Aligning device and method for glass processing

A technology for aligning devices and glass, applied in measuring devices, stone processing equipment, working accessories, etc., can solve the problems of large machining allowance, inaccurate alignment and positioning, waste of raw materials, etc., to facilitate overall processing and accurate alignment , The effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

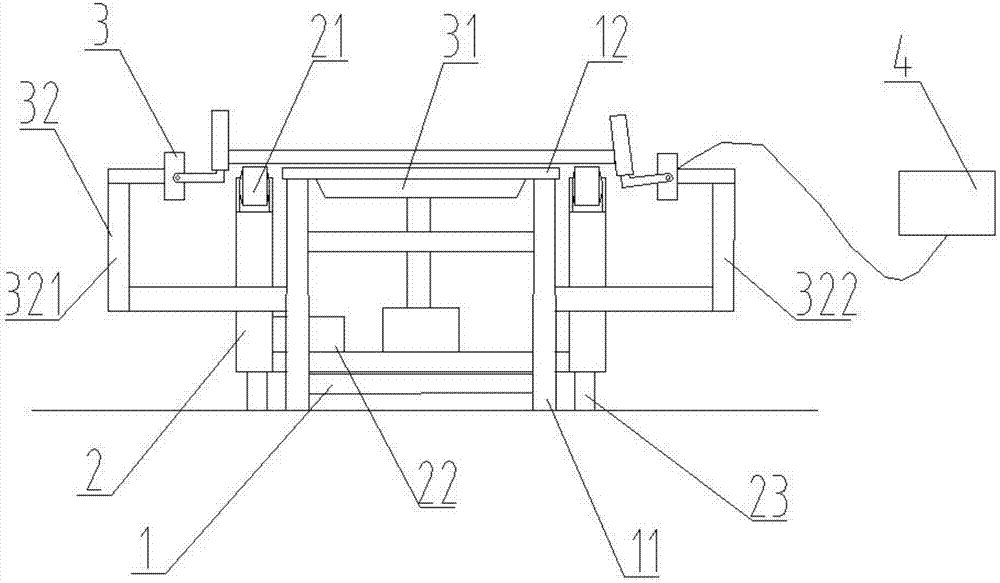

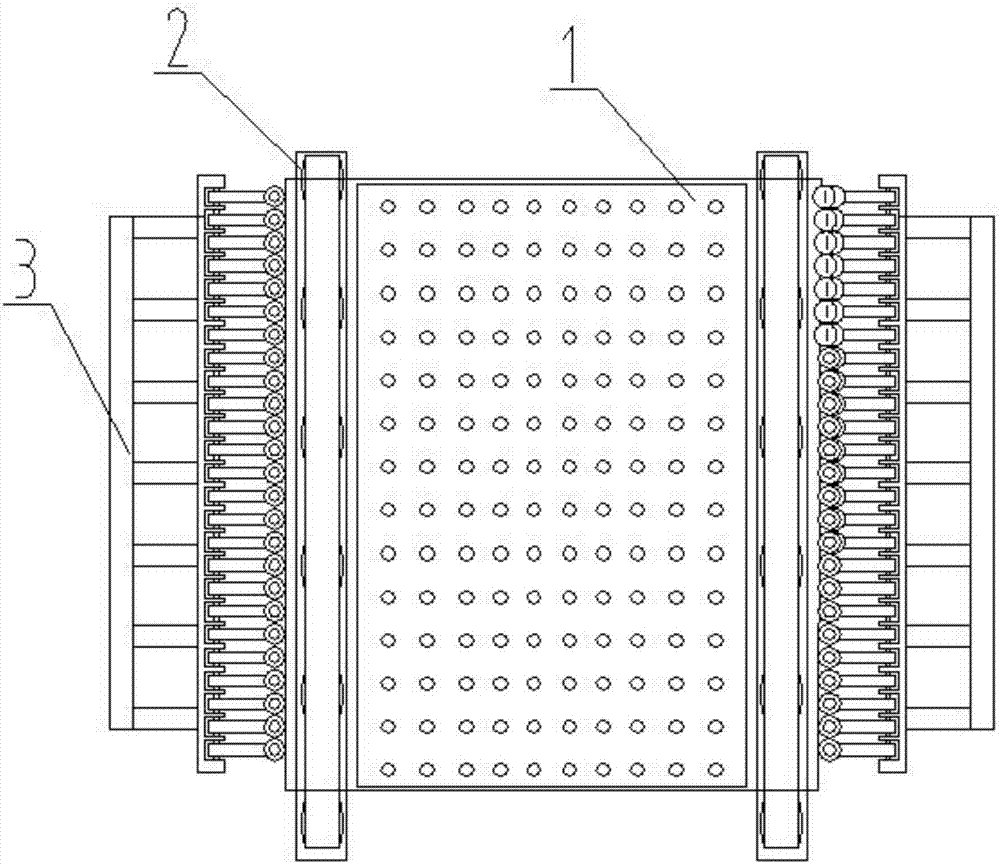

[0030] The invention relates to a glass processing alignment device, the structure diagram of which is as follows figure 1 with figure 2 As shown, it includes a supporting unit 1 , a moving unit 2 , an adjusting unit 3 , and a processing unit 4 .

[0031] The support unit 1 is fixed on the ground, and the support unit 1 is used to support the original glass sheet. The supporting unit 1 includes a bracket 11 and a desktop 12 . The adjustment unit 3 includes an air cushion device 31 and an adjustment device 32 . The moving unit 2 is fixedly connected with the supporting unit 1, and the moving unit 2 is used to move the original glass sheet into or out of the supporting unit 1. The moving unit 2 includes a conveyor belt 21, a transmission device 22 and Lift up the unit 23 . The adjustment unit 3 is fixed on the support unit 1, the adjustment unit 3 measures the data of the original glass sheet placed on the support unit 1, and transmits the data to the processing unit 4 ; T...

Embodiment 2

[0037] The present invention relates to an alignment method using the glass processing alignment device, the specific steps are:

[0038] S1, establish a coordinate system XYZ, the center of the support unit 1 is the origin O, the traveling direction of the original glass sheet is the Y axis, the vertical direction passing through the origin O is the Z axis, and the direction perpendicular to the Y axis and the Z axis is the X axis The glass original sheet is transported to the support unit 1 by the moving unit 2, and the original position of the glass original sheet is initially positioned, and the adjustment device 32 is placed on the support unit along the X-axis direction The original glass sheet on 1 is closed, so that the adjustment device 32 is in contact with both sides of the original glass sheet, and the adjustment device 32 transmits the movement data to the processing unit 4;

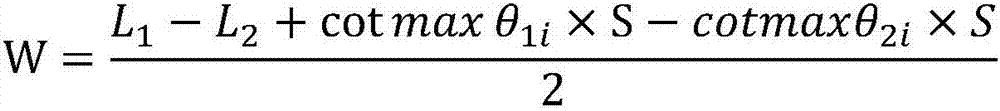

[0039] S2, collect data through the adjustment device 32, and transmit the data to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com