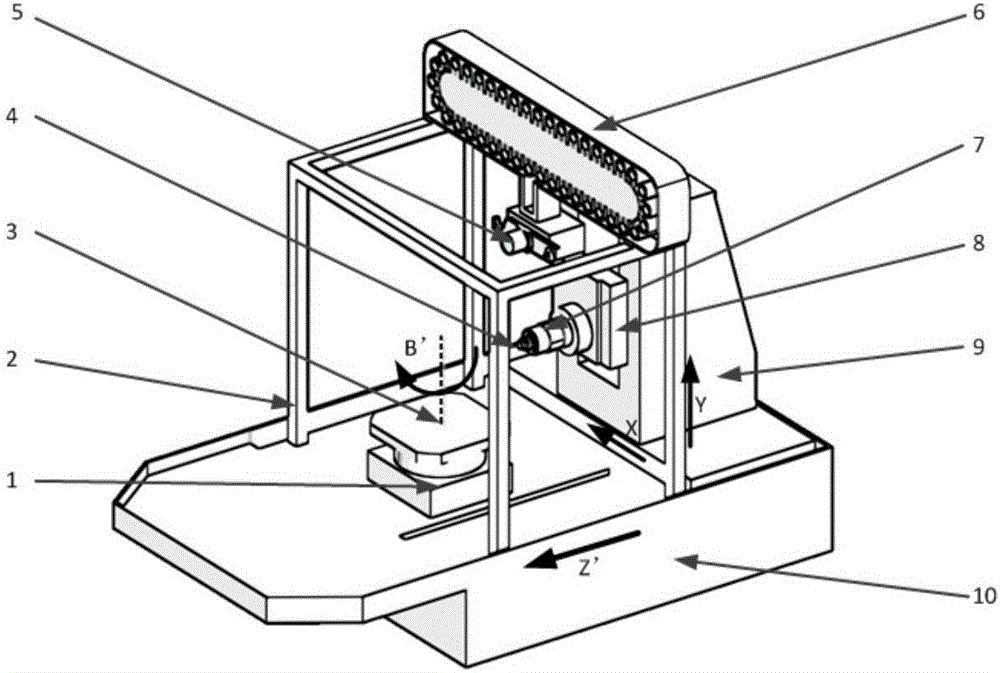

Real-time anti-collision method for numerically-controlled machine tool

InactiveCN106202767AReduce processing preparation timeProcessing focusMeasurement/indication equipmentsDesign optimisation/simulationPrediction algorithmsSoftware system

The invention discloses and realizes a real-time anti-collision method weakly associated with a numerical control system for a numerically-controlled machine tool. Three-dimensional real-time processing simulation is carried out by virtue of the numerically-controlled machine tool, a signal of interest is acquired by virtue of an anti-collision system and is processed by adopting a prediction algorithm in a software system, then a virtual numerically-controlled machine tool is driven to carry out simulation, prediction simulation is carried out on wrongful collision or interference appearing in a machining process or when an operator operates the numerically-controlled machine tool and warning is carried out, and a numerical control system stopping signal is returned and the machine tool is protected.

Owner:XI AN JIAOTONG UNIV

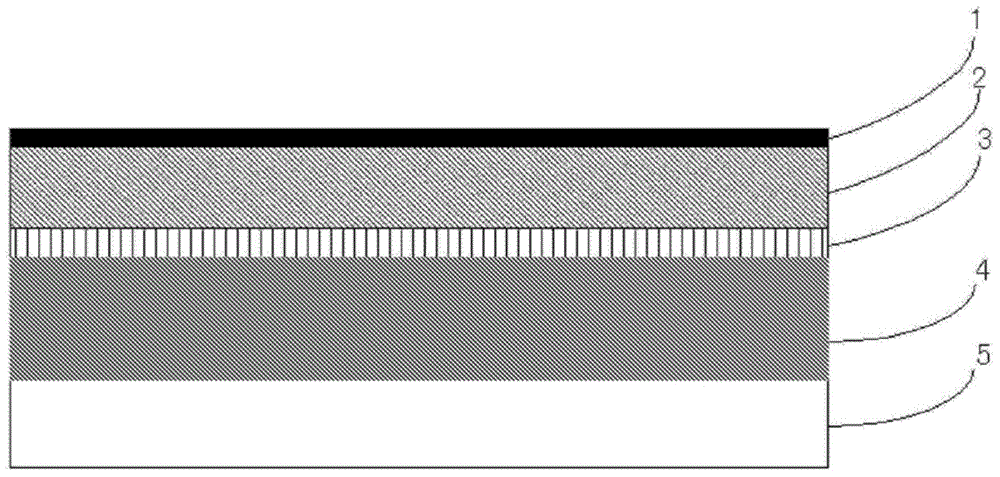

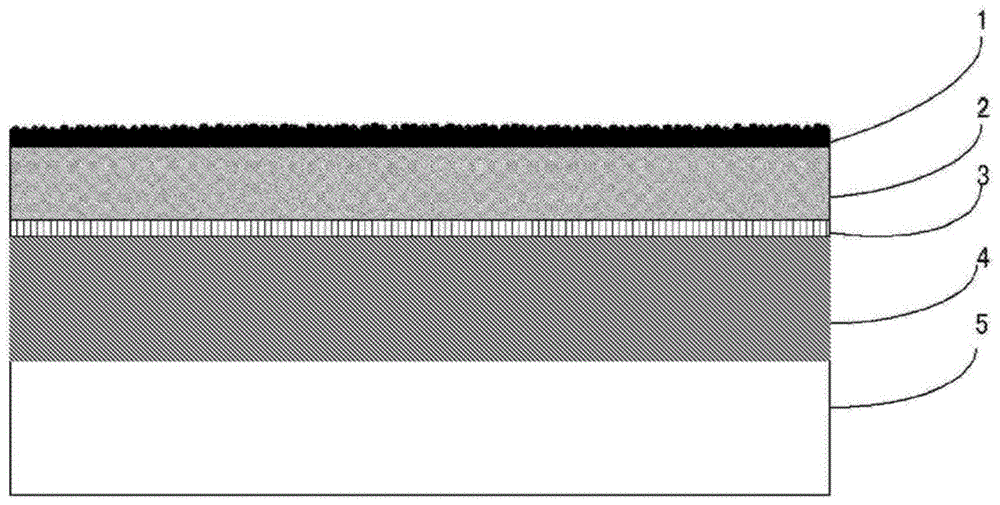

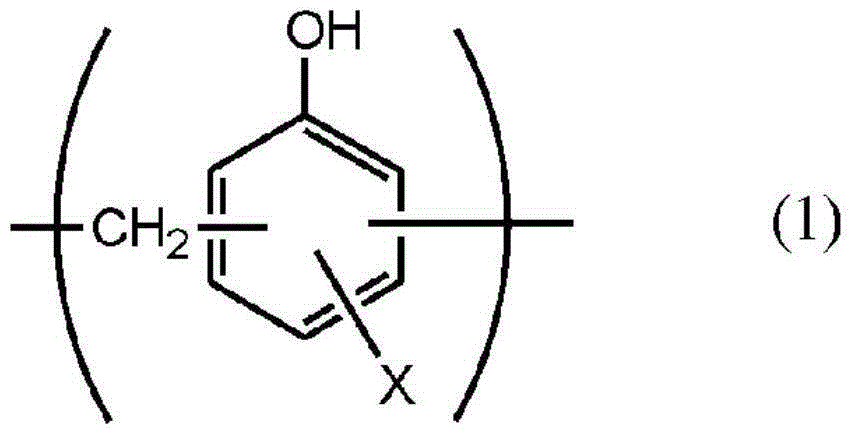

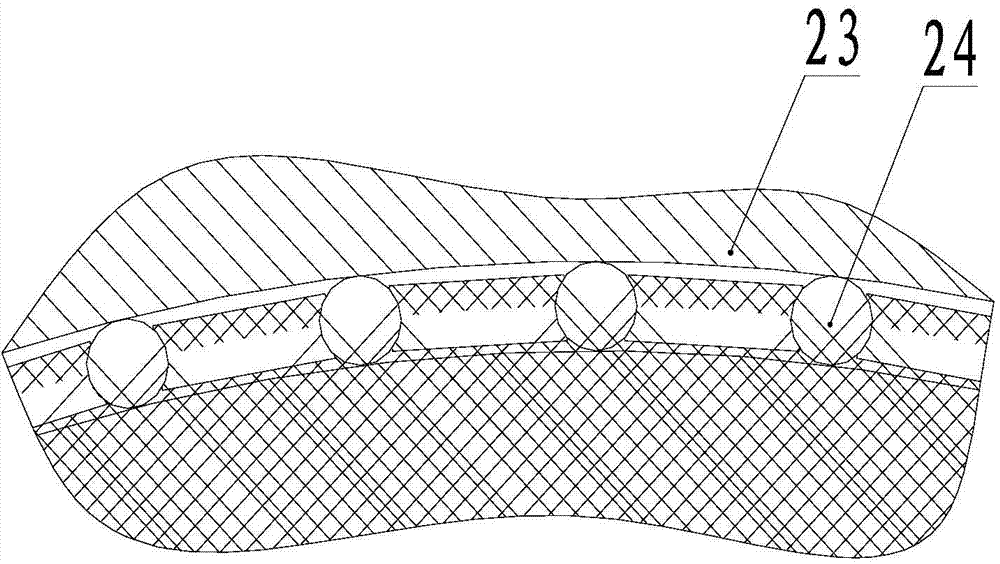

Battery packaging material

ActiveCN105144422AGood medicineReduce processing preparation timeSynthetic resin layered productsJackets/cases materialsPack materialSealant

The purpose of the present invention is to provide a film-like battery packaging material in which a coating layer, which can be cured in a short time and exhibits superior chemical resistance, is provided to a substrate layer surface. In the battery packaging material, which comprises a laminate body that includes at least a coating layer (1), a substrate layer (2), an adhesive layer (3), a barrier layer (4), and a sealant layer (5), in that order, the use of a resin composition containing a heat-curable resin and a curing accelerator as the coating layer (1) enables the formation of a coating layer that can be cured in a short time and contributes to electrolyte liquid, etc., resistance.

Owner:DAI NIPPON PRINTING CO LTD

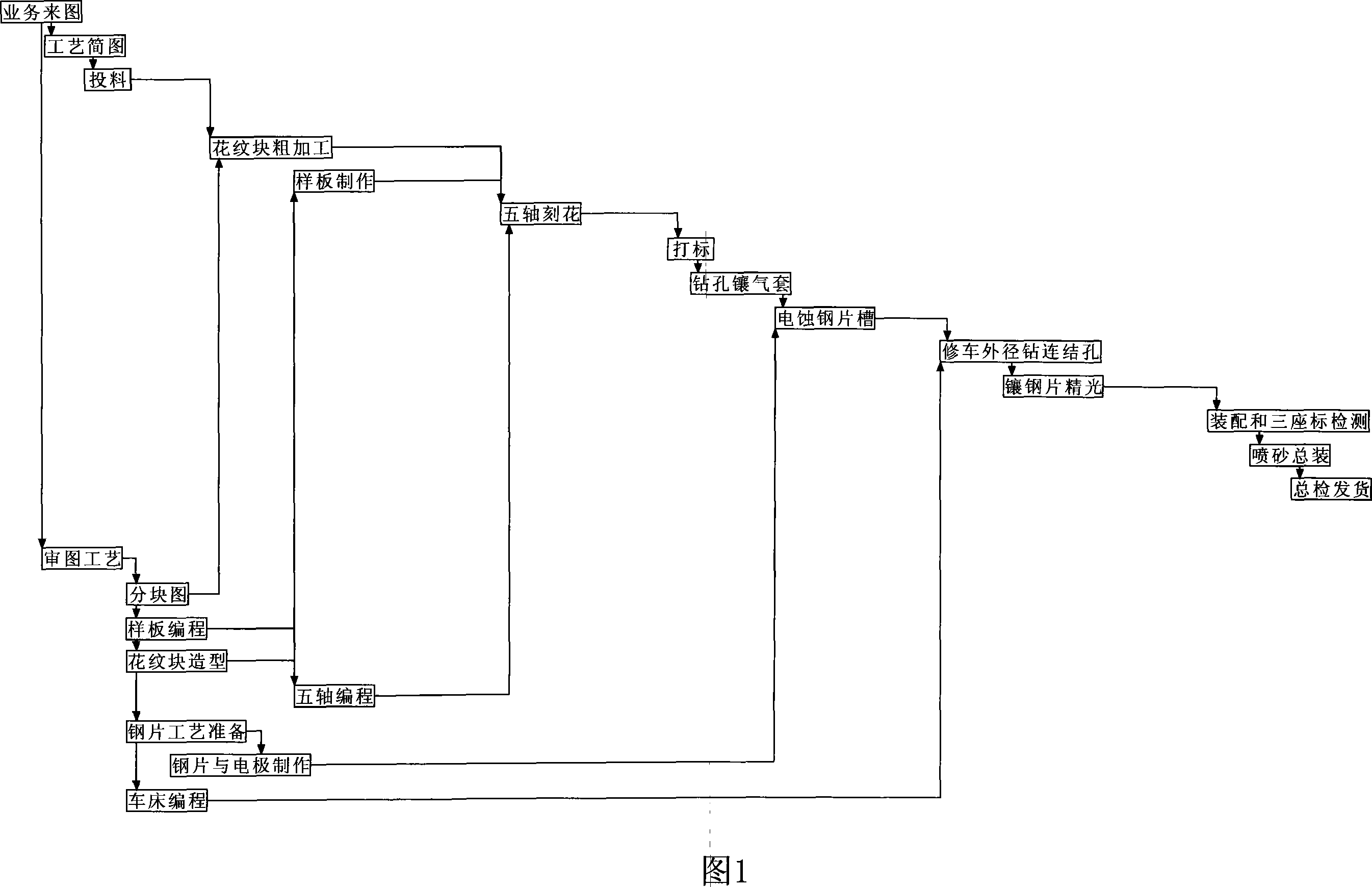

Tire mold high speed high precision parallel machining constitution method

InactiveCN101236416AShorten the design cycleReduce process preparation timeProgramme controlComputer controlNumerical controlEngineering

The invention relates to a high velocity and high precision constituting method for collaterally elaborating a tyre mould, comprising the following steps of a concurrence of designing and manufacture processing; a concurrence of designing and material purchasing; a concurrence of technology planning, rough machining and semifinishing; a concurrence of designing and numerical control process programming; and an elaboration for a single piece with high velocity and high precision. The high velocity and high precision constituting method for collaterally elaborating a tyre mould has the advantages of improving an elaborating precision of a product, shortening a delivery date for the mould and reducing the cost, and is suitable for collaterally elaborating the tyre mould with high velocity and high precision.

Owner:GREATOO INTELLIGENT EQUIP INC

Electrospark machining equipment

InactiveCN1890045AAvoid vibrationExtended replacement cycleElectrical-based machining electrodesElectric dischargeFixed position

An electric discharge machine comprising a hollow rod-like guide electrode containing a thin wire electrode for discharge machining slidably, guide electrode grasping means for grasping the guide electrode at a fixed position, pressure fluid supply means for supplying pressure fluid into the guide electrode to feed the thin wire electrode to the discharge machining side from the inside of the guide electrode, and a thin wire electrode grasping means for automatically grasping the thin wire electrode fed out from the guide electrode

Owner:MITSUBISHI ELECTRIC CORP

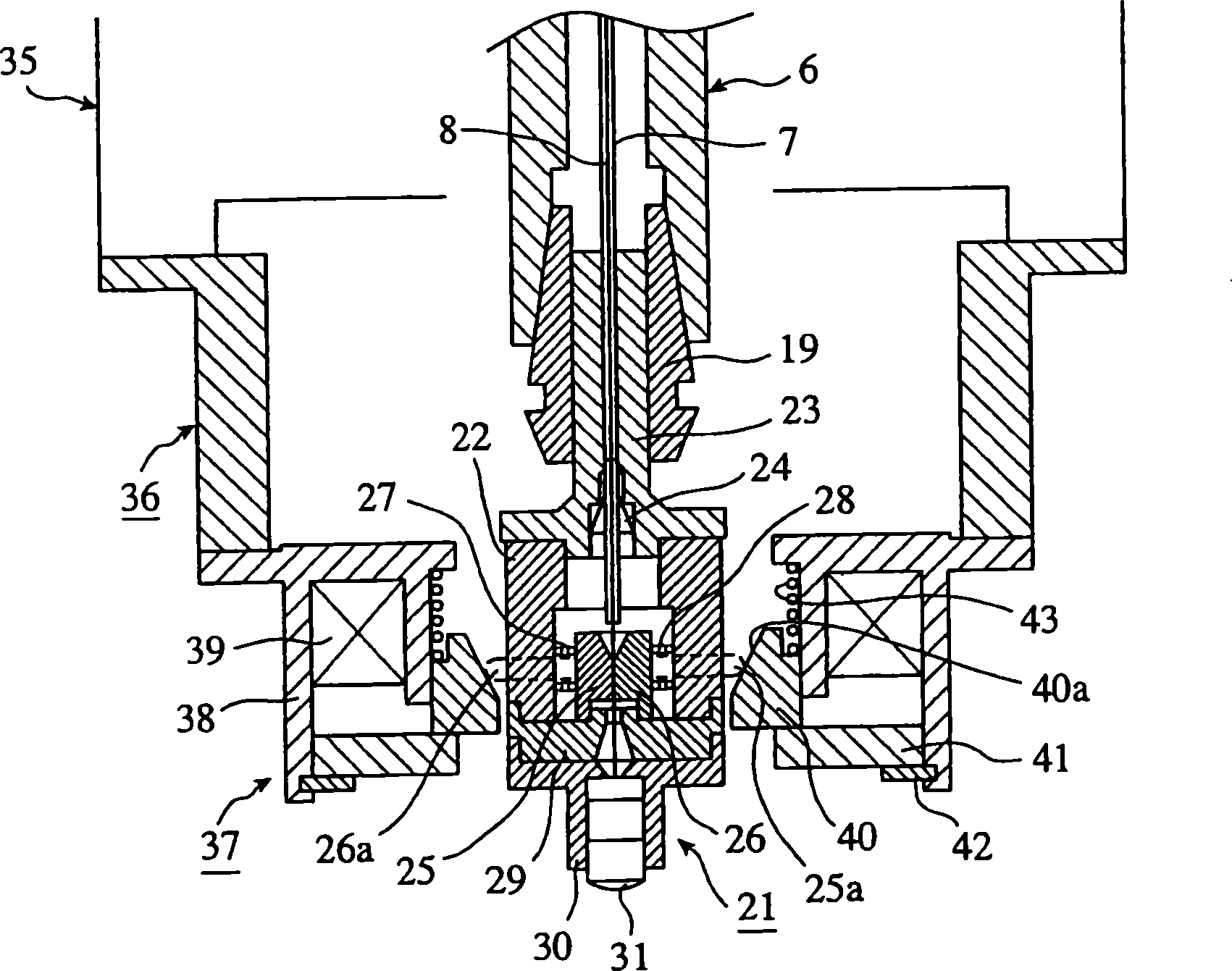

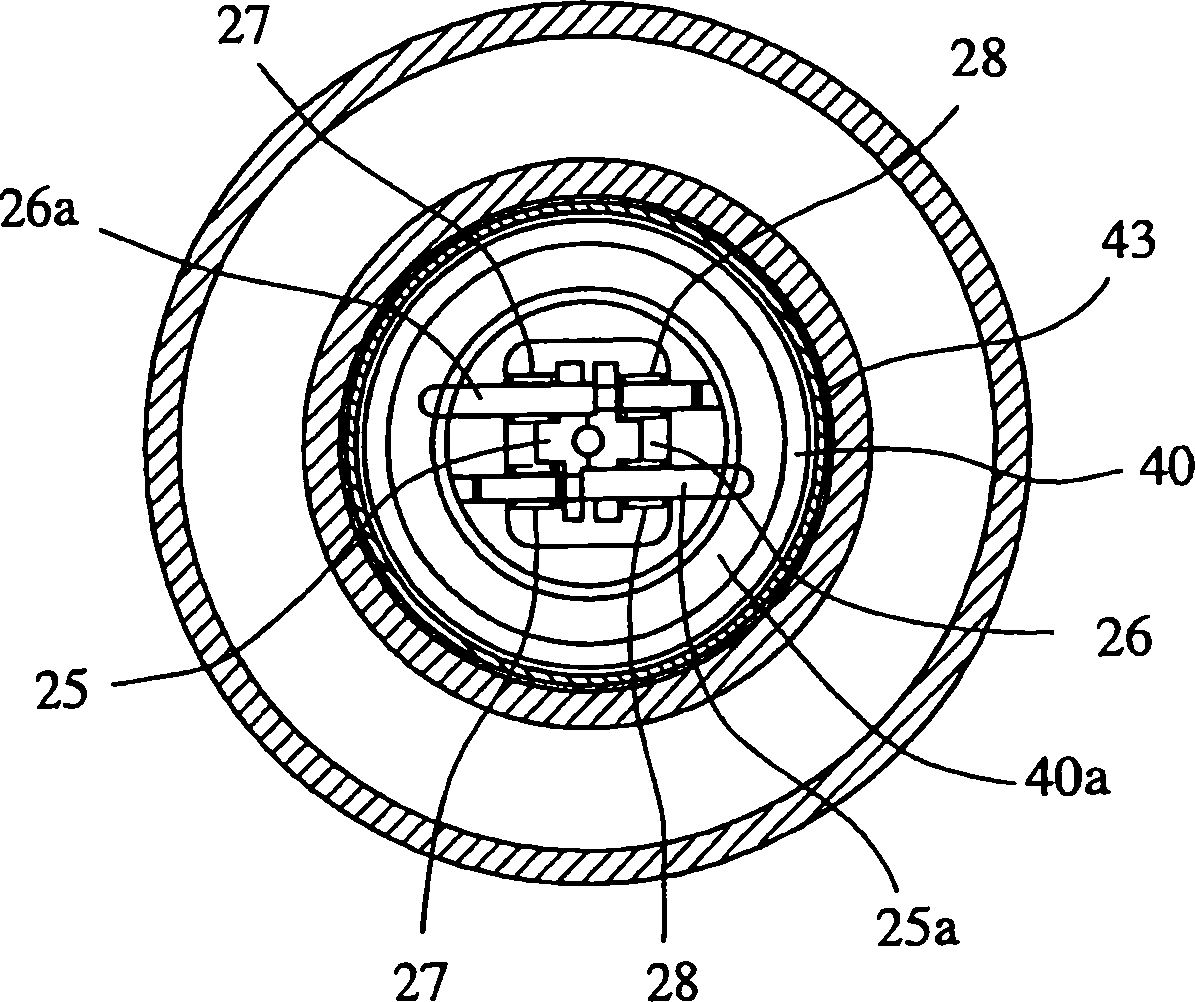

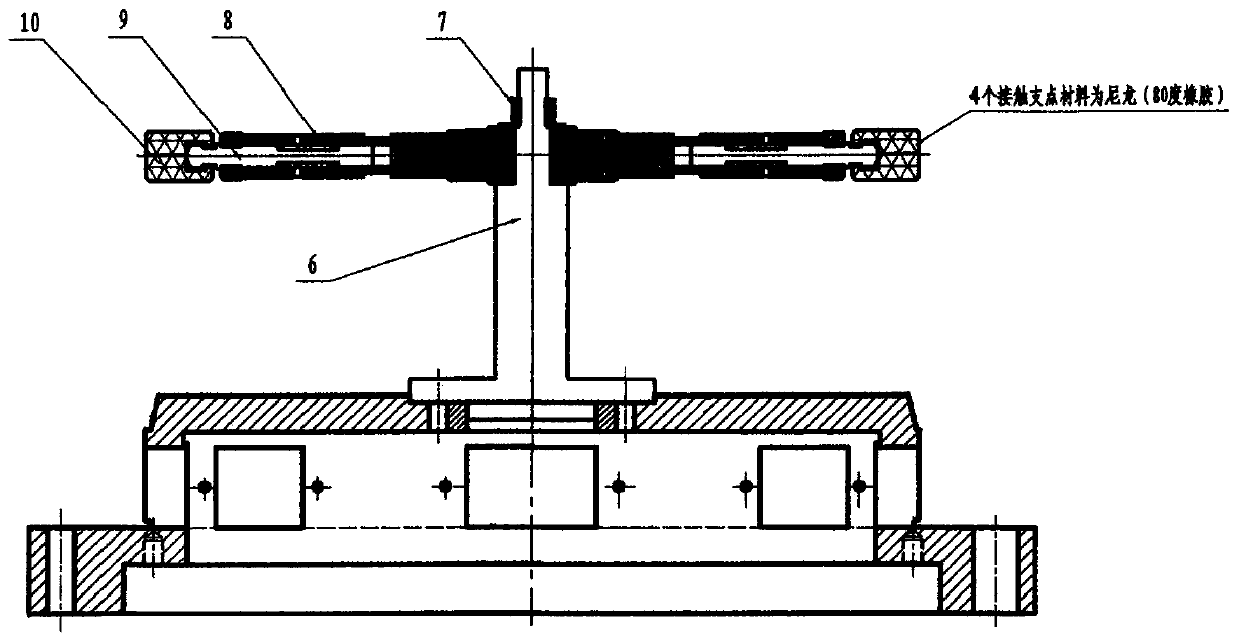

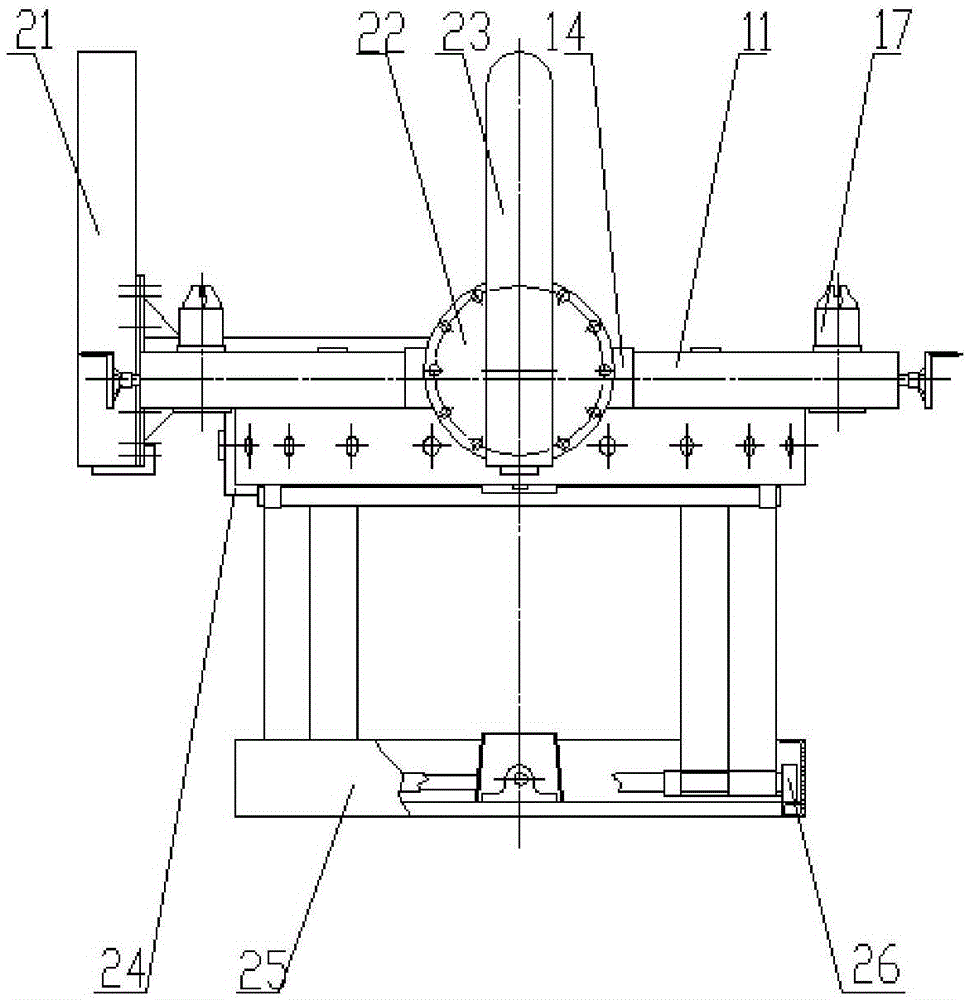

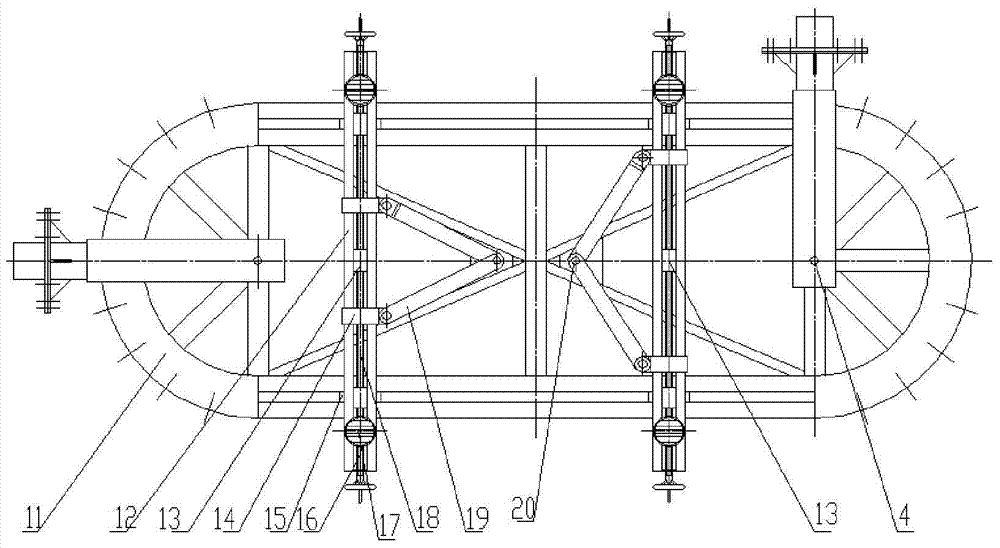

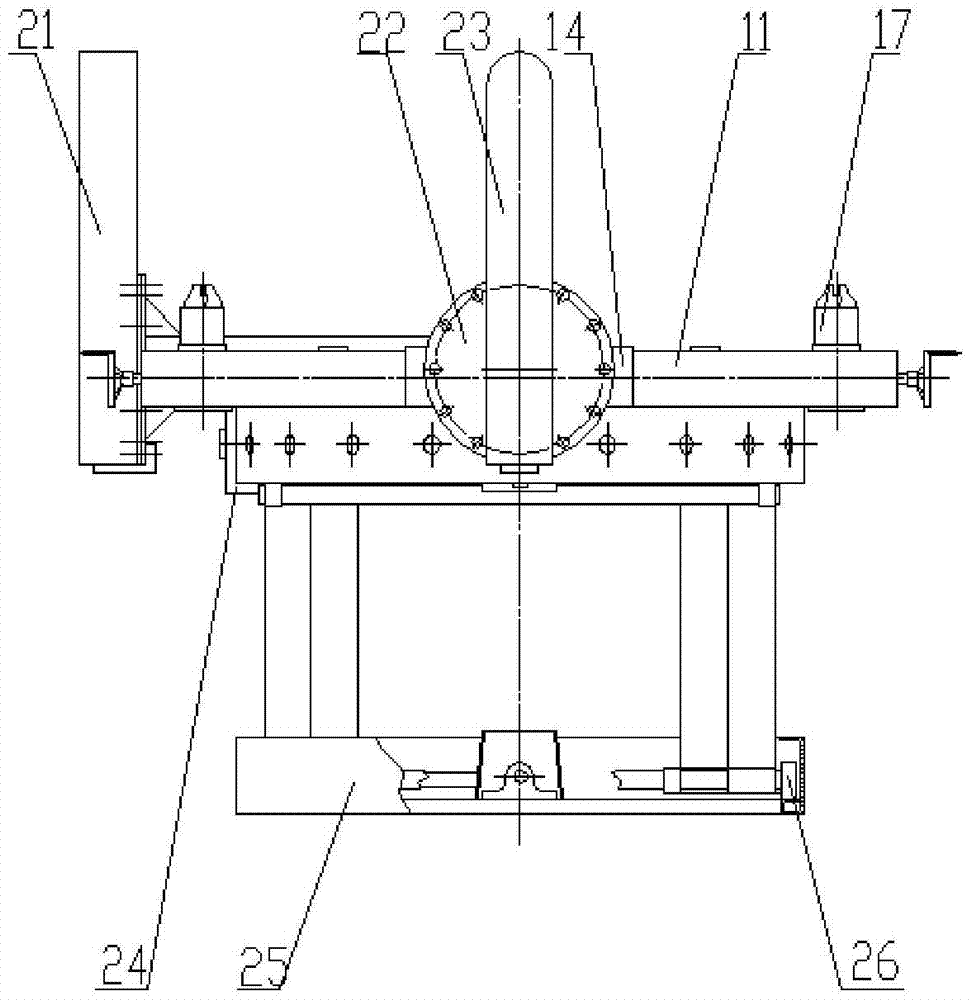

Machining device and method for double-layer casing of aero-engine

InactiveCN110774002ALoading and unloadingReasonable arrangementAircraft componentsOther manufacturing equipments/toolsAviationMechanical engineering

The invention discloses a machining device and method for a double-layer casing of an aero-engine. The device comprises an end surface gland, a shell, an inner sleeve, movable tensioning blocks, an air bag, a supporting rod, supporting arm nuts, supporting arms, a connecting seat, a ball head guiding rod, an inner hole fixing claw, an outer stand column, a transverse top head and a pressing plate.A turning and milling compound machining method is adopted, when an inner hole and an end surface are turned, the mode that an outer supporting is matched with the air bag for tensioning is adopted,and when an outer boss is milled, the mode that an inner supporting is matched with the air bag for tensioning is adopted; and according to the machining device, the high-quality and high-efficiency machining of the similar thin-wall double-layer casing can be achieved, and it is ensured that the circular degree of the casing meets the requirement.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

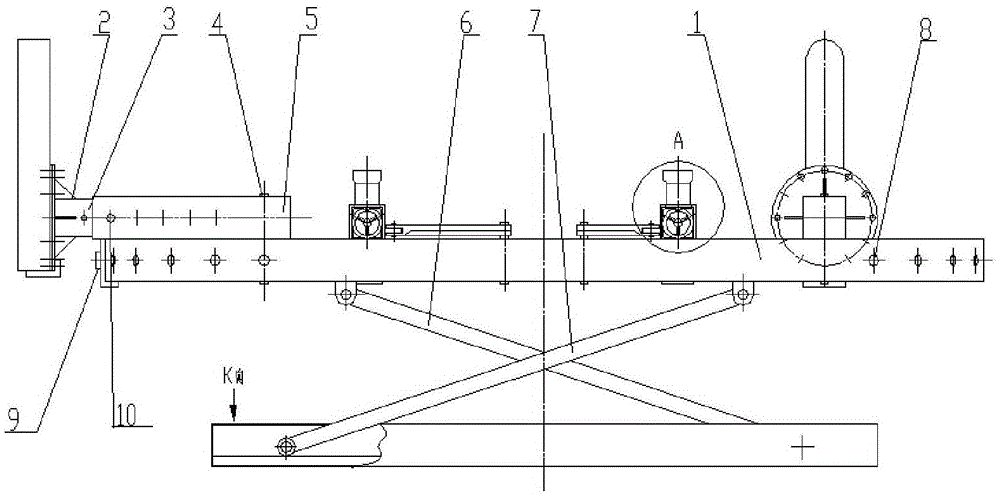

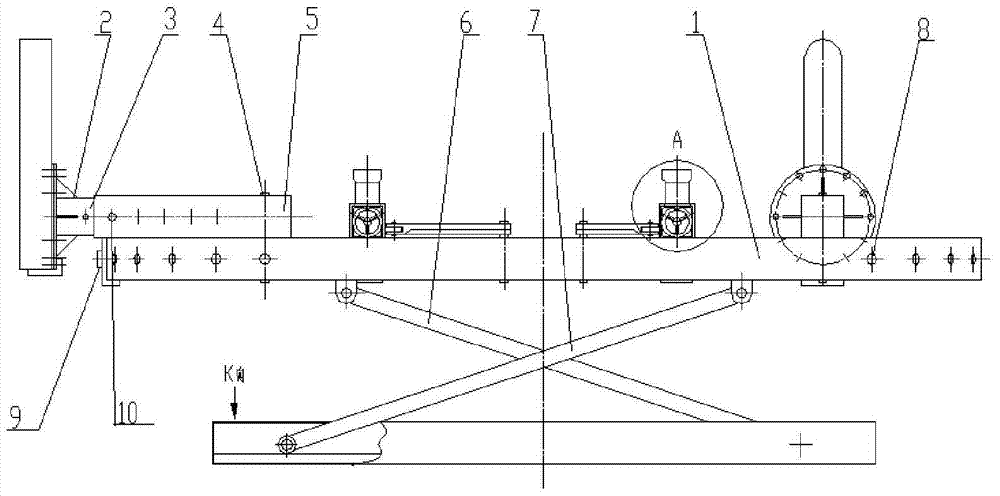

Rapid automotive sheet metal workbench

ActiveCN105537322AEasy to operateReduce processing preparation timeMetal-working feeding devicesPositioning devicesSelf lockingEngineering

The invention provides a rapid automotive sheet metal workbench. Transverse supporting beams can move transversely along a main supporting platform. Clamping module sets are arranged at the two ends of each transverse supporting beam. The clamping module sets can move longitudinally along the transverse supporting beams and can rotate horizontally. Movement switching of the transverse supporting beams and the clamping module sets is achieved through spline structures. A traditional positioning and clamping way using bolts for fastening is replaced through the transverse supporting beams and the clamping module sets by means of the self-locking function of lead screws, so that position determination in the horizontal direction is achieved; meanwhile, primary positioning and clamping of an automobile body are completed by means of the dead weight of an automobile. According to the rapid automotive sheet metal workbench, operation is rapid, and the function of correcting light automobile bodies is achieved; a sheet metal part, damaged due to collision, in the automobile body can be stretched and corrected, the workbench can also serve as an auxiliary operation platform for other sheet metal maintenance work, and favorable auxiliary conditions for shorting the process time are provided while the process preparation time is effectively and greatly shortened.

Owner:臧汝涛

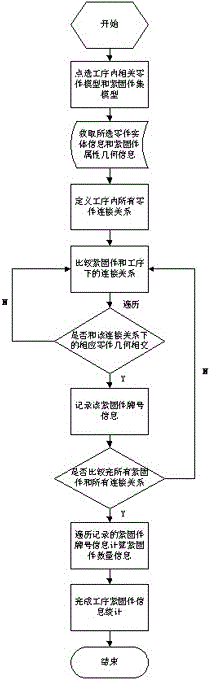

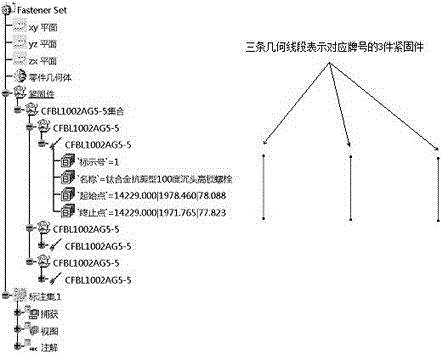

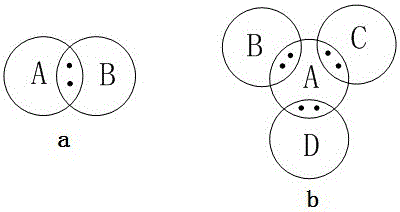

Method for quickly counting fasteners in aircraft assembly procedures

ActiveCN106055823AImprove statistical efficiencyImprove accuracyGeometric CADSpecial data processing applicationsEngineeringAirplane

The invention relates to a method for quickly counting fasteners in aircraft assembly procedures, in particular to the method for quickly counting the fasteners in the aircraft assembly procedures when relatively multiple aircraft assembly procedures are involved and related procedures also involve relatively multiple assembly parts and fasteners. The method is characterized by comprising the steps of inputting information of a procedure part model and a fastener set model; obtaining input entity information of the procedure part model and attributes and geometrical information of the fasteners; defining connection relationships between all parts in each procedure; traversing all fasteners under a fastener set and comparing the fasteners with all connection relationships under the procedure one by one and judging whether one fastener belongs to the corresponding connection relationship or not; recording mark information of the fasteners belonging to the connection relationship; after all fasteners are compared with the connection relationships under the procedure, finishing mark information recording of the fasteners under the procedure; calculating the occurrence number of the mark of each fastener as the number of the fasteners with the mark under the procedure; and finishing information counting of the fasteners under the procedure.

Owner:江西洪都商用飞机股份有限公司

Dynamic refrigerator refrigeration performance testing system

ActiveCN102944442AReduce process preparation timeImprove ergonomicsStructural/machines measurementRefrigerated temperatureRefrigeration

The invention discloses a dynamic refrigerator refrigeration performance testing system. The dynamic refrigerator refrigeration performance testing system is characterized in that a lower computer and a testing tool of the testing system and a refrigerator to be tested move on a production line together, a collector simultaneously collects setup parameters so as to obtain test data, the test data are sent to an upper computer in a wireless transmission manner, and the upper computer analyzes the test data according to a set technological program so as to judge the performance of the refrigerator. As adopting a multi-condition comprehensive judgment model, the testing system can judge the performance of the refrigerator more exactly, and is better adaptive to product performance tests of different refrigerators.

Owner:CHANGHONG MEILING CO LTD

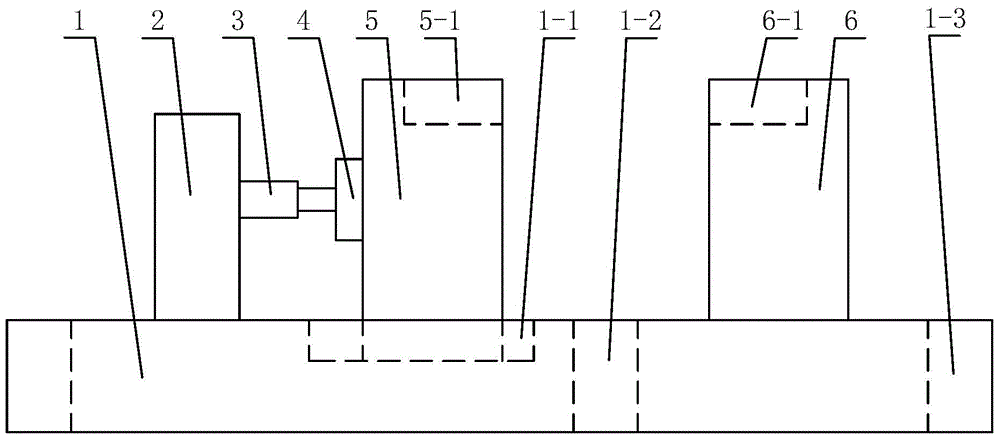

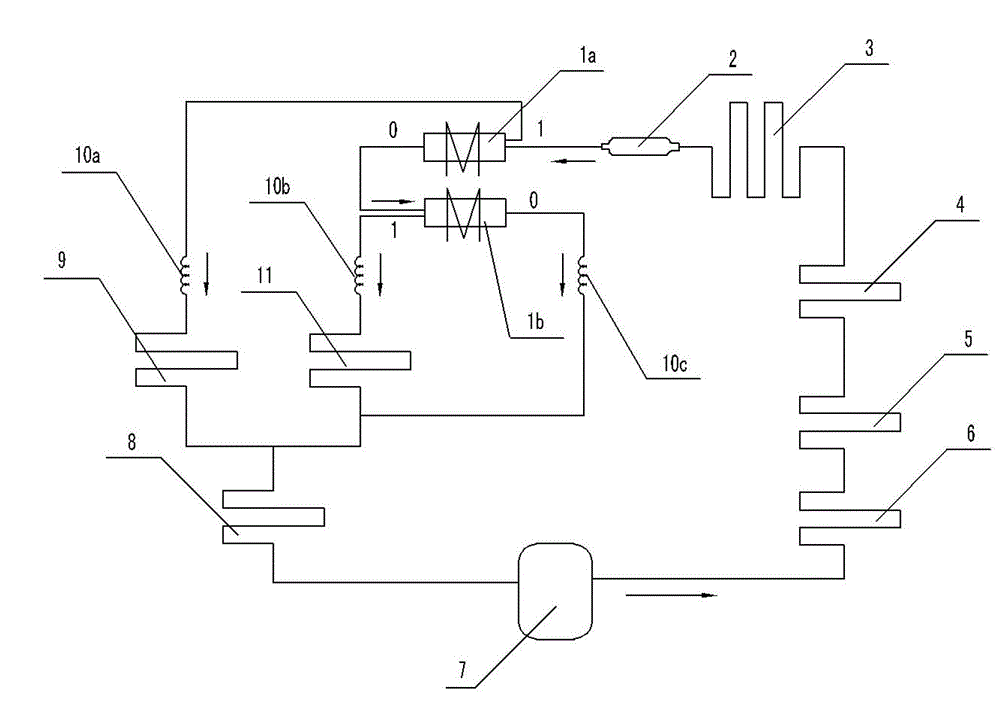

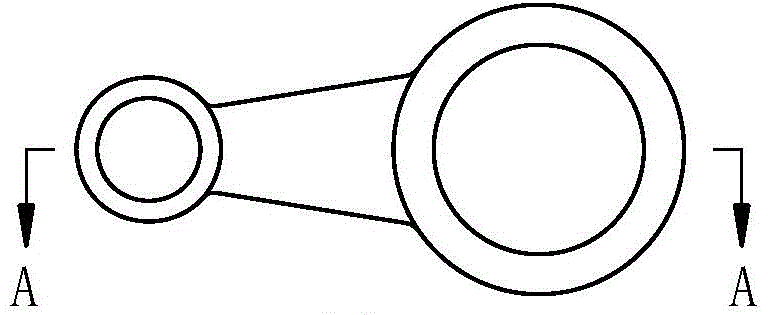

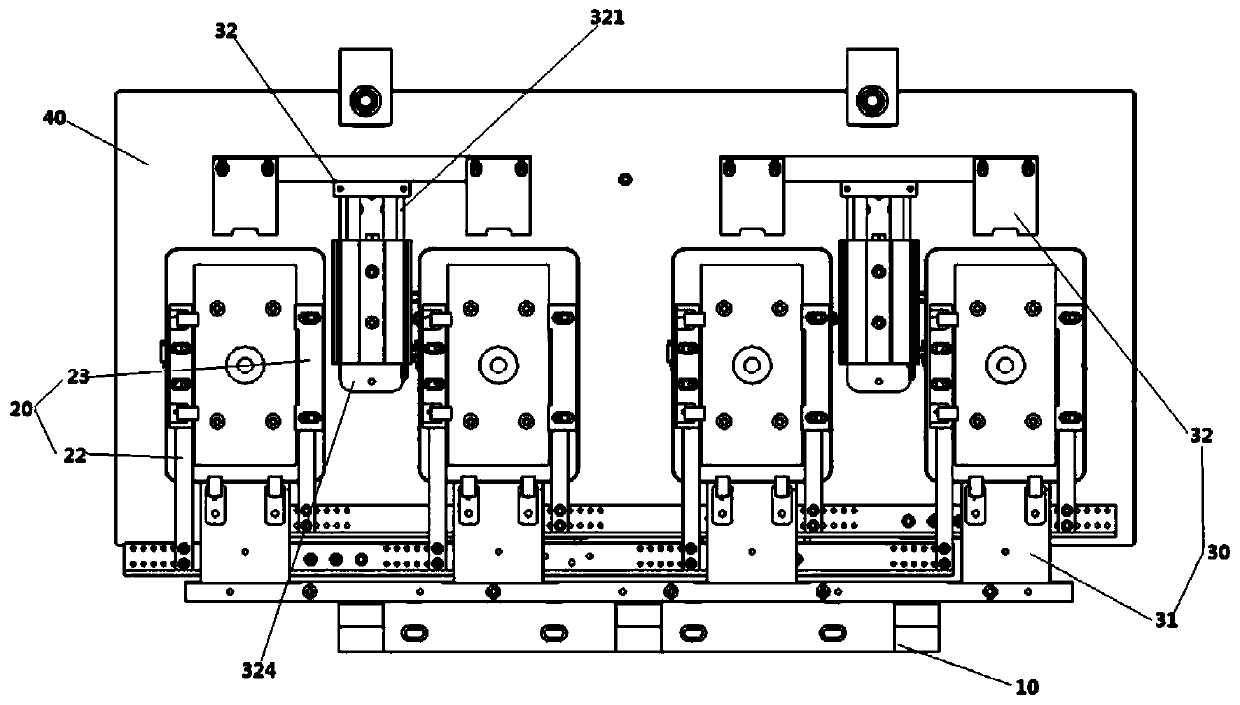

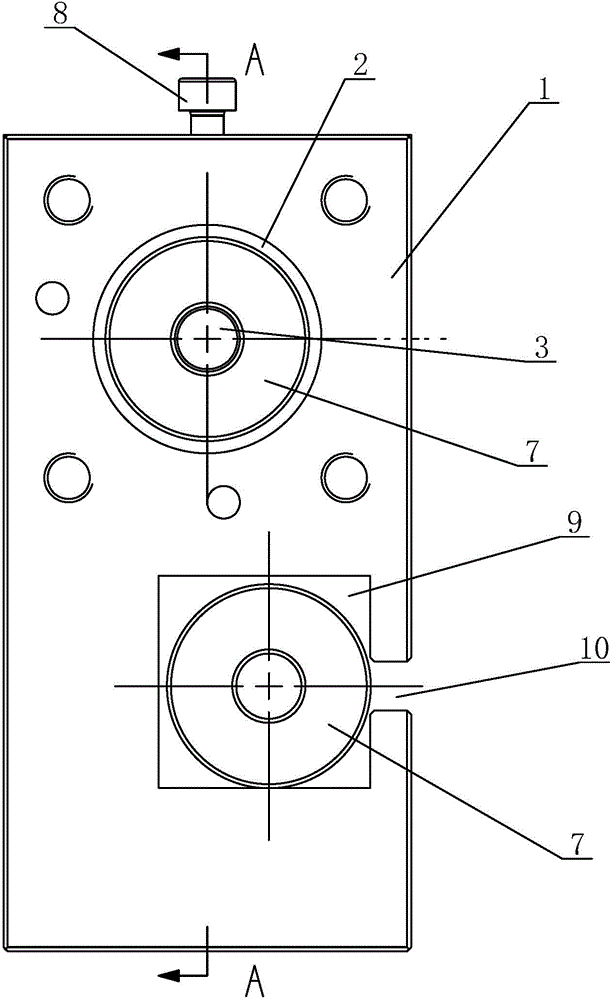

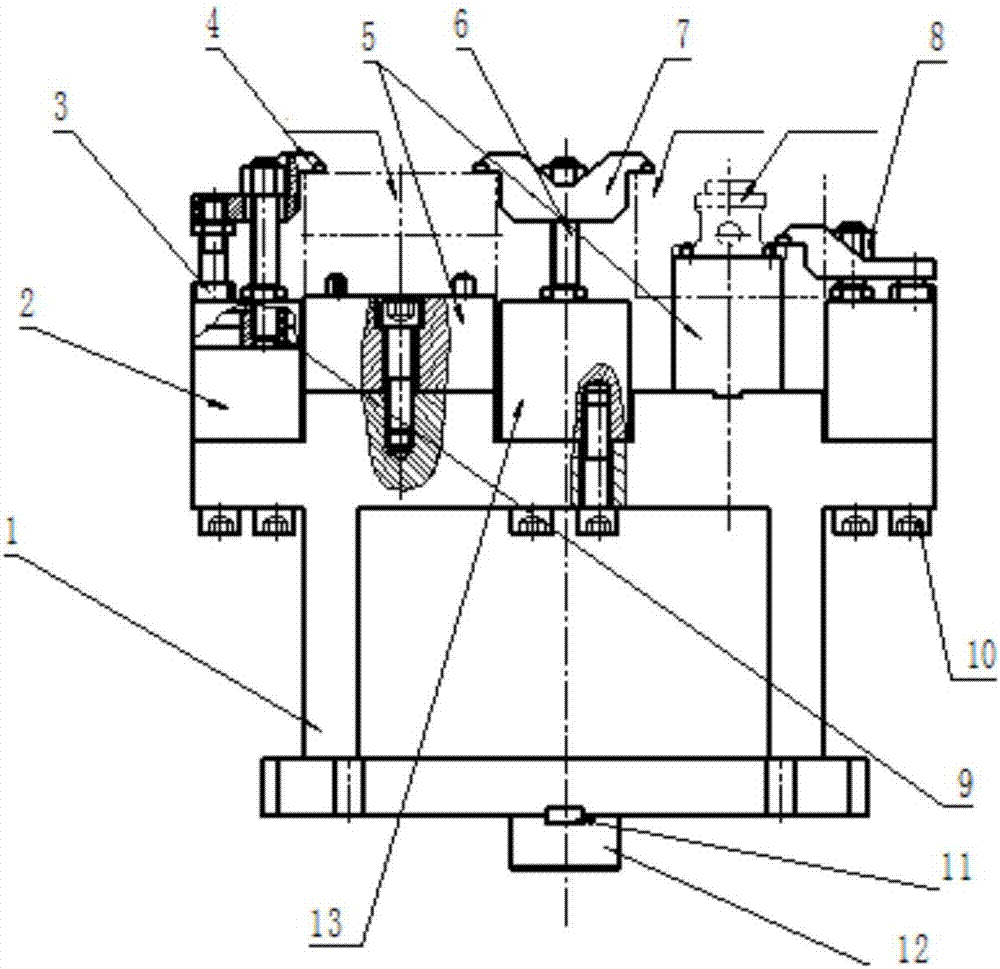

Double-station connecting rod hole milling and pressing device and hydraulic system thereof

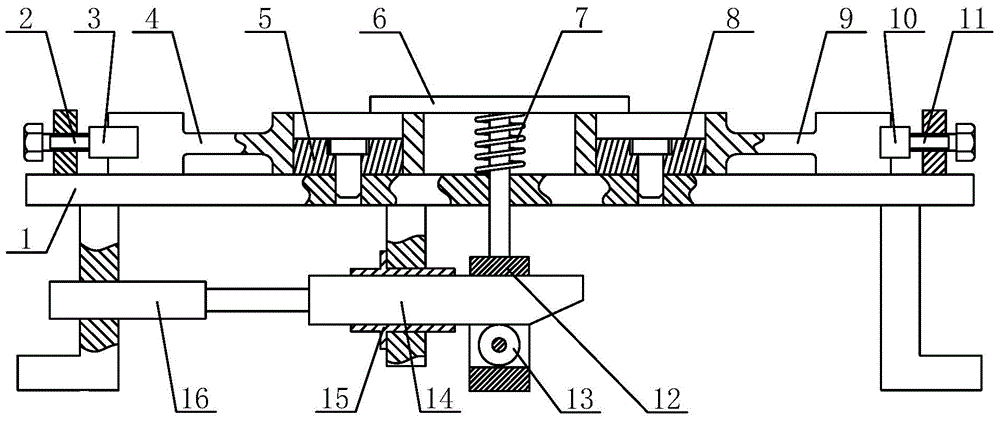

InactiveCN104440286AReasonable designImprove machining accuracyServomotor componentsWork clamping meansHydraulic cylinderFuel tank

The invention discloses a double-station connecting rod hole milling and pressing device and a hydraulic system thereof. The device comprises a frame and an inclined surface slide rod, wherein a T-shaped pressure plate is arranged in the middle of the frame; a positioning block 1 and a positioning block 2 are symmetrically arranged at the upper side of the frame; a V-shaped push head 1 and a V-shaped push head 2 are symmetrically mounted at the two ends of the upper side of the frame; a roller frame is fixed and mounted at the lower end of the T-shaped pressure plate; a roller is rotationally mounted on the roller frame; the end of the inclined surface slide rod is fixedly connected with the end of a piston rod of a hydraulic cylinder; a rodless cavity and a rod cavity of the hydraulic cylinder are respectively communicated with a first working port and a second working port of a reversing valve; a third working port of the reversing valve is communicated with an oil tank; and a fourth working port of the reversing valve is communicated with an oil outlet of a hydraulic pump. The device has the characteristics of reasonable design, high processing precision, capability of performing double-station clamping by one time, high production efficiency, simplicity and convenience for operation, high automation degree and low labor intensity.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

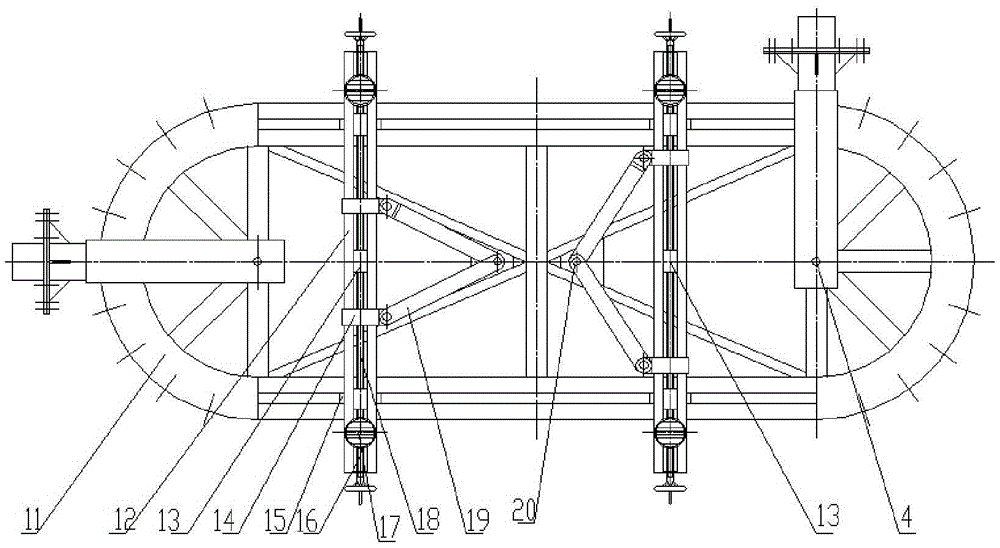

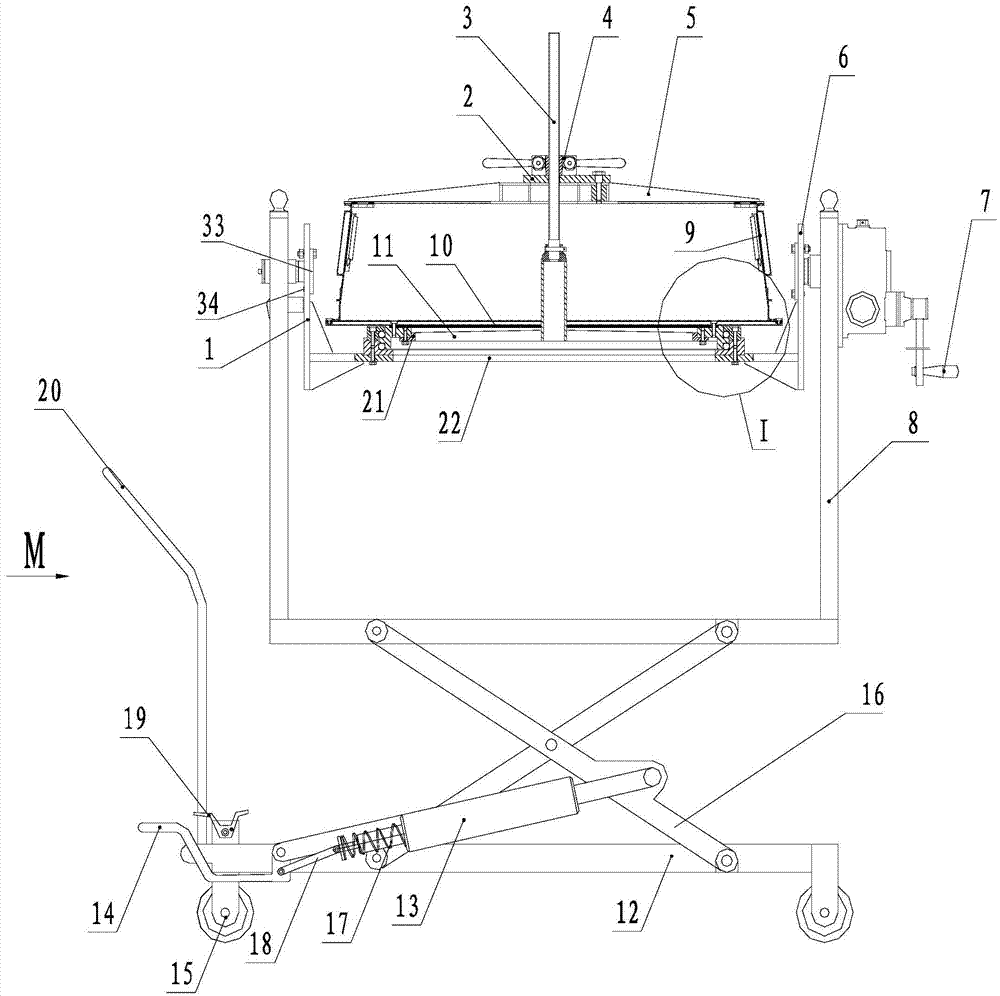

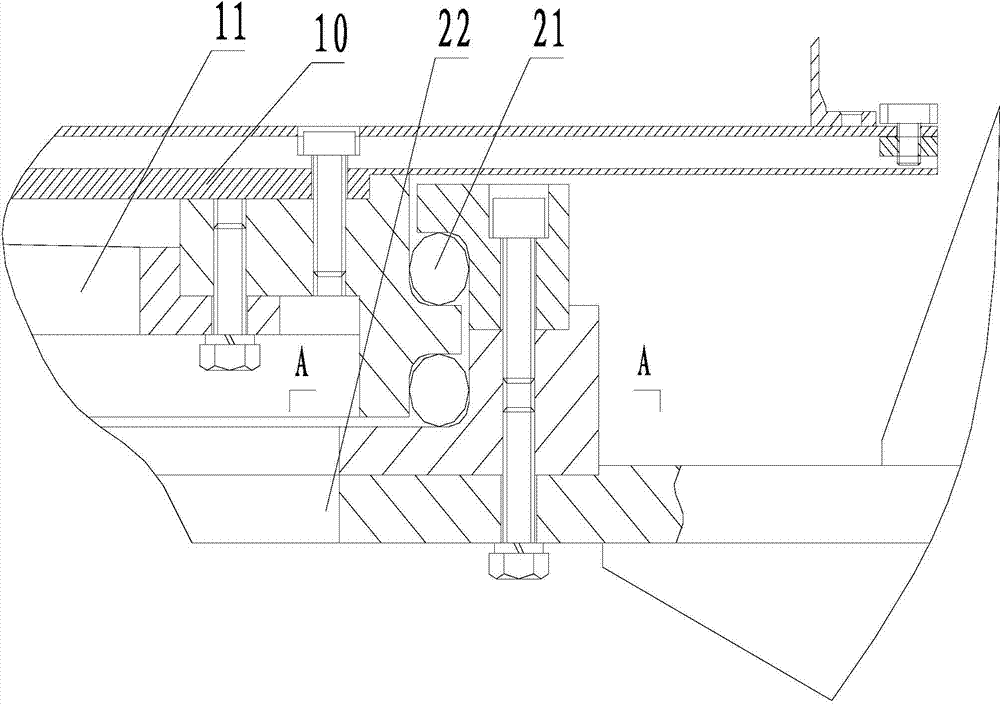

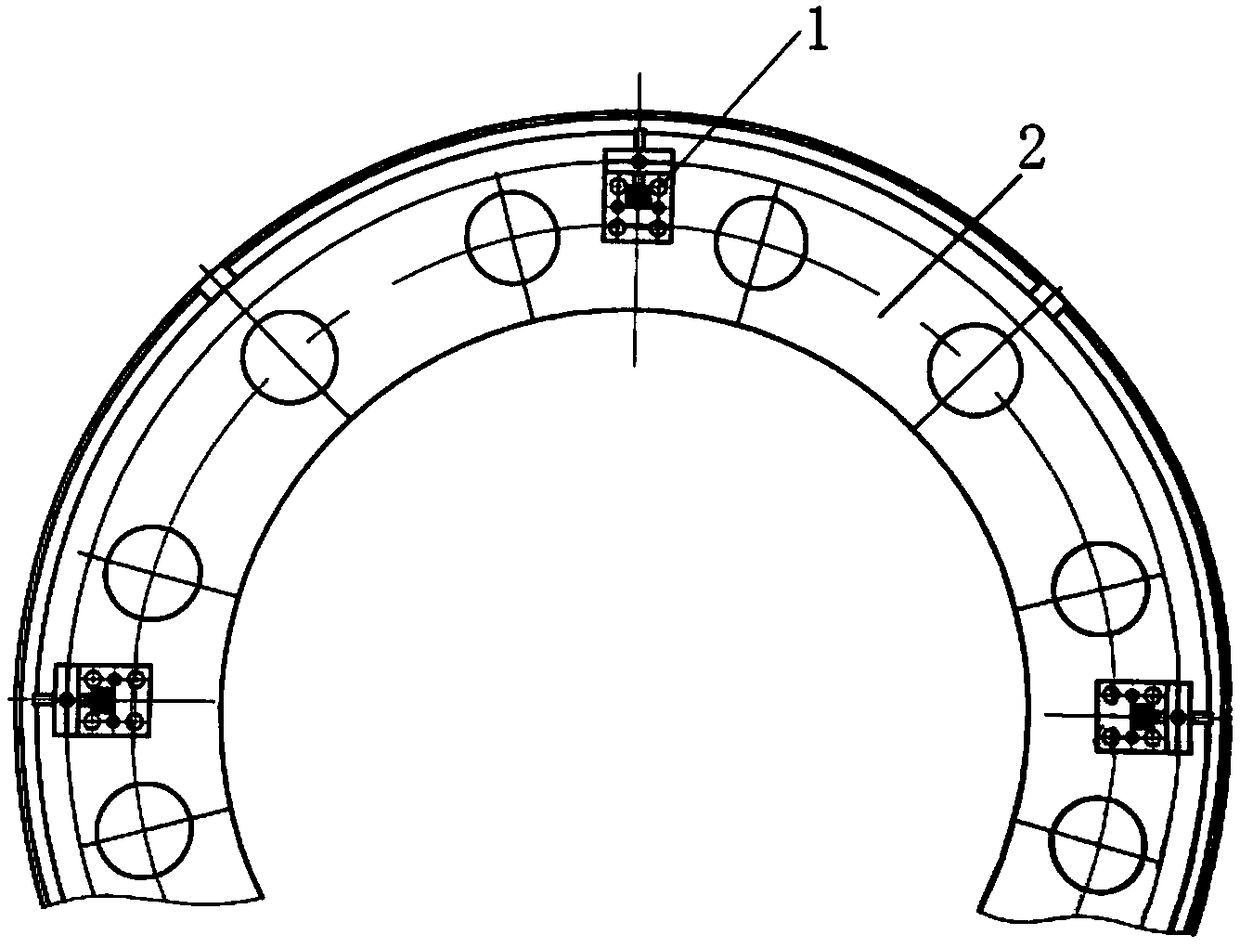

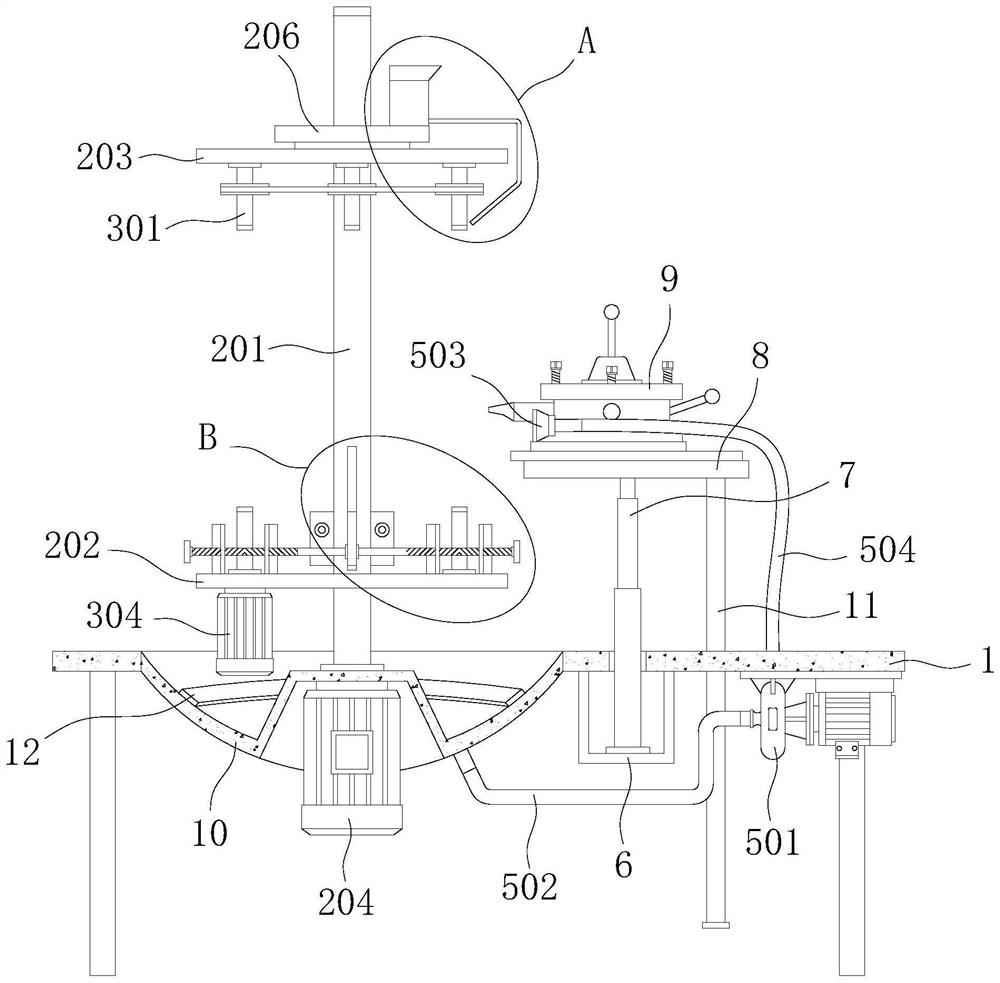

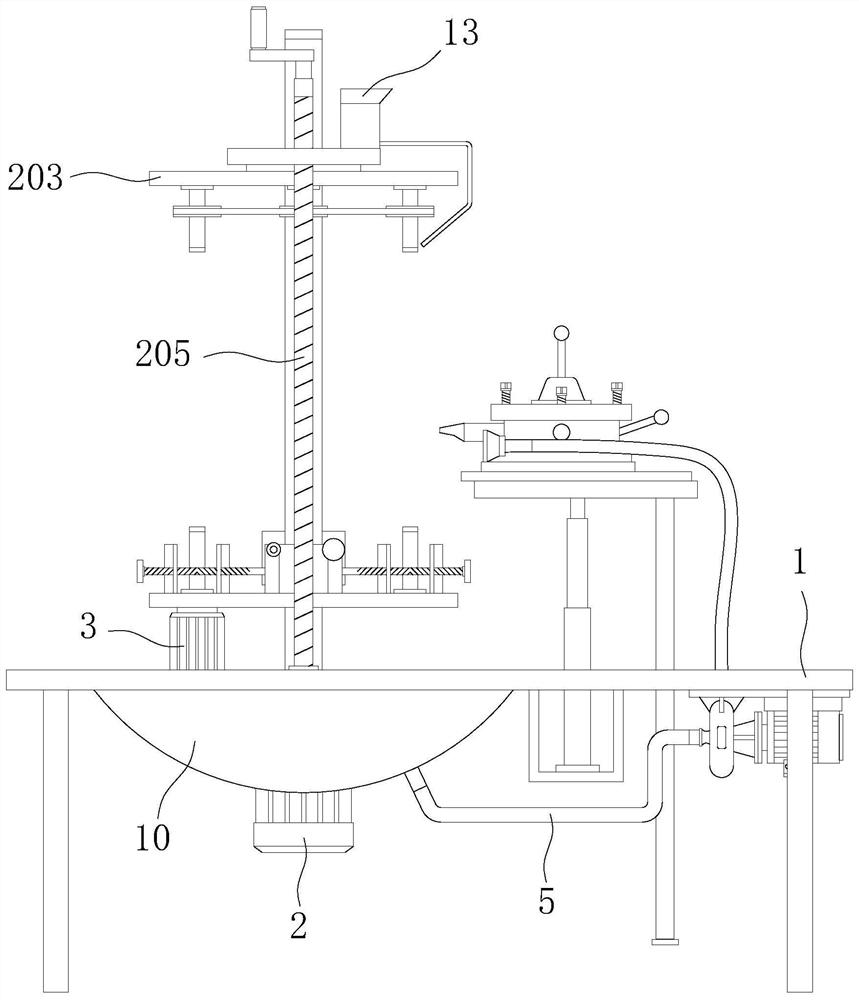

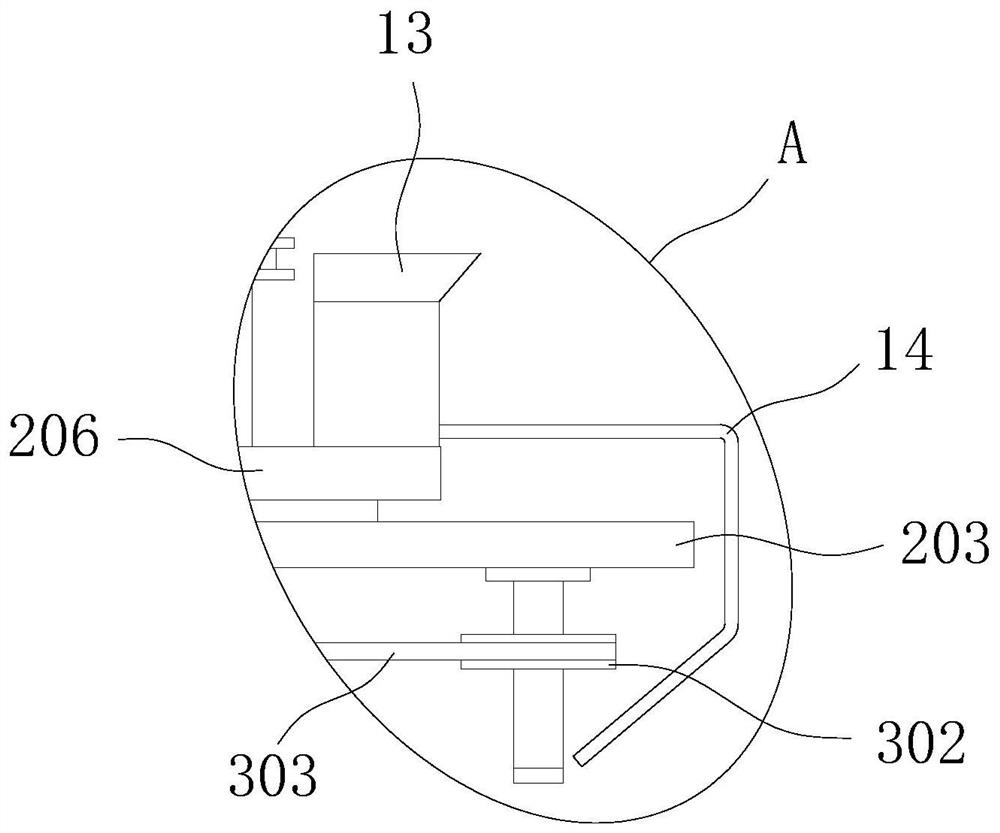

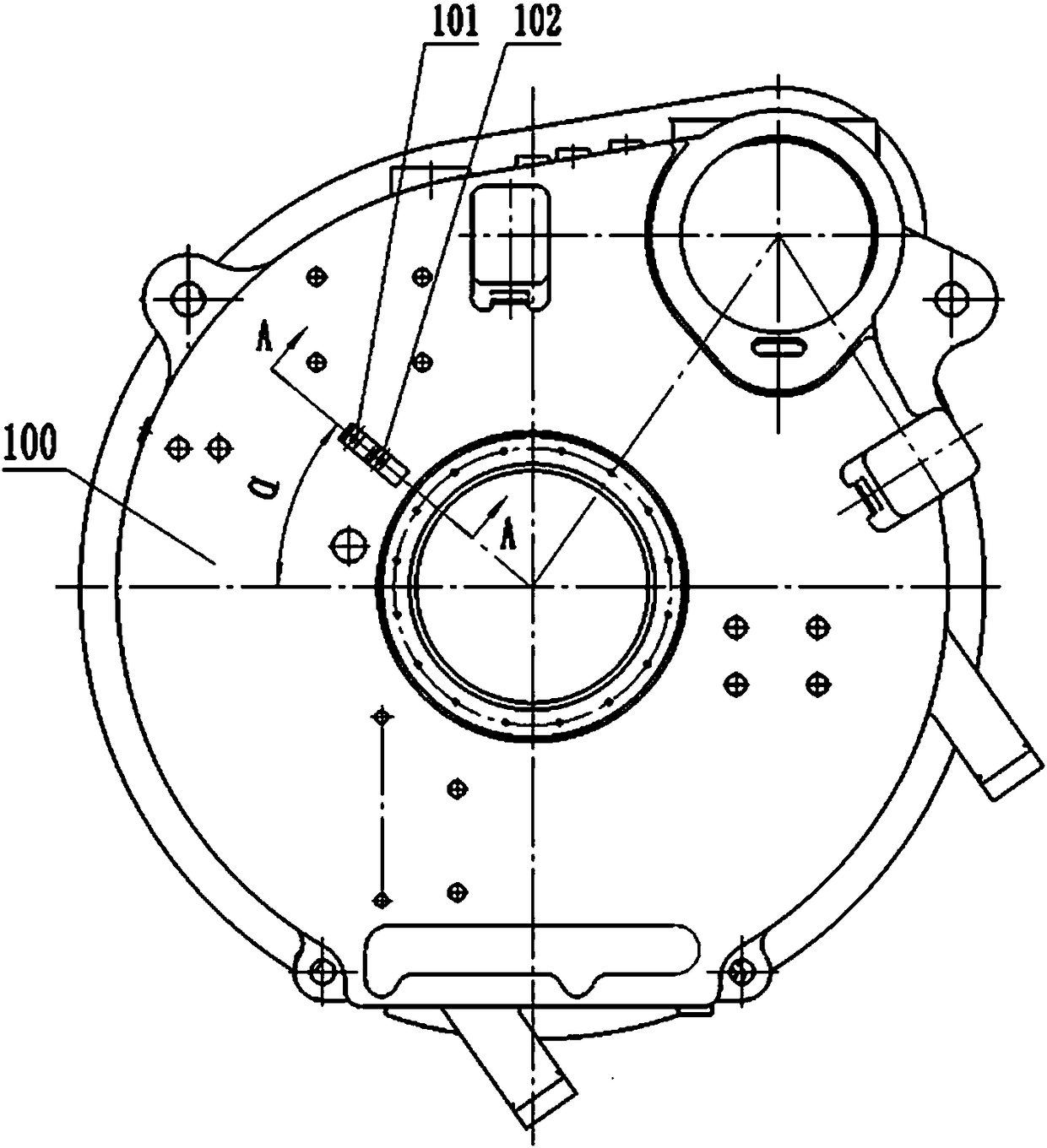

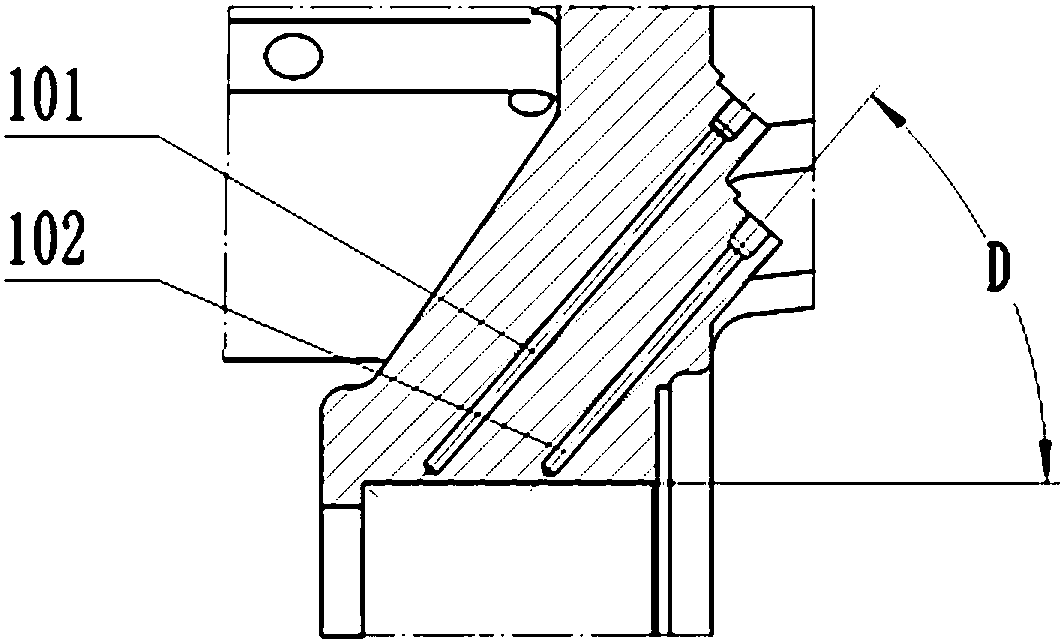

Stress detection device for rotating member of aero engine

The invention provides a stress detection device for a rotating member of an aero engine, and belongs to the technical field of stress detection of rotating members of aero engines. The stress detection device comprises a hydraulic platform, wherein movable casters are arranged on the bottom of the hydraulic platform, a frame is arranged on the upper portion of the hydraulic platform, the frame is connected with the hydraulic platform through a lifting support, one end of a hydraulic cylinder is hinged to the lifting support, the other end of the hydraulic cylinder is hinged to one end of a switchover block, and a cylinder body of the hydraulic cylinder is fixed to the hydraulic platform; one end of a hydraulic pedal is hinged to the hydraulic platform, and one end, hinged to the hydraulic platform, of the hydraulic pedal is hinged to the other end of the switchover block; a left bracket and a right bracket are arranged on two sides inside the frame respectively, the left bracket is connected with the frame through a bearing, the right bracket is fixedly connected with a handle mechanism arranged on the external of the frame through the frame, and the right bracket is connected with the frame through a bearing; the left bracket is fixedly connected with the right bracket through a horizontal bracket; a rolling bearing mechanism is arranged on the upper portion of the horizontal bracket, and a main supporting disc is arranged on the upper portion of the rolling bearing mechanism.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

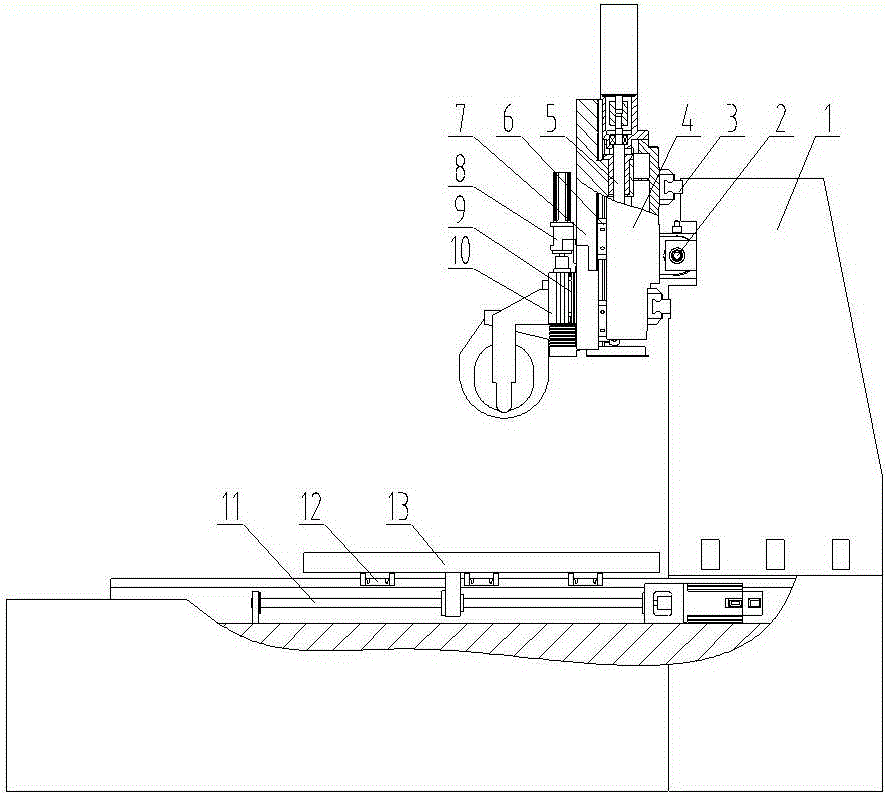

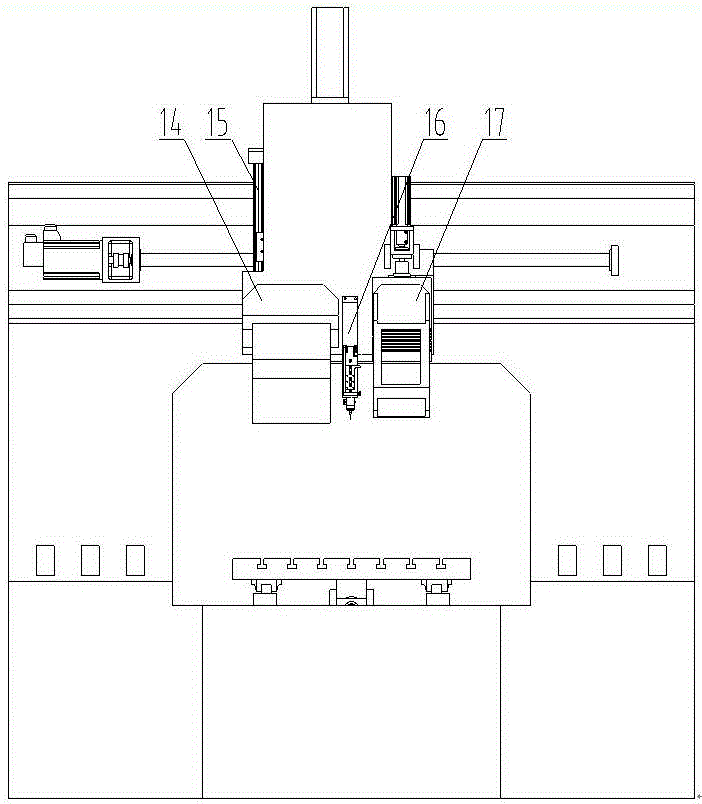

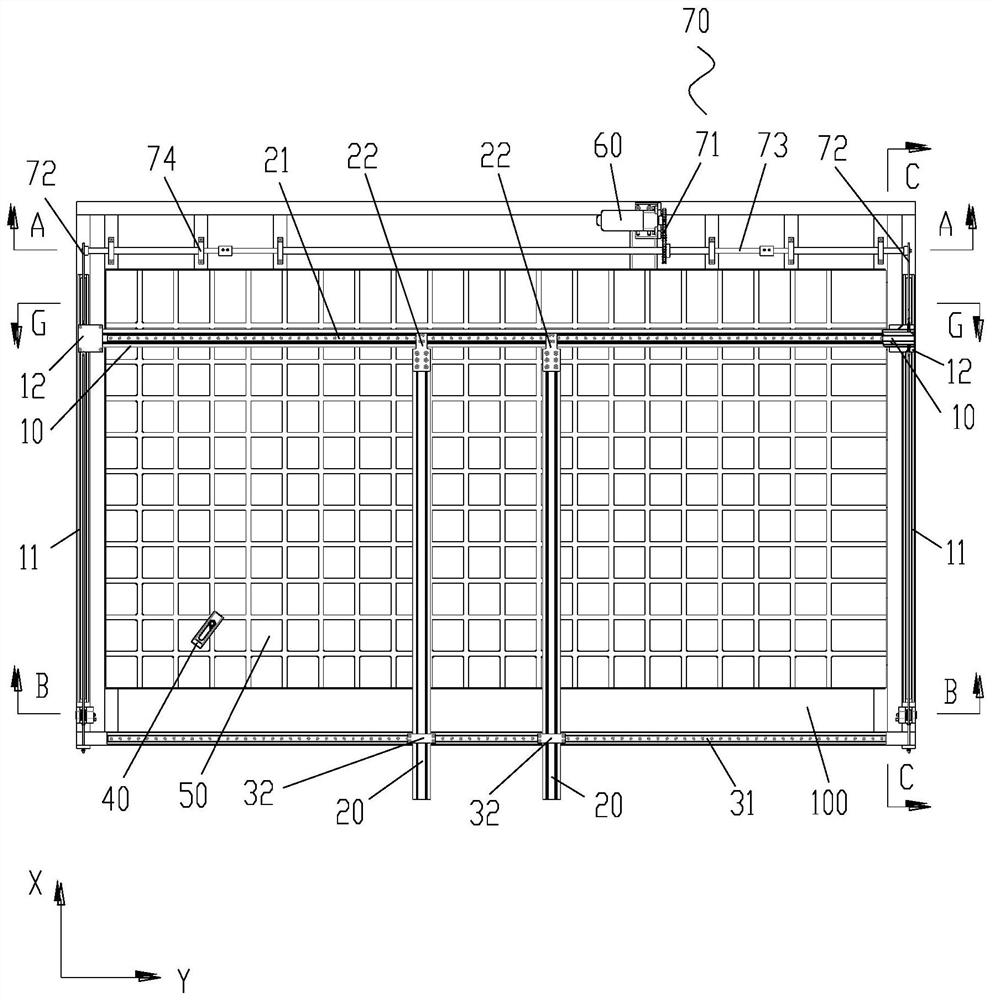

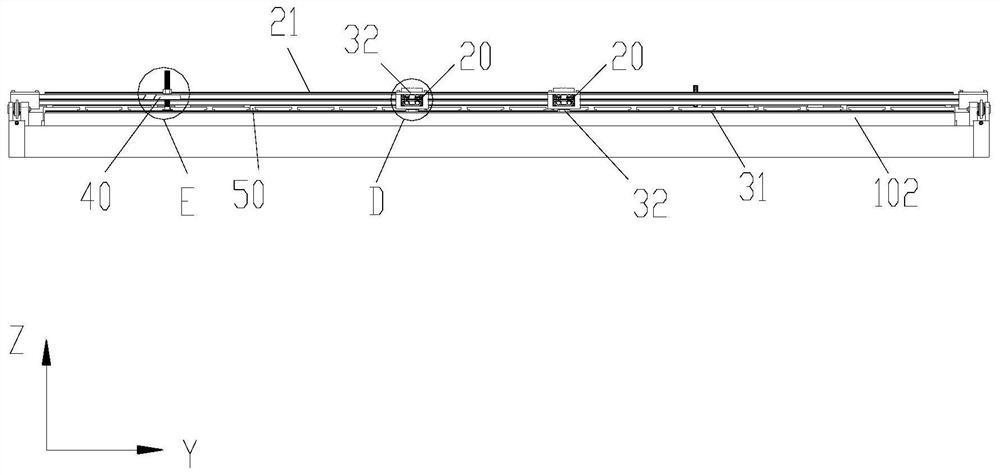

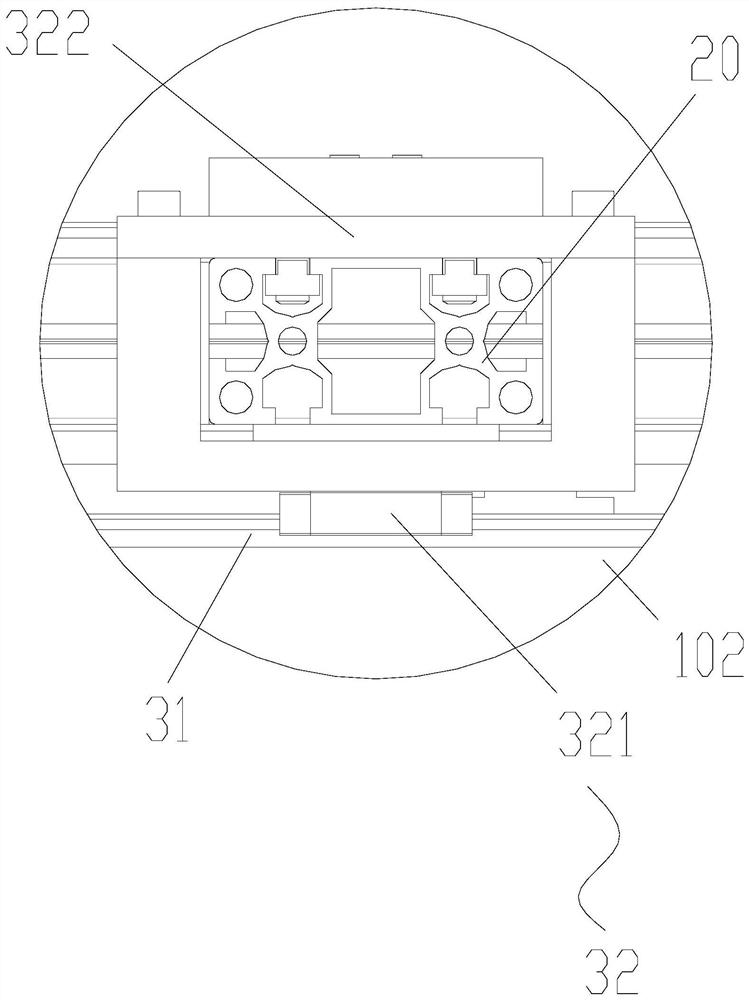

Master-slave gantry lathe bed structure with double Z axes

InactiveCN104625885AReduce processing preparation timeFast processingGrinding carriagesMeasurement/indication equipmentsHydraulic cylinderEngineering

The invention provides a master-slave gantry lathe bed structure with double Z axes. The master-slave gantry lathe bed structure is characterized in that an X axis is configured on a base of a gantry lathe bed, a Y axis is configured on an upright column of the gantry lathe bed, the Z<1> axis is configured on a slide carriage of the Y axis, the Z<2> axis is configured on a slide carriage of the Z<1> axis, and the Z<1> axis is balanced by the aid of counterweights of a hydraulic cylinder. The master-slave gantry lathe bed structure has the advantages that the Z<2> axis is fixed onto the Z<1> axis, moves along with the Z<1> axis and can move independently, accordingly, machining tasks can be independently executed by an executing mechanism fixed onto the Z<1> axis and an executing mechanism fixed onto the Z<2> axis, the executing mechanism fixed onto the Z<1> axis and the executing mechanism fixed onto the Z<2> axis can be matched with each other to completely carry out different working procedures on the same workpiece, and the machining efficiency can be obviously improved.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

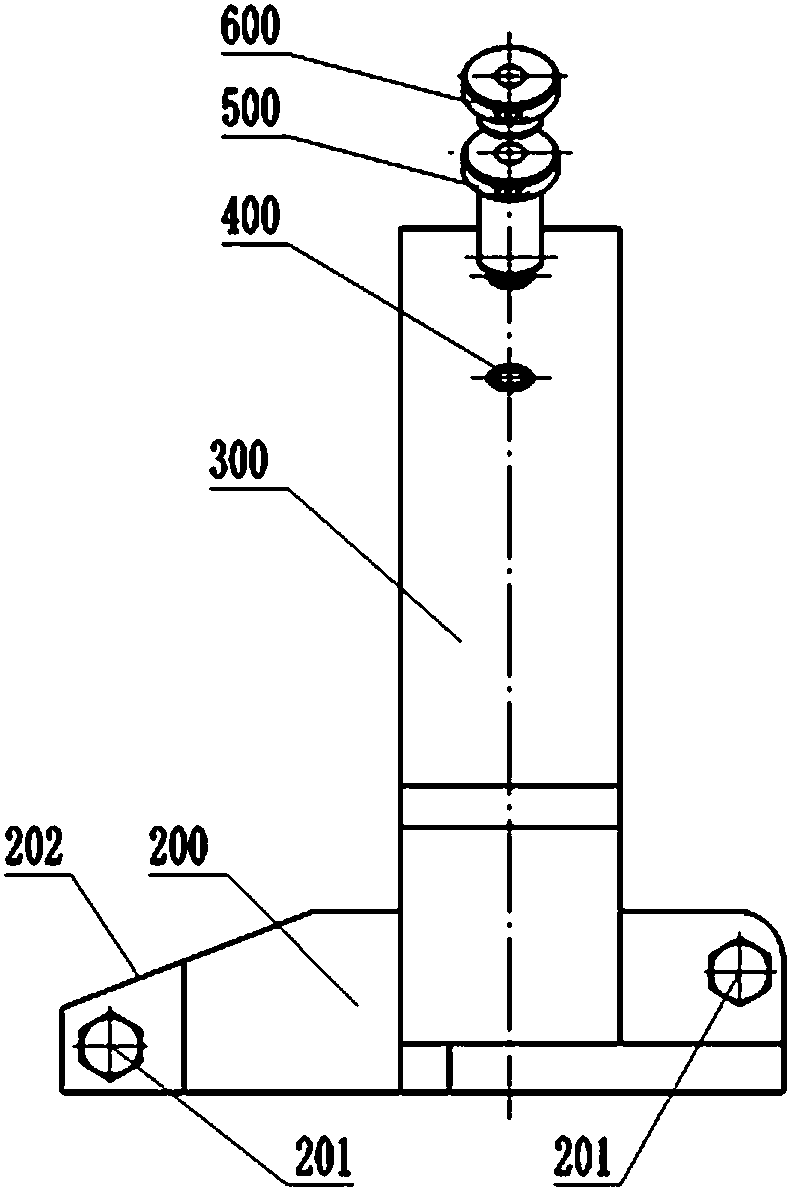

Positioning clamp

PendingCN109940431AReduce occupancyReduce processing preparation timePositioning apparatusMetal-working holdersEngineeringTorsion spring

The invention provides a positioning clamp. The positioning clamp comprises a support, a left-and-right positioning mechanism, a front-and-back positioning mechanism and a worktable board, wherein thesupport supports the left-and-right positioning mechanism, the left-and-right positioning mechanism comprise a left-and-right installing bottom plate, a left positioning mechanism and a right positioning mechanism, wherein the left positioning mechanism comprises a driving air cylinder I, an air cylinder connecting block I, an air cylinder fixing block I, a left positioning base, a sliding wire rail, a line rail installing base I, a left torsion spring base, a torsion spring installing base and a torsion spring positioning block; the right positioning mechanism comprises a driving air cylinder II, an air cylinder connecting block II, an air cylinder fixing block II, a right positioning base, a sliding wire rail, a line rail installing base II, a right base and a right positioning block; the front-and-right positioning mechanism comprises a front positioning mechanism and a back positioning mechanism, wherein the front positioning mechanism comprises a front positioning base, a front installing base and a front positioning block; and the back positioning mechanism comprises a bottom plate cushion block, an adsorbing table base, an adsorbing table, an air cylinder installing base, adriving air cylinder III, an installing base and a back positioning block. According to the clamp, centring can be achieved, a plurality of workpieces can be positioned at the same time and the clampdoes not greatly occupy the worktable board.

Owner:宇晶机器(长沙)有限公司

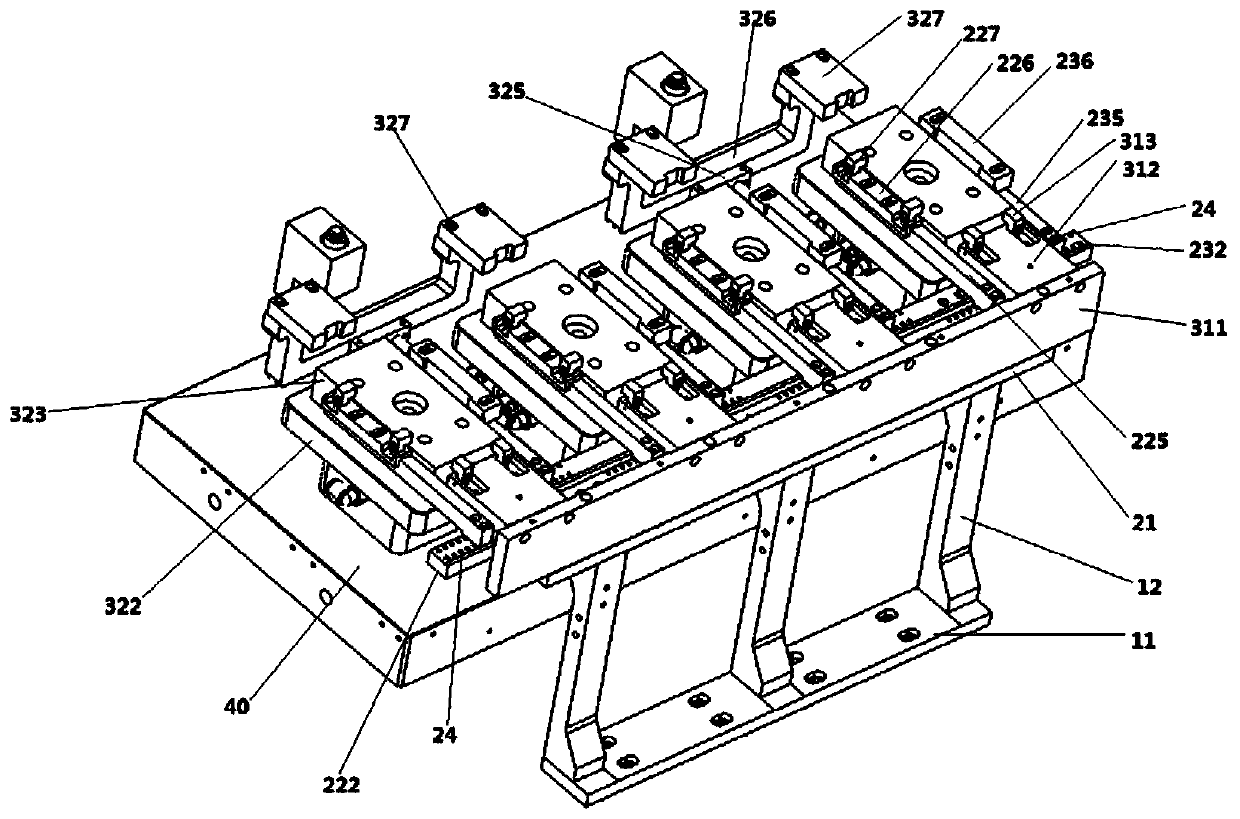

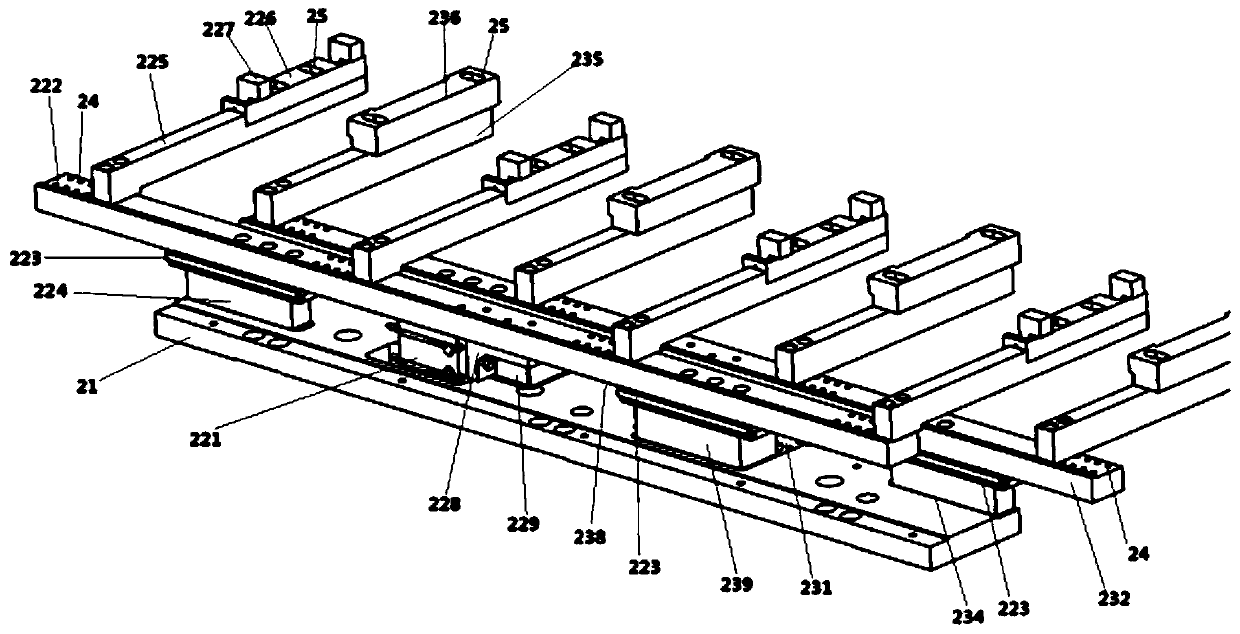

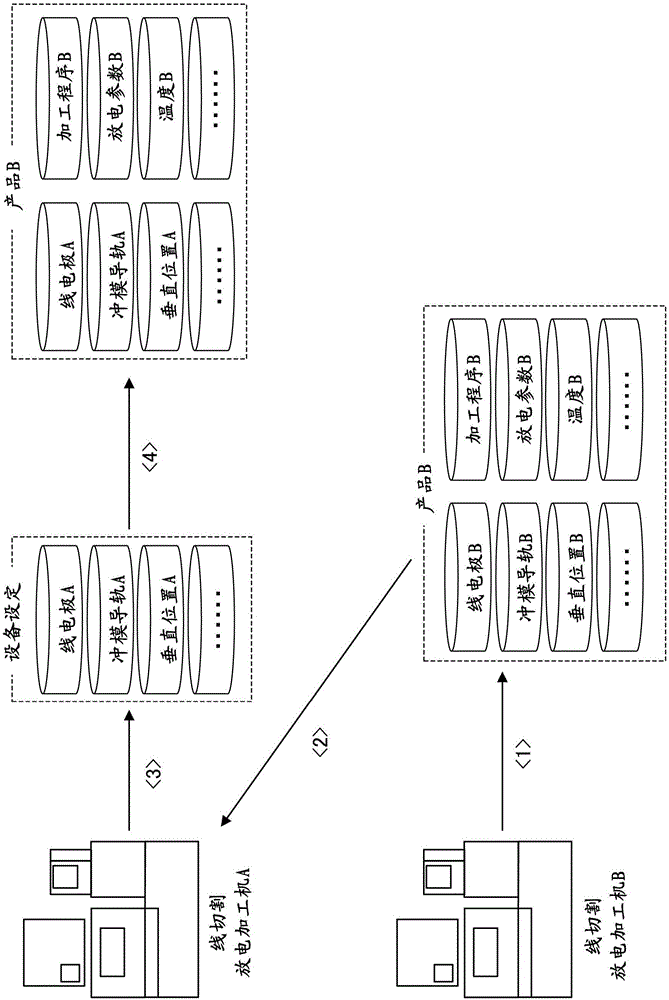

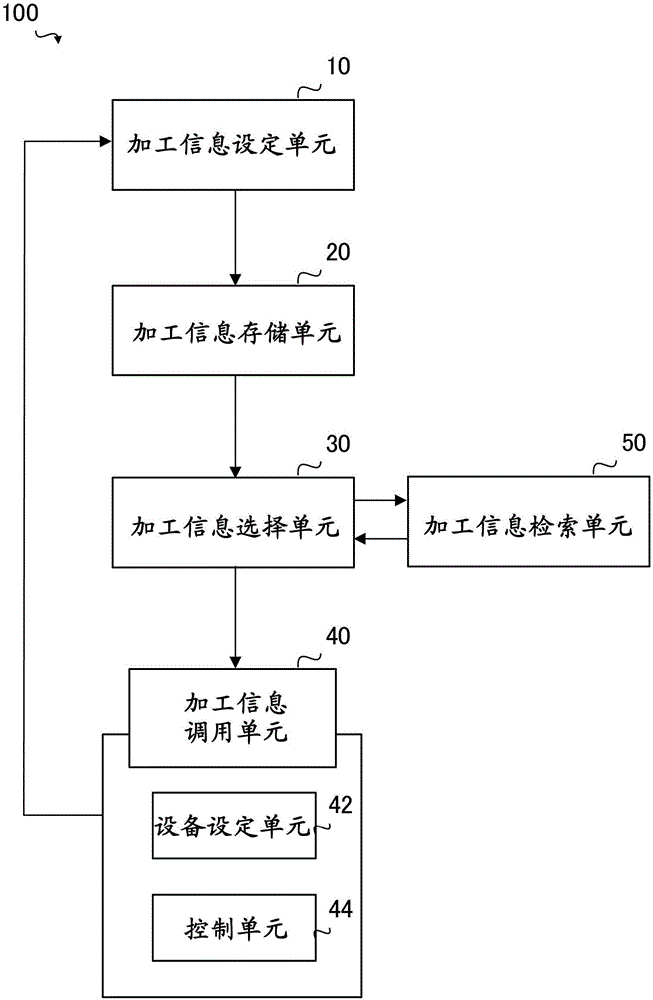

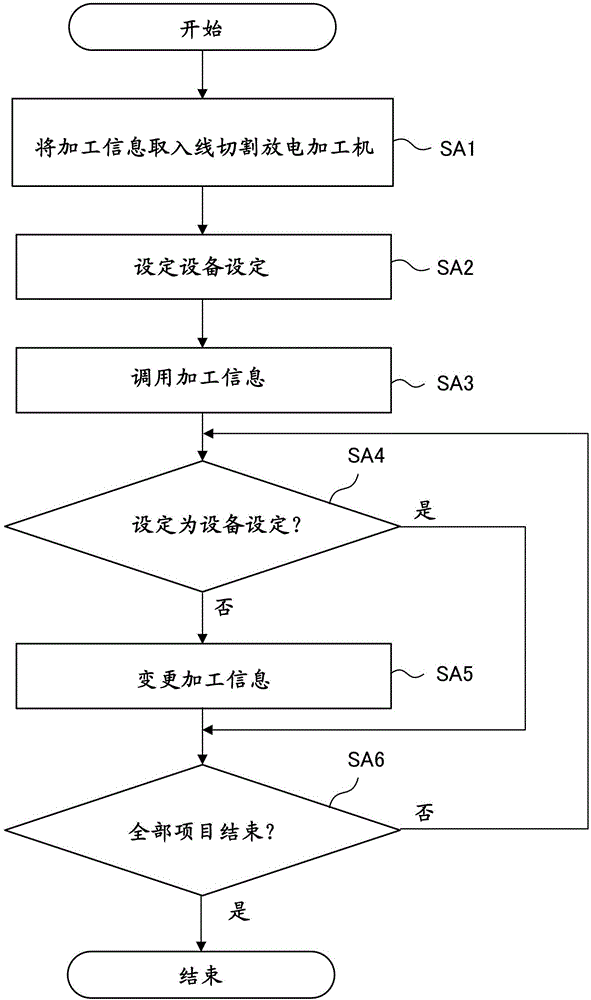

A wire-electrode cutting discharging processing machine with a processing information management function

InactiveCN105382358AReduce processing preparation timeEasy to manageElectric circuitsTotal factory controlVia deviceComputer science

Owner:FANUC LTD

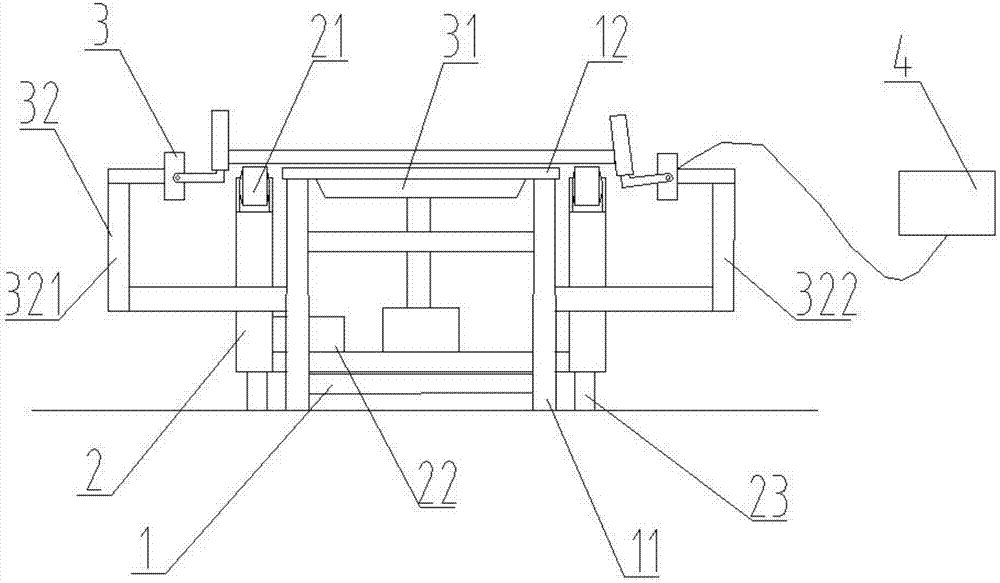

Aligning device and method for glass processing

ActiveCN107379299AOverall processing is simpleReduce processing preparation timeWorking accessoriesApparatus for force/torque/work measurementFixed positionElectrical and Electronics engineering

The invention discloses an aligning device and method for glass processing. The aligning device for glass processing comprises a supporting unit, a moving unit, a regulating unit and a processing unit; the supporting unit is used for supporting a raw glass sheet; the regulating unit and the moving unit are arranged on the supporting unit; the moving unit is used for moving the raw glass sheet on a fixed position; the regulating unit is used for detecting and regulating the position of the raw glass sheet; the processing unit is connected with the regulating unit by data and is used for controlling the regulating unit; and the regulating unit comprises a regulating device which is used for detecting and regulating the position of the raw glass sheet. According to the aligning device, the position of the raw glass sheet is located by the moving unit and the regulating unit, and the center position of the raw glass sheet is arranged on a center position of a table top, so that the processing unit is not needed to be repeatedly located before processing, an the processing setup time is shortened.

Owner:湖南邵虹特种玻璃股份有限公司

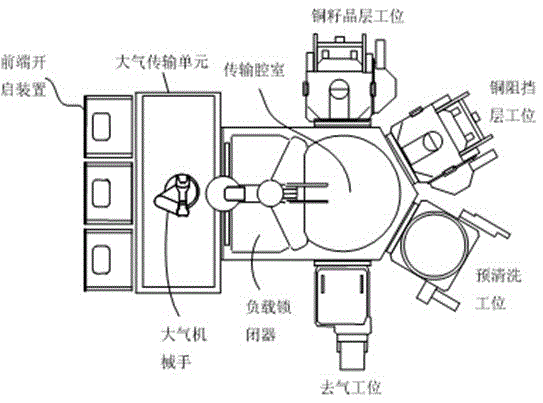

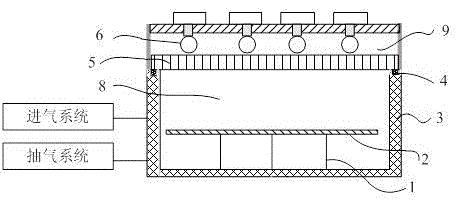

De-gassing chamber

ActiveCN105734522AReduce processing preparation timeShort cycleVacuum evaporation coatingSputtering coatingRadiant heatingVacuum chamber

The invention discloses a de-gassing chamber. The de-gassing chamber comprises a vacuum chamber and a radiation source, wherein the radiation source is arranged in the vacuum chamber for directly carrying out radiant heating on a to-be-processed chip placed in the vacuum chamber below. According to the de-gassing chamber, the conventional method of arranging the radiation source outside the vacuum chamber is changed, and the radiation source is directly arranged in the vacuum chamber, so that the defect caused by the conventional quartz window is eliminated, and therefore, the heating flow is simplified, the process preparation time of a de-gassing process is shortened, the period of the de-gassing process is greatly shortened, and conditions are created for increasing the yield of PVD equipment.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

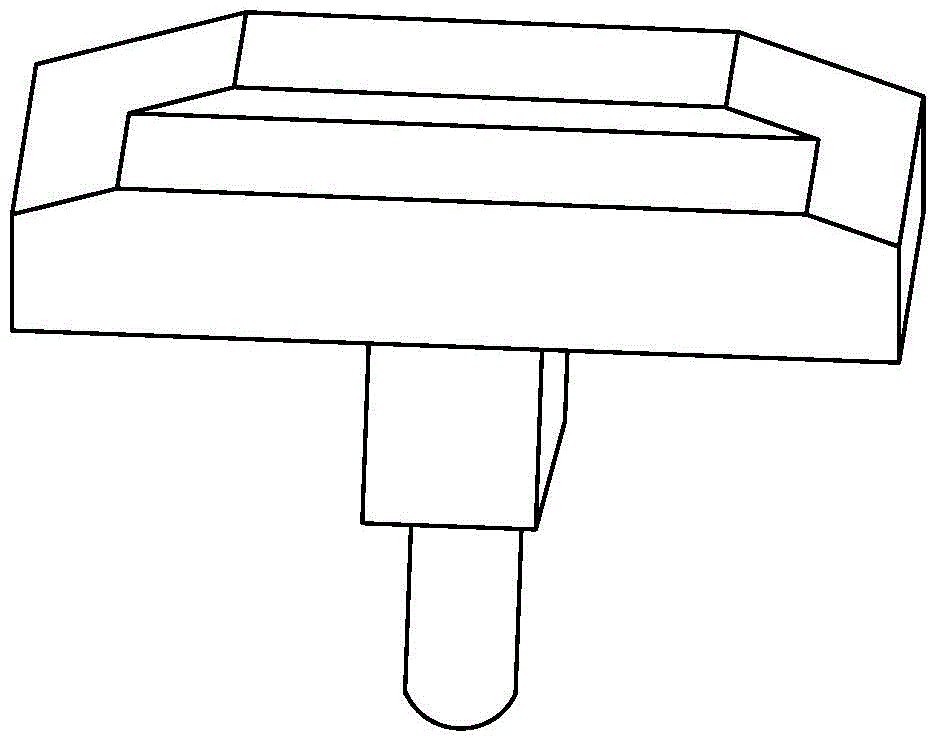

Machining device for deep-hole high-precision sealing surface

The invention discloses a machining device for a deep-hole high-precision sealing surface. The machining device of the deep-hole high-precision sealing surface comprises a sleeve and a pin rod, wherein the sleeve is T-shaped; a cylinder which protrudes outwards is formed in the centre of the bottom surface of the sleeve; the size of the outside diameter of the cylinder is adapted to that of the inside diameter of a deep hole to be machined; two mounting holes which are symmetrical with the cylinder are formed in the bottom surface; the size of the diameter of the pin rod is adapted to that ofthe inside diameter of the cylinder; knurls are formed along the outer wall of the upper end of the pin rod; a lug boss is formed at the lower end of the pin rod; the size of the countertop of the lugboss is adapted to that of a sealing surface with the deep hole to be machined; the countertop of the lug boss is a grinding surface; after the sealing surface is machined by using the machining device, the hole machining deformation of a part is greatly improved; the part yield is improved; the machining preparation time is greatly shortened, and meanwhile, the size precision is greatly improved; the technical requirement of 100 percent coloring of an end surface of the part can be met; the machining device can be popularized and applied to the machining of parts of the same type of other machine models; and the machining performance of a casing is improved.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Technology for electrocoppering

InactiveCN104988545AEasy to grind and shapeReduce process preparation timeSemiconductor devicesCopper wireSemiconductor

The invention relates to a technology for electrocoppering, and belongs to the field of semiconductor preparation. The technology for electrocoppering comprises the specific steps that sedimentation is conducted on an etching stop layer; an insulating layer is arranged on the etching stop layer; a wiring trough is manufactured in the insulating layer; metallic copper is arranged in the wiring trough; the metallic copper forms a copper wire along the wiring trough; quick cooling is conducted in the low-temperature environment; electroplating is conducted on the metal copper wire after cooling to a certain temperature; polishing and cleaning treatment are conducted after surface polishing is finished. The technology for electrocoppering has the advantages that fixing and nature determination are conducted on the wire by using the low-temperature environment, polishing and forming in the following step are convenient, the low-temperature environment contributes to wire forming, the time on technological preparation can be reduced, and the working efficiency is improved greatly.

Owner:SUZHOU HUARI JINLING MACHINERY

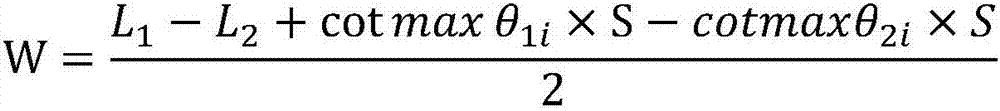

Method and clamp for machining thin-walled cylinder provided with groups of dense holes and oblique end faces

ActiveCN109500527AEasy to operateReduce processing preparation timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled cylinder

The invention provides a method and clamp for machining a thin-walled cylinder provided with groups of dense holes and oblique end faces. By adoption of the method and clamp for machining the thin-walled cylinder provided with the groups dense holes and the oblique end faces, the problems that the machining efficiency of thinned-walled cylinders provided with groups of dense holes and oblique endfaces which are produced in batches and are of specified models is low, and the material utilization rate is low are solved. Complementary integrated machining of two parts is adopted, namely waste generated when one part is machined is converted into a main body of the other part, so that the problem of the low material utilization rate of the parts is effectively solved; meanwhile, laser machining is used for functional machining in the height direction, so that the problems that oblique end face clamps need to be designed to the parts, and the parts are placed on the oblique end face clampsso as to be machined horizontally are solved; and two times of clamping are replaced by one time of clamping, and two times of alignment are replaced by one time of alignment, so that complex operation by workers is avoided, and the problem that the highest points and the lowest points of the parts cannot be easily aligned is solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

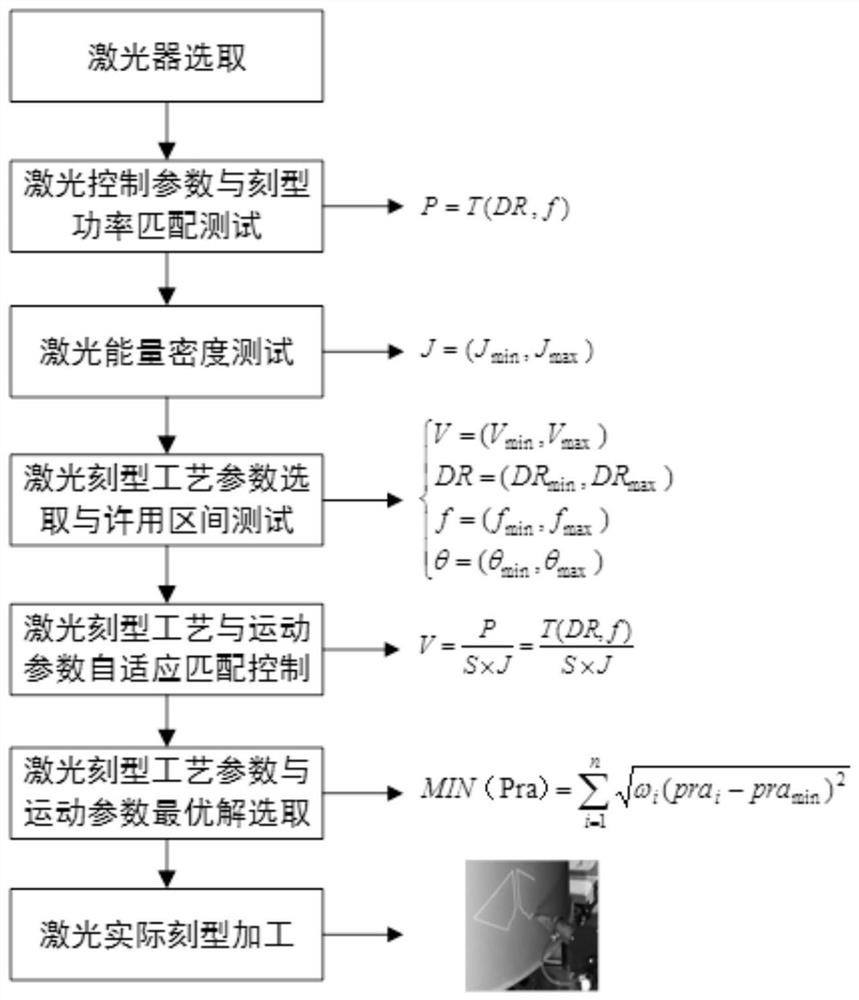

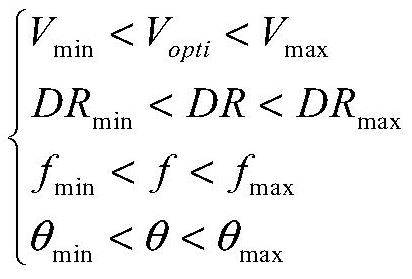

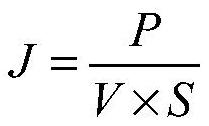

Self-adaption control method for laser engraving

ActiveCN111673265ALow experience requirementReduce processing preparation timeLaser beam welding apparatusLaser engravingErbium lasers

The invention discloses a self-adaption control method for laser engraving, and belongs to the technology of laser surface engraving. The technique and method related to the invention comprise the steps of selecting a laser device, conducting match testing between laser control parameters and engraving power, measuring laser engraving energy density, selecting a laser engraving technique and testing an allowable range, conducting self-adaption match control between laser engraving technological parameters and motion parameters, and conducting laser engraving machining on multiaxial laser engraving equipment. On the basis that according to traditional laser engraving, single laser technological parameters are input, matching control of laser power and machine tool is introduced, optimum selection of laser engraving parameters is achieved, the laser engraving precision and quality of laser engraving at acceleration and deceleration positions in the laser engraving process can be better achieved, and the engraving technique is more intelligent.

Owner:BEIHANG UNIV +1

Welding positioning auxiliary device

InactiveCN111761288AGuarantee welding qualityReduce processing preparation timeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a welding positioning auxiliary device. The welding positioning auxiliary device comprises a welding platform, a first moving shaft movably arranged relative to the welding platform in a first preset direction so as to limit a workpiece positioned on the welding platform, a second moving shaft movably arranged relative to the welding platform in a second preset direction soas to limit the workpiece positioned on the welding platform, and a pressing member, wherein at least part of the pressing member is movably arranged in a third preset direction relative to the welding platform so as to press the workpiece on the welding platform; and any two of the first preset direction, the second preset direction and the third preset direction are arranged perpendicular to each other. Through the arrangement, the problem that a welding positioning mode in the prior art is low in efficiency is solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

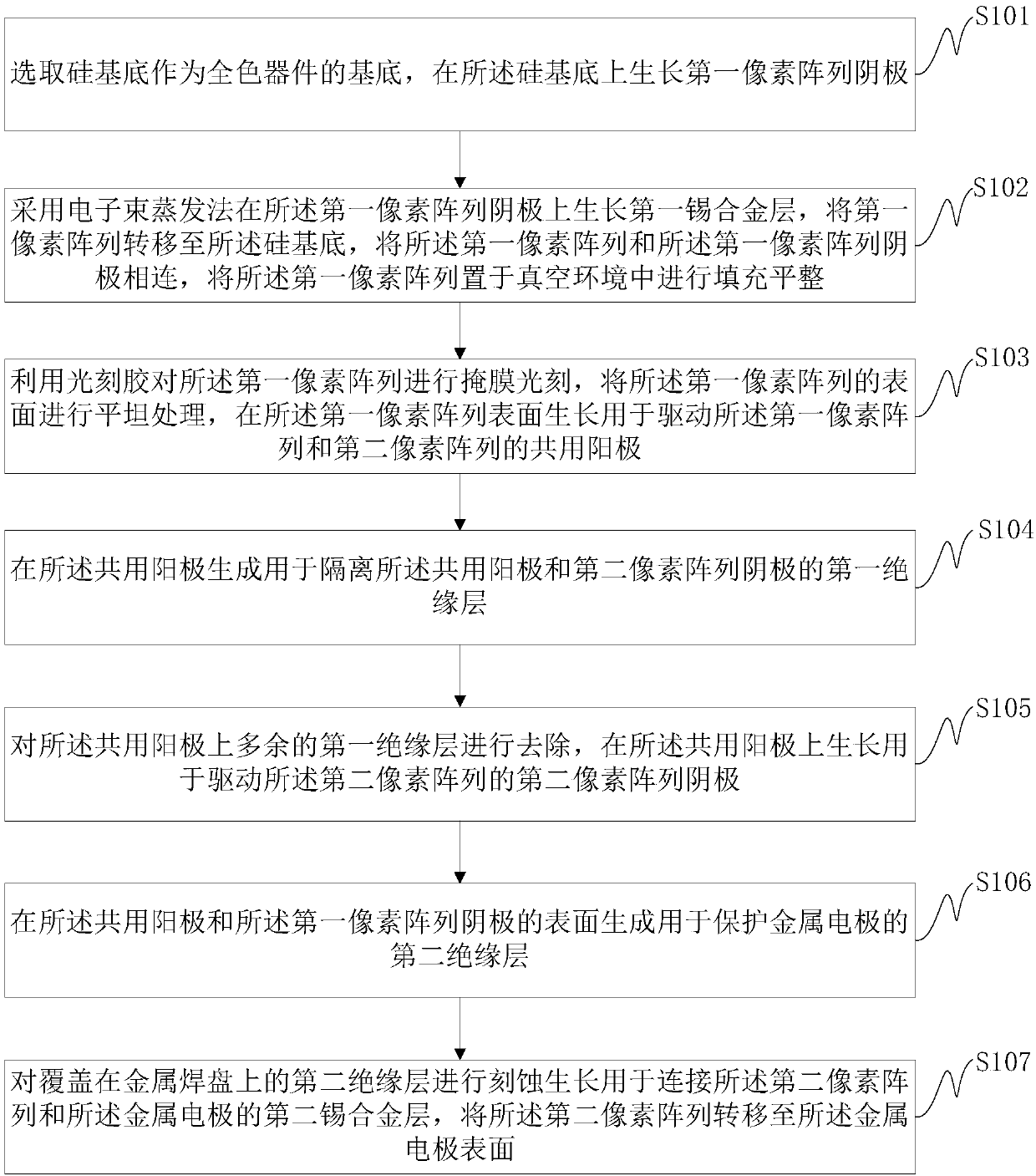

Full-color LED array device integrated manufacturing method

ActiveCN110970458AHigh resolutionOptimizing PhotosynthesisSolid-state devicesSemiconductor devicesLed arrayFull color

The invention discloses a full-color LED array device integrated manufacturing method. A stacking and integration mode is adopted, and red and green pixels and red and blue pixels are overlapped without spacing, so that the preparation of a full-color array device with higher resolution is realized; besides, the photosyntheticity of the red, green and blue three-color pixel units of a panchromaticarray is optimized by adopting a superposition integration mode; the display characteristic of the micro full-color LED array device is further improved; and moreover, according to the manufacturingmethod disclosed by the invention, the pixel spacing can be properly adjusted to meet different application requirements, the process difficulty that the pixel unit spacing cannot be reduced due to the fact that an electrode lead occupies space is avoided, red, green and blue pixel units are transferred to a circuit substrate in batches, and the process preparation time is shortened.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Part fast hole drilling and thread tapping clamp

ActiveCN104827311AEasy clampingReduce processing preparation timeWork clamping meansPositioning apparatusBiomedical engineeringDrill hole

The invention discloses a part fast hole drilling and thread tapping clamp, which comprises a clamp body, wherein one end of the clamp body is provided with a first installing and clamping hole for carrying out hole drilling processing on a part; a positioning core is arranged in the first installing and clamping hole; the positioning core is arranged on the clamp body through a connecting and fixing component; a first processing hole communicated with the first installing and clamping hole is formed in the clamp body; a second installing and clamping hole used for carrying out thread tapping processing on the part is formed in the clamp body and at one side of the first installing and clamping hole; a second processing hole used for being communicated with the second installing and clamping hole is formed in the clamp body. The part fast hole drilling and thread tapping clamp has the advantages that the part hole drilling and the thread tapping installing and clamping can be integrated onto one clamp, and the installing and the clamping are convenient and fast; in addition, after the hole drilling completion, the thread tapping without tooling replacement can be realized after the hole drilling is completed, the processing preparation time is shortened, and the processing cost is saved.

Owner:WUXI XINHONGTAI ELECTRIC TECH CO LTD

Hardware part machining machine tool for field of mechanical engineering

ActiveCN112571103AImprove practicalityImprove the protective effectLarge fixed membersCleaning using liquidsMechanical engineering technologyEngineering

The invention discloses a hardware part machining tool for the field of mechanical engineering, and relates to the technical field of mechanical engineering. The hardware part machining machine tool for the field of mechanical engineering comprises a machine tool body, a rotary clamping mechanism, a transmission mechanism, an auxiliary clamping mechanism and a circulating flushing mechanism are arranged on the machine tool body, a mounting frame is welded to the outer surface of the bottom of the machine tool body, and an electric push rod is welded to the bottom of the inner side of the mounting frame; and a bearing table is welded to the free end of the electric push rod, a guide rail is welded to the outer surface of the top of the bearing table, a sliding base is slidably installed onthe guide rail, and a machining cutter is welded to the outer surface of the top of the sliding base. According to the hardware part machining machine tool for the field of mechanical engineering, repeated workpiece clamping operation is not needed, the labor intensity of operators is relieved, the machining preparation time is shortened, and the production and machining efficiency is improved; and compared with a machining machine tool which does not facilitate continuous operation, the machine tool is higher in practicability and higher in integrality.

Owner:WEIFANG UNIV OF SCI & TECH

A quick automobile sheet metal workbench

ActiveCN105537322BEasy to operateReduce processing preparation timeMetal-working feeding devicesPositioning devicesEngineeringSelf locking

The invention provides a rapid automotive sheet metal workbench. Transverse supporting beams can move transversely along a main supporting platform. Clamping module sets are arranged at the two ends of each transverse supporting beam. The clamping module sets can move longitudinally along the transverse supporting beams and can rotate horizontally. Movement switching of the transverse supporting beams and the clamping module sets is achieved through spline structures. A traditional positioning and clamping way using bolts for fastening is replaced through the transverse supporting beams and the clamping module sets by means of the self-locking function of lead screws, so that position determination in the horizontal direction is achieved; meanwhile, primary positioning and clamping of an automobile body are completed by means of the dead weight of an automobile. According to the rapid automotive sheet metal workbench, operation is rapid, and the function of correcting light automobile bodies is achieved; a sheet metal part, damaged due to collision, in the automobile body can be stretched and corrected, the workbench can also serve as an auxiliary operation platform for other sheet metal maintenance work, and favorable auxiliary conditions for shorting the process time are provided while the process preparation time is effectively and greatly shortened.

Owner:臧汝涛

Machining device for space deep inclined holes in large wind power box

PendingCN108543996ASimple structureEasy to manufactureDrill jigsBoring/drilling machinesElectricityPilot hole

The invention discloses a machining device for space deep inclined holes in a large wind power box, wherein the machining device is low in input-output ratio. A connecting positioning plate is connected with the large wind power box, and the inclined face at one corner of the connecting positioning plate corresponds to the inner circular-arc face of the periphery of the mounting face on the largewind power box. The face, facing the large wind power box, of the connecting positioning plate is the positioning face. A guiding positioning plate comprises a transition part and a guiding part whichis flush with the upper surface of the transition part to form the guiding positioning face provided with a magnetic electric drill. Corresponding corners corresponding to the inclined corners of thefirst space deep inclined hole and the second space deep inclined hole in the large wind power box are formed between the guiding positioning face and the positioning face on the connecting positioning plate. A first guiding hole and a second guiding hole which correspond to the first space deep inclined hole and the second space deep inclined hole correspondingly are formed in the guiding part.Two linings are assembled in the first guiding hole and the second guiding hole in an interference mode correspondingly, and a deep hole quick-changing drill bushing and a screw hole quick-changing drill bushing are in clearance fit with the two linings correspondingly. The hole diameters of the deep hole quick-changing drill bushing and the screw hole quick-changing drill bushing are slightly larger than the outer diameter of a drill bit of the magnetic electric drill.

Owner:CHONGQING WANGJIANG IND

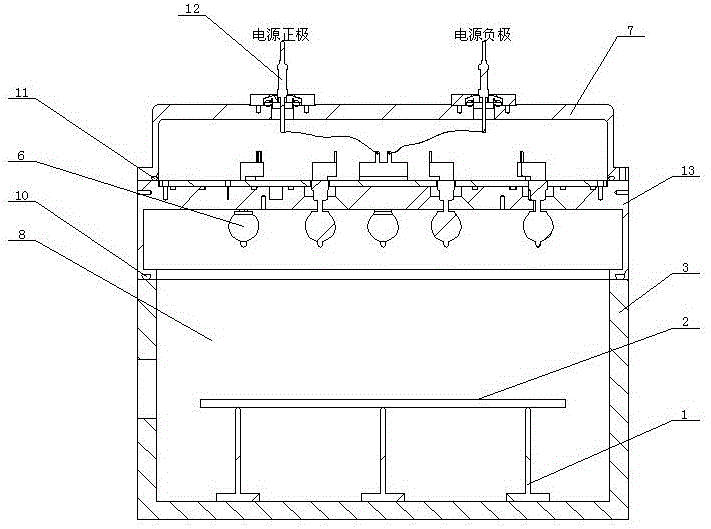

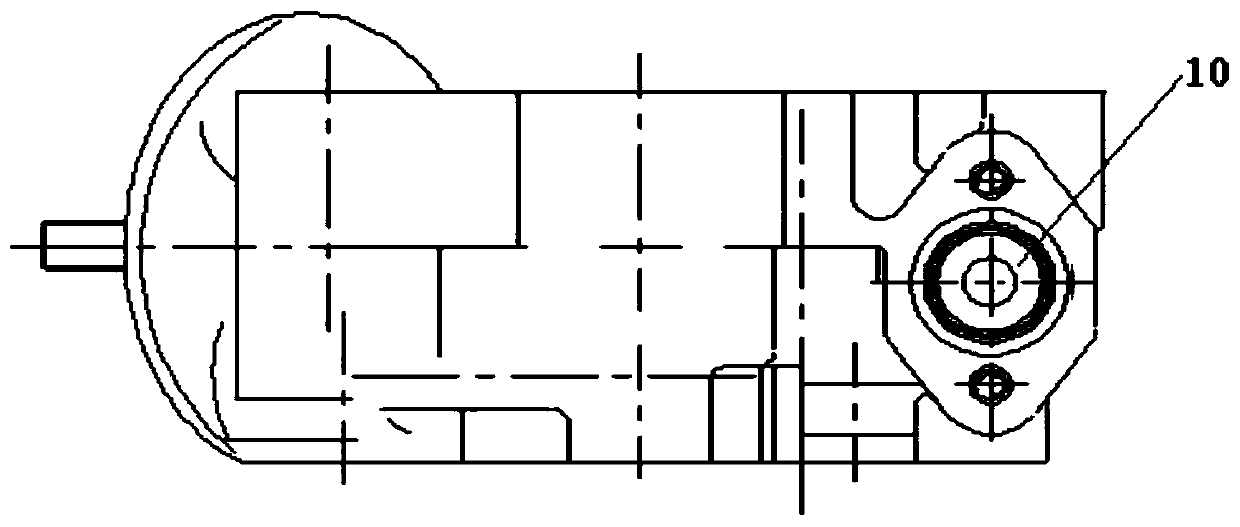

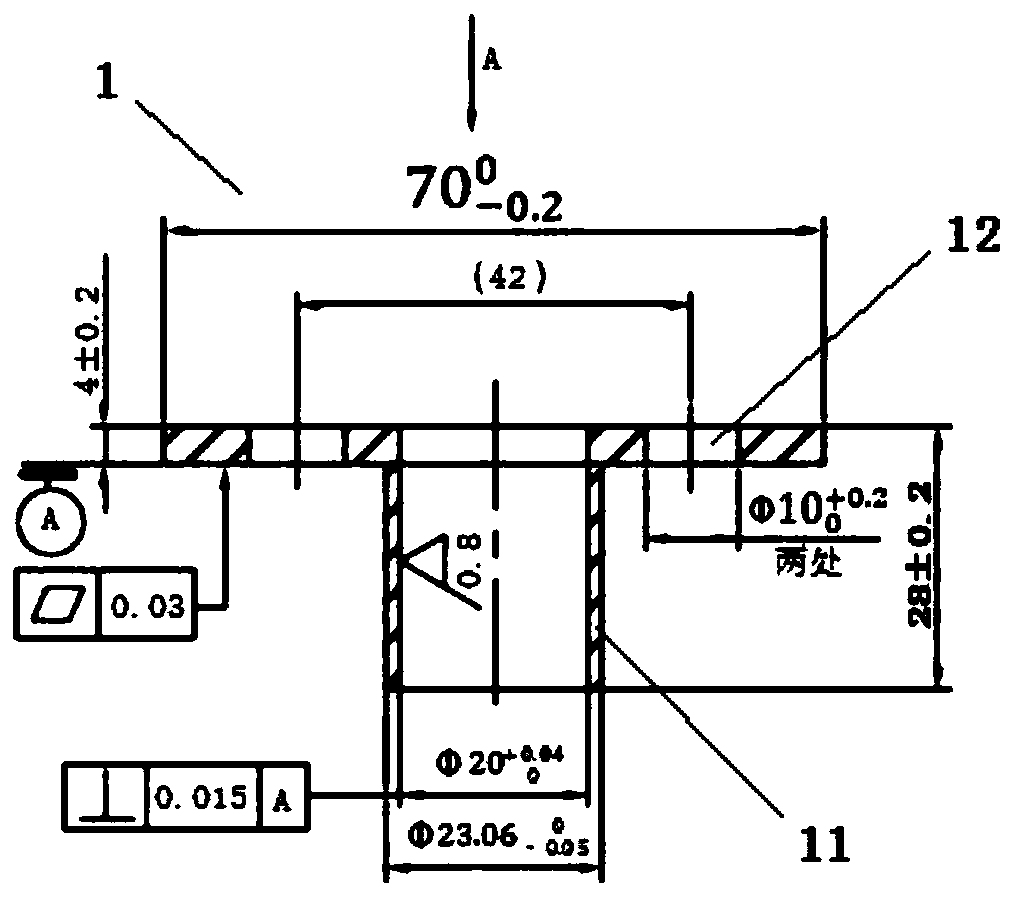

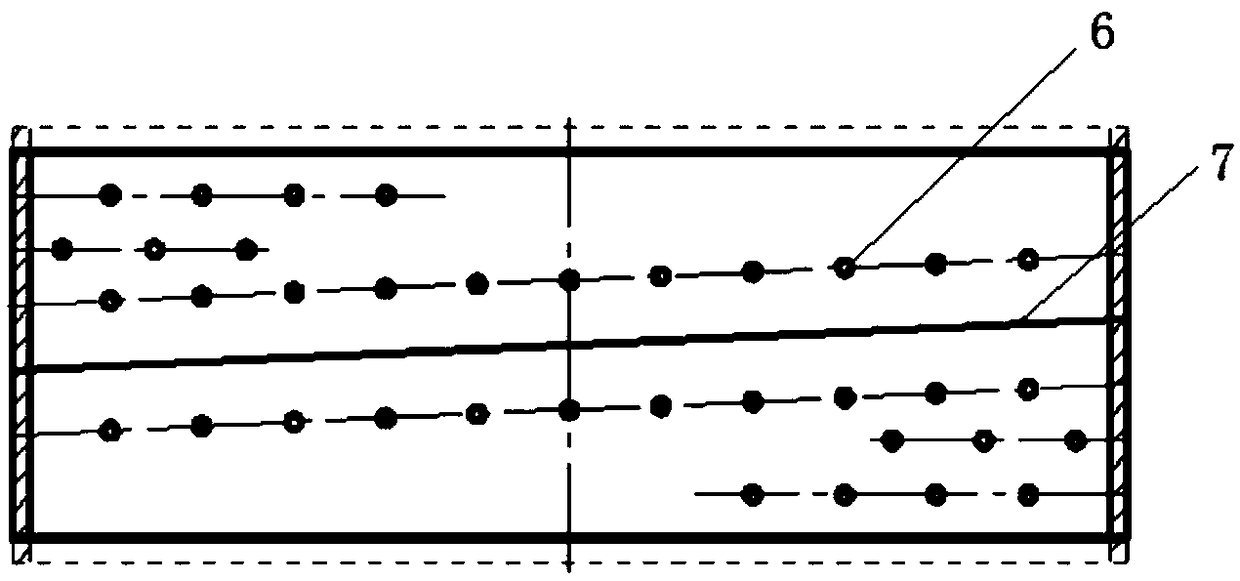

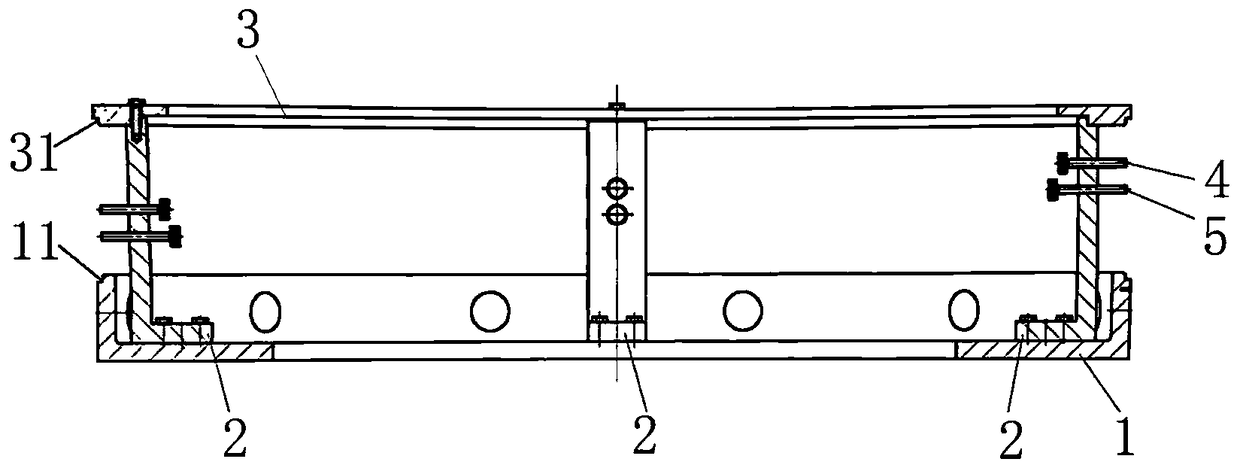

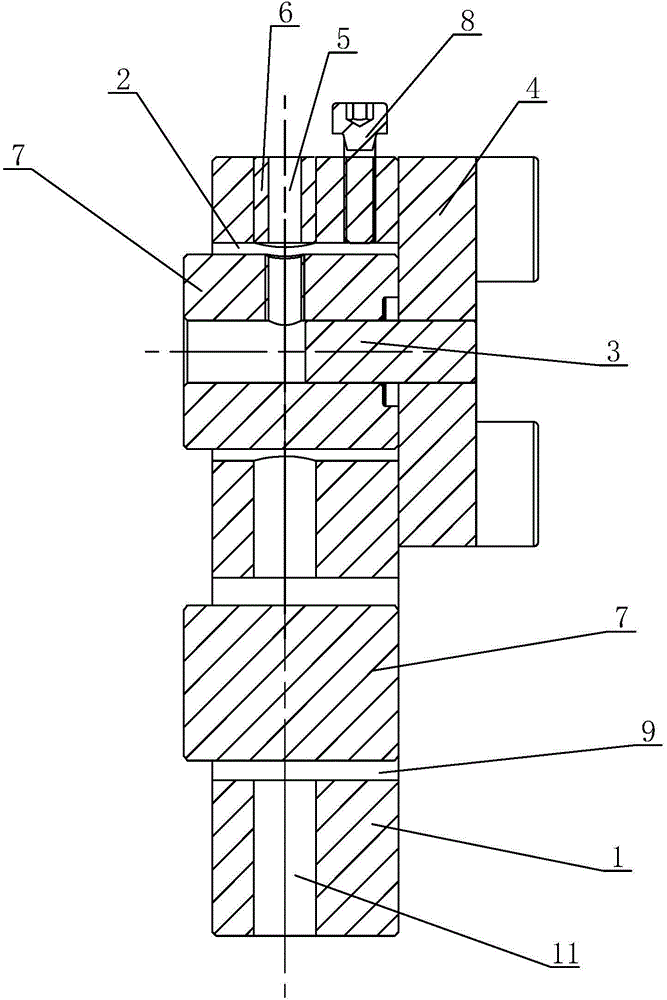

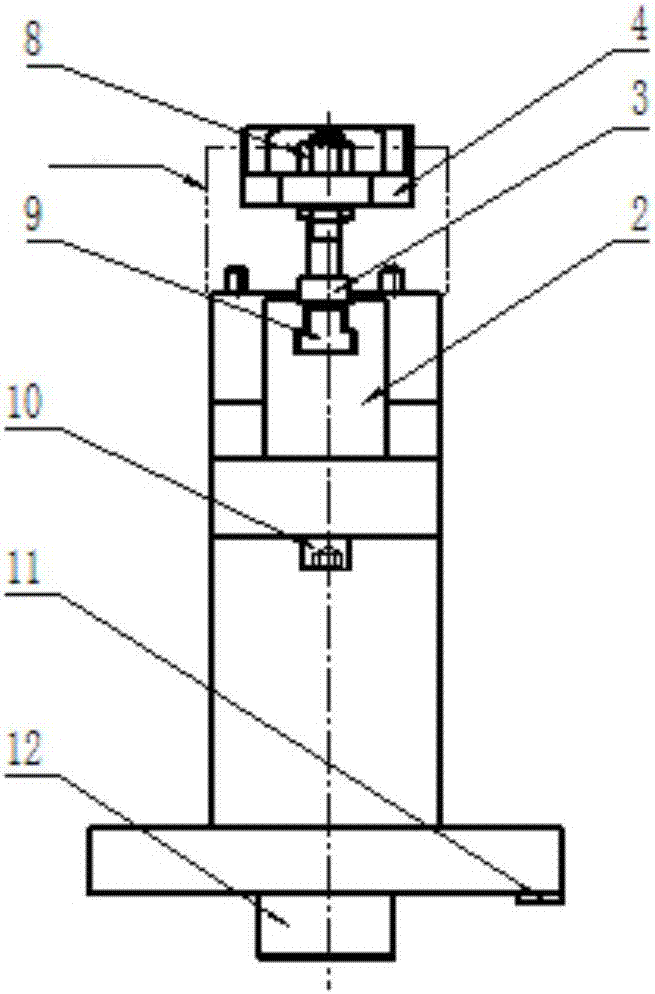

Milling rapid reloading fixture for servo valve shell parts

InactiveCN107962414AReduce processing preparation timeImprove operational efficiencyPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention belongs to the technical field of precision machining of servo parts, and particularly relates to a milling rapid reloading fixture for servo valve shell parts. According to the millingrapid reloading fixture for servo valve shell parts, a base frame is fixedly connected with a machine table through a positioning key and a positioning shaft; a connecting block II is fixedly connected with a groove in the middle of the base frame; series positioning blocks are installed on bosses on two sides of the groove in the middle of the base frame, and cross-shaped convex grooves in the bottom ends of the series positioning blocks are engaged with grooves in the bosses of the base frame for positioning and fixedly connected with the grooves; connecting blocks I are fixedly installed ingrooves in the two ends of the base frame; the connecting blocks I and the connecting block II are provided with T-shaped grooves, and T-shaped nuts are installed in the T-shaped grooves; and the connecting blocks I are fixedly connected with series supporting nails, and series pressing plates are fixedly installed on the series supporting nails. By means of the milling rapid reloading fixture for servo valve shell parts, the same class of parts can be machined through only one basic fixture, the machining preparation time is shortened, and operation efficiency is improved.

Owner:北京实验工厂有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com