Preparation process and casting mould for cast product based on 3D printing technology

A preparation process and 3D printing technology, applied in the field of mold processing, can solve problems such as complex procedures, material consumption, and high production costs, and achieve the effects of high processing accuracy, low production costs, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a preparation process for castings based on 3D printing technology, including the following process steps:

[0051]Utilize three-dimensional software to design the pouring mold model, convert the pouring mold model into STL data format, and import it into the slicing software for slicing processing, the layer thickness is 0.05mm, and the wall thickness of the pouring mold model is 0.5mm, and the pouring mold is obtained. 3D model data;

[0052] Then import the obtained three-dimensional model data of the casting mold into the 3D printing device, and print and form the casting mold;

[0053] Finally, the fluid raw material is injected into the cavity of the above casting mold to obtain the casting.

[0054] The above-mentioned fluid raw materials are silica gel and curing agent, and are prepared according to the mass ratio of 100:3.5.

[0055] At the same time, the prepared fluid is also vacuumized before being injected into the casting mold: p...

Embodiment 2

[0063] This embodiment provides a preparation process for castings based on 3D printing technology, including the following process steps:

[0064] Utilize three-dimensional software to design the pouring mold model, convert the pouring mold model into STL data format, and import it into the slicing software for slicing processing, the layer thickness is 2mm, the wall thickness of the pouring mold model is 1mm, and the three-dimensional model of the pouring mold is obtained data;

[0065] Then import the obtained 3D model data of the casting mold into the 3D printing equipment, and put acrylonitrile-butadiene-styrene copolymer as the printing material; after coating the printing surface of the printing base with glue, print the casting mold It is formed by light curing; the molded casting mold is polished to make the inner surface of the cavity of the casting mold form a smooth layer;

[0066] Finally, inject the fluid raw material that has been evacuated into the cavity of t...

Embodiment 3

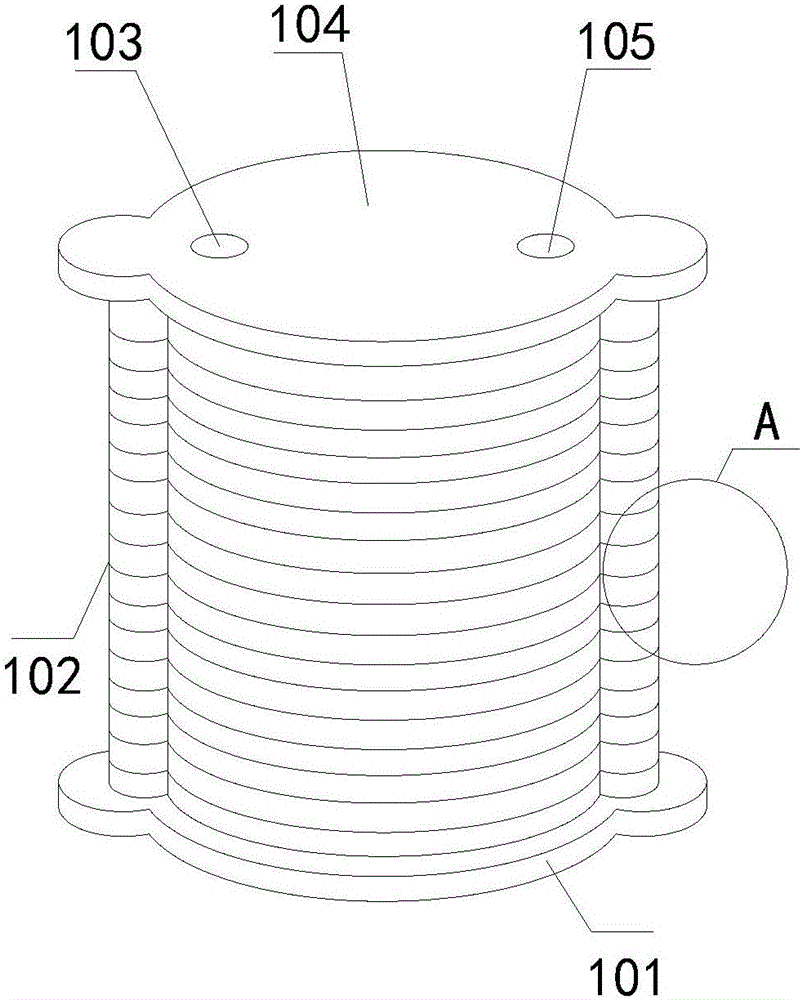

[0072] Such as figure 1 and Figure 4 As shown, according to the 3D printing technology of embodiments 1 and 2, this embodiment provides a casting mold, which includes: a cavity wall and a cavity 107 surrounded by the cavity wall, and the wall thickness of the cavity wall 1mm.

[0073] Preferably, the cavity coaming comprises a bottom plate 101, a side coaming 102 and a cover plate 104; the cover plate 104 is provided with an injection hole 103 and an overflow hole 105, and the injection hole 103 and the overflow hole 105 are respectively communicated with the cavity 107 ; The inner surface of the cavity 107 is a smooth layer, and the smooth layer is provided with a release agent layer.

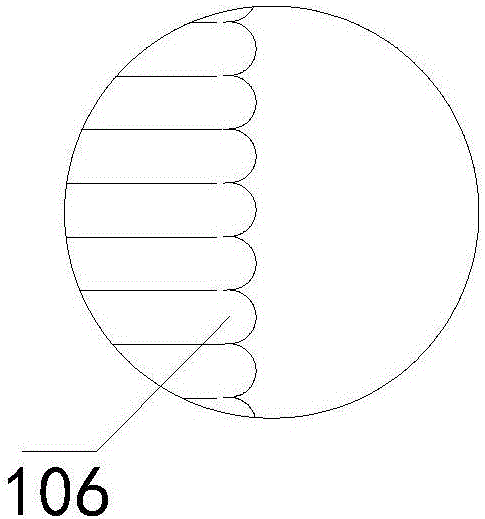

[0074] Such as figure 2 As shown, the outer surface of the cavity coaming has laminations 106, and the distance between two adjacent laminations 106 is 0.05mm; the interior of the cavity coaming is filled with honeycomb.

[0075] As a preferred solution of this embodiment, such as imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com