Peelable glue coating composition and peelable glue coating as well as preparation method and application of peelable glue coating

A coating composition and stripping technology, applied in the direction of coating, can solve the problems of low light transmittance, high haze and discomfort of strippable coatings, and achieve high strippability, low haze, and bubbles and warpage problem improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

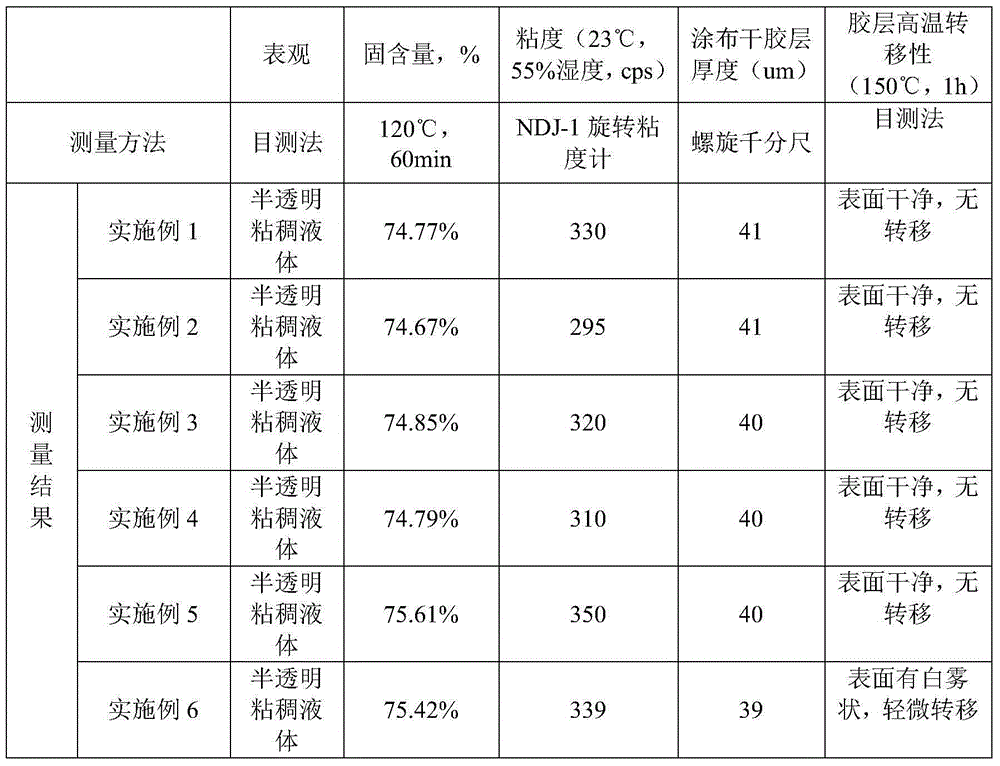

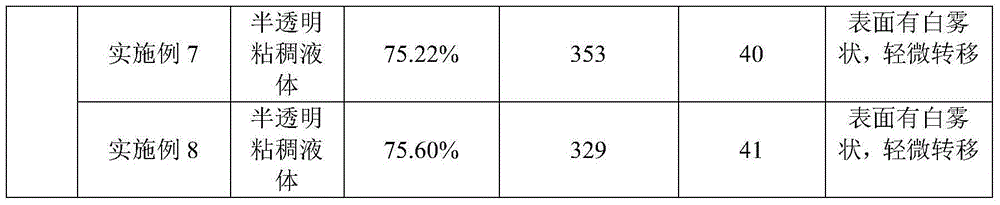

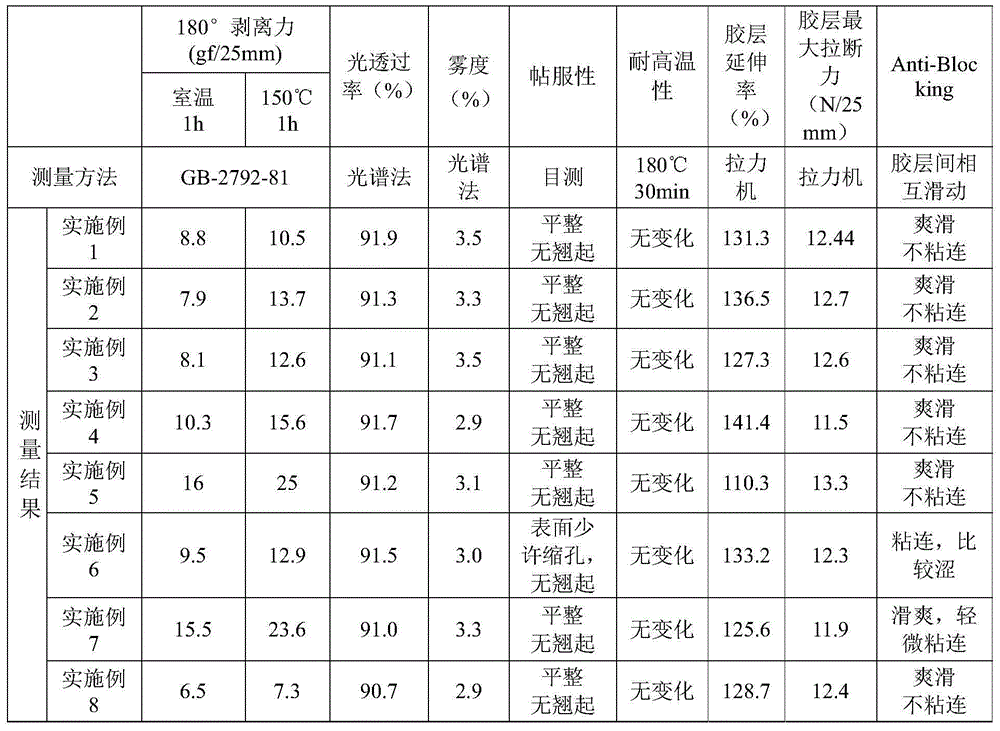

Examples

preparation example Construction

[0039] According to another aspect of the present invention, there is also provided a method for preparing a peelable adhesive coating, which includes the following steps: S1, configuring a peelable adhesive coating composition; S2, coating the peelable adhesive coating composition Cover and cure to obtain a peelable adhesive coating.

[0040] When the peelable adhesive coating composition provided by the present invention is used to prepare the peelable adhesive coating, it can be directly coated, cured and shaped. The method has simple process and low operation cost.

[0041] According to the above teaching of the present invention, those skilled in the art can select a specific curing process. In a preferred embodiment, the above step S2 includes: S21, coating the peelable adhesive coating composition to obtain the layer to be cured; S22, keeping the layer to be cured at a temperature of 80-110°C for 80-100s , to obtain the pre-cured layer; S23, the pre-cured layer was ex...

Embodiment 1

[0046] (1) drop into 100g aliphatic urethane acrylate 6148J-75 (manufactured by Changxing Chemical Co., Ltd.), 16g ethoxylated trimethylolpropane triacrylate EM2380 (manufactured by Changxing Chemical Co., Ltd.) and 40g isopropanol in a 500ml shading bucket , Stir evenly with a high-speed disperser. Then add 0.4g leveling agent BYK378 (manufactured by BYK), 0.5g leveling agent 9137 (manufactured by Double Bond Chemical Co., Ltd.), 0.6g peeling force modifier methylcellulose (National Medicine) while stirring in order. 2g anti-blocking agent MEK-AB-402 (nanometer silica slurry, manufactured by Nissan Chemical Co., Ltd.) and 5g photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.). After the addition, stir at a high speed of 1200rpm for 60 minutes, then let it stand for more than 60 minutes to defoam naturally, and obtain a peelable coating composition;

[0047] (2) Coat the prepared peelable adhesive coating composition on the functional hardened coating sur...

Embodiment 2

[0049](1) Put 70 g of aliphatic urethane acrylate 6148J-75 (manufactured by Changxing Chemical Co., Ltd.), 30 g of aliphatic urethane acrylate EBECRYL9260 (manufactured by Allnex), and 13 g of propoxylated neopentyl glycol diacrylate EM2251 into a 500 ml shading bucket (manufactured by Changxing Chemical Co., Ltd.) and 40g of isopropanol, stirred evenly with a high-speed disperser. Then add 0.4g leveling agent BYK-UV3505 (manufactured by BYK), 0.5g leveling agent 9137 (manufactured by Double Bond Chemical Co., Ltd.), 0.6g peeling force modifier methyl cellulose (manufactured by Sinopharm) while stirring in order. ), 2g anti-blocking agent MEK-AB-402 (nano silica slurry, manufactured by Nissan Chemical Co., Ltd.), 3g photoinitiator 184 (manufactured by Tianjin Tianjiao Chemical Co., Ltd.) and 2g photoinitiator TPO (Double Bond Chemical Co., Ltd. Ltd.). After the addition, stir at a high speed of 1200rpm for 60 minutes, then let it stand for more than 60 minutes to defoam natur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com