Large-scale flexible work workshop scheduling optimization method

A flexible operation and workshop scheduling technology, applied in genetic models, genetic laws, instruments, etc., can solve problems such as complex solution space, insufficient solution quality and solution time to meet requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

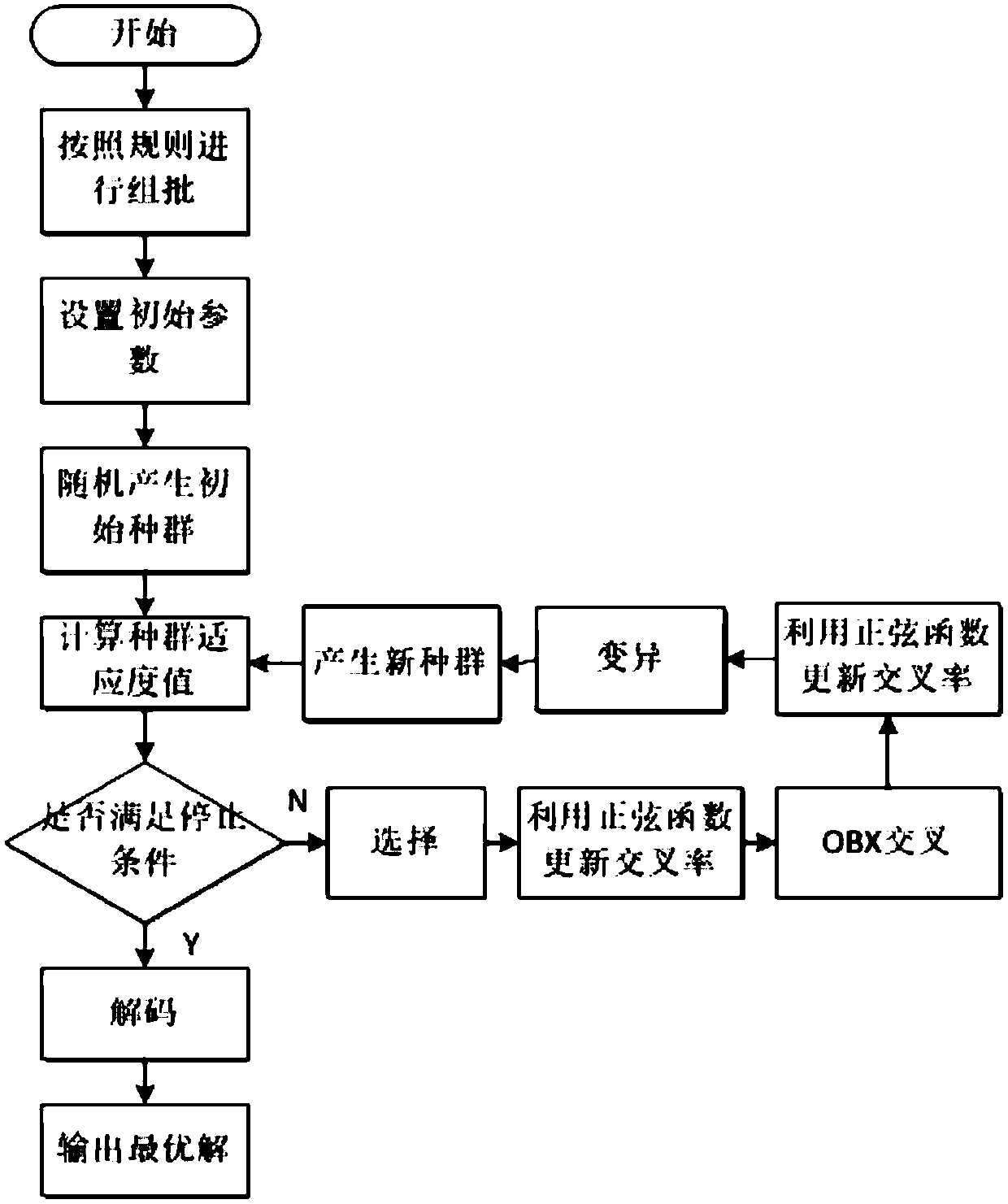

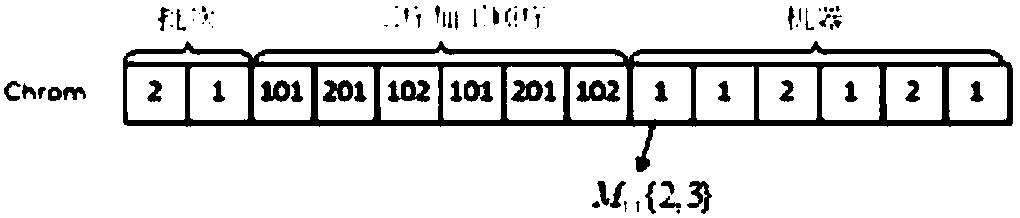

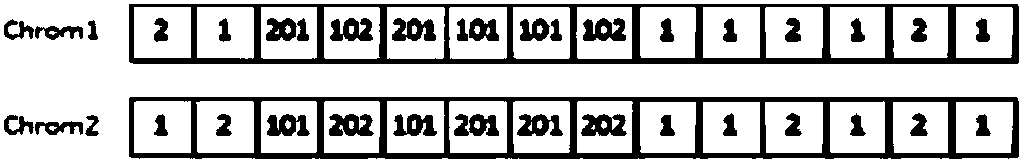

Method used

Image

Examples

example 1

[0066] Example 1 adopts a JSP problem with a scale of 230×18, that is, 230 workpieces are processed on 18 machines. Each workpiece includes four processes, and the processing sequence is Qi1, Qi2, Qi3, Qi4. Among them, Qi1, Qi2 and Qi3 are processing operations, which can only be operated on the processing machine; Qi4 is the detection operation, which can only be selected to be operated on the detection machine. The distribution of machines is that machines 1-15 are processing machines, and machines 16-18 are testing machines.

example 2

[0068] Example 2 adopts a JSP problem with a scale of 460×18, that is, 460 workpieces are processing machines in 18, and the distribution of processing machines and testing machines is the same as that of Example 1.

[0069] specific operation

[0070] First, group batches based on similar workpiece characteristics

[0071] This method first clusters and batches parts with similar processing technology, workpiece sizes within the same range, and the same blank material, and randomly forms different batches. Each workpiece has its own delivery date. The earliest delivery date is scheduled. For example, there are 10 conduit workpieces, and their main characteristics are shown in Table 1. The pipe diameter has two size ranges of 6mm-12mm and 14mm-38mm. The main process of the workpiece is replaced by A, B, C, D, E, F, and G. Among them, E and F can be processed by the same machine, and the process sequence is the same Under certain conditions, the process can be considered as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com