Dynamic refrigerator refrigeration performance testing system

A technology for dynamic testing and refrigeration performance, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., which can solve problems such as error-prone refrigerator performance and complicated operation, so as to save process preparation time, make accurate judgments, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

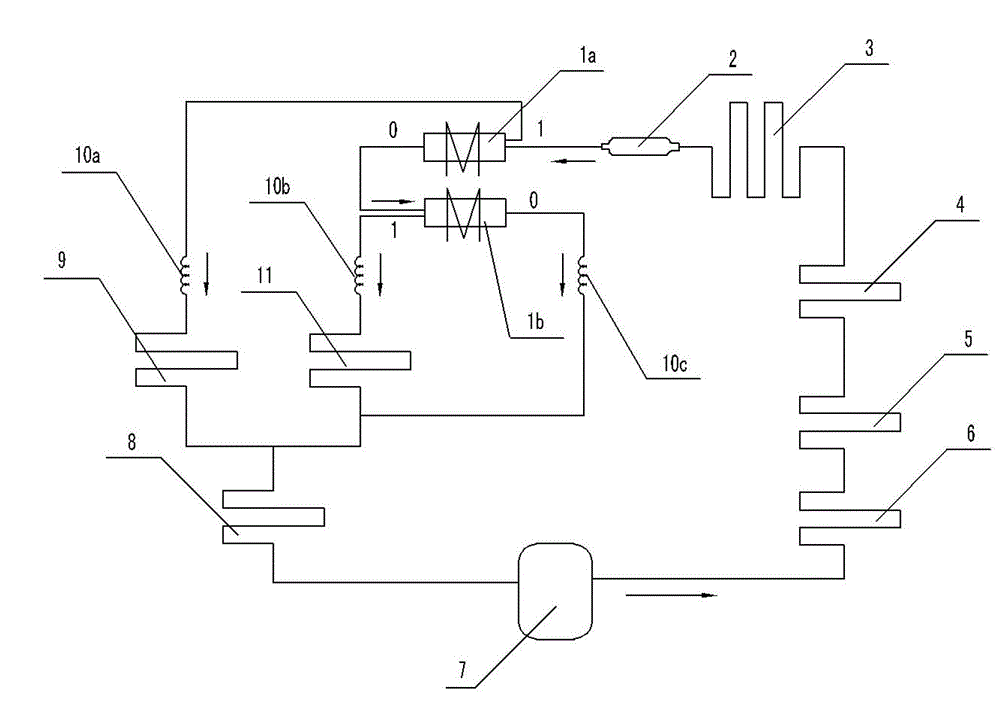

Image

Examples

Embodiment Construction

[0019] In this embodiment, the refrigeration performance dynamic test system of the refrigerator is to run the lower computer and test tooling of the test system on the assembly line together with the refrigerator under test, and the collector simultaneously collects the set parameters to obtain test data, and transmits the test data through wireless transmission. The test data is sent to the upper computer, and the upper computer analyzes the test data according to the set process plan, and then judges the performance of the refrigerator.

[0020] Selection of refrigerator test location: At present, household refrigerators use vapor compression refrigeration. When the refrigerator is running stably, the refrigerant is in a state of saturated steam in the evaporator, which absorbs "latent heat". no big difference. When the refrigerator is blocked or the refrigerant leaks, the end of the evaporator will be in an "overheated" state, and the temperature at the end of the evaporat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com