Novel pulverized coal metering and conveying equipment

A technology for conveying equipment and pulverized coal is applied in the field of optimization and improvement of pulverized coal metering and conveying systems, which can solve the problems of difficult maintenance, large area of a single equipment, and difficulty in ensuring the machining accuracy and installation accuracy of screw rods, and achieve equipment maintenance. Ease of use, reduced footprint, and easier installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

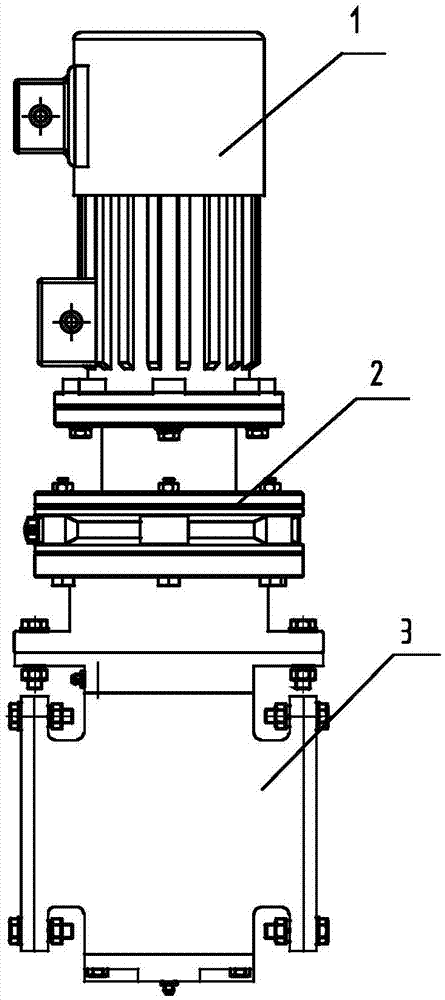

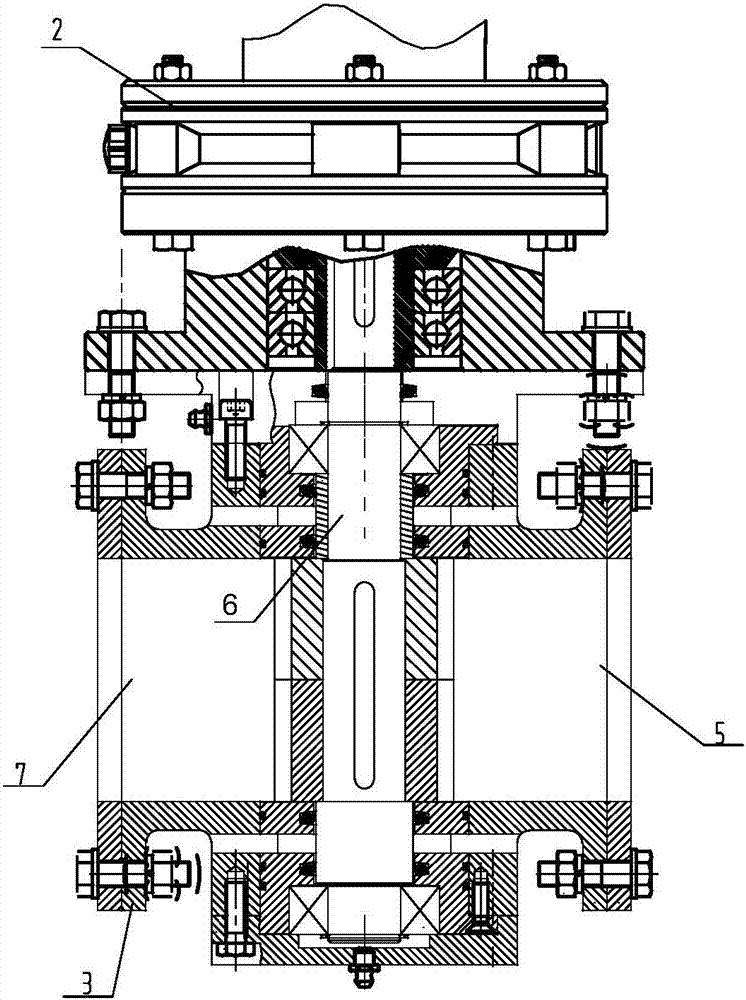

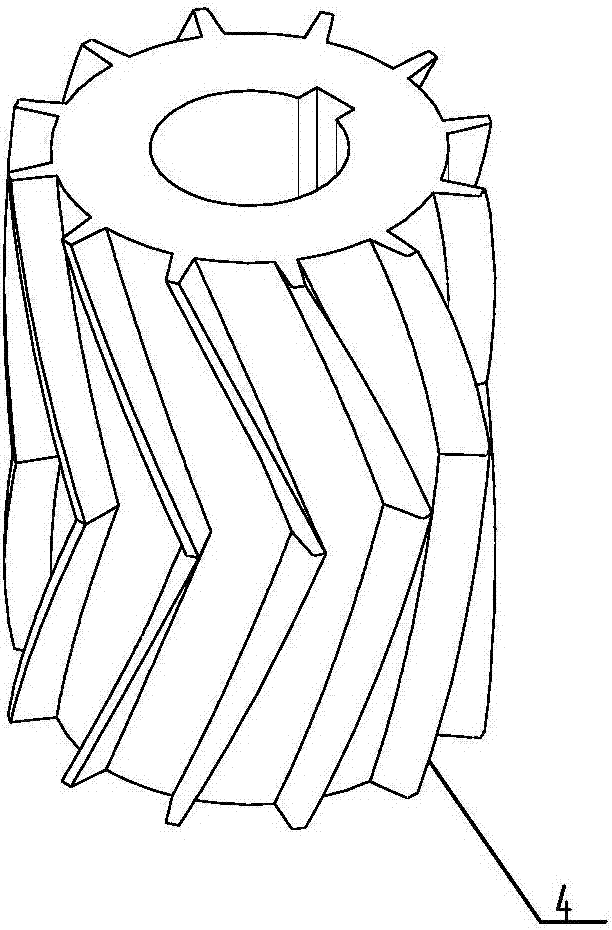

[0021] Such as figure 1 As shown, a new type of pulverized coal metering and conveying equipment is provided, which includes a feed bin 3 and a drive motor 1, the drive motor is connected with a drive shaft 6, the drive motor is connected with a reducer, and the The drive shaft is connected to the output end of the reducer. The feeding bin is an integral casting device with an inner cavity for the feeding gear and bearing seats at both ends. The material inlet 5 and the material outlet 7, the drive shaft is inserted into the feeding bin, and an end cover is provided at both ends of the feeding bin 3, and a bearing is installed in each bearing seat and passes through the end cover Sealed in the bearing seat, there is a through hole communicating with the bearing seats at both ends on the feeding bin, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com