Method for quickly measuring blade surfaces by inductive measuring instrument

An inductance and blade technology, applied in electromagnetic measurement devices, electric/magnetic profile/curvature measurement, instruments, etc., can solve the problems of difficult manufacturing of standard parts, long manufacturing cycle, etc., to eliminate the long process preparation cycle and manufacturing The effect of cost reduction and enhanced quality assurance capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a method for quickly realizing the detection of the profile surface of the blade by the inductance meter, which is characterized in that: the method for quickly realizing the detection of the profile surface of the blade by the inductance meter is as follows:

[0038] Preparation:

[0039] First, implement the measurement of the blade structure

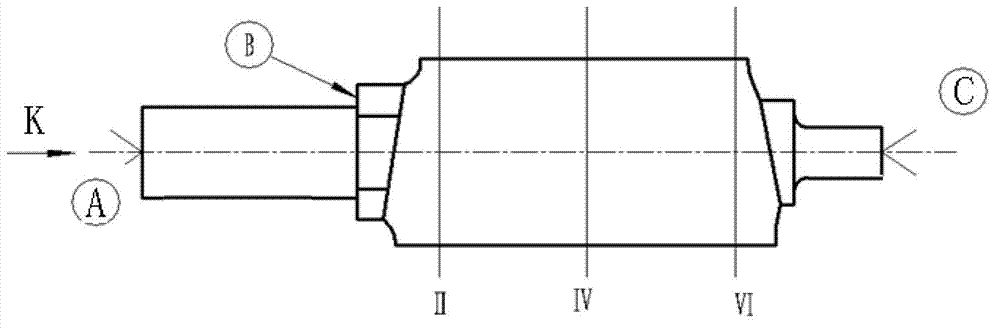

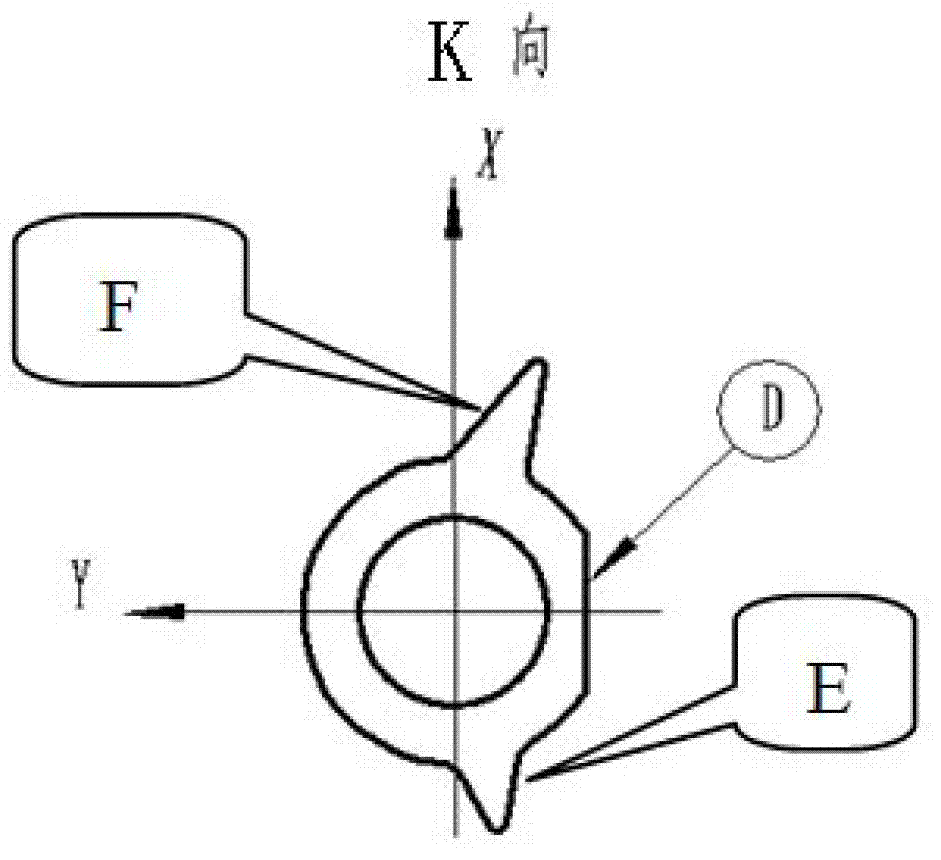

[0040] In the blade structure where the measurement is carried out, the blade measurement and positioning references are the tip holes A and B on the front and rear journal end faces, the outer end surface C of the blade front end edge plate, and the angular positioning plane D of the blade front end edge plate; the measurement compression part is B , D;

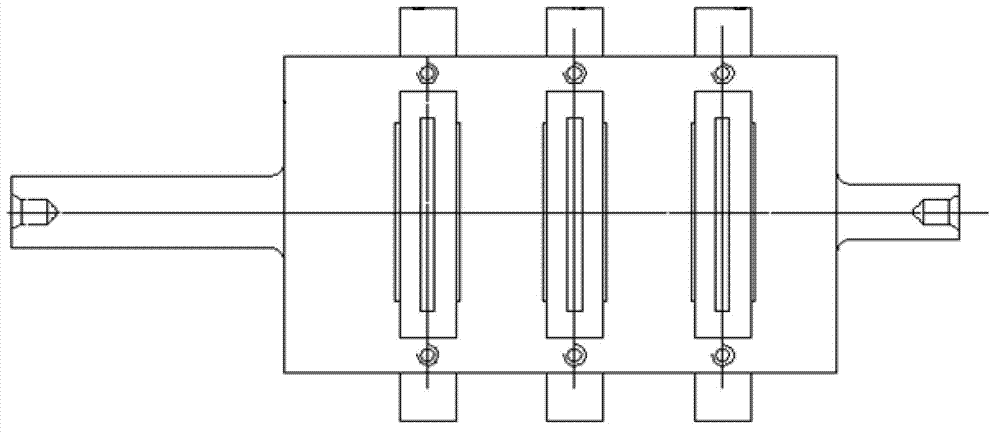

[0041] Second, the standard part structure used for blade measurement

[0042]The standard part structure used for the blade measurement is shown in the attached figure. The standard part of the blade includes the reference frame, the curved surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com