Microshell vibrating gyroscope and preparation method thereof

A technology for vibrating gyroscopes and shells, which is applied to gyroscopes/steering sensing equipment, gyro effects for speed measurement, and measurement devices. It can solve the problems of difficult to achieve arc surface capacitance processing, low driving and detection efficiency, and small capacitance area. problems, to achieve the effects of simplifying the mode and frequency trimming process, improving the processing accuracy and structural symmetry of the three-dimensional curved surface, and simplifying the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

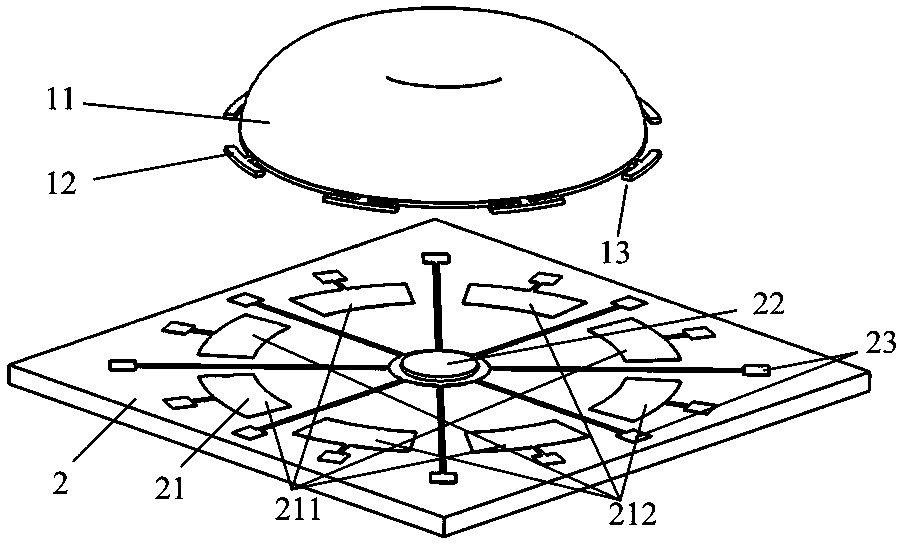

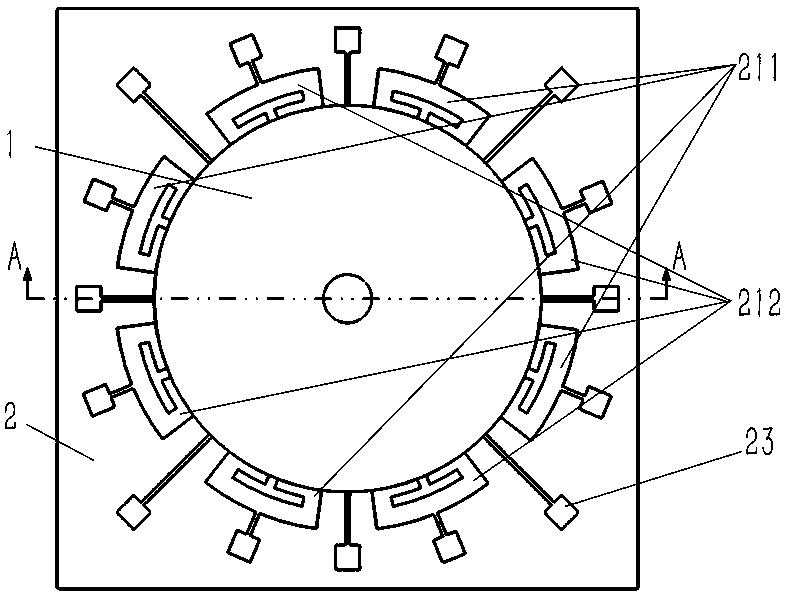

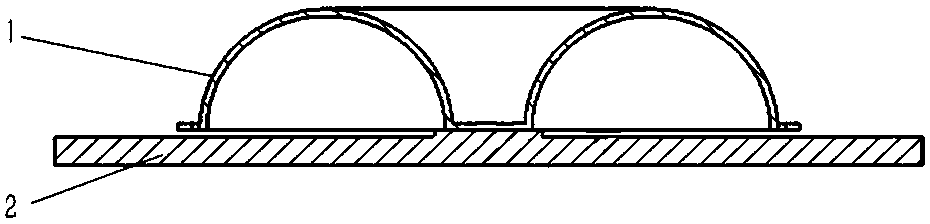

[0039] Such as Figure 1 to Figure 5 The embodiment of the microshell vibrating gyroscope of the present invention is shown, the microshell vibrating gyroscope includes a microshell gyro resonator 1 and a glass substrate 2, the microshell gyro resonator 1 is arranged on the glass substrate 2, and the microshell The bulk gyro resonator 1 includes a rotary housing 11 and a plurality of sensitive mass elements 12, the plurality of sensitive mass elements 12 are evenly distributed on the outer circumference of the bottom of the rotary housing 11, and the rotary housing 11 and the plurality of sensitive mass elements 12 are opposite to the glass A metal film 13 is provided on the surface of the substrate 2 , and the glass substrate 2 includes a plurality of fixed capacitor plates 21 corresponding to a plurality of sensitive mass elements 12 on the plurality of fixed capacitor plates 21 . There is a gap between each fixed capacitor plate 21 and its corresponding sensitive mass eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com