Positioning clamp

A positioning fixture and front positioning technology, which is applied in the direction of positioning devices, clamping, manufacturing tools, etc., can solve the problems of increasing the overall size of the worktable, occupying a large space, and low applicability, so as to reduce the processing preparation time and improve efficiency. , great applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

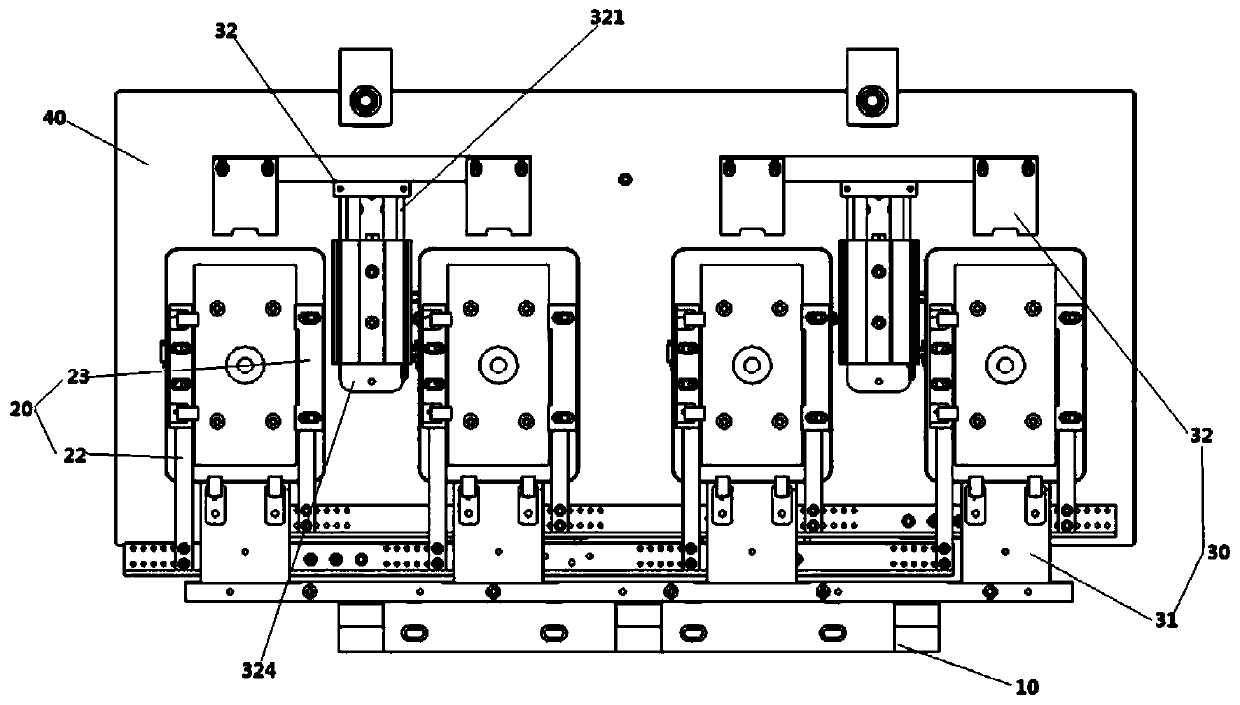

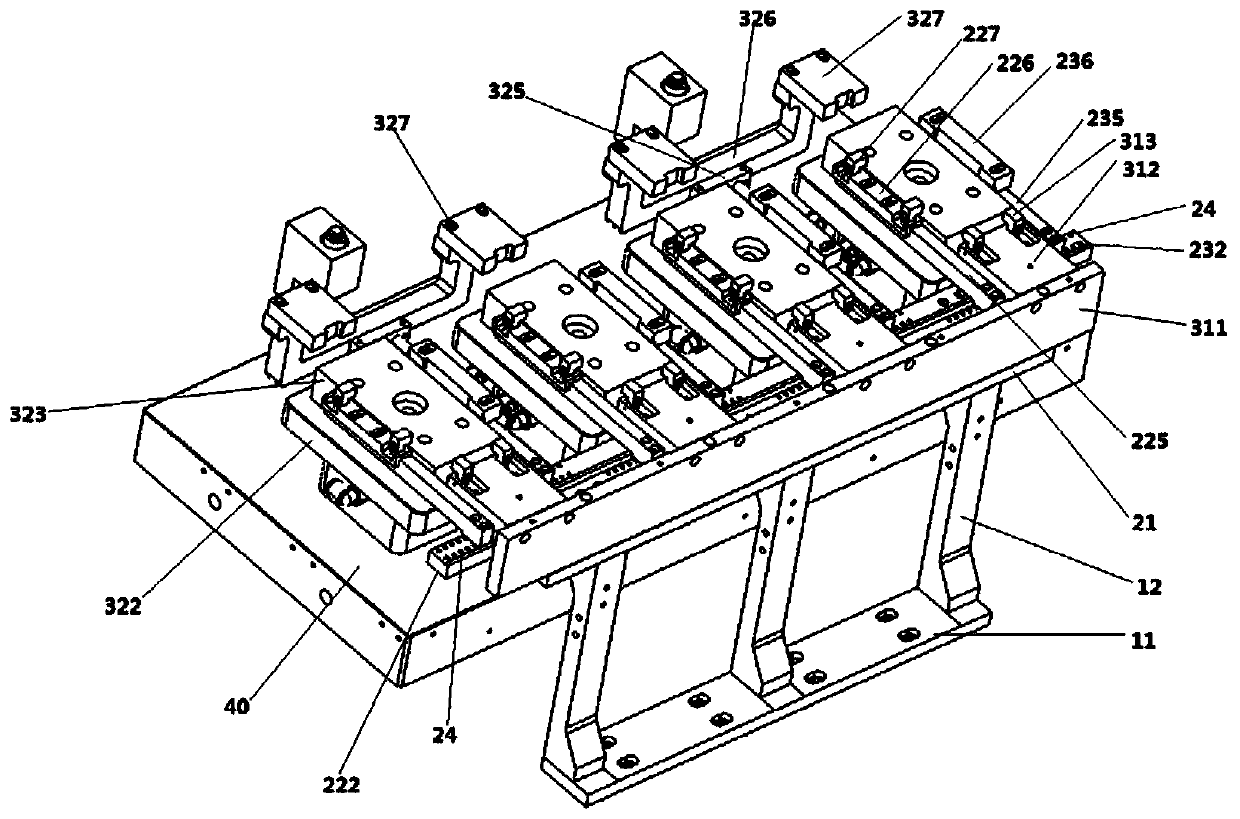

[0026] refer to figure 1 , the present embodiment includes a bracket 10, a left and right positioning mechanism 20, a front and rear positioning mechanism 30 and a working surface 40;

[0027] The support 10 includes a base mounting plate 11, the base mounting plate 11 can be installed on the machine tool, a plurality of support plates 12 are installed on the base mounting plate 11, and the support plates 12 support the left and right positioning mechanisms 20;

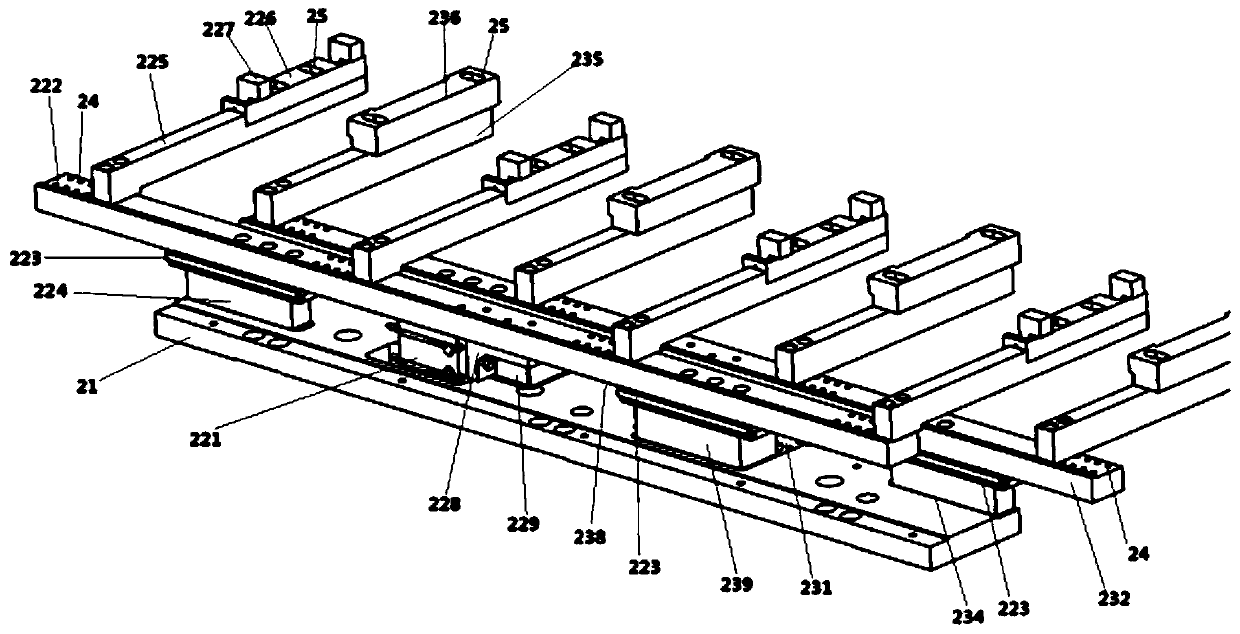

[0028] The left and right positioning mechanism 20 includes a left and right mounting base plate 21, a left positioning mechanism 22 and a right positioning mechanism 23;

[0029] Described left positioning mechanism 22 comprises driving cylinder one 221, cylinder connection block one 228, cylinder fixed block one 229, left positioning base 222, sliding line rail 223, line rail mounting seat o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com