Anti-static polyester film and preparing method thereof

A polyester film and antistatic technology, applied in the field of antistatic polyester film and its preparation, can solve the problems of inconvenience, safety and hidden dangers, and achieve the effects of normal haze, high gloss and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

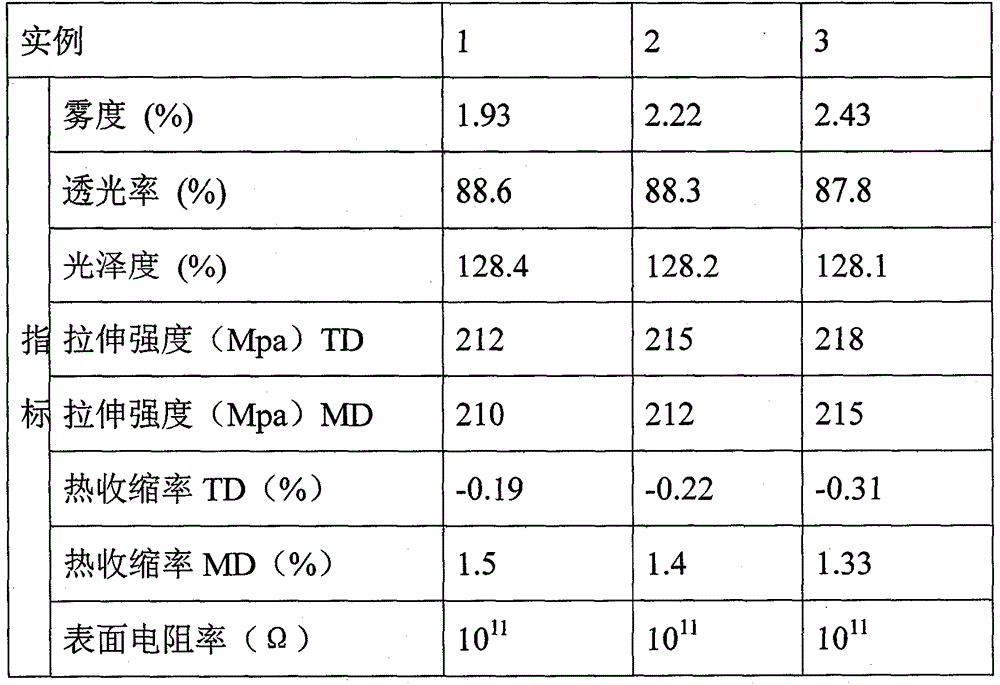

Examples

Embodiment 1

[0031] An antistatic polyester film, comprising an ABC three-layer structure, the B layer is the middle core layer, and the material is a super bright polyester chip; the A layer is an antistatic layer on the upper surface, and the material includes an antistatic and anti-blocking polyester Slices and super-bright polyester chips; layer C is the antistatic layer on the lower surface, and the materials include antistatic and anti-blocking polyester chips and super-bright polyester chips.

[0032] Layers A and C are the upper and lower surface antistatic layers, and the materials have the following components in mass percentage: 5-10% of antistatic and anti-adhesion polyester chips and 90%-95% of super-bright polyester chips. The titanium dioxide (TiO2) content of super-bright polyester chips is zero. The thickness of layer B accounts for 60%-80%, the thickness of layer A accounts for 10%-20%, and the thickness of layer C accounts for 10%-20%.

[0033] In the antistatic layer o...

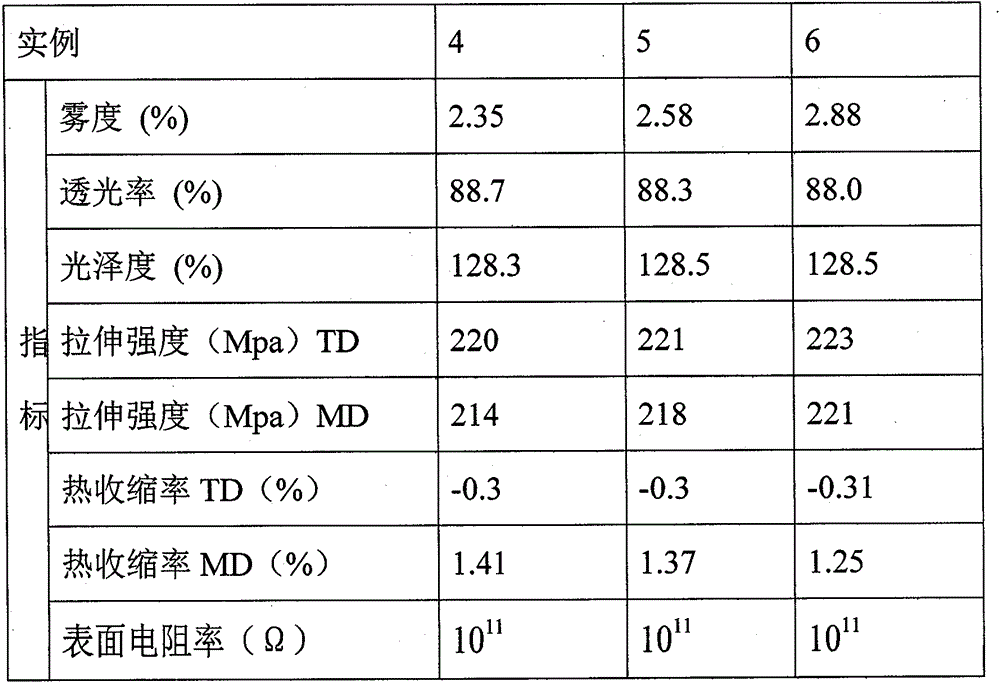

Embodiment 2

[0043] A kind of preparation method of antistatic polyester film, the component composition by weight percentage:

[0044] The ratio of the raw materials of the auxiliary twin-screw extruder (A layer) is 90% super glossy polyester chips and 10% antistatic antistatic anti-blocking polyester chips by mass percentage, and the raw materials are sent into the extrusion after precise metering and mixing machine extrusion; the raw material ratio of the main extruder (B layer) is 100% super glossy polyester chips by mass percentage, and the raw materials are sent to the main extruder for extrusion after accurate measurement; the auxiliary twin-screw extruder ( The ratio of raw materials for layer C) is 90% super-bright polyester chips and 10% antistatic and anti-blocking polyester chips by mass percentage, and the raw materials are sent to the extruder for extrusion after accurate metering and mixing. The mass ratio of the material extruded by the main extruder and two auxiliary twin-...

Embodiment 3

[0047] The difference between this embodiment and embodiment 2 is: the mass ratio of the material extruded by the main extruder and two auxiliary twin-screw extruders is 15:70:15, and the antistatic and antisticking layer thickness of the 23um film A layer is 3.45um , C layer antistatic anti-adhesive layer thickness is 3.45um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com