Nanometer composite material high in air barrier property and preparation method thereof

A nanocomposite material and gas barrier technology, applied in the field of nanocomposite materials, can solve the problems of limited enhancement of gas barrier performance, unsatisfactory improvement of gas barrier performance, poor dispersion of nano fillers, etc., to achieve excellent gas barrier performance and comprehensive mechanics Good performance and excellent gas barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

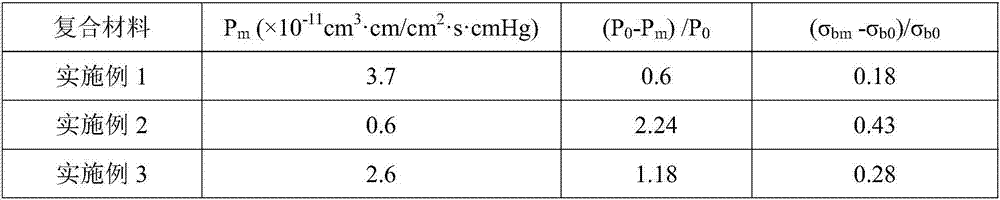

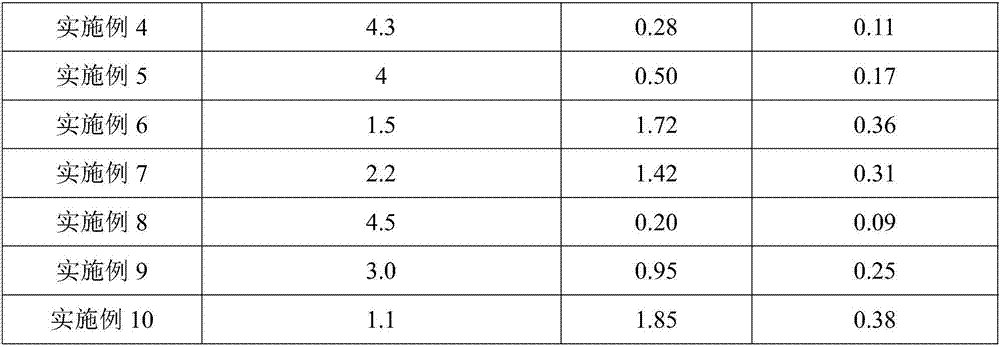

Examples

Embodiment 1

[0027] (1) Add 0.1g of graphene to 100mL of 0.10% tannic acid N,N-dimethylformamide solution, ultrasonically disperse for 20min (frequency 25KHZ, power 200W), then stir at 200rpm for 3h at room temperature After filtering, washing and drying, the tannic acid-modified graphene was obtained.

[0028] (2) Put 0.1g tannic acid modified graphene and 19.9g polylactic acid (PLA) into the internal mixer after premixing, heat and melt and mix for 20min to obtain the nanocomposite material, put the obtained nanocomposite material into The barrier nanocomposite film was obtained after hot pressing in a standard mold at 155°C and a pressure of 10 MPa. Wherein the mass fraction of tannic acid modified graphene in the composite material is 0.5%.

[0029] In addition, as a comparative example, the same method was used to prepare nanocomposites by modifying polylactic acid with unmodified graphene as barrier filler. The barrier performance test results show that the barrier performance of t...

Embodiment 2

[0031] (1) Add 0.2g nano-graphite flakes to 100mL of sodium humate aqueous solution with a mass concentration of 0.5%, ultrasonically disperse for 30 minutes (frequency 25KHZ, power 100W), then stir at 200rpm for 1h at room temperature, filter, wash, After drying, the sodium humate modified graphite nano sheet is obtained.

[0032] (2) 0.4g sodium humate modified nano-graphite sheet and 19.6g ethylene-vinyl alcohol copolymer (EVOH) are premixed and then put into a banbury mixer, heated and melted and mixed for 40min to obtain a nanocomposite material, which will be obtained The nano-composite material was put into a standard mold and hot-pressed at 170°C and a pressure of 15 MPa to obtain a barrier nano-composite film. The mass fraction of the sodium humate-modified nano-graphite sheet in the composite material is 2%.

[0033] In addition, as a comparative example, the same method was used to prepare nanocomposites by modifying polylactic acid with unmodified nano-graphite sh...

Embodiment 3

[0035] (1) Add 0.4g of boron nitride nanosheets to 100mL of 3% dopamine aqueous solution, ultrasonically disperse for 40 minutes (frequency 25KHZ, power 200W), then stir at 500rpm at room temperature for 4h, filter, wash and dry After that, the dopamine-modified boron nitride nanosheets are obtained.

[0036] (2) Mix 0.2g of dopamine-modified boron nitride nanosheets with 19.8g of nylon (PA) and put them into an internal mixer, heat and melt them and knead them for 25 minutes to obtain a nanocomposite material, and put the obtained nanocomposite material into a standard The barrier nanocomposite film was obtained after hot pressing in the mold at 280° C. and a pressure of 20 MPa. The mass fraction of the dopamine-modified boron nitride nanosheets in the composite material is 1%.

[0037] In addition, as a comparative example, the same method was used to prepare nanocomposites by modifying polylactic acid with unmodified nano-graphite sheets as barrier fillers. The barrier pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com