Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

272results about How to "Reduce crush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

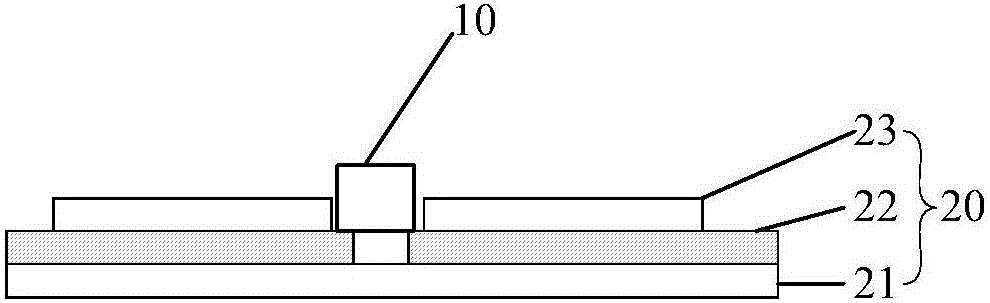

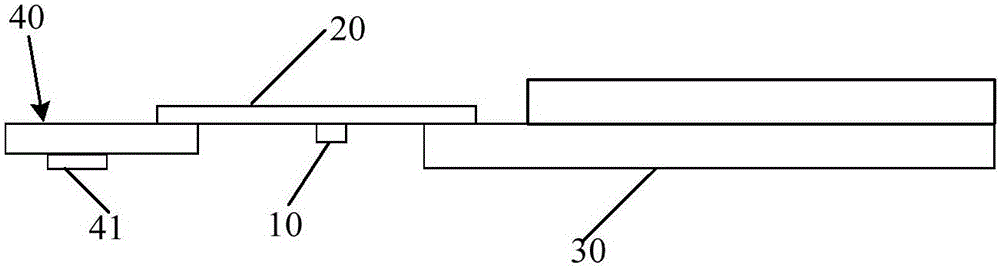

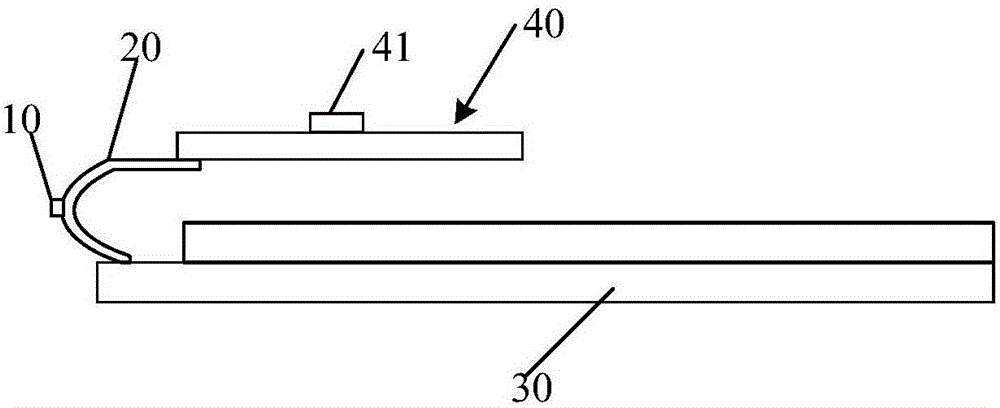

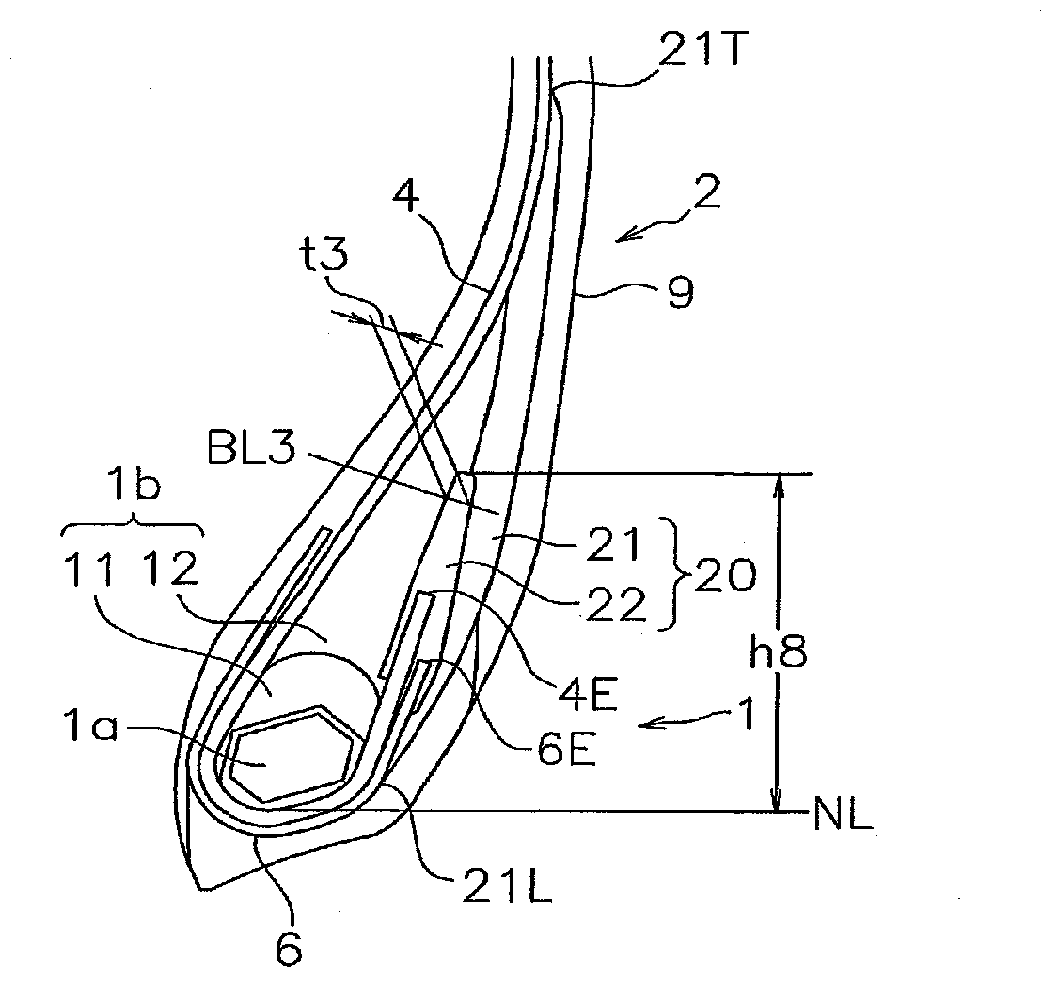

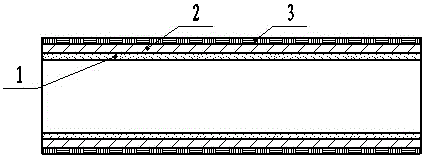

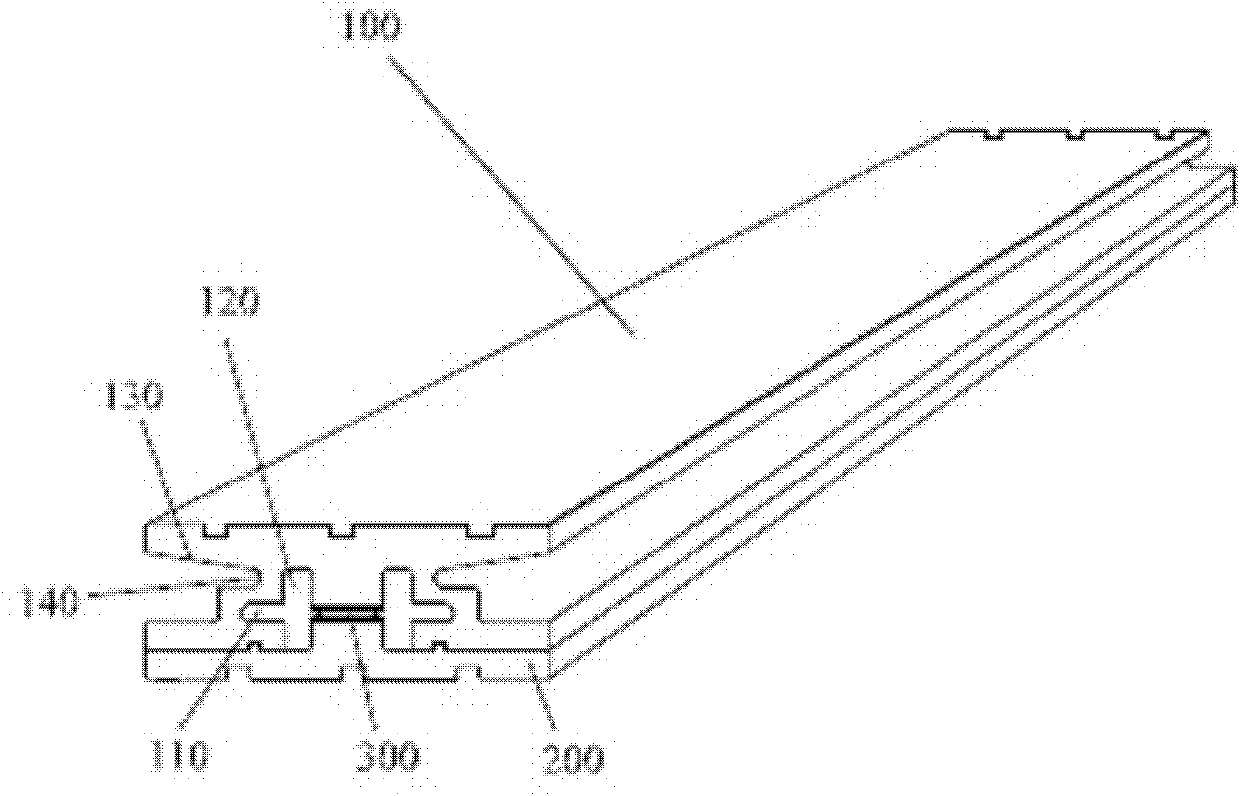

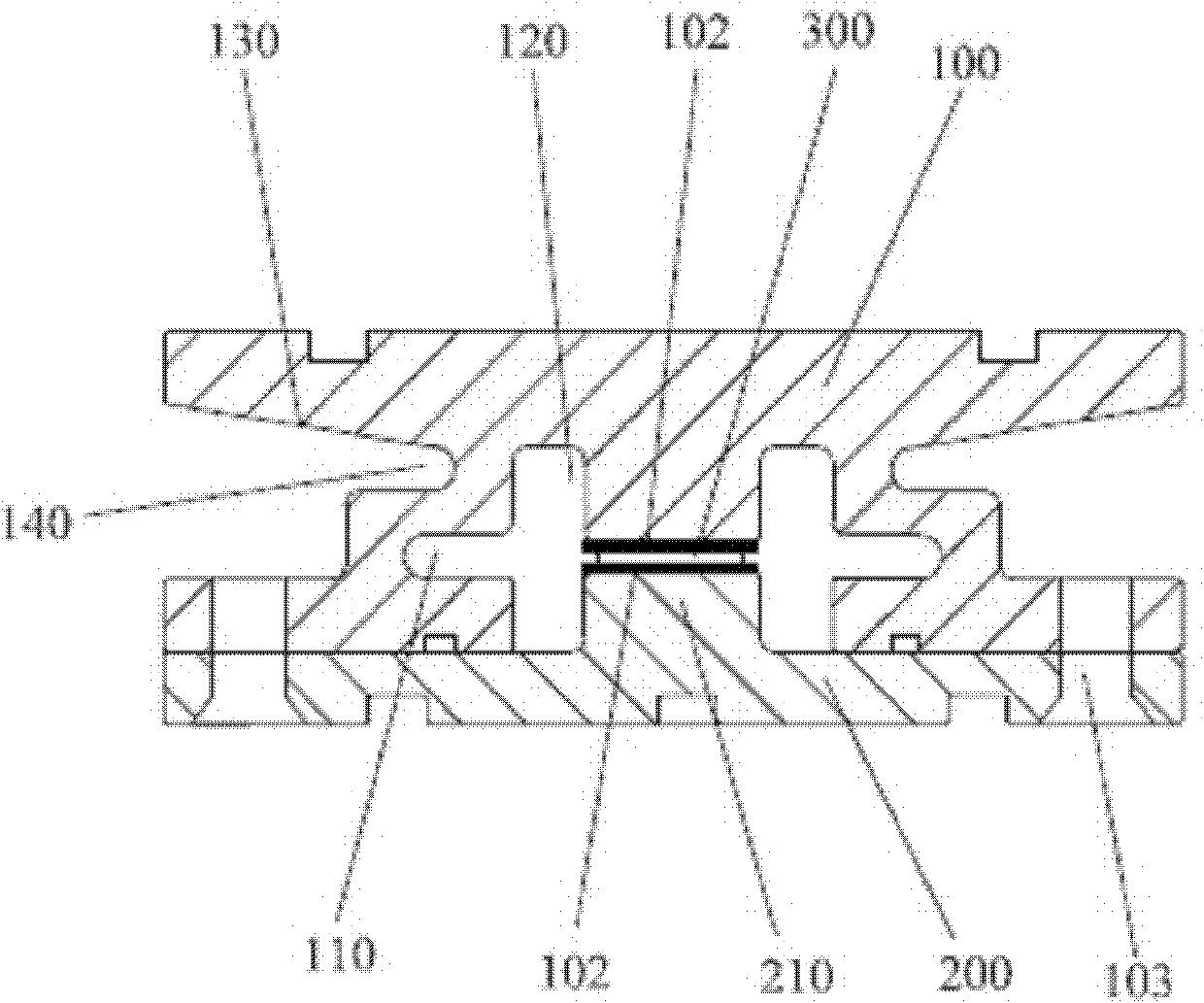

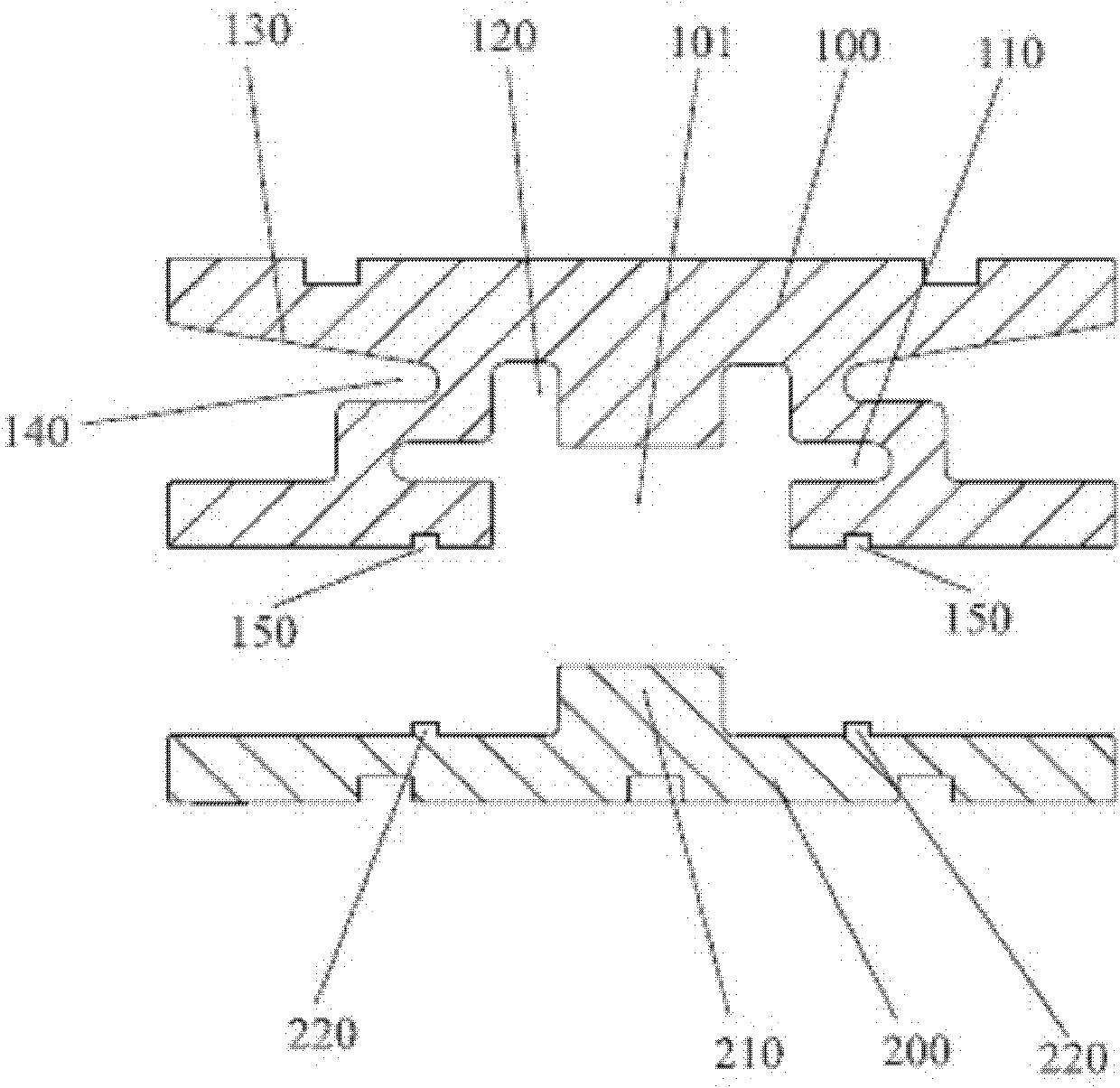

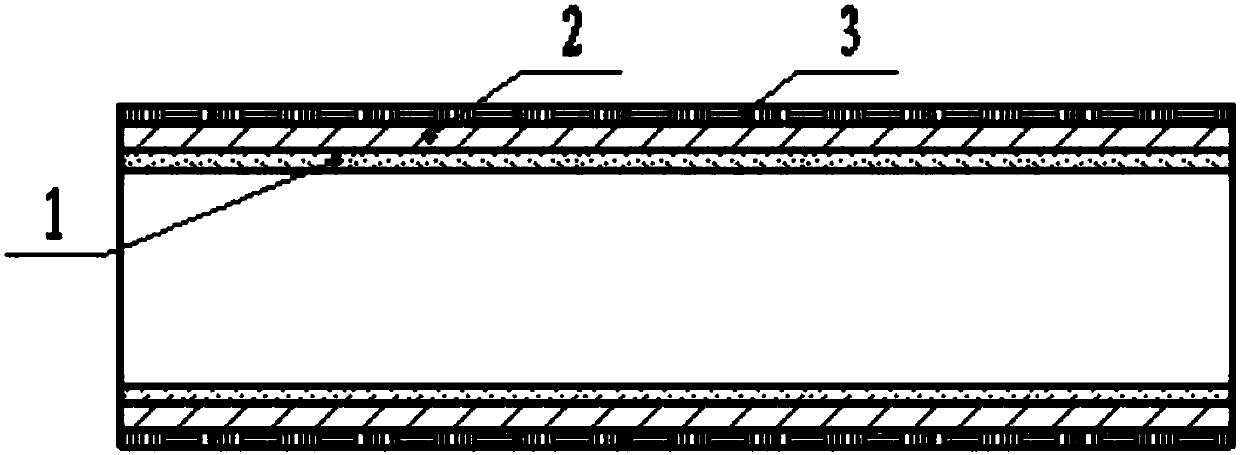

Chip on film and display device

InactiveCN105826353AThe overall thickness is thinReduce crushSolid-state devicesSemiconductor devicesChip on filmFlexible circuits

The present invention provides a chip on film. The chip on film comprises a flexible circuit board, and the flexible circuit board includes a conductive layer consisting of a first binding zone located at the first end of the conductive layer and a second binding zone located at the second end of the conductive layer; the first binding zone is configured to bind a display substrate, and the second binding zone is configured to bind a printing circuit board, wherein the first binding zone and the second binding zone are respectively located at two opposite surfaces of the conductive layer. Correspondingly, the present invention further provides a display device. The chip on film and the display device are able to reduce the whole thickness of the display device and prevent the chip on the chip on film from being extruded.

Owner:BOE TECH GRP CO LTD

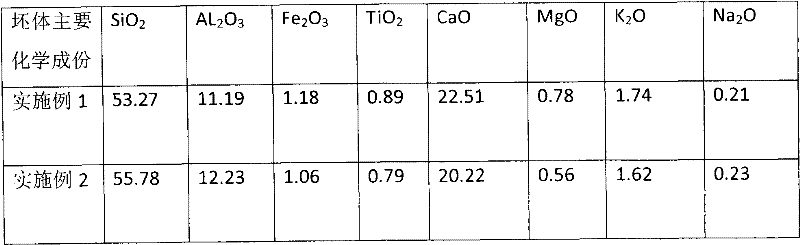

Method for manufacturing glazed brick by utilizing silico-calcium slag

InactiveCN102173740AEmission reductionReduce production energy consumptionClaywaresCalcium silicateBrick

The invention relates to a method for manufacturing a glazed brick by utilizing silico-calcium slag, belonging to the technical field of ceramic manufacture. The glazed brick comprises the following raw materials in percentage by weight: 5%-40% of the silico-calcium slag, 0%-10% of Dongsheng clays and 50%-95% of bamboo partridge tower clays. Due to the adoption of the invention, the shortage crisis of raw mineral materials is weakened and the discharge of the silico-calcium slag is reduced, and an energy-saving type ceramic product is produced; the production energy consumption of ceramics can be reduced and the utilization efficiency of resources is enhanced by preparing low-temperature glaze materials adapted to calcium silicate because the firing temperature of a blank body is reduced through the calcium silicate contained in the silico-calcium slag; the invention not only reduces the pollution, but also increases a new member for building materials; and in addition, the novel glazed brick prepared by using the method has various properties which all accord with or surpass the national standard.

Owner:ORDOS CITY TAOERSI CERAMIC

Production process of colored tissue paper

InactiveCN101748644AQuantitative lowGood strength requirementsCoatings with pigmentsPulp beating methodsFiber bundleColor tissue

The invention discloses a process for producing colored tissue paper by using 100 percent of wastepaper pulp. The process comprises the following steps of: pulp preparation: adding 100 percent of wastepaper pulp into a hydrapulper for breaking; removing impurities of thin films and the like by using a jig sieve; pulping through a high-frequency fluffer and a raffinator; and finally adding chemical raw materials and dye in a pulp blending tank, adjusting the density and feeding the mixture into a paper-making flow delivering system; paper making: diluting the pulp for making in a slushing tank by slushing, then removing sand by a deslagger and long fibers and fiber bundles by a selectifier screen, pumping into a head box and flowing into a net trough for filtering through a net; and finally squeezing, drying, reeling, splitting, packaging and warehousing. The quality of products reaches the national quality standard of 100 percent of wood pulp products and further reaches over B class according to the national standard.

Owner:福建省晋江优兰发纸业有限公司

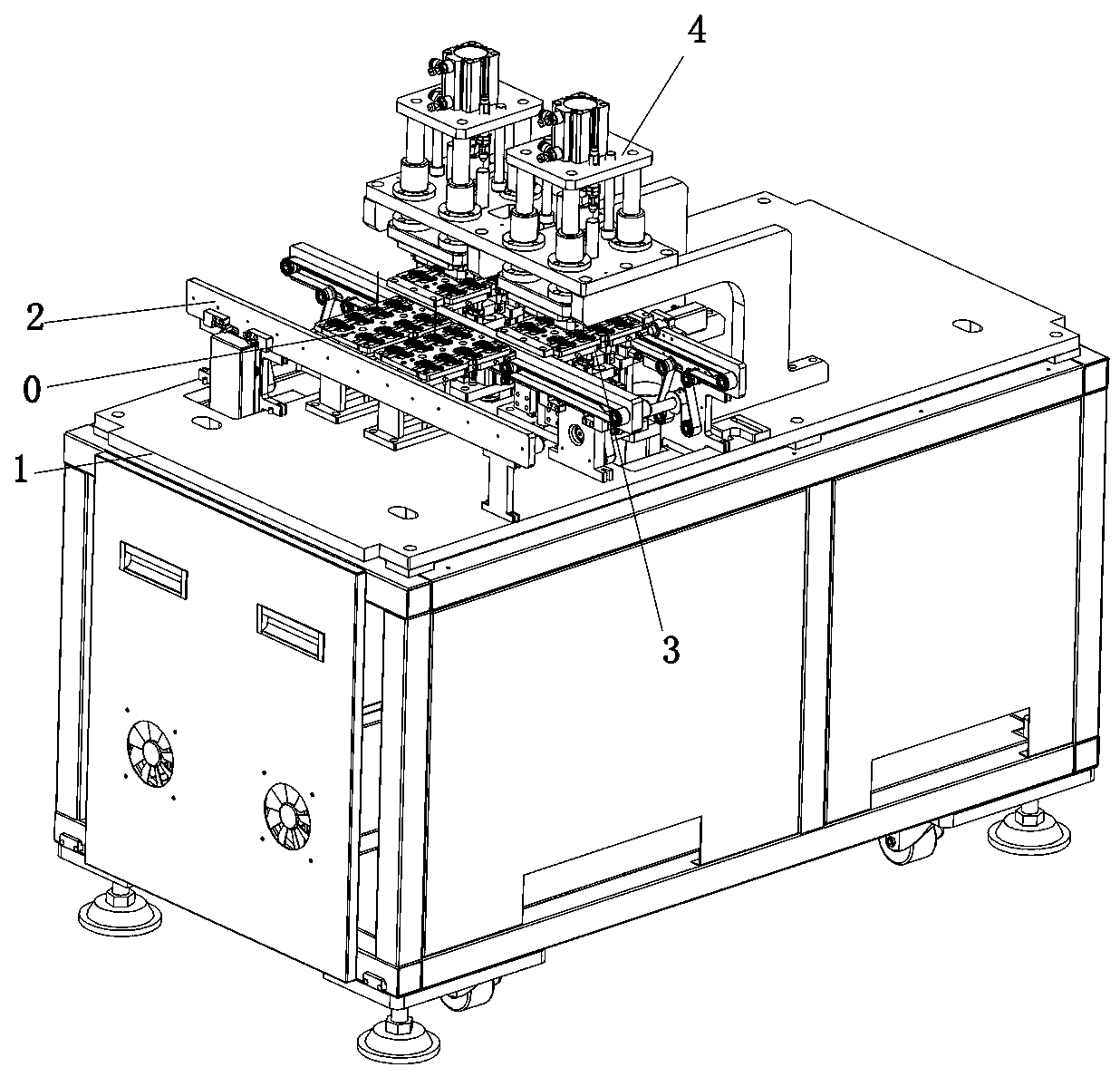

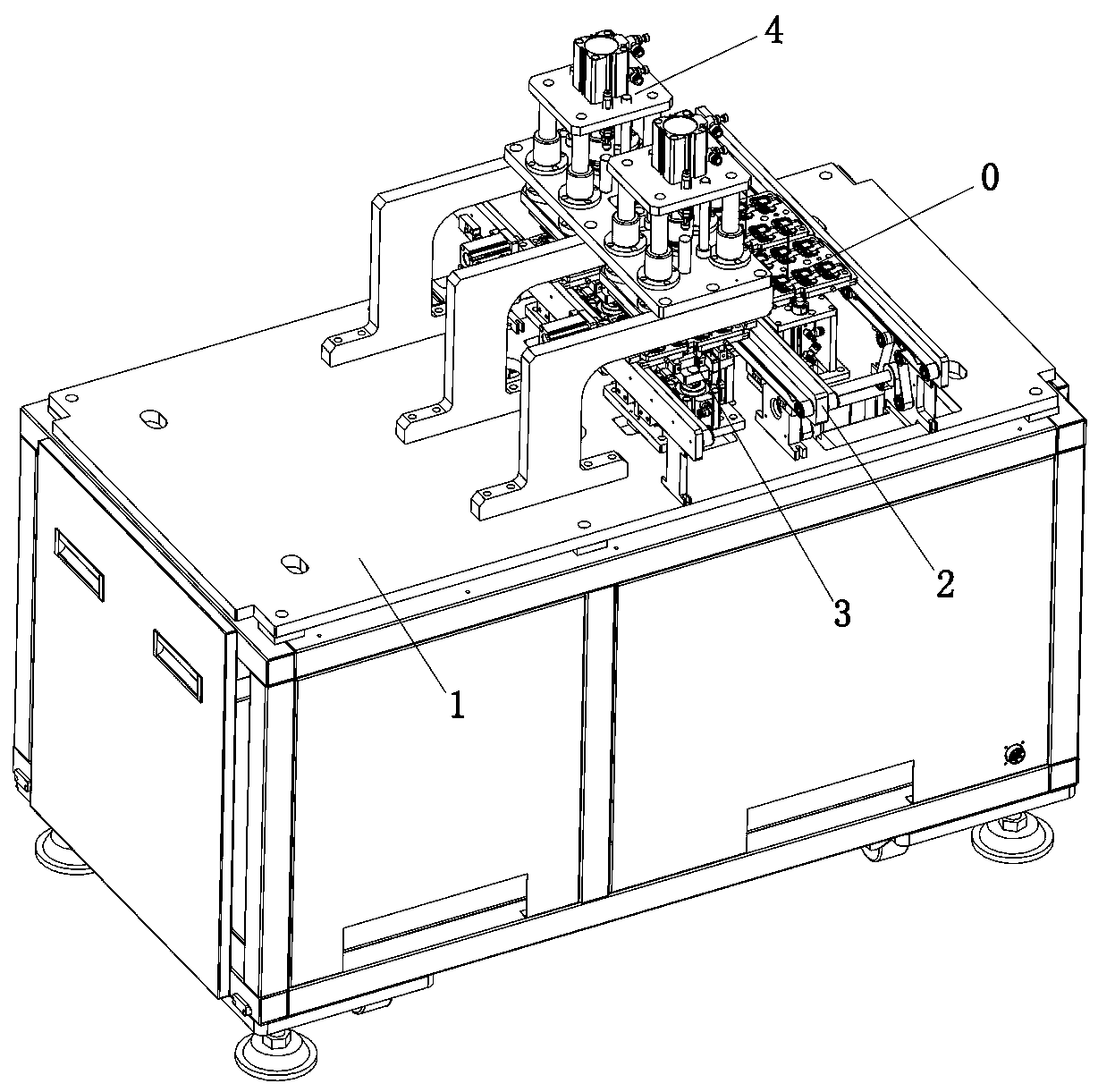

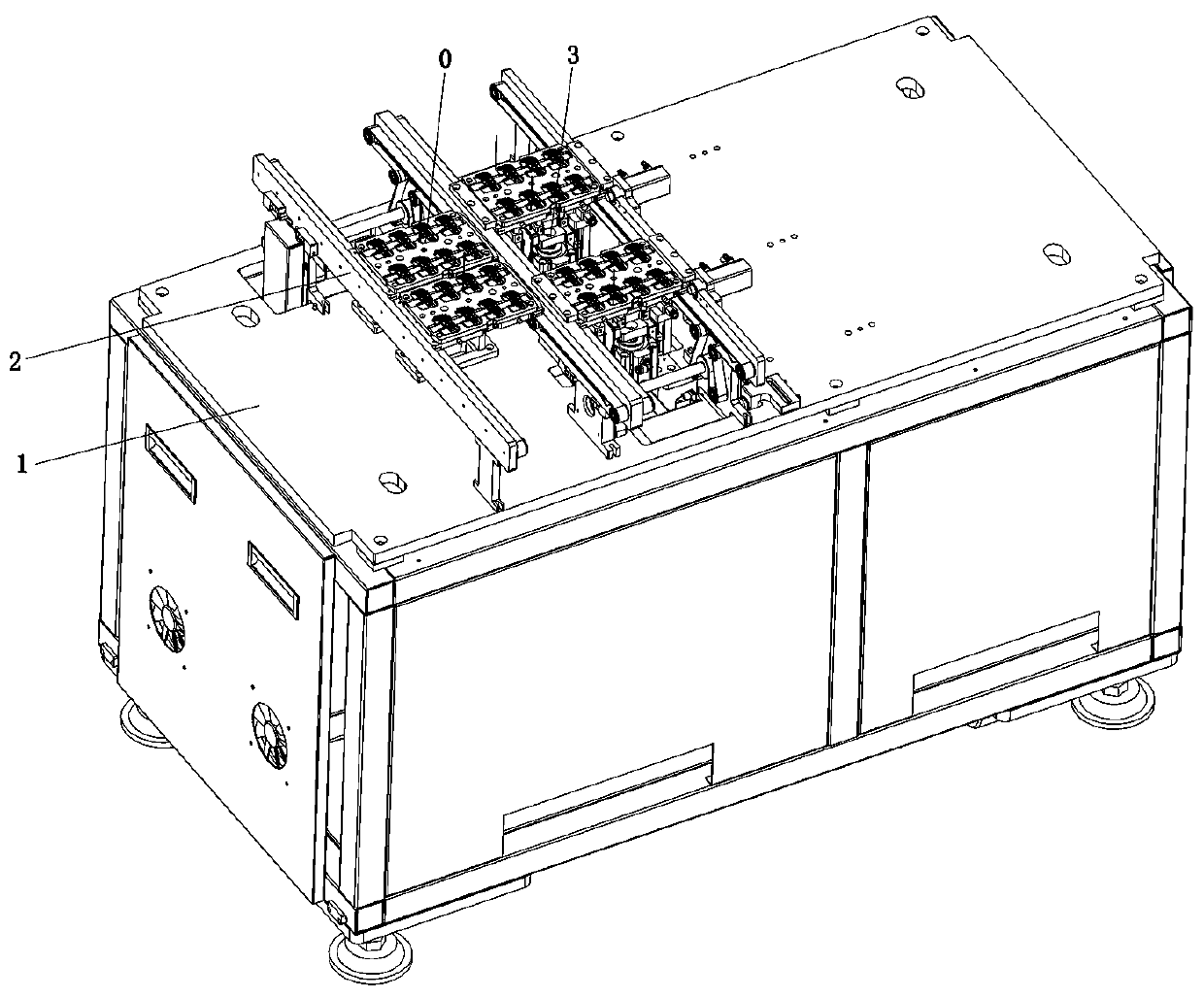

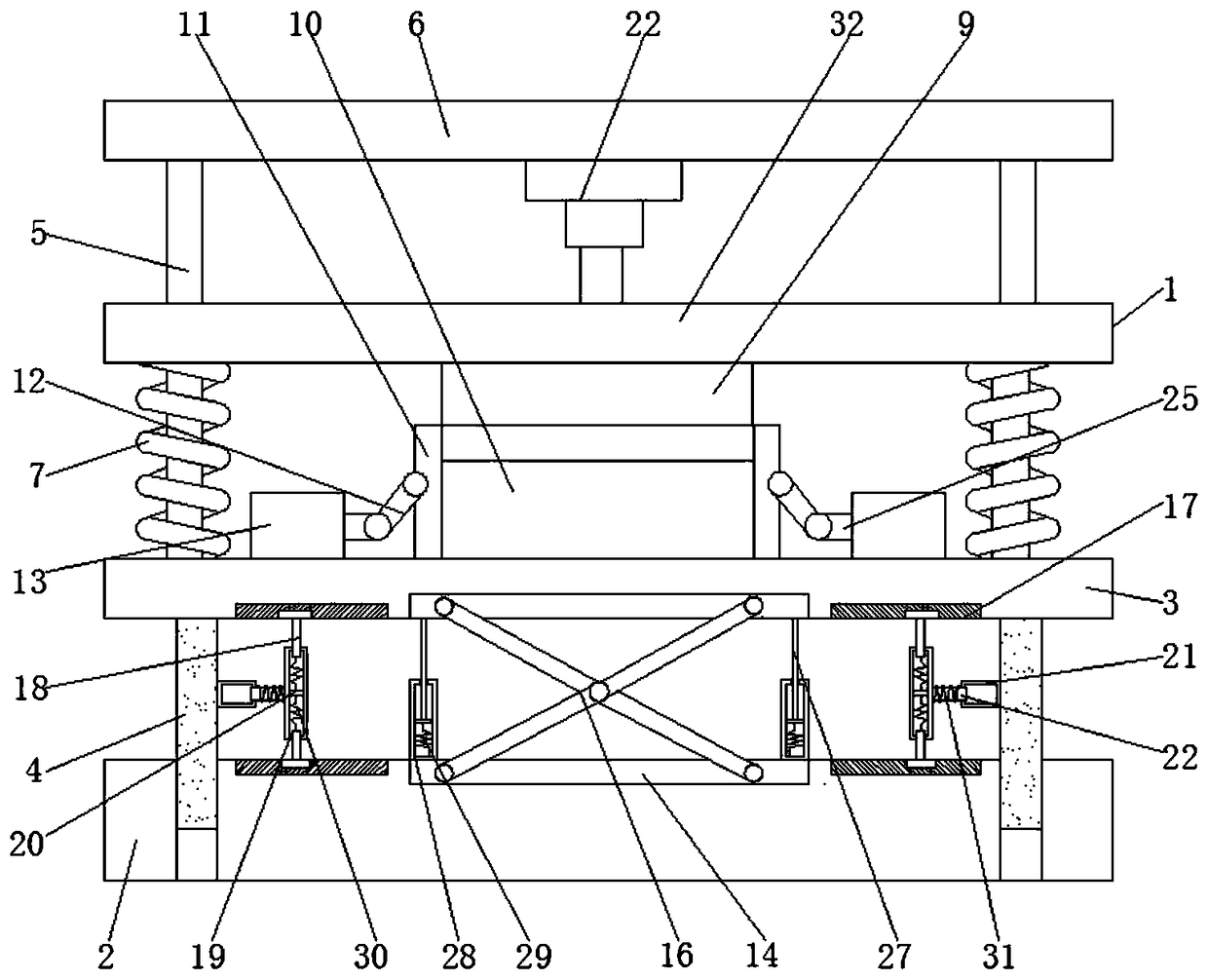

Automatic pressure-keeping machine for electronic product assembling

PendingCN109676350AAvoid positionEnsure consistencyMetal working apparatusEngineeringMechanical engineering

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

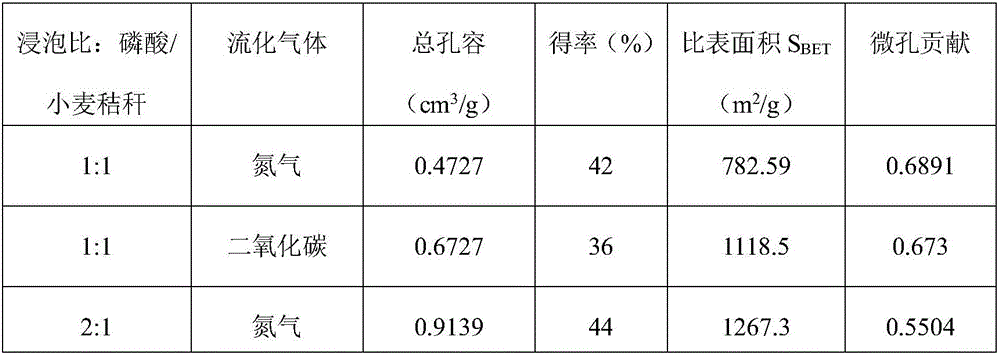

Method for preparing activated carbon with high specific surface area through rapid activation under fluidization

ActiveCN106006635AShort activation timeLarge amount of processingCarbon compoundsActivation methodParticulates

The invention relates to a method for preparing activated carbon with the high specific surface area through rapid activation under fluidization. The method is characterized by comprising steps as follows: 1) a biomass raw material with the particle size ranging from 0.3 mm to 0.9 mm is selected, soaked in a chemical reagent for 3-6 h and dried in a constant-temperature drying box at the temperature of 100-150 DEG C after soaking; 2) after drying, the dried material is stirred or crushed to form particulate materials; 3) a fluidized bed or a spouted bed is used as an activation reactor, the activation reactor is heated to 700-800 DEG C, fluidizing gas is introduced, quartz sand and the particulate materials obtained in the step 2) are placed, activation is performed for 1-10 min, a mixture is discharged immediately after activation and washed to be neutral with water, and the activated carbon with the specific surface area being 1267-1359 m<2> / g is obtained. According to the method, a chemical activation method is combined with the fluidized bed technology, rapid activation preparation of the activated carbon can be realized, the activation time is short, the prepared activated carbon has the relatively high specific surface area, the energy consumption is effectively reduced, and the production cost is reduced.

Owner:TIANJIN UNIV OF SCI & TECH

Method for printing bar codes on iridescent paper

InactiveCN101973169AReduce sheddingReduce accumulationPhotomechanical apparatusOther printing apparatusInfrared lampBarcode

The invention discloses a method for printing bar codes on iridescent paper. The method comprises the following steps of: making films with the bar code pattern into a PS (Photoshop) printing plate; making a on-the-spot bar code pattern 1 to 2 mm longer than each side of the bar code pattern and making a photosensitive resin flexographic plate with the on-the-spot bar code pattern; printing a layer of UV (Ultra Voilet) base oil on the iridescent paper by utilizing an offset press and a polishing set and irradiating the printed UV base oil for drying through an infrared lamp; printing a layer of bar codes at the position the UV base oil printed on the surface of the iridescent paper by utilizing an offset press first set and irradiating for solidification and drying through an ultraviolet lamp; and printing a layer of UV gloss oil or UV matt oil on the solidified and dried surface of the bar codes, and solidifying and drying the printed UV gloss oil or the UV matt oil through the ultraviolet lamp to obtain the iridescent paper printed with the bar codes. The method has the characteristic of less printing process failure; and the bar codes printed on the iridescent paper according to the method has the characteristics of smooth ink layers, good hand touch and easy recognition.

Owner:SHAANXI UNIV OF SCI & TECH

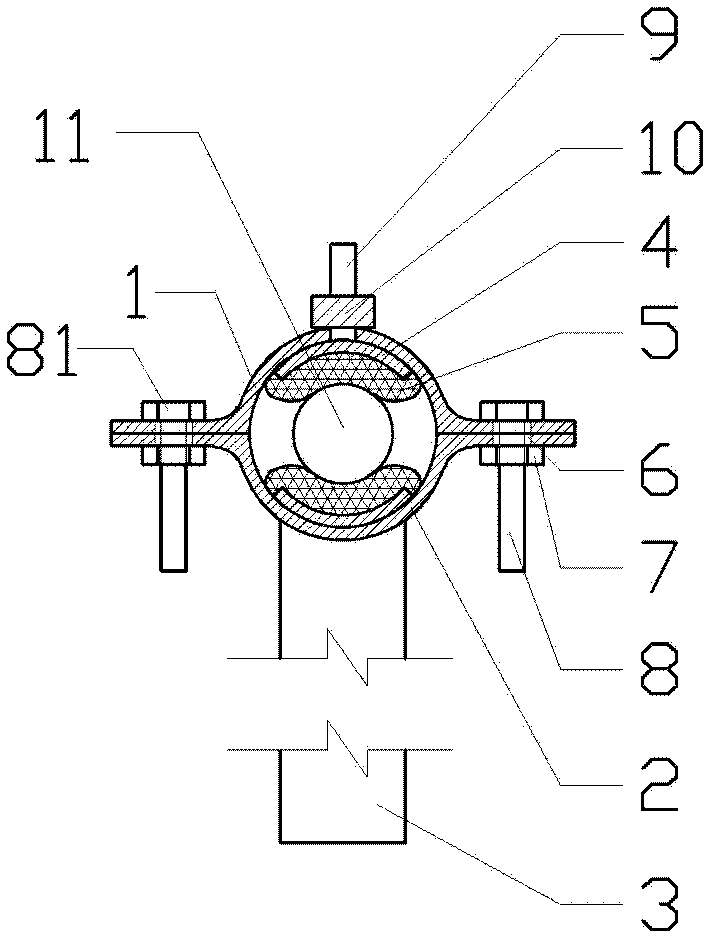

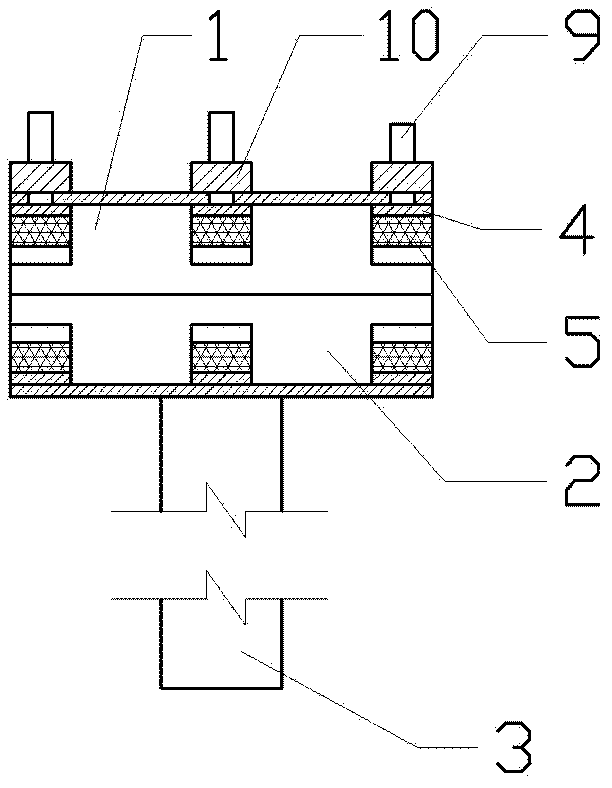

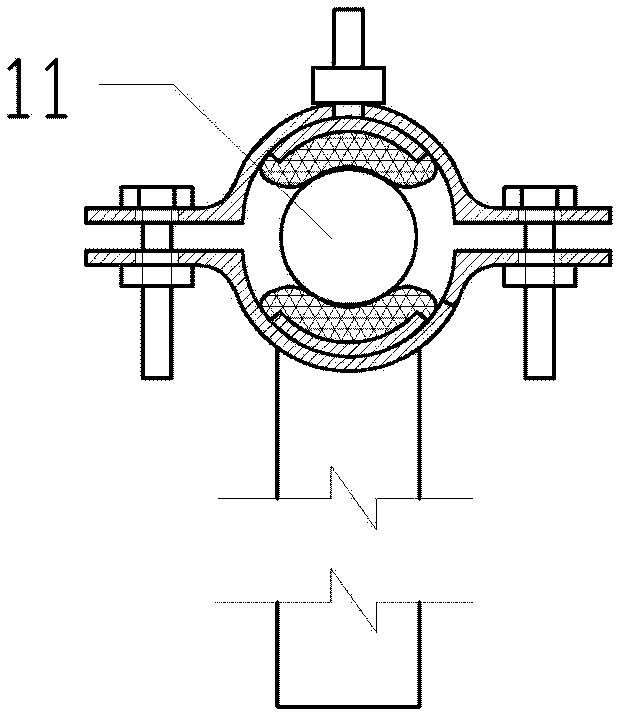

Clamp for crop stem bending test

InactiveCN102620987AOvercome the deficiency of full contactIncrease contact areaStrength propertiesEngineeringMechanical engineering

A clamp for crop stem bending test comprises a clamp holder (3) and a fixed chuck with an annular clamping cavity. The fixed chuck comprises a semicircular upper chuck (1) and a lower chuck (2), the bottom of the lower chuck (2) is fixedly connected with the clamp holder (3), and the upper chuck (1) is detachably connected with the lower chuck (2). A pushable arc-shaped inner chuck (4) is arranged in the annular clamping cavity of the clamp, the top of the inner chuck is vertically, upwardly and fixedly connected with a pitch adjusting screw (9), the pitch adjusting screw (9) is connected with a pitch adjusting nut (10) outside the fixed chuck through a hole at the top of the fixed chuck in a threaded manner, and a clamp groove (102) is arranged at the bottom of the pitch adjusting nut (10) and slidably clamped with a clamp ring (103) corresponding to the upper chuck (1). Straw positions with different diameters are fastened by the pushable arc-shaped inner chuck, the contact area of the inner surface of the clamp and surfaces of straws is increased, the pulling resistance of the clamp is improved, and the problem that ends of the straws are squashed is effectively reduced.

Owner:ANHUI AGRICULTURAL UNIVERSITY

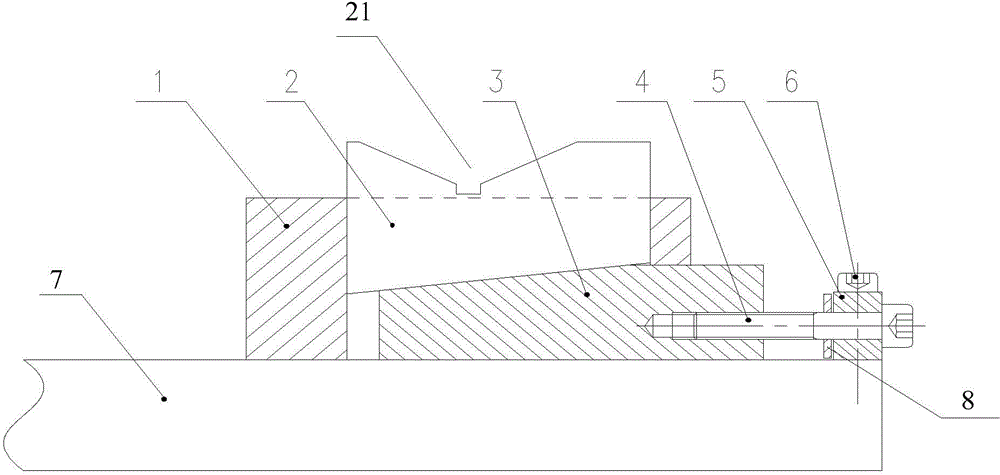

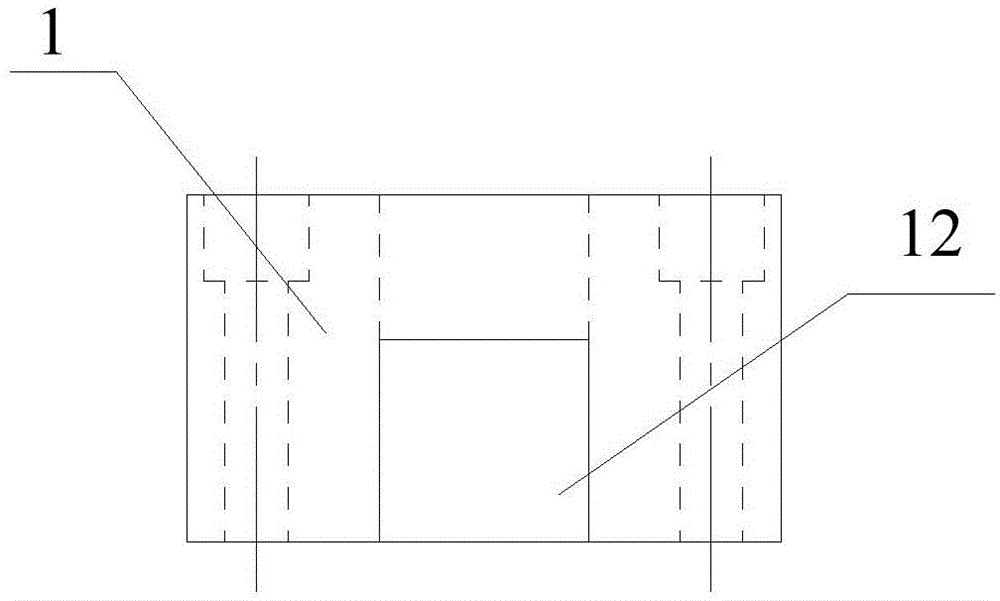

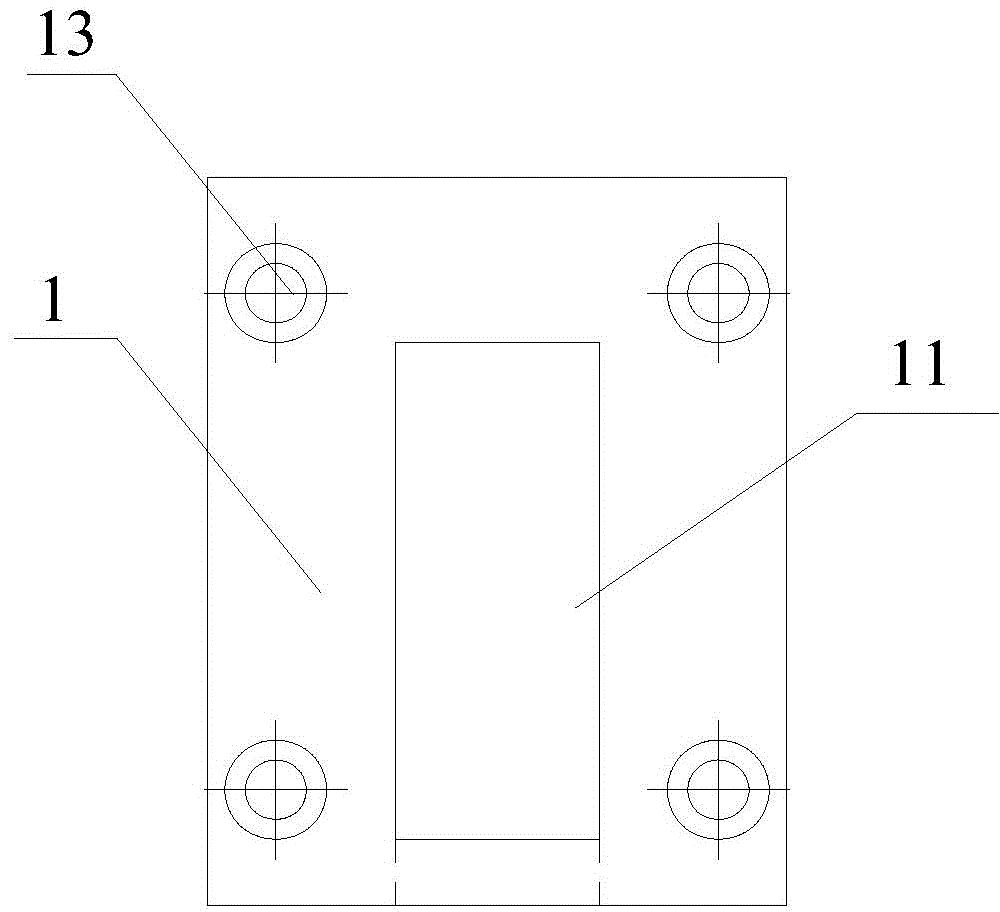

Double boring bottom cylinder supporting tool

InactiveCN104551755AEasy to operateClamping saves time and effortLarge fixed membersPositioning apparatusRelative displacementEngineering

The invention provides a double boring bottom cylinder supporting tool. The double boring bottom cylinder supporting tool comprises a pedestal, and a positioning base, a slide block and an adjusting supporting base which are arranged on the pedestal, wherein a chute is formed along the vertical direction in the positioning base; a supporting block is arranged in the chute; an adjusting bolt is horizontally arranged on the adjusting supporting base and is connected with the slide block; the slide block is arranged below the supporting block; the bolt is connected with the slide block; the slide block is arranged below the supporting block; the matched surface between the upper surface of the slide block and the lower end of the supporting block is an inclined surface; a workpiece supporting opening is formed in the upper end of the supporting block. The angle of the combination surface between the supporting block and the slide block is reasonably used, the telescopic height of the tool is adjusted by relative displacement between the supporting block and the slide block, replacement of the tool during machining is avoided, the structure is convenient to operate, the double boring bottom cylinder supporting tool can be suitable for clamping bottom cylinders or cylindrical workpieces with different diameters, time and labor are saved during clamping, convenience is improved for workers, the production efficiency is improved, and the cost is reduced.

Owner:CHONGQING YAOYONG SHOCK ABSORBER

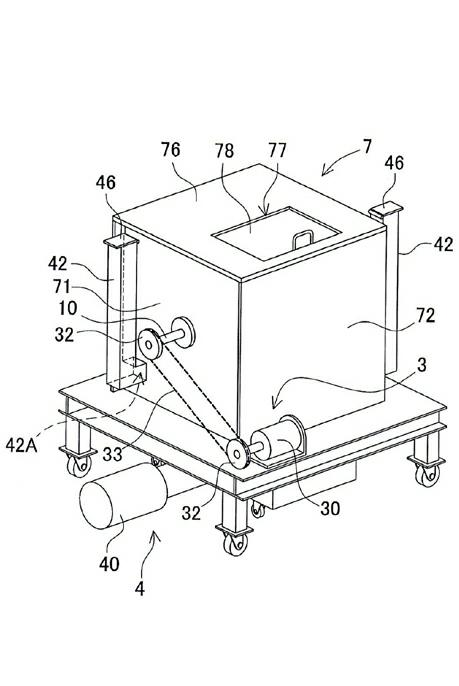

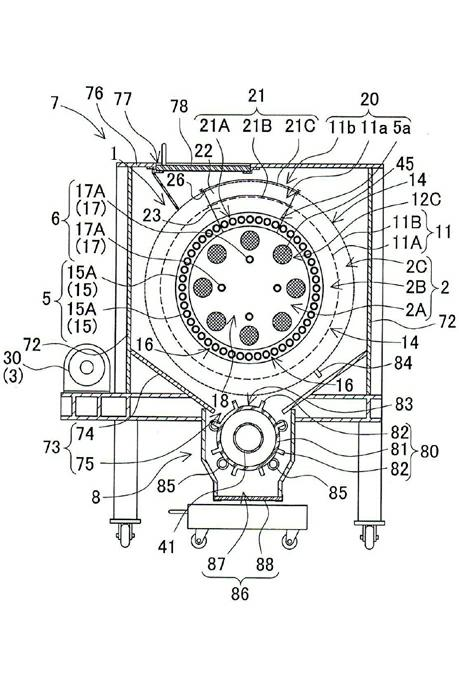

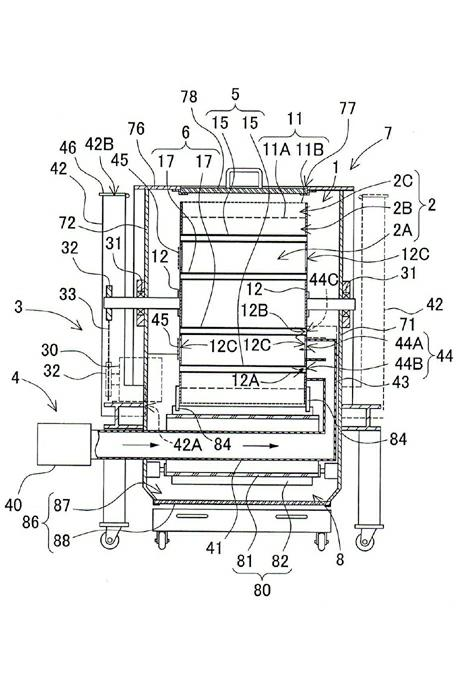

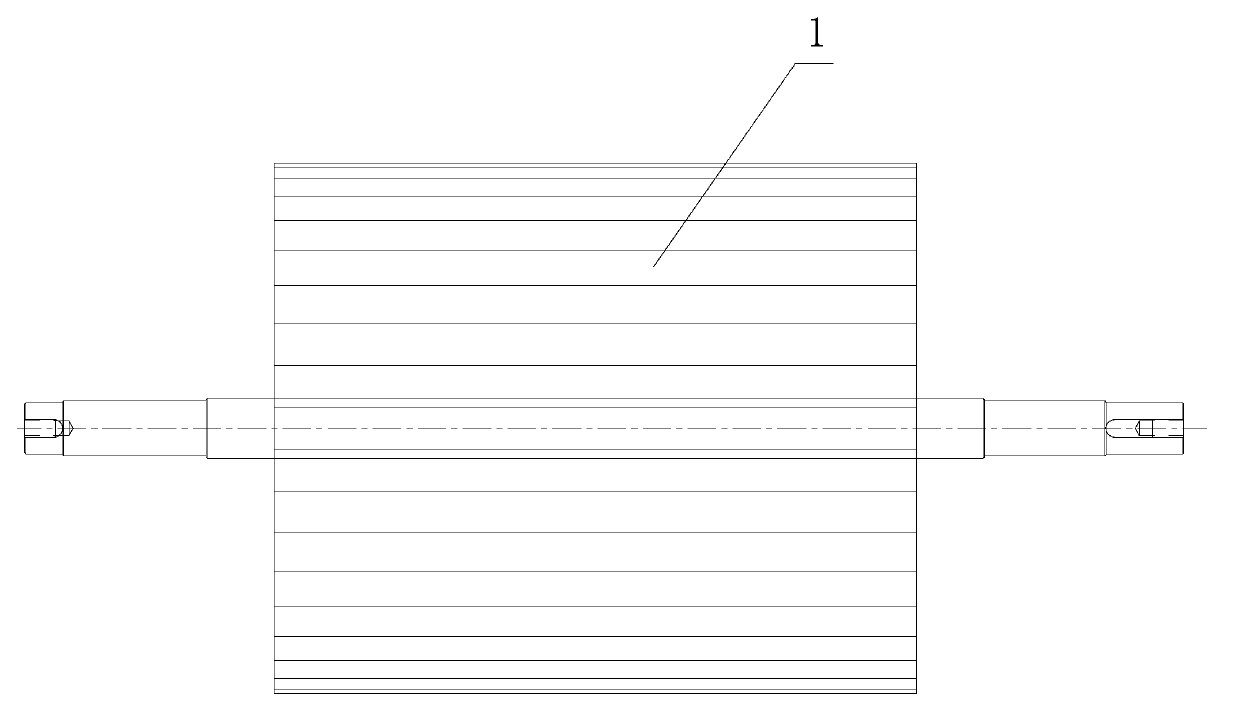

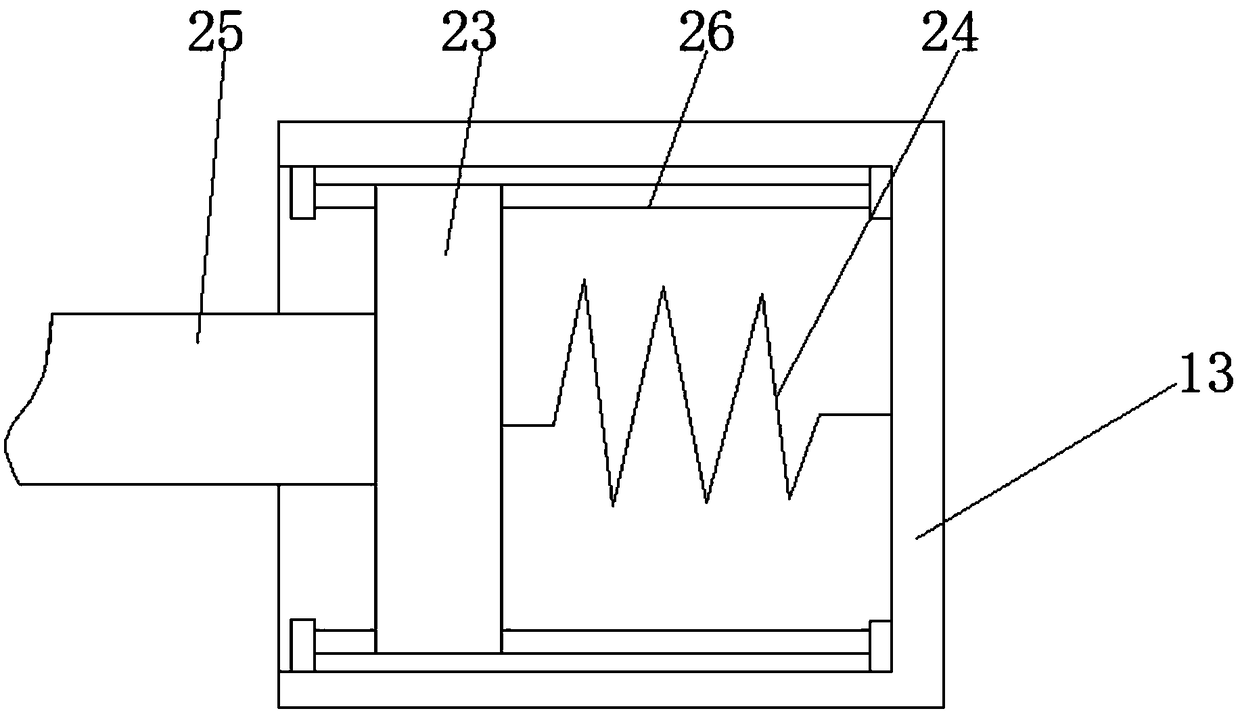

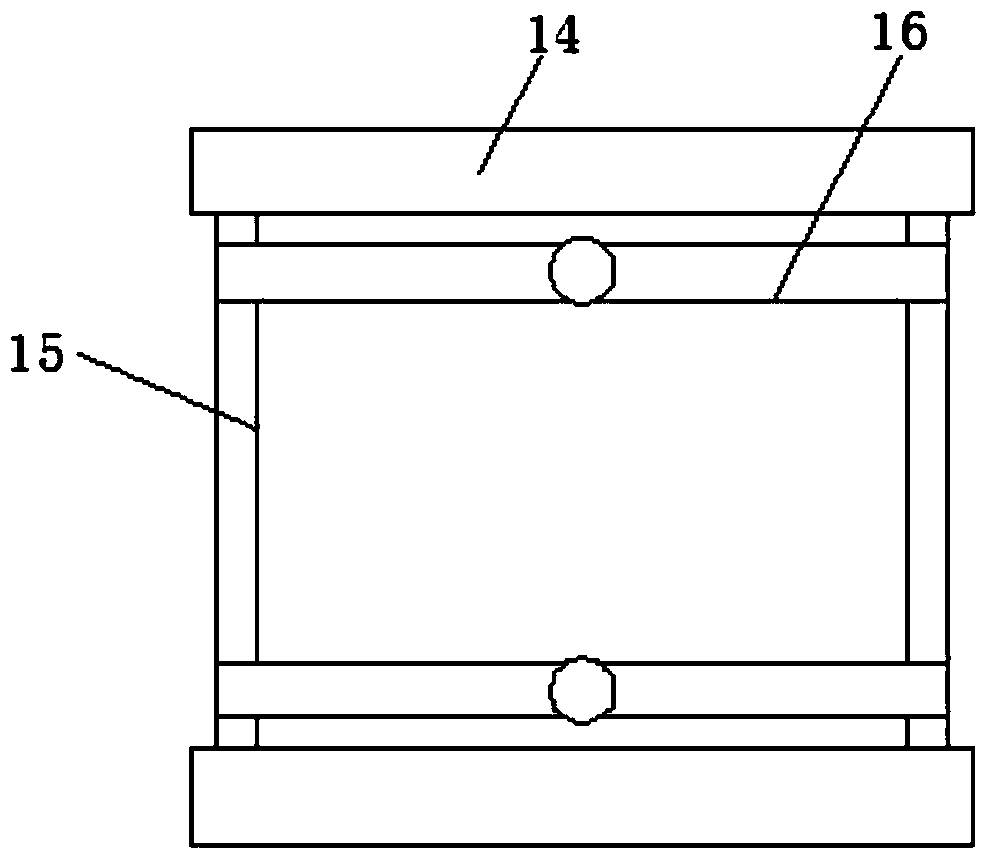

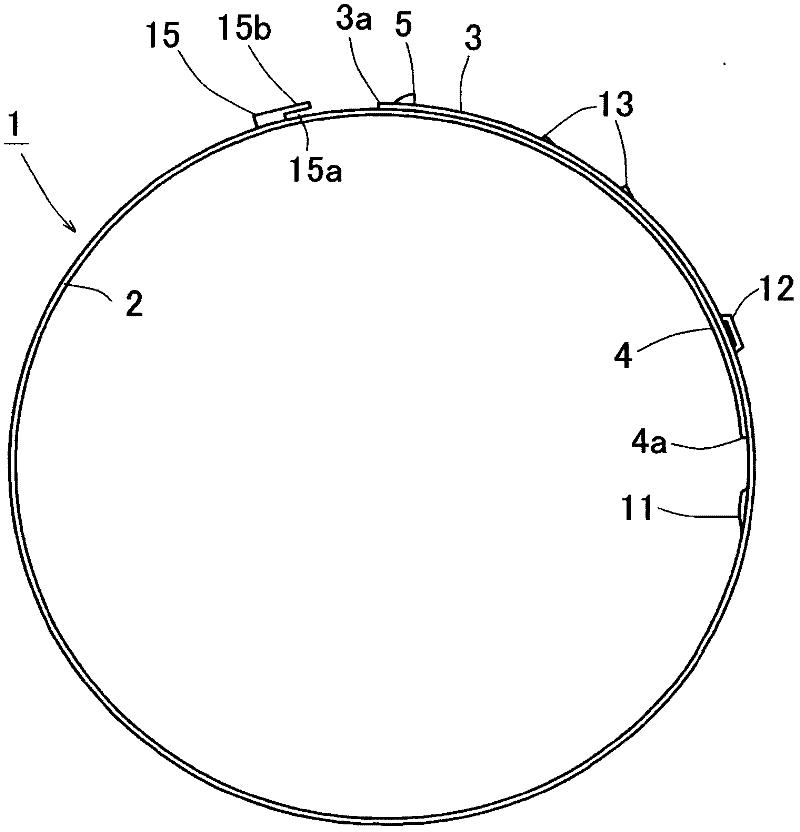

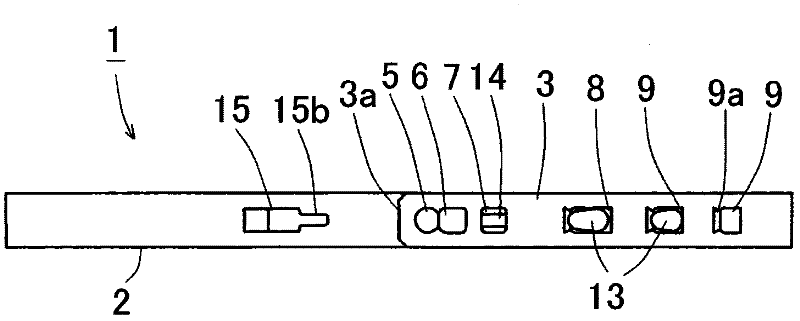

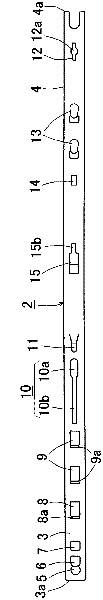

Drying device

ActiveCN102564082AReduce crushEfficient use of drum energyDrying gas arrangementsDrying chambers/containersEngineeringMechanical engineering

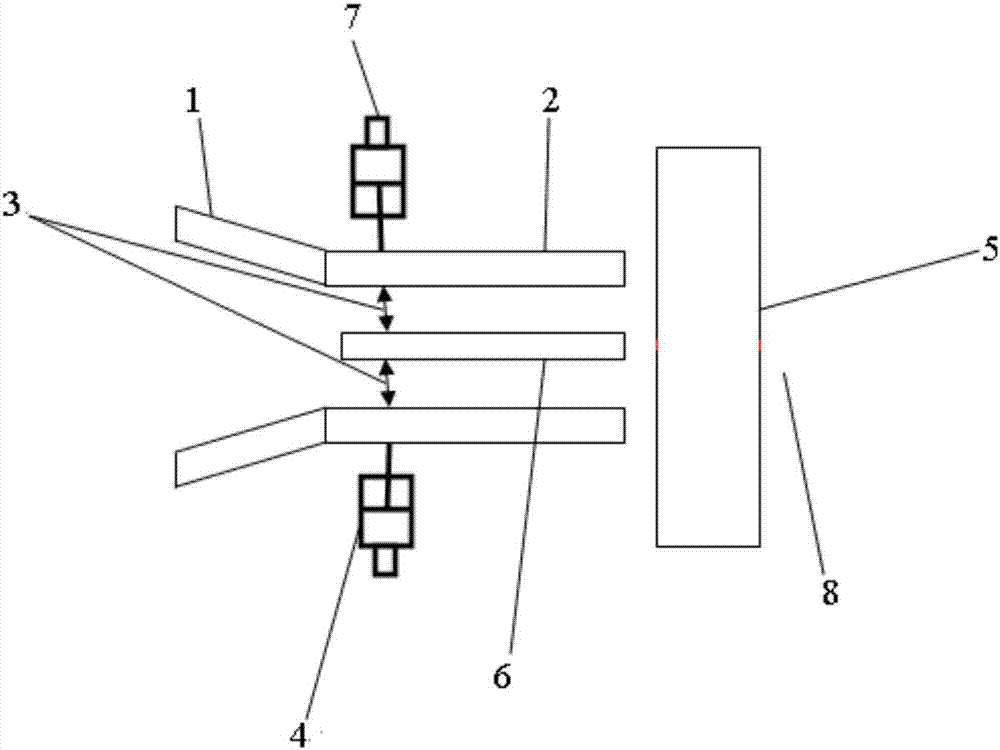

The invention provides a drying device, which comprises a cylindrical filter cartridge 11 coiled by a porous plate 13. The two ends of the cylindrical filter cartridge 11 are sealed by end plates 12. The inner side of the cylindrical filter cartridge 11 is served as a rotary barrel 1 for a drying chamber 2. The rotary barrel is driven to rotate by a drive mechanism 3. A heating air supply mechanism 4 forcibly sends heating air into the rotary barrel 1. In the rotary barrel 1, a plurality of rods 15 are arranged to be away from the inner side of the filter cartridge 11 so as to be into a cylindrical rod cylinder 5 and divide the drying chamber 2 into a first drying chamber 2A and a second drying chamber 2B. Due to the adoption of the drying device, materials to be dried are fed into the first drying chamber 2A through an opening part 20 and are dried in the first drying chamber 2A of the rotary barrel 1. Therefore, the materials fall through a dropping gap 16 into the second drying chamber 2B. Then the materials are further dried in the second drying chamber 2B and are discharged to the outside through the through holes 14 of the porous plate 13.

Owner:MUTSUMI GIKEN

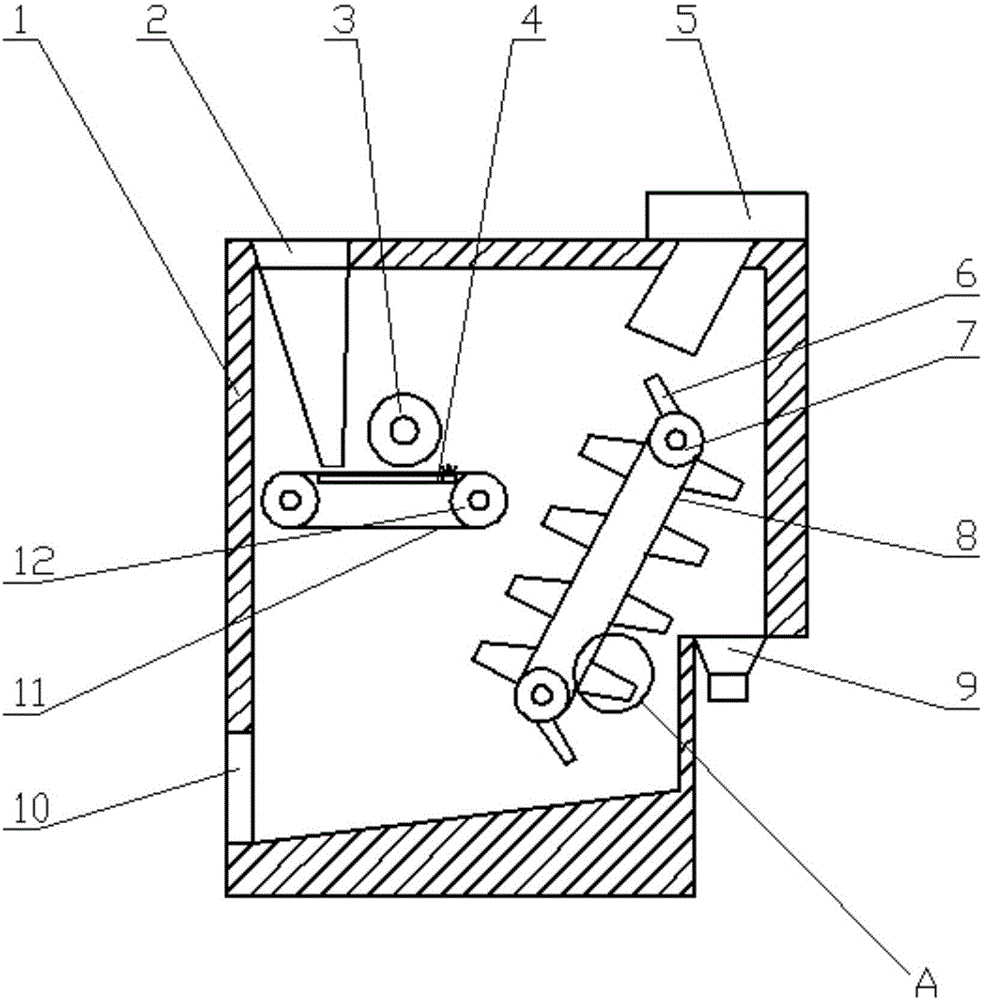

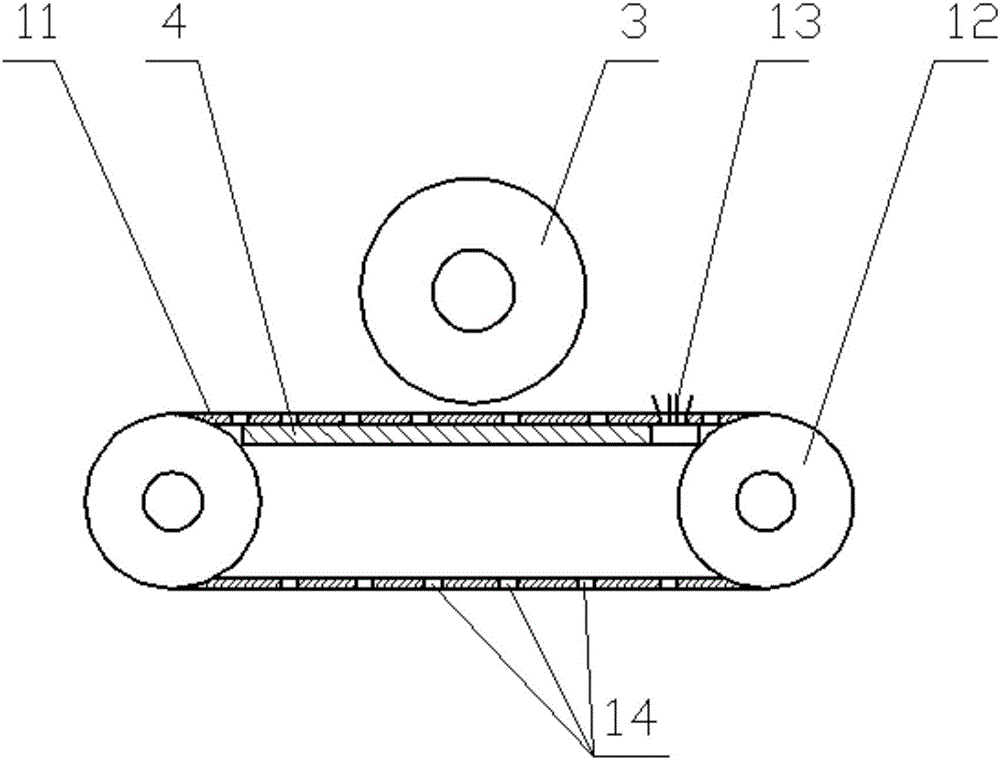

Peanut shelling and sorting machine

The invention discloses a peanut shelling and sorting machine which comprises a machine body, a shelling device, a sorting mechanism and a discharging port. The machine body is provided with a feeding port, the shelling device comprises a conveying mechanism, a pressing roller and a squeezing plate, a squeezing gap is formed between the pressing roller and the squeezing plate to crack shelled peanuts, the conveying mechanism comprises a first conveying belt, a first driven drum and a first driving drum, the upper portion of the first conveying belt is positioned in the squeezing gap, and driven by the first driving drum, the first conveying belt can convey the shelled peanuts to the squeezing gap; the sorting mechanism comprises a plurality of sorting frames, a second conveying belt and an air blower, the sorting frames are all arranged on the second conveying belt, and the air blower is arranged above the second conveying belt and can blow air into the sorting frames. The shelled peanuts are squeezed and cracked through squeezing force between the pressing roller and the squeezing plate in the shelling mechanism, and then peanut shells and peanut kernels are separated through air flow generated by the air blower, so that the peanut shelling and sorting machine has good separation effect.

Owner:陆高尚

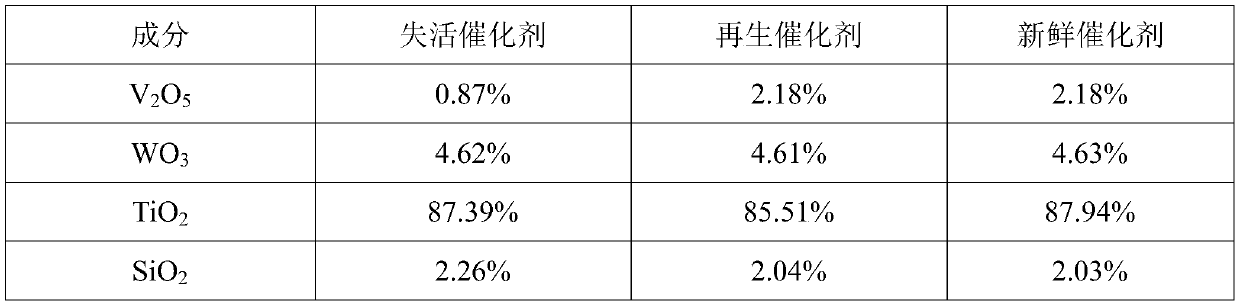

Reutilization method of inactivated SCR denitration catalyst

ActiveCN110354914ARealize resource utilizationReduce crushGas treatmentHeterogenous catalyst chemical elementsSulfurActive component

The invention belongs to the field of environmental protection technology and denitration catalysis, and particularly relates to a reutilization method of an inactivated SCR denitration catalyst. Thereutilization method specifically comprises the following steps: soot blowing, cleaning by a cleanout fluid, reductive acid leaching, auxiliary agent loading, active component loading and the like. Bytaking the integral inactivated SCR denitration catalyst as a raw material, the low-temperature SCR denitration catalyst is obtained by carrying out in situ regeneration. The regeneration catalyst has very high catalytic activity and sulfur poisoning resistance in a temperature range of 150-300 DEG C.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Forming method for modifying biomass fuel by rapid thermal treatment process

The invention discloses a forming method for modifying biomass fuel by a rapid thermal treatment process in the technical field of biomass fuel preparation. The preparation method of the forming fuel comprises the following steps: crushing biomass material into particles of which the diameter is less than 1 cm; performing rapid thermal treatment in a condition of limited oxygen supply or without oxygen, and collecting and obtaining thermo-modified biomass; crushing the obtained thermo-modified biomass; and adding binder and mixing in a forming machine to prepare the forming fuel. Through the method disclosed by the invention, the fiber structure of the biomass raw material can be damaged, and the flexibility is reduced so that the biomass raw material is easier to crush and grind; thus, the crushing and forming power consumption is obviously reduced, and the heat value and stability of the forming fuel are remarkably improved; moreover, as the liquid byproduct is used as the binder, heating is not required in the forming agglomeration process, the abrasion of the mechanical equipment is reduced, the durability of the forming fuel is improved, and the preparation cost is effectively lowered.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

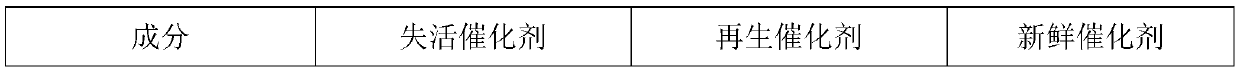

Method and device for improving opening degree control precision of finish rolling side guide plate

ActiveCN107413859AHigh control precisionImprove stabilityGuiding/positioning/aligning arrangementsRoll mill control devicesStrip steelEngineering

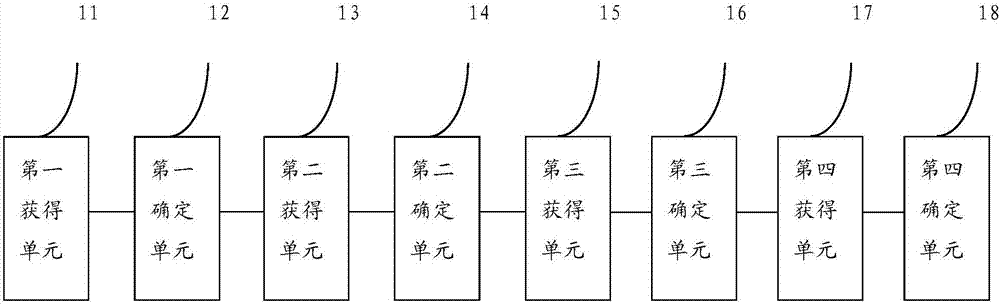

The invention provides a method and device for improving the opening degree control precision of a finish rolling side guide plate, and relates to the technical field of silicon steel production. The first set value of the side guide plate is obtained; according to the first set value, it is determined that the side guide plate is closed to the first opening degree, and calibration is conducted; when strip steel arrives at an inlet of a finishing mill, the second set value of the side guide plate is obtained; the side guide plate is opened to the third opening degree, the side guide plate is closed to the second opening degree; after the strip steel enters a roller, the third set value of the side guide plate is obtained; it is determined that the side guide plate is closed to the fourth opening degree; before the tail of the strip steel arrives at the side guide plate, the fourth set value of the side guide plate is obtained; and it is determined that the side guide plate is opened to the fifth opening degree. The technical problem that due to the frame allowance of the side guide plate, the opening degree precision is influenced, and consequently steel clamping is likely to be caused during strip steel rolling is solved, and the technical effects that the influences of the frame allowance of the side guide plate on the opening degree precision are weakened, and the strip steel threading stability is improved are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Polytetrafluoroethylene punched felt and manufacturing method thereof

ActiveCN101805958AHigh saturationReduce voidsHeating/cooling textile fabricsNon-woven fabricsMaterial consumptionEngineering

The invention relates to a polytetrafluoroethylene punched felt. From the outside to the inside, the structure of the punched felt comprises a polytetrafluoroethylene crimped staple layer, a polytetrafluoroethylene filament base fabric and a polytetrafluoroethylene crimped staple layer, wherein the thickness of the punched felt ranges from 0.8 to 1.8 millimeters; polytetrafluoroethylene crimped staples mutually hooked and crossed are inserted in the base fabric from upside and downside and tightly connected with the base fabric. The punched felt produced by the invention has the advantages of stable chemical properties, high filtering effect, high strength, low heating shrinkage, low material consumption, low cost, no smoke pollution and the like.

Owner:常州华福环境科技股份有限公司

Proppant Mixtures

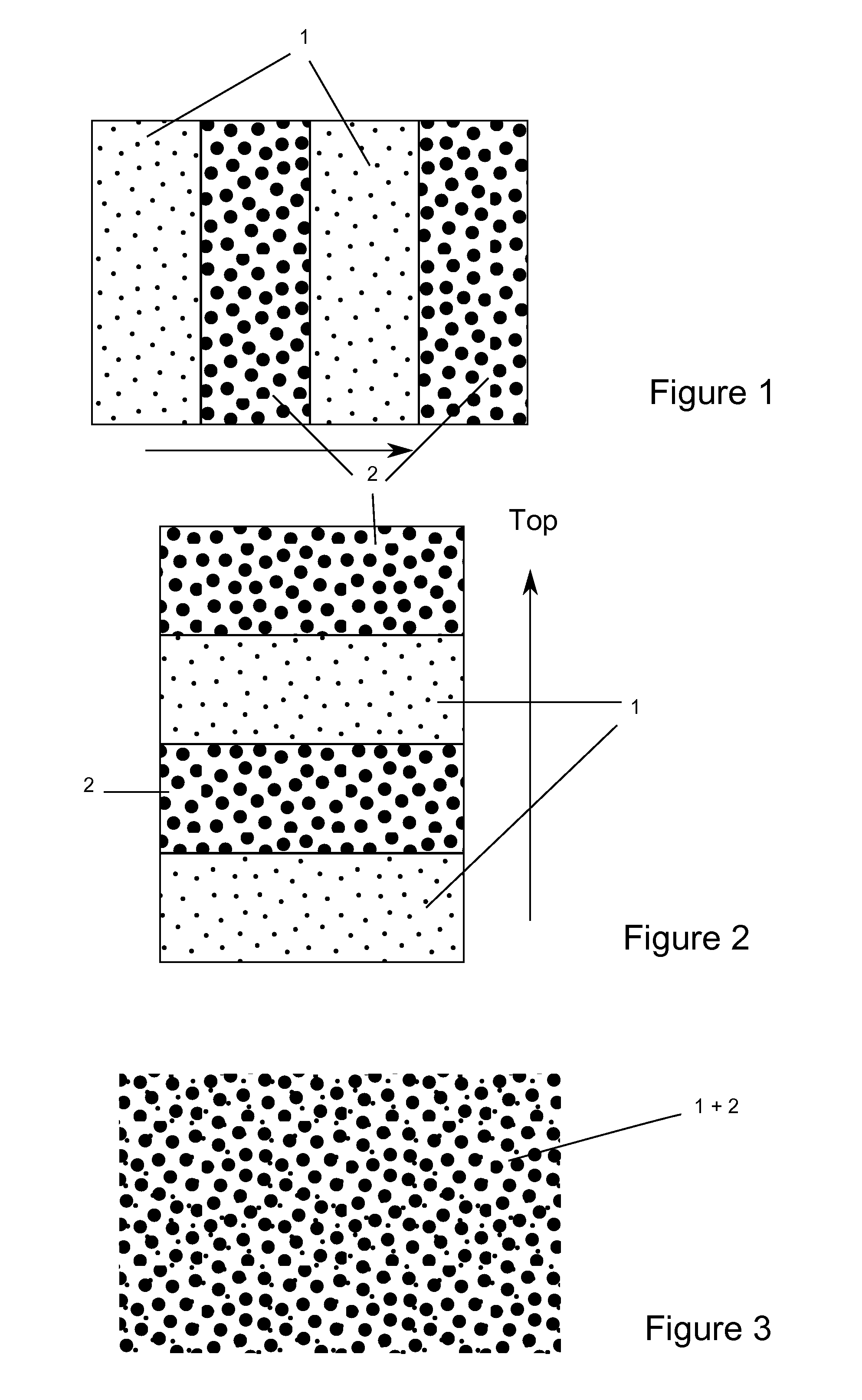

ActiveUS20150315892A1Less squeezeReduction in created fineFluid removalDrilling compositionResin coatingUltimate tensile strength

The invention relates to a propped, fractured, subterranean field with (a) a first proppant and (b) a second proppant that exhibits a relatively higher average crush strength and / or an ability to form a particle to particle bonded structure than the first proppant. Preferably, the first proppant is uncoated sand and the second proppant is resin-coated sand. The proppants can be deposited as a substantially homogeneous mixture or in layered structures (vertical or horizontal) within the fractured field. Deformation of the second proppant under closure stress acts to spread out the compression pressures in a mixture so as to reduce failure of the first proppant. Similar protective effects are found when the proppants are deposited in layers. When formed as vertical pillar structures, the second proppant structures can also act as in-situ screens that inhibit formation fines from migrating through the proppant pack to the detriment of field conductivity.

Owner:PREFERRED TECH

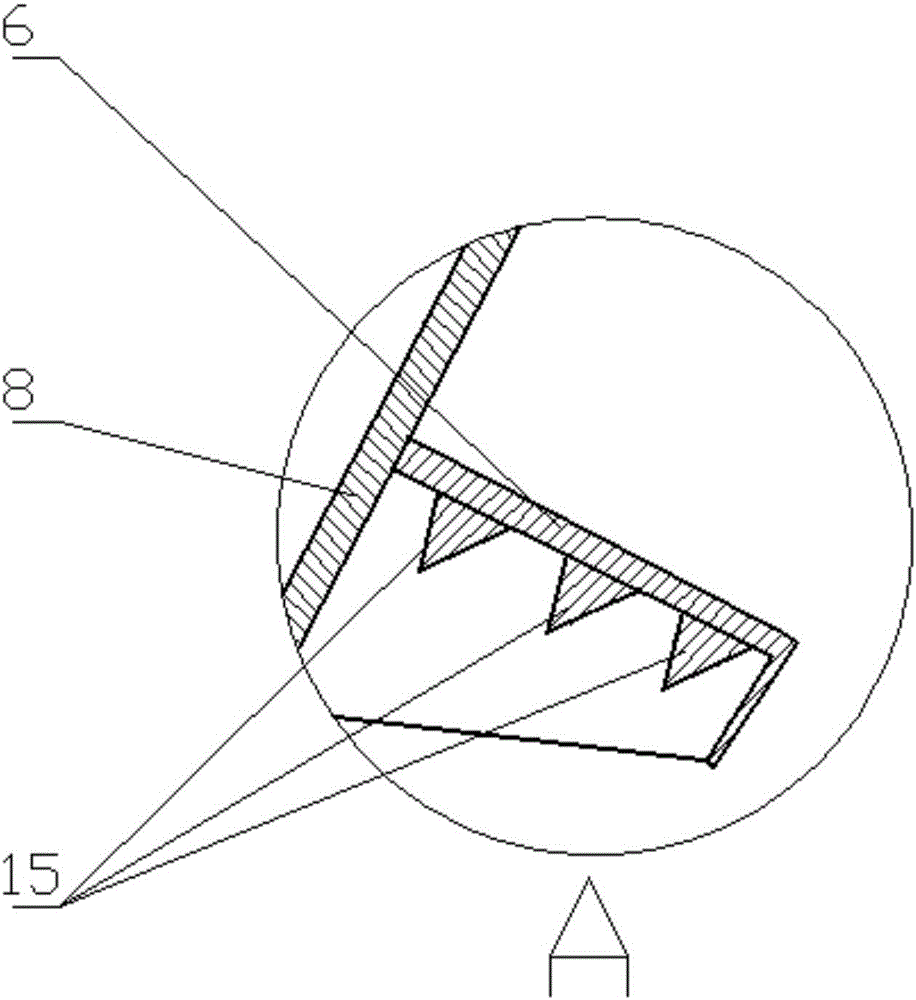

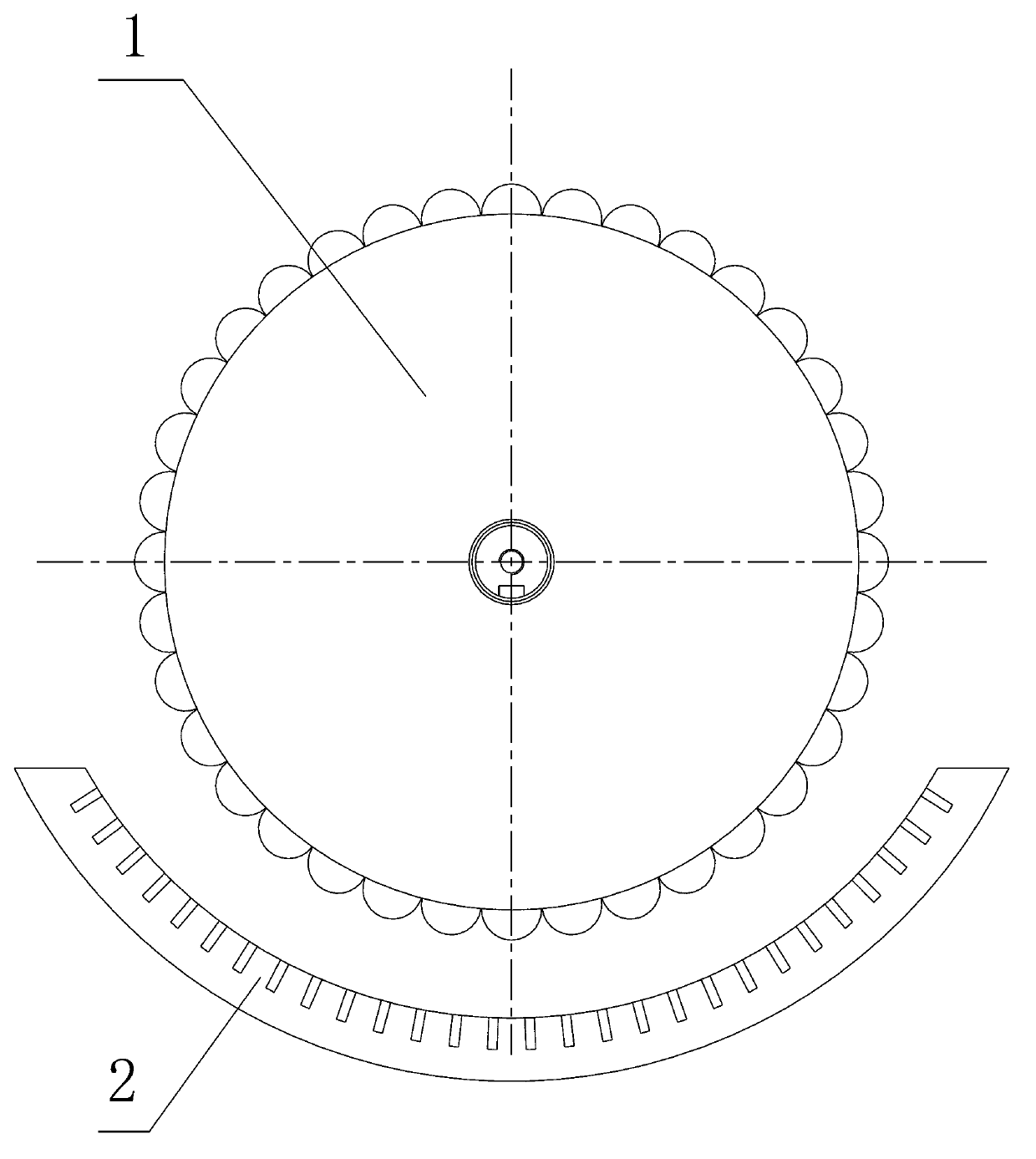

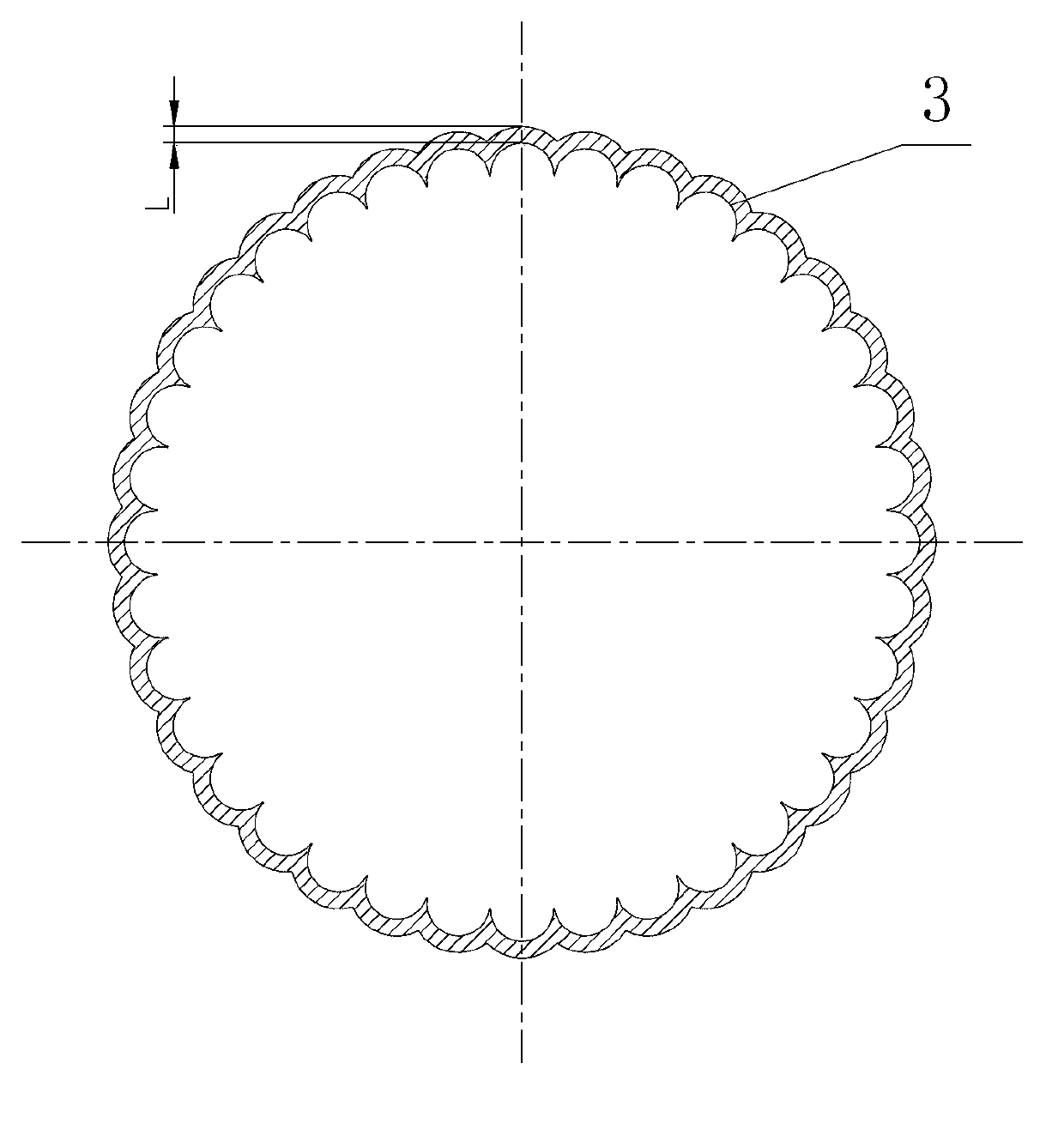

Flexible hitting-rod assembly structure for squeezing type breeding-peanut shelling machine

The invention relates to a component improvement structure for a peanut shelling machine particularly relates to a flexible hitting-rod assembly structure for a squeezing type breeding-peanut shelling machine, and belongs to the agricultural machinery. A hitting-rod roller (1) is a cylindrical soft elastomer, the middle part of the cylindrical soft elastomer is provided with a rotating shaft, and the periphery of the cylindrical soft elastomer is provided with semi-circular raided bars, i.e., the cross section of the cylindrical soft elastomer is in the shape of a flower disc, the middle part of the cross section is a circle, and a plurality of semi-circular raised sheets are raised outwards at the periphery of the circle, wherein the extradius of each semi-circular raised sheet is 1-2cm; a hitting-rod adjusting sleeve (3) can be used or not used according to the volume of the peanut pods; the hitting-rod adjusting sleeve (3) is a ringlike sleeve (soft elastomers) of different thickness; the inner circle of the hitting-rod adjusting sleeve (3) is a semi-circular groove, and the outer circle is a raised semi-circular sheet. The shape of the hitting rod of the existing hitting type peanut shelling machine is changed, the material of the hitting rod roller is changed, and the gap between an upper semi-circular raided bar and a lower concave grid can be adjusted conveniently and rapidly in a shorter time, the adaptability of the peanut shelling machine to the shelling of breeding peanuts of different varieties can be improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

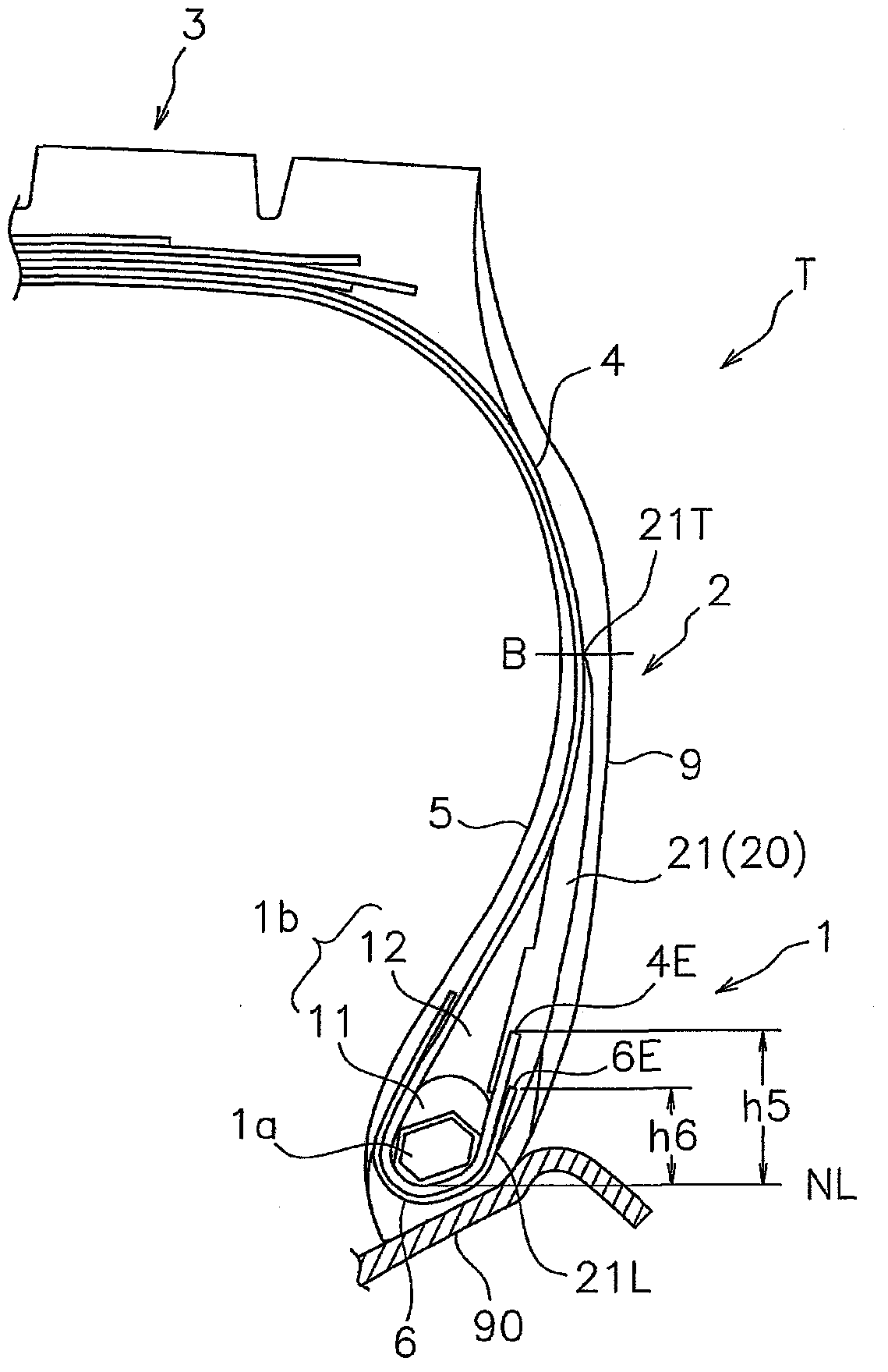

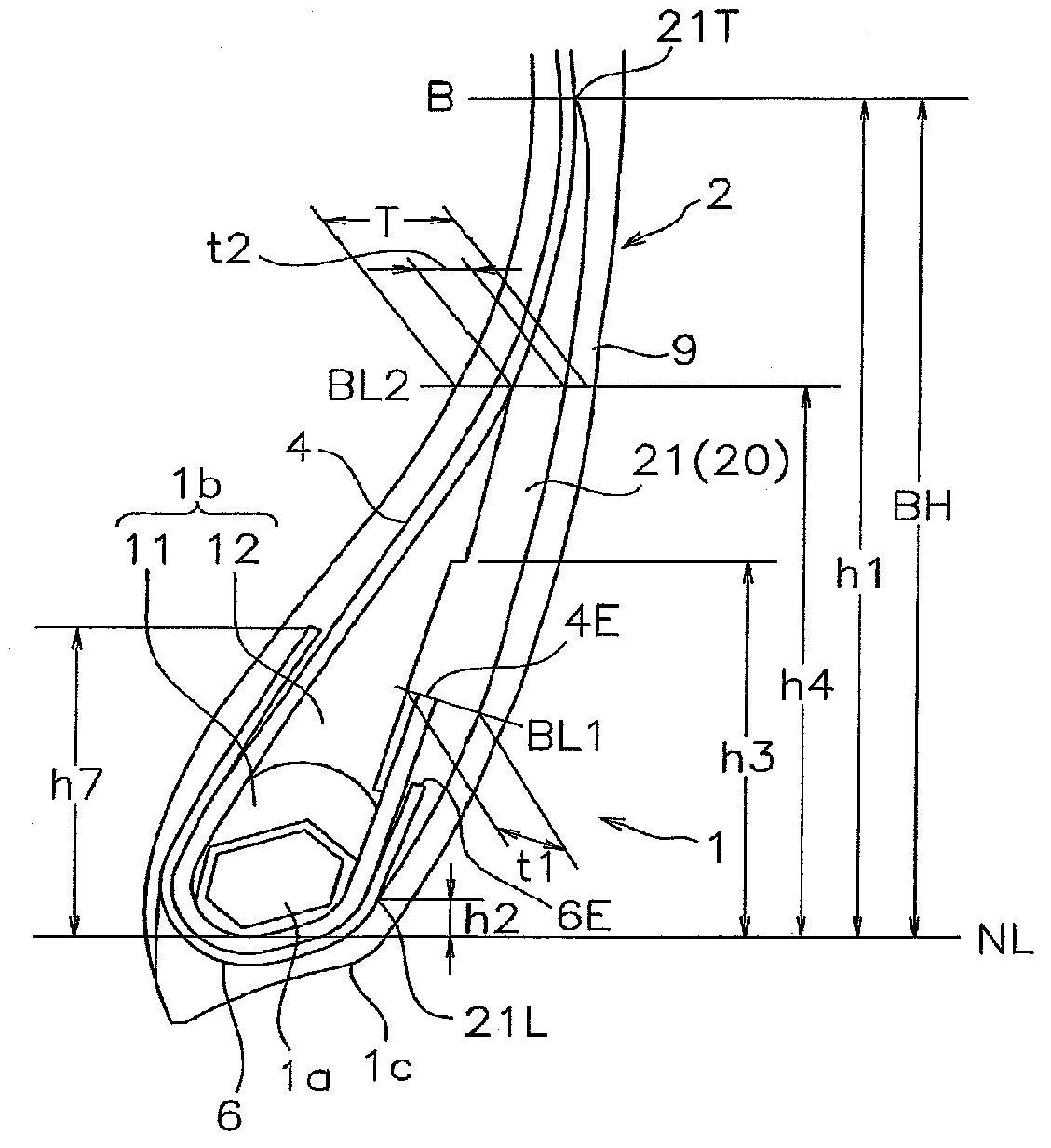

Pneumatic radial tire

A pneumatic radial tire has a carcass ply wound up around a bead core, a chafer wound up around the bead core to be arranged in an outer side of the carcass ply, and a side wall rubber. A reinforcing rubber is provided between a rubber filler and the side wall rubber to pinch a wind-up end of the carcass ply and a wind-up end of the chafer. The reinforcing rubber has a monolithic layer extending in a tire diametrical direction. An upper end of the monolithic layer is positioned at a height which is 0.9 to 1.1 times a height of a tire maximum width position based on a rim reference line. A lower end of the monolithic layer is positioned in an outer side of the chafer at a height within +-10 mm based on the rim reference line.

Owner:TOYO TIRE & RUBBER CO LTD

Method for modified silicon iron boron soft magnetic powder core with magnetic conductivity of 90

ActiveCN103500643AImprove noise defectsImprove high frequency characteristicsInorganic material magnetismInductances/transformers/magnets manufactureSilicon ironMaterials science

The invention belongs to the field of metal soft magnetic material manufacturing, and particularly relates to a method for manufacturing a modified silicon iron boron soft magnetic powder core with magnetic conductivity of 90. The method comprises the first step of embrittlement treatment, the second step of crushing, the third step of screening and matching, the fourth step of passivating treatment and insulation covering, the fifth step of modifying agent adding, the sixth step of compression moulding and the seventh step of annealing treatment and spraying. According to the method, the noise defect of the silicon iron boron soft magnetic powder core can be overcome, and the high-frequency performance of the silicon iron boron soft magnetic powder core can be improved.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Manufacturing method for express plastic packaging bags

The invention discloses a manufacturing method for express plastic packaging bags, and relates to the technical field of plastic products. A packaging bag includes an inner layer, a pressing preventing middle layer made of an air cushion film and an abrasion resistant outer layer; the manufacturing method includes the following steps: making an abrasion resistant plastic film of the abrasion resistant outer layer; sleeving a degradable plastic inner layer by the abrasion resistant outer layer; adding the air cushion film between the inner layer and the outer layer; sewing the outer layer, the middle layer and the inner layer together to obtain the packaging bag. Compared with the prior art, the method has the advantages that the manufacture is simple, the manufactured packaging bag is light, elastic and has the shock-proof and abrasion resistant performances as the shock-proof middle layer made of the air cushion film and the abrasion resistant outer layer are arranged and the air cushion film middle layer is filled with air; as the abrasion resistant layer adopts polyimide added with glass fiber and talcum powder, excellent abrasion resistance is achieved, and the probabilities of crushing damage of objects inside packages and abrasion damage of package bags are greatly reduced in case of crude package conveying manner.

Owner:柳州蔚园塑料彩印包装有限责任公司

Automatic punching die for prolonging service life

InactiveCN108687240AExtended service lifeImprove shock absorptionShaping toolsNon-rotating vibration suppressionPunchingEngineering

The invention provides an automatic punching die for prolonging the service life. The automatic punching die includes a punching die body; the punching die body comprises a base, a lower template is arranged at the top of the base, first connecting rods are connected with both sides of the bottom of the lower template, and the bottoms of the first connecting rods are arranged in the base in a sleeved mode; and the two sides of the top of the lower template are connected with second connecting rods, an upper template is arranged at the top of the lower template, and an ejecting plate is arranged at the top of the upper template. According to the automatic punching die for prolonging the service life, damping legs are arranged to be matched with damping sliding grooves, moving boxes can movehorizontally, fixed legs are arranged to be matched with supporting boxes and second springs, the damping effect of the die punching is improved, telescopic columns and sleeves are arranged to be matched with third springs, so that the moving boxes are stabilized during moving, through matching of the moving boxes and spring plates and the left transformation function of first springs, the pressure resistance of the die is improved, the base is prevented from being pressed and damaged by a lower die, and the service life of the die is prolonged.

Owner:杨美玲

Steam explosion and gelatinization method of Chinese liquor raw grains

ActiveCN102127498ALoose structureContent remains constantAlcoholic beverage preparationChinese liquorBran

The invention discloses a steam explosion and gelatinization method of Chinese liquor raw grains. The steam explosion and gelatinization method comprises the following steps of: washing and soaking grains by using hot water, exhausting water and naturally air-drying to ensure that the grains fully absorb the water and have the aperture opening ratio of 93 to 95 percent and the water content of 40to 45 percent; and putting the grains into a steam explosion tank at the temperature of between 80 and 90 DEG C, introducing dry steam until the pressure in the steam explosion tank is 1.5 to 3.0MPa,adjusting steam flow, keeping the pressure for 5 to 10 minutes, opening a discharge valve of the steam explosion tank, blowing the grains in a normal pressure material-accommodating tank through steam explosion, opening a door of a material-accommodating bin until the grain materials are all discharged and the pressure of the steam explosion tank is reduced to be zero, and collecting the grain materials. The steam explosion and gelatinization method has the advantages that: through a steam explosion effect, the utilization rate of the raw materials is increased, the using amount of bran hullsis reduced, and liquor yield is remarkably improved; and by the steam explosion, methanol in the Chinese liquor can be reduced and even eliminated, so that the safety of the Chinese liquor is improved; and crushing and cooking steps are removed from the liquor making process, so environmental pollution is avoided, and labor, energy consumption, and the brewing cost of the Chinese liquor are reduced.

Owner:SICHUAN TUOPAI SHEDE WINE

High efficiency soya-bean milk making method

InactiveCN105942853AIntegrity guaranteedImprove hydrophilic abilityBeverage vesselsMilk substitutesElectricityLiquid temperature

The invention relates to a high efficiency soya-bean milk making method. A motor, a crushing cutter, a heating device, an anti-overflow electrode, a control unit and a cup are provided; and the control unit is electrically connected to the motor, the heating device and the anti-overflow electrode. The high efficiency soya-bean milk making method at least includes the flowing stages: (1) a preheating stage: the heating device heats water and a material in the cup, and when the temperature of liquid is less than a first preset temperature, the control unit neglects an overflow signal detected by the anti-overflow electrode; (2) a crushing stage: the motor drives the crushing cutter to rotate so as to crush the water and the material into milk, and then the next stage starts; and (3) a boiling stage: the heating device heating the milk till the milk is well done. Compared with the prior art, the high efficiency soya-bean milk making method can allow the temperature of the liquid to rise continuously and stably, can avoid influence on the milk making period due to fake boiling, and then achieves high efficiency soya-bean milk making.

Owner:JOYOUNG CO LTD

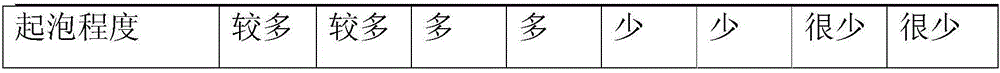

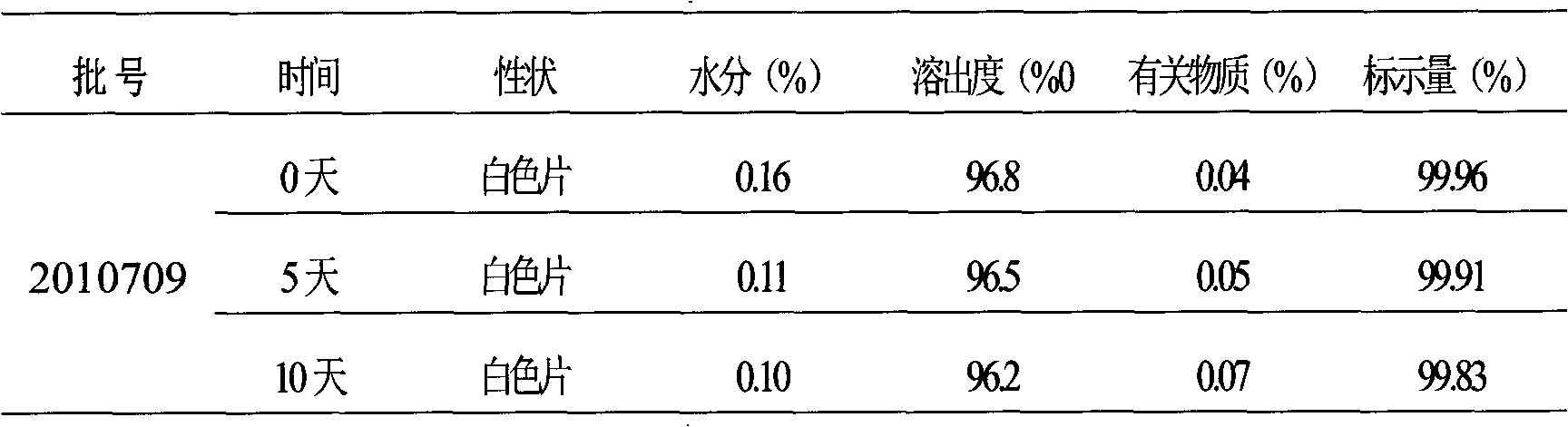

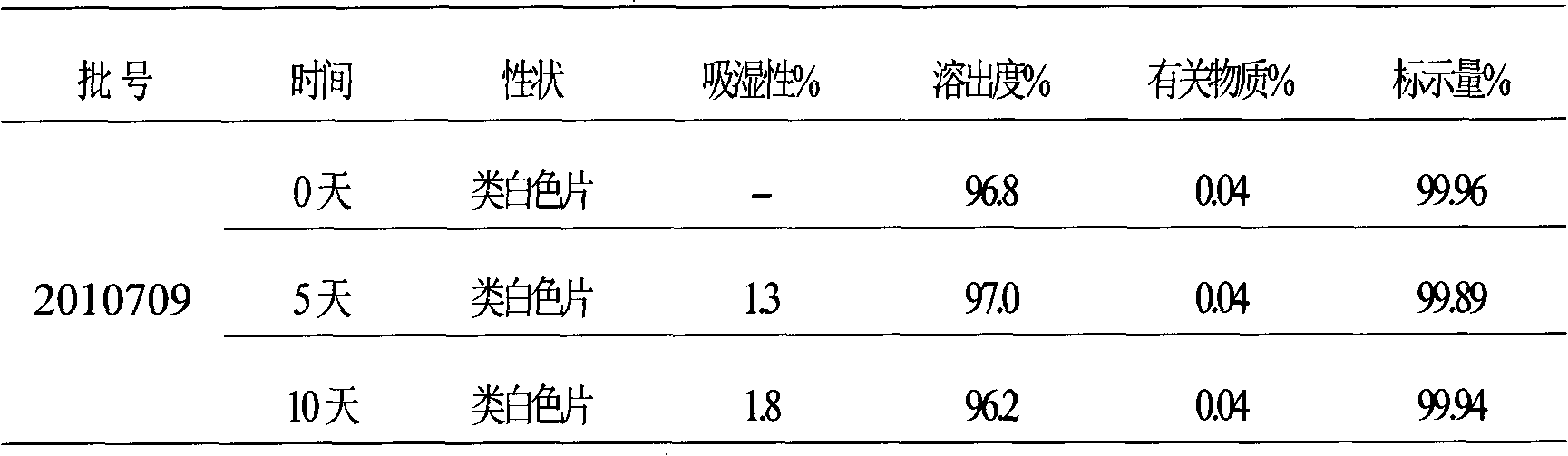

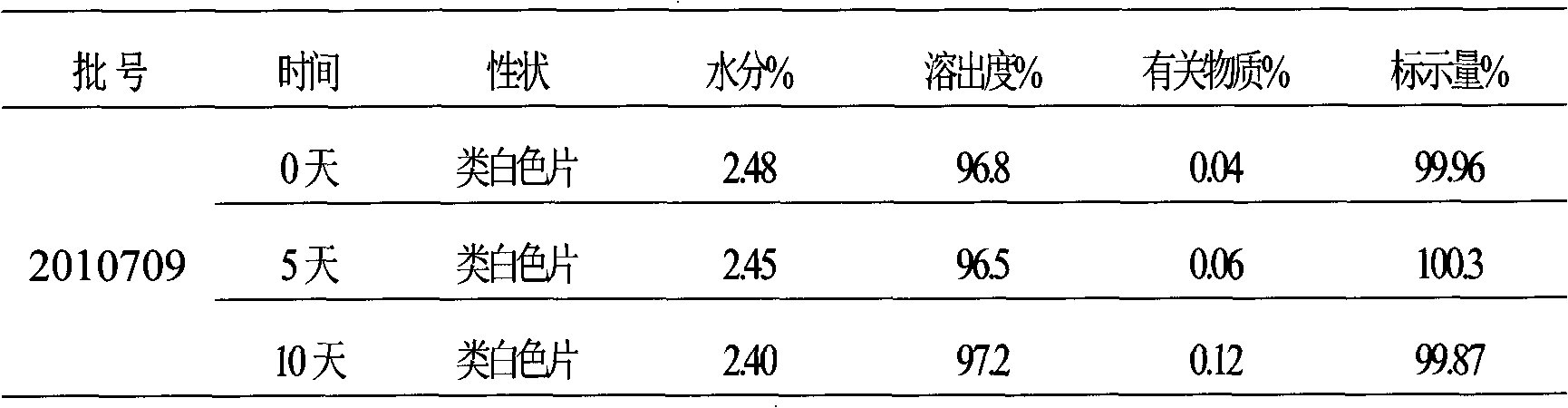

L-alpha-glycerophosphoryl choline film-coated tablet and preparation method thereof

InactiveCN102525992AReduce crushReduce the sieving processOrganic active ingredientsNervous disorderFiller ExcipientPolyethylene glycol

The invention discloses an L-alpha-glycerophosphoryl choline film-coated tablet, which is applied to the pharmaceutical industry. The L-alpha-glycerophosphoryl choline film-coated tablet comprises an L-alpha-glycerophosphoryl choline tablet core and a coating layer, wherein the L-alpha-glycerophosphoryl choline tablet core comprises the following components in percentage by weight: 45-55wt% of L-alpha-glycerophosphoryl choline, 40-50wt% of filler, 0.5-5wt% of flow aid and 0.5-3wt% of lubricant; the coating layer is divided into an isolated coat layer and a moisture-proof coat layer; the filler is one or several of microcrystalline cellulose, lactose, calcium hydrophosphate, hydroxypropyl cellulose and pregelatinized starch; the flow aid is one or several of silicon dioxide and talc powder; the lubricant is one or several of magnesium stearate, polyethylene glycol and leucine; and the isolated coat layer of the coating layer is one or several of film-forming materials of hydroxypropyl methyl cellulose, ethyl cellulose and polyvinylpyrrolidone or premix comprising the above film-forming materials. According to prescription screening, the L-alpha-glycerophosphoryl choline film-coated tablet core is prepared by a direct tableting technology and is easy to operate and control, the processes of smashing and screening raw materials are omitted, the phenomenon that the raw materials are easy to adsorb moisture after being smashed is avoided, the technology is simplified, the production cost is lowered, and the production technology is improved.

Owner:徐奎

Sensor used for dynamic weighing

The invention discloses a sensor used for dynamic weighing, which comprises an elastic support piece, a quartz wafer and a bottom plate, wherein the elastic support piece is loaded on the bottom plate; the quartz wafer is fixed in the elastic support piece; the lower part of the elastic support piece is provided with at least one lateral groove; the quartz wafer is fixed in the lateral groove; and the width of the lateral groove is less than the width of the elastic support piece. The sensor used for dynamic weighing has the beneficial effects that the weighing result is more accurate, pressure on the quartz wafer can be effectively reduced so that the quartz wafer can be protected from being damaged, the service life of the whole dynamic weighing sensor is prolonged, and the dynamic weighing cost is reduced.

Owner:SICHUAN XINGDA MINKO ELECTR MECHANICAL ENG

Clamping band

ActiveCN102562731ASimple structurePrevent crushingYielding couplingFriction grip releasable fasteningsEngineeringMechanical engineering

The clamping band has a simple structure and is capable of preventing crush of an engaging claw and buckle of an inner band part, which are caused when an outer band part and the inner band part are moved close to each other to reduce an inner diameter of a band section. In the clamping band, an overriding guide is formed between the engaging claw and a second tool-catching claw of the inner band part. The overriding guide is outwardly projected to radially outwardly guide an outer end of the outer band part when the engaging claw is moved to an engage hole from a temporary engage hole.

Owner:MIHAMA

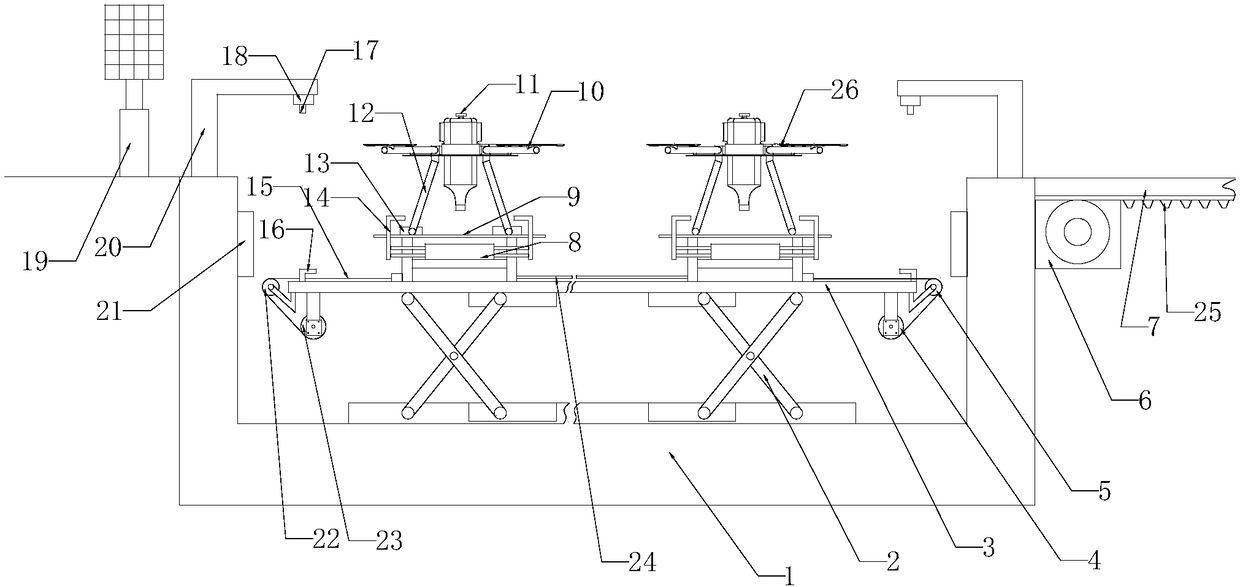

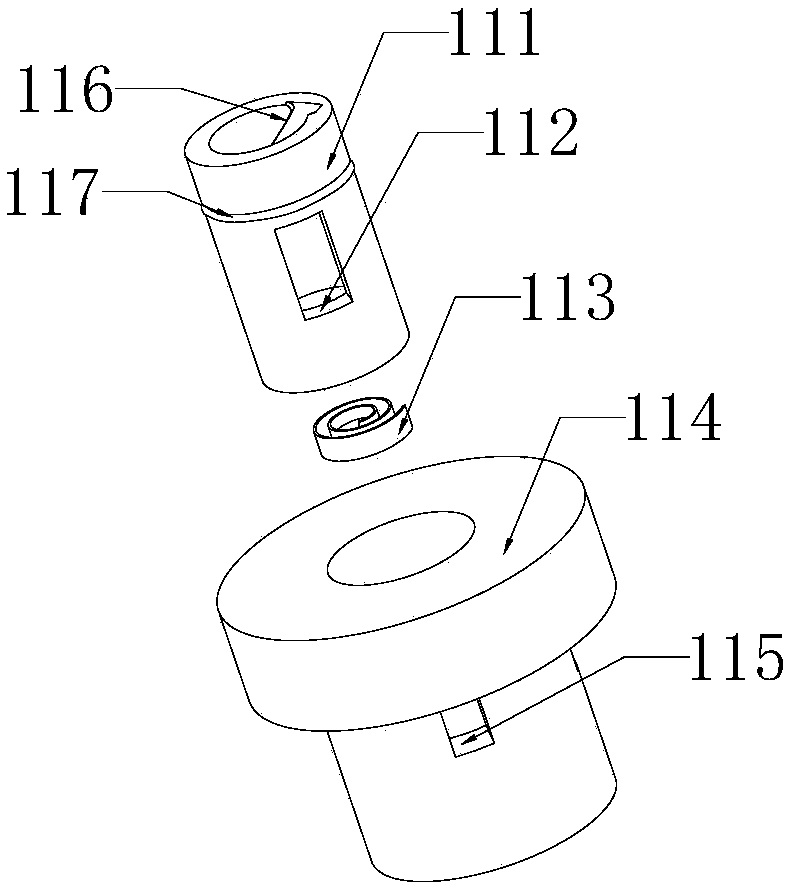

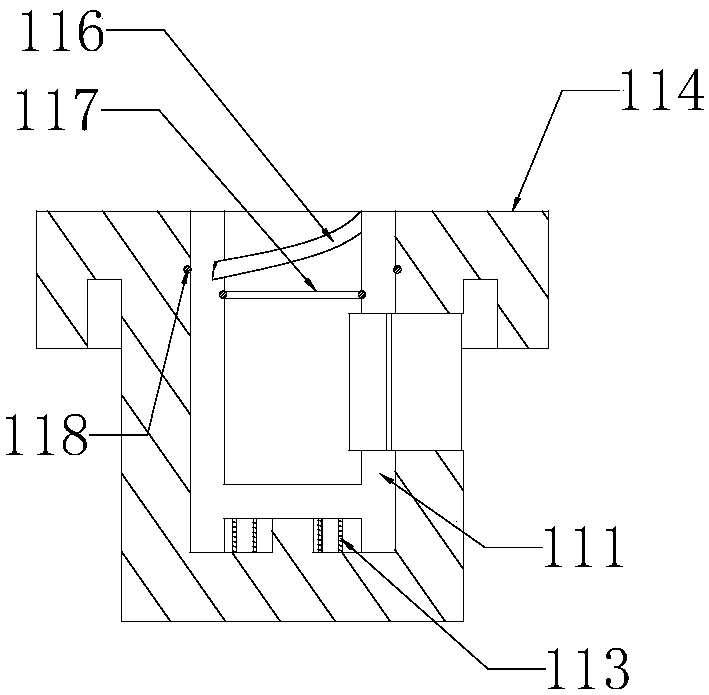

Plant protection unmanned aerial vehicle automatic pesticide filling system

PendingCN108496939AImprove plant protection efficiencyEasy turnoverInsect catchers and killersSingle degree of freedomUncrewed vehicle

The invention discloses a plant protection unmanned aerial vehicle automatic pesticide filling system. The automatic pesticide filling system comprises a base, a platform used for parking the unmannedaerial vehicle, a pesticide injection assembly which is arranged on the base and used for filling liquid pesticide and a charging device. The automatic pesticide filling system also comprises a conveying device and a self-closing type barrel cover, wherein the conveying device is arranged on the base and is used for driving the platform to move close to or far away from the pesticide injection assembly, and the self-closing type barrel cover is arranged on the upper portion of the pesticide barrel; the liquid injection assembly comprises a liquid guide pipe, a liquid injection pipe which is connected with the liquid guide pipe, a cantilever beam and an electric water valve, wherein the cantilever beam is connected with the base in the single-degree-of-freedom sliding connection and used for supporting the liquid injection pipe, and the electric water valve is used for controlling the liquid injection of the liquid injection pipe; the platform comprises a bearing platform for bearing the unmanned aerial vehicle, a weighing element and a positioning device, wherein the weighing element is arranged on the bearing platform and is used for weighing the liquid in the pesticide barrel and the positioning device is used for limiting the unmanned aerial vehicle. According to the unmanned aerial vehicle, electric energy and liquid pesticide can be timely supplied to the unmanned aerialvehicle, when the pesticide is added, the pesticide barrel changing is not needed, the whole process does not need manual participation, and time and labor are saved.

Owner:山东鸟人航空科技有限公司

Plastic packing bag for express delivery

InactiveCN109850341AReduce crushSmallSynthetic resin layered productsBagsGlass fiberPlastic packaging

The invention discloses a plastic packing bag for express delivery, and relates to the technical field of plastic products. The plastic packing bag for express delivery comprises an inner layer, a pressure-resistant middle layer and a wear-resistant outer layer, wherein the inner layer is made of degradable plastics; the anti-vibration middle layer is made of an air cushion film; and the wear-resistant outer layer is prepared from the raw material components: polyethylene, polyimide, glass fiber, talcum powder and polyphenylene sulfide. Compared with the prior art, the plastic packing bag forexpress delivery provided by the invention is provided with the anti-vibration middle layer and the wear-resistant outer layer, the anti-vibration middle layer is made of the air cushion film, and airis fully filled in the air cushion film middle layer, so that the plastic packing bag is light in weight and high in resilience, and has anti-vibration and wear-resistant performances; and the wear-resistant layer adopts the polyimide added with the glass fiber and the talcum powder as the material so as to have an excellent wear-resistant performance, so that under the rough parcel delivery manner, the probabilities of crushing articles in parcels and wearing the packing bag are greatly reduced.

Owner:绍兴时薪塑料有限公司

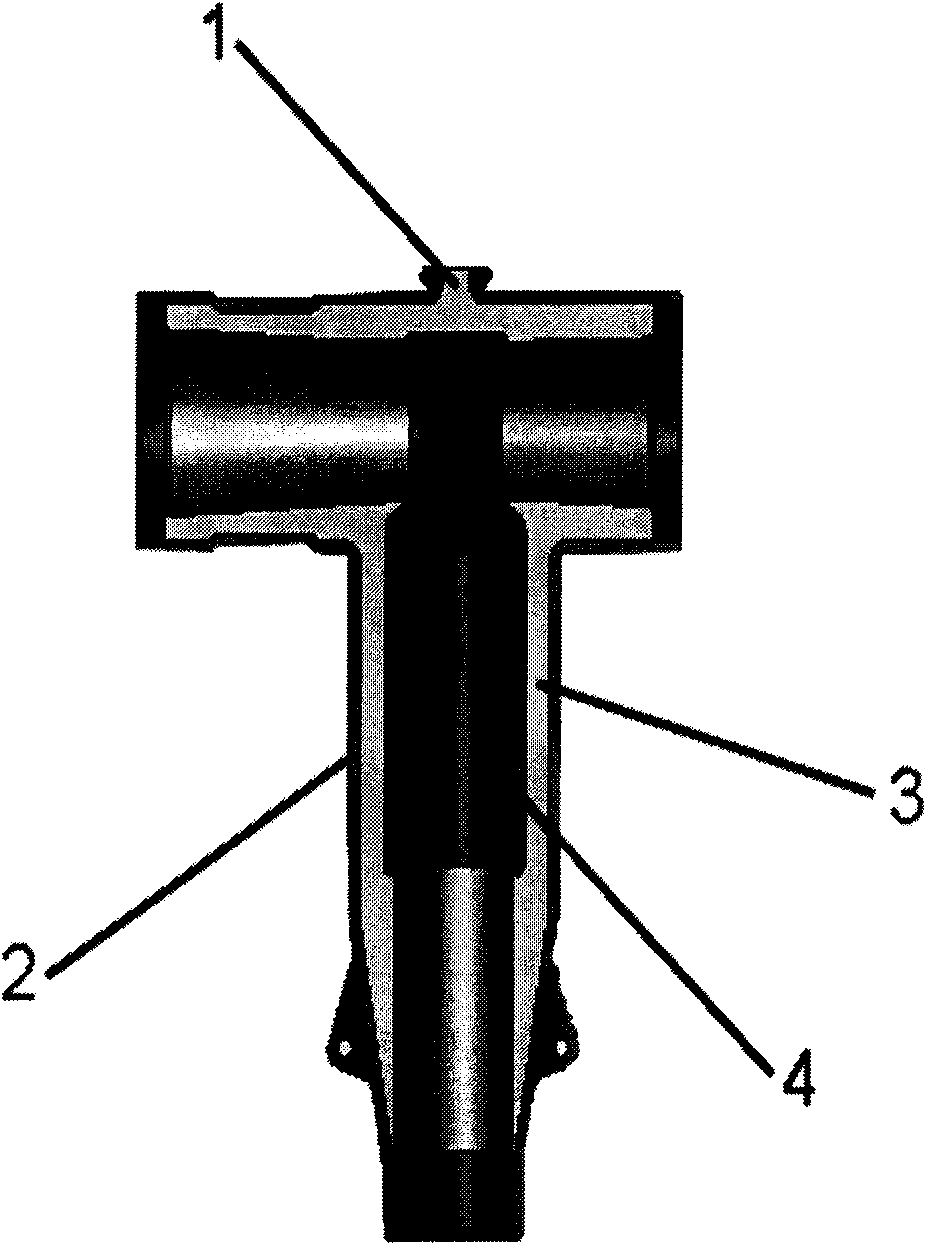

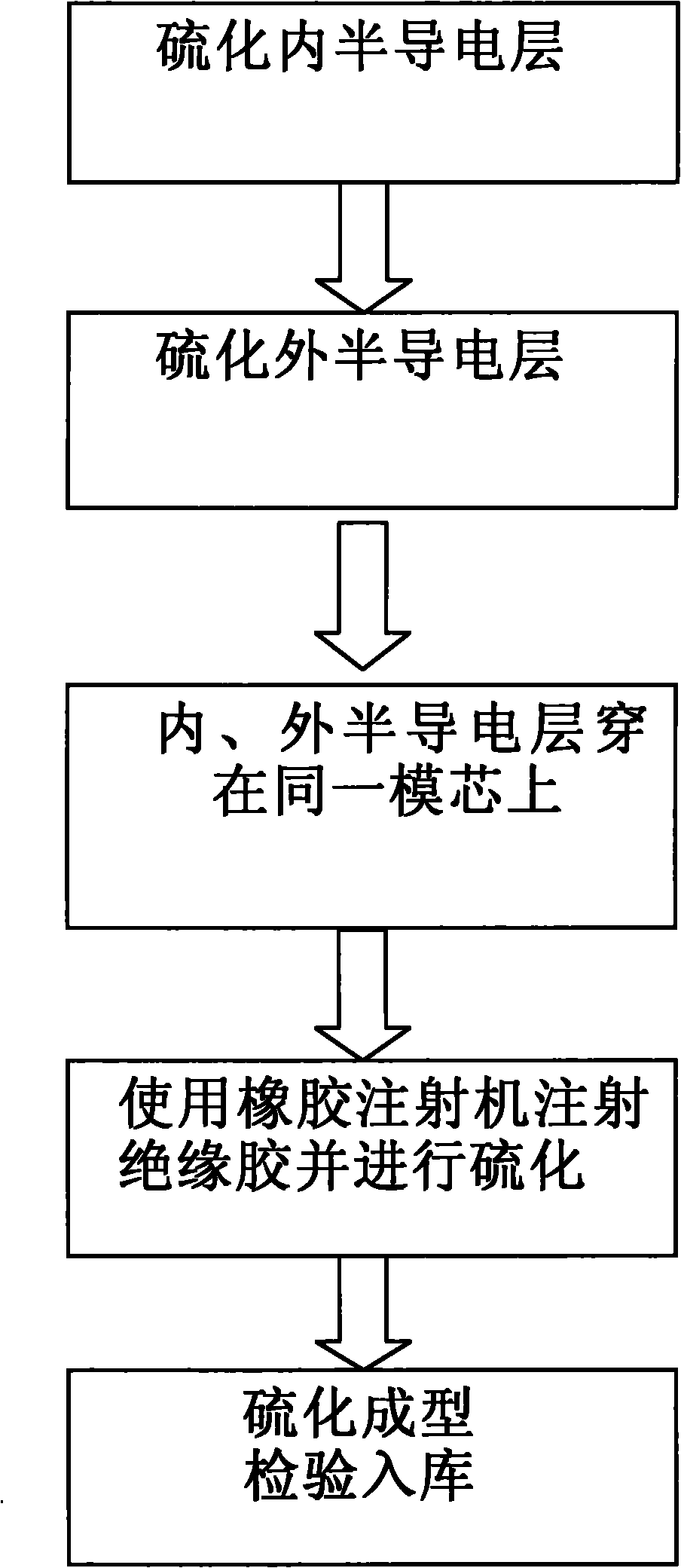

Preparation method for rubber cable connector

ActiveCN102054546ASimple vulcanization processReduce crushInsulatorsApparatus for joining/termination cablesBonding strengthEngineering

The invention provides a preparation method for a rubber cable connector. The preparation method comprises the following steps of: 1, preparing an inner semiconductive layer of the cable connector; 2, preparing an outer semiconductive layer of the cable connector; sleeving the inner semiconductive layer and the outer semiconductive layer together, sleeving the same on a mold core and horizontally placing into an injection moulding mold; 4, rubberizing by using a rubber injection moulding machine and vulcanizing; and 5, taking the mold core out after vulcanization to obtain the product. By the method, the operation is easy and convenient, the product percent of pass is high, the bonding strength between the inner and outer semiconductive layers and an insulating layer is enhanced greatly, the electric performance is perfect, and the service life of the rubber cable connector is extended.

Owner:HEBEI KELI HENGJIU INTELLIGENT SWITCH CO LTD

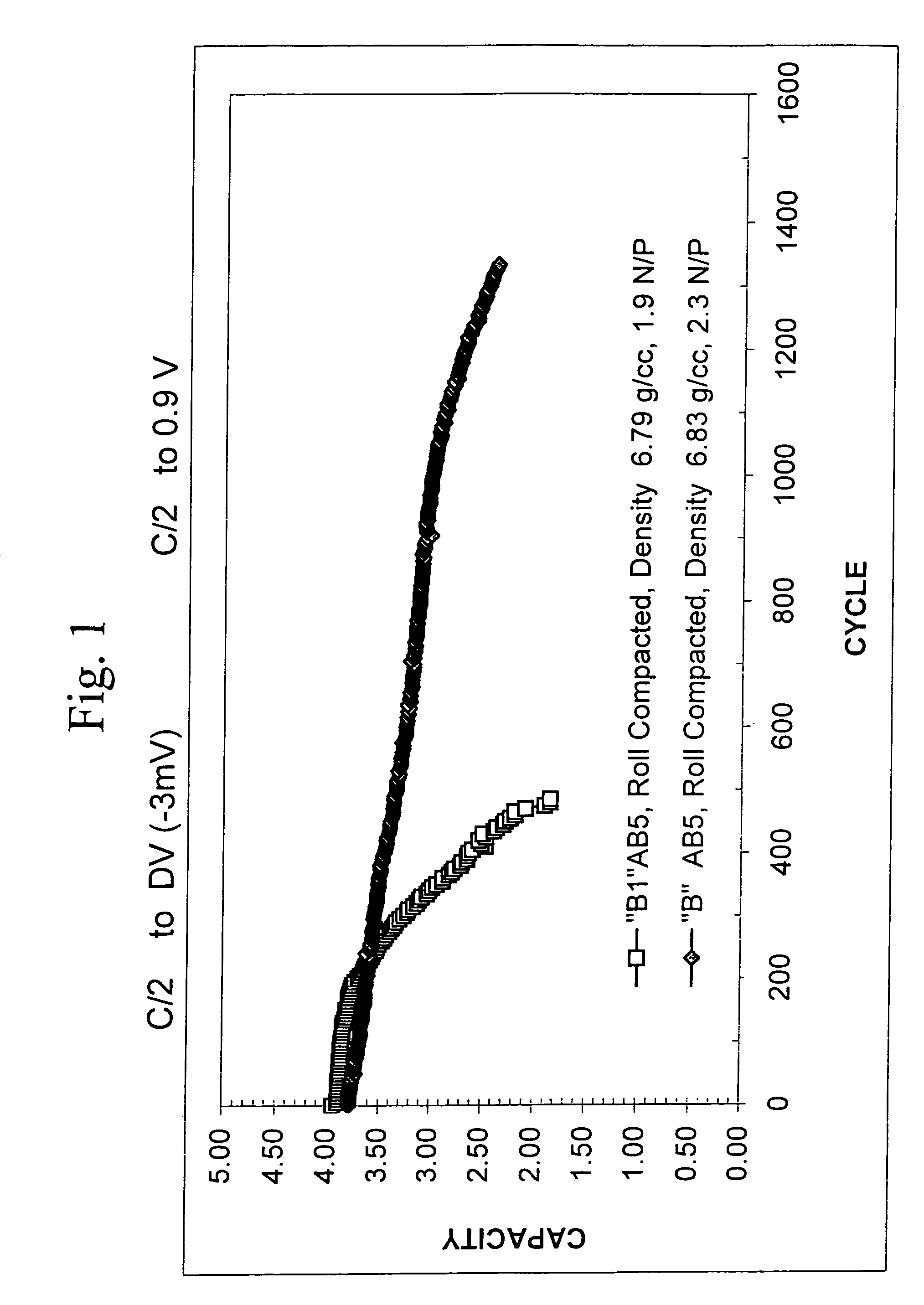

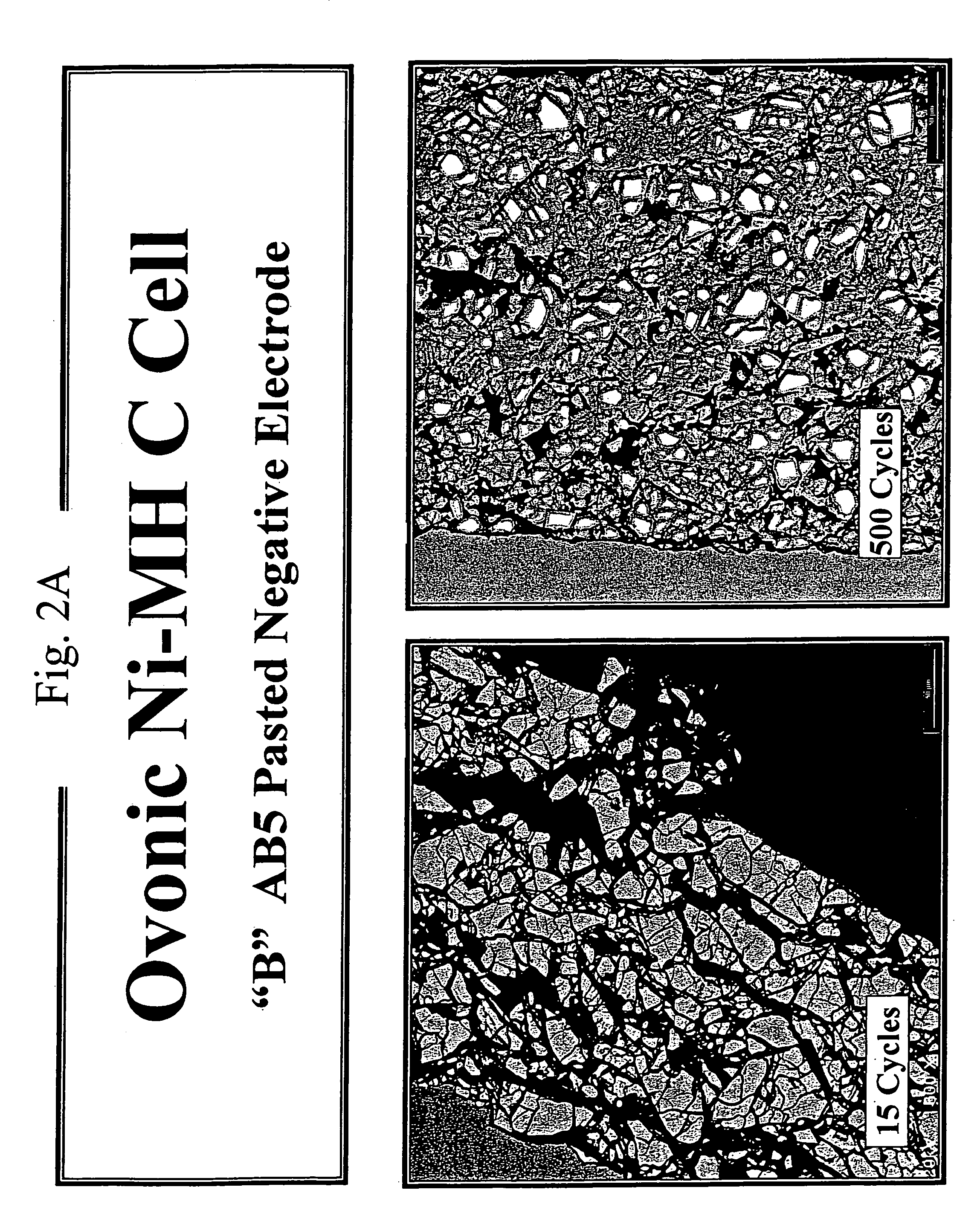

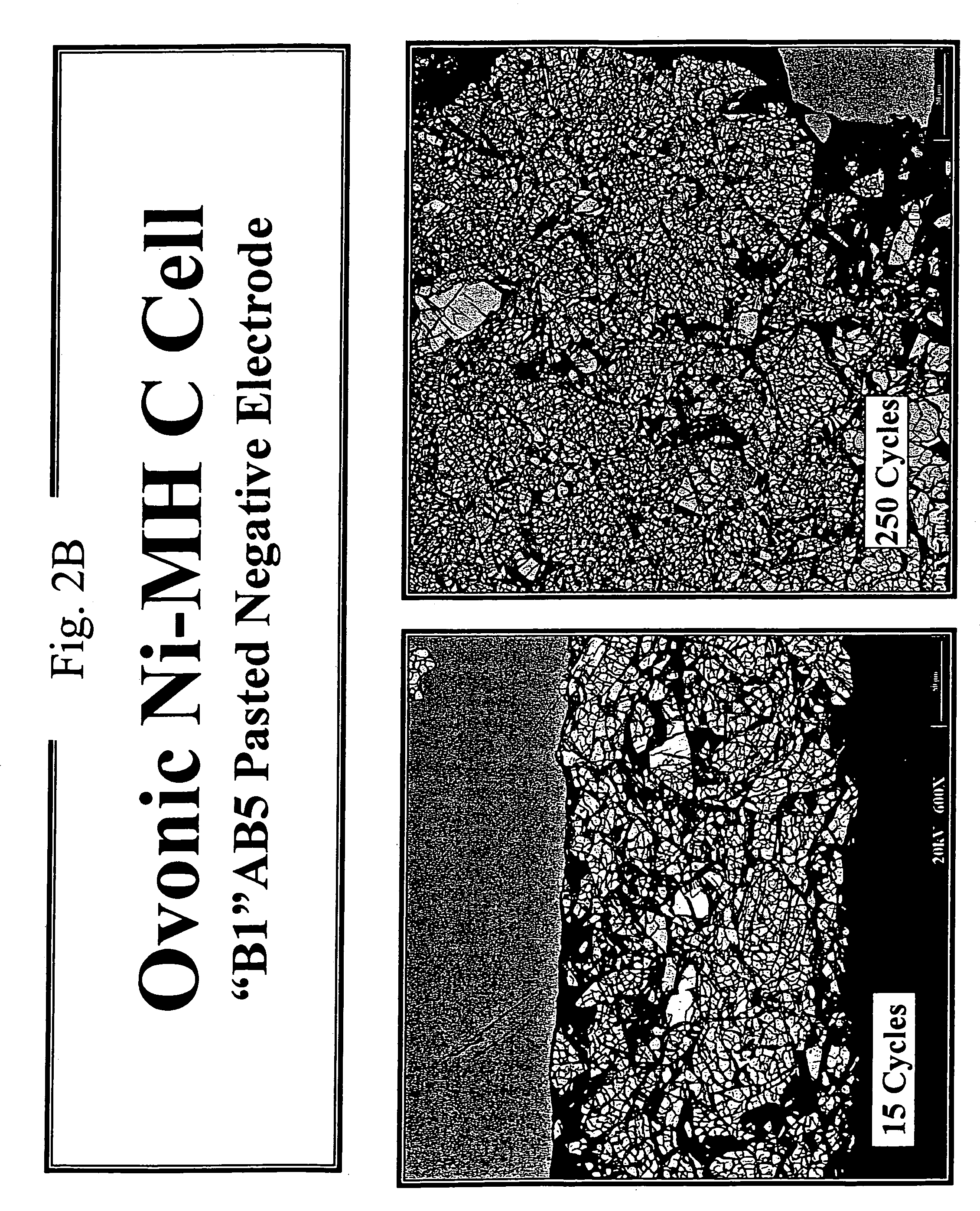

Hydrogen storage alloys having improved cycle life and low temperature operating characteristics

InactiveUS7393500B2Increase production capacityImproved cycle life characteristicsNon-aqueous electrolyte accumulator electrodesMetal/metal-oxides/metal-hydroxide catalystsHysteresisGas phase

Electrochemical and gas phase hydrogen storage alloy compositions that provide superior performance, especially at low temperature, and excellent cycle life characteristics. The alloys of this invention are AB5 type alloys that include a cycle life enhancement element and a low Co concentration. The preferred cycle life enhancement elements include Zr and Si. The cycle life enhancement elements increase the cycle life of the instant alloys by reducing the pulverization of alloy particles upon repeated cycles of charging-discharging or hydriding-dehydriding. The alloys are characterized by low hysteresis on cycling, where hysteresis is measured in terms of mass concentration difference, a parameter related to the activation energy associated with the incorporation of hydrogen into the alloy. The instant alloys are designed to have a low activation energy for hydrogen incorporation and as a result, provide low hysteresis and a more uniform concentration of absorbed hydrogen within the material. As a result, differential lattice expansion effects associated with the absorption of hydrogen are minimized and the tendency for particle pulverization on cycling is minimized. Alloys having a low Co concentration and long cycle life are thus provided for.

Owner:TEXACO OVONIC BATTERY SYST LLC +1

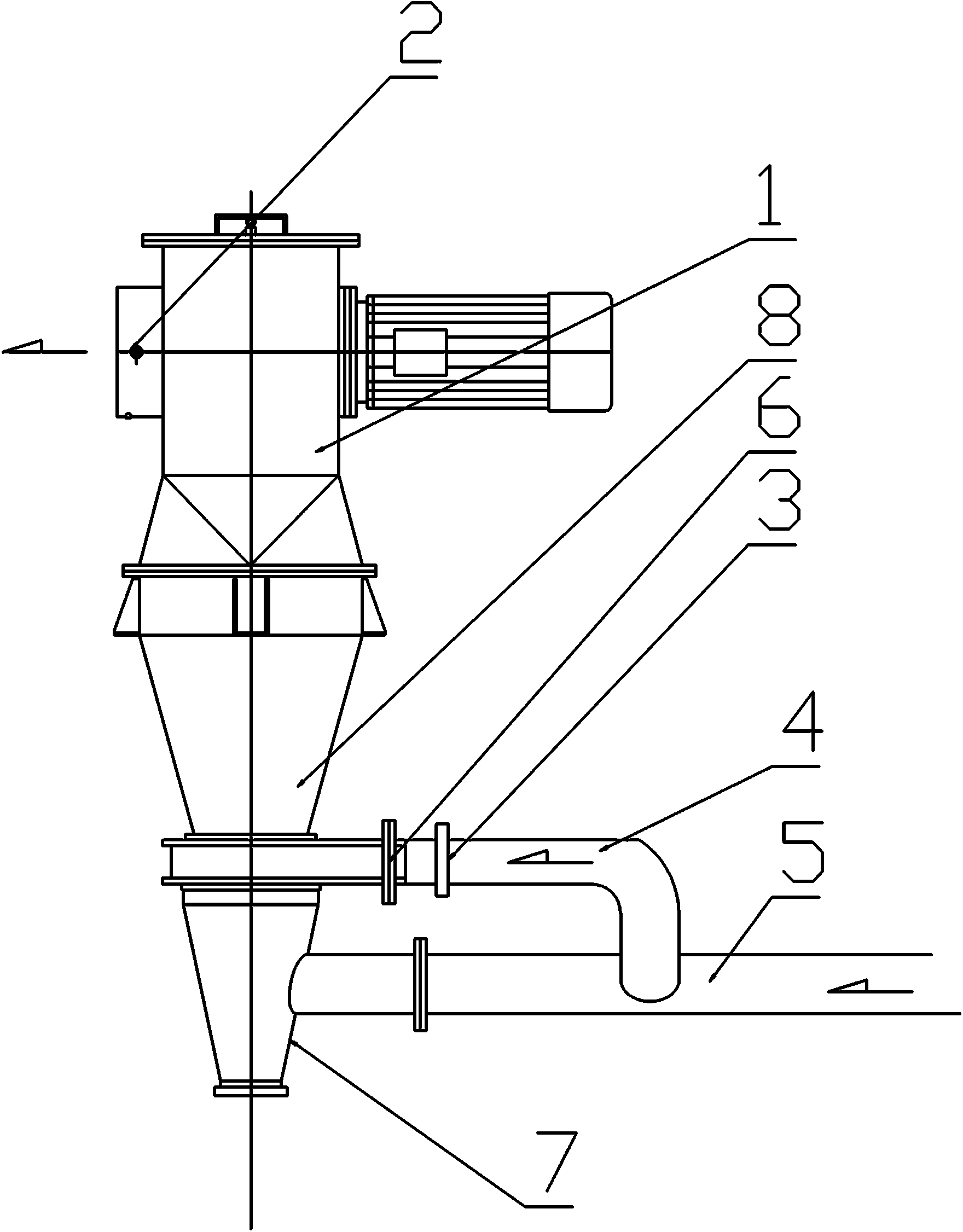

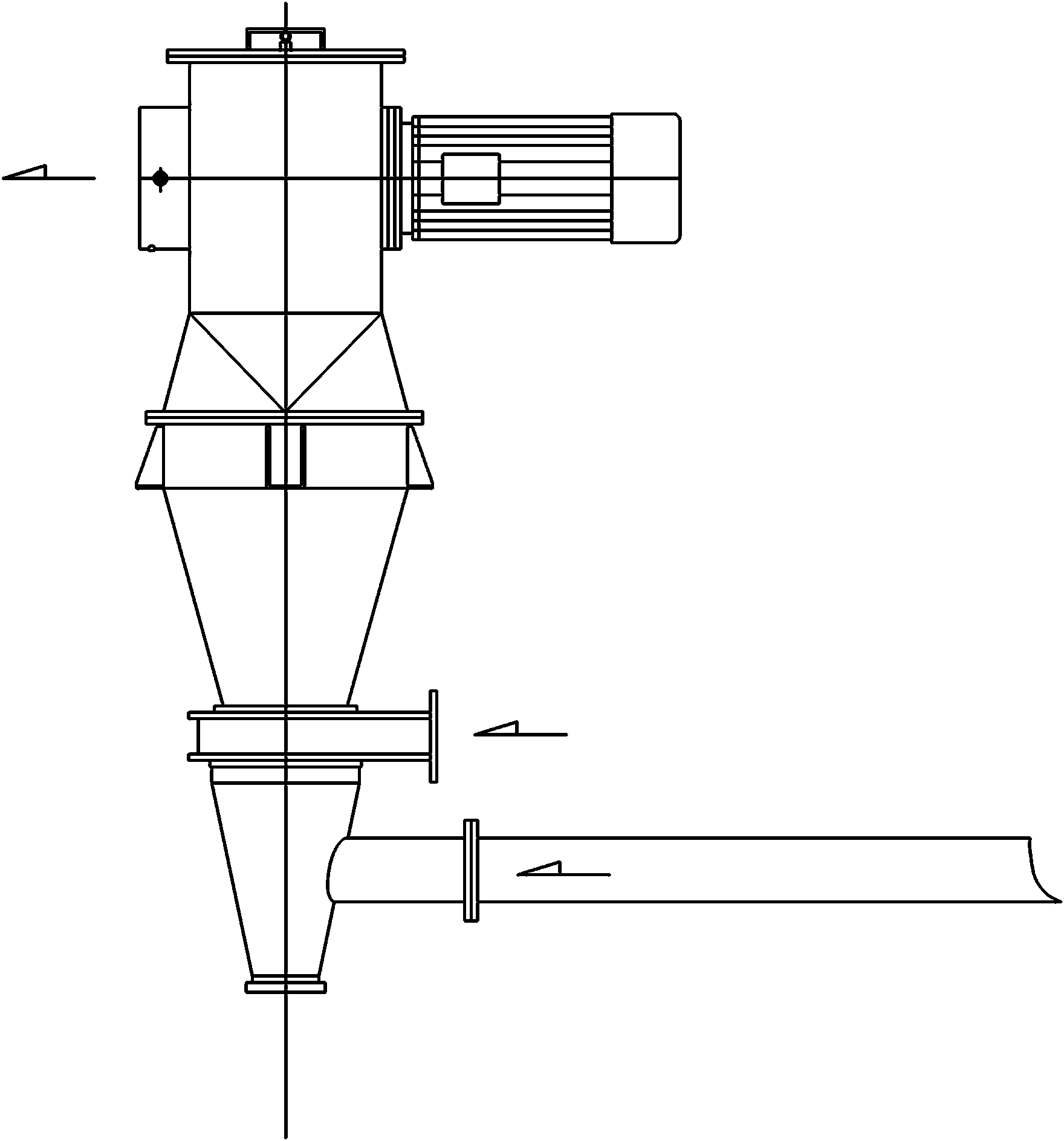

Spherical graphite superfine classifier

InactiveCN103100494AImprove quality stabilitySmall pressure lossReversed direction vortexSuperfine grindingAir volume

The invention discloses a spherical graphite superfine classifier. The spherical graphite superfine classifier comprises a classifier and is characterized in that a secondary air inlet is communicated with a material inlet pipe by a branch pipe and an air valve is arranged on the branch pipe. According to the spherical graphite superfine classifier, the technical problem of incontrollable secondary air inlet caused by inconvenient control of atmospheric pressure due to direct introduction of secondary inlet air from the atmosphere from a lower barrel body in the prior art is solved; air is introduced by the material inlet pipe; the material inlet pipe and the secondary air inlet have the same atmospheric pressure; the air volume is adjusted by the air valve so as to adjust the wind speed; the air flow pressure loss of a draught fan cannot be influenced; the air volume of other equipment directly connected with the lower barrel body also cannot be influenced; and the quality stability of a superfine grinding and classifying system is improved. In addition, as the pressure loss in a secondary air inlet cavity body is small, the wind pressure between the grinding process and the classifying process can be conveniently distributed and adjusted; and meanwhile, as the pressure loss in a secondary air inlet cavity is small, the grinding load and the classifying load can be greatly reduced, and the grinding and classifying energy consumption is reduced.

Owner:CHINA SCI HENGDA GRAPHITE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com