Battery packaging material

A technology for packaging materials and batteries, which is applied in battery box/cover materials, household packaging, packaging, etc., can solve the problems of insufficient curing of thermosetting resins, defective products, and inability of the coating layer to have chemical resistance, etc., to achieve Excellent slip effect, prevent product failure, and shorten processing preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A-32A and comparative example 1A-18A

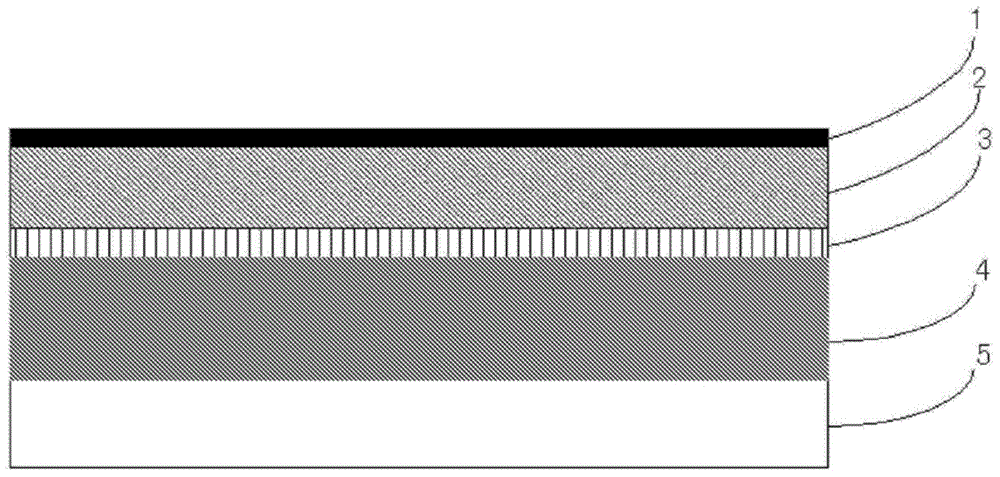

[0178] [Manufacture of packaging materials for batteries]

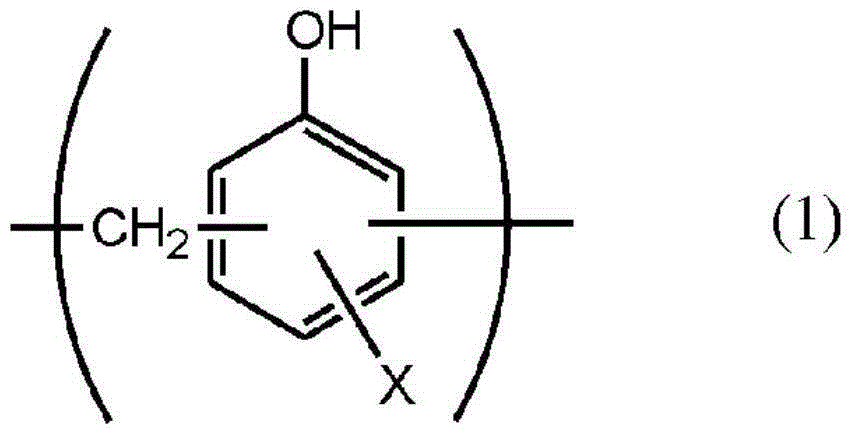

[0179] Using a dry lamination method, a barrier layer 4 composed of aluminum foil (thickness 40 μm) that was chemically converted on both sides was laminated on the base layer 2 composed of a biaxially stretched nylon film (thickness 25 μm). Specifically, a two-component urethane adhesive (polyol compound and aromatic isocyanate compound) is applied to one surface of the aluminum foil, and an adhesive layer 3 (thickness 4 μm) is formed on the barrier layer 4. Next, the adhesive layer 3 and the base material layer 2 on the barrier layer 4 are bonded under pressure and heating, and then subjected to an aging treatment at 40°C for 24 hours, thereby preparing the base layer 2 / adhesive layer 3 / barrier layer 4 laminated body. Among them, the chemical conversion treatment of the aluminum foil used as the barrier layer 4 is performed by applying a treatment solution containing a phenolic resin, a chromium fluoride compound,...

Embodiment 1B-32B

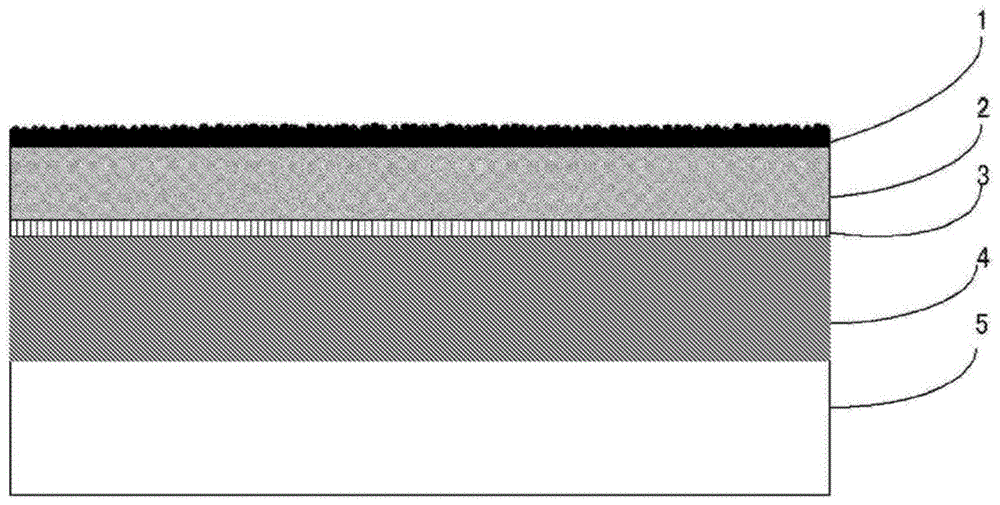

[0204] Examples 1B-32B and Comparative Examples 1B-18B (the resin forming the coating layer contains a slip agent Case)

[0205] [Manufacture of packaging materials for batteries]

[0206] Using a dry lamination method, a barrier layer 4 composed of aluminum foil (thickness 40 μm) that was chemically converted on both sides was laminated on the base layer 2 composed of a biaxially stretched nylon film (thickness 25 μm). Specifically, a two-component urethane adhesive (polyol compound and aromatic isocyanate compound) was applied to one surface of the aluminum foil, and an adhesive layer 3 (thickness 4 μm) was formed on the barrier layer 4. Next, the adhesive layer 3 and the base material layer 2 on the barrier layer 4 are bonded under pressure and heating, and then subjected to an aging treatment at 40°C for 24 hours, thereby preparing the base layer 2 / adhesive layer 3 / barrier layer 4 laminated body. Among them, the chemical conversion treatment of the aluminum foil used as...

Embodiment 1C~68

[0234] Examples 1C to 68C and Comparative Examples 1 to 3C (the resin forming the coating layer contains reactive (In the case of resin beads)

[0235] [Manufacture of packaging materials for batteries 1C]

[0236] Using the dry lamination method, a barrier layer composed of aluminum foil (thickness 40 μm) that was chemically converted on both sides was laminated on a base layer composed of a biaxially stretched nylon film (thickness 25 μm). Specifically, a two-component polyurethane adhesive (polyol compound and aromatic isocyanate compound) was applied to one surface of the aluminum foil to form an adhesive layer (thickness 4 μm) on the barrier layer. Next, the adhesive layer on the barrier layer and the base layer were bonded under pressure and heating, and then subjected to an aging treatment at 40° C. for 24 hours to prepare a laminate of base layer / adhesive layer / barrier layer. Among them, the chemical conversion treatment of the aluminum foil used as the barrier layer is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com