Flexible electronic circuits and displays

a technology of applied in the field of flexible electronic circuits and displays, can solve the problems of insufficient service life of these displays, preventing their widespread use, and stainless steel and similar metal foils having the disadvantage of being substantially denser than other potential substrate materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

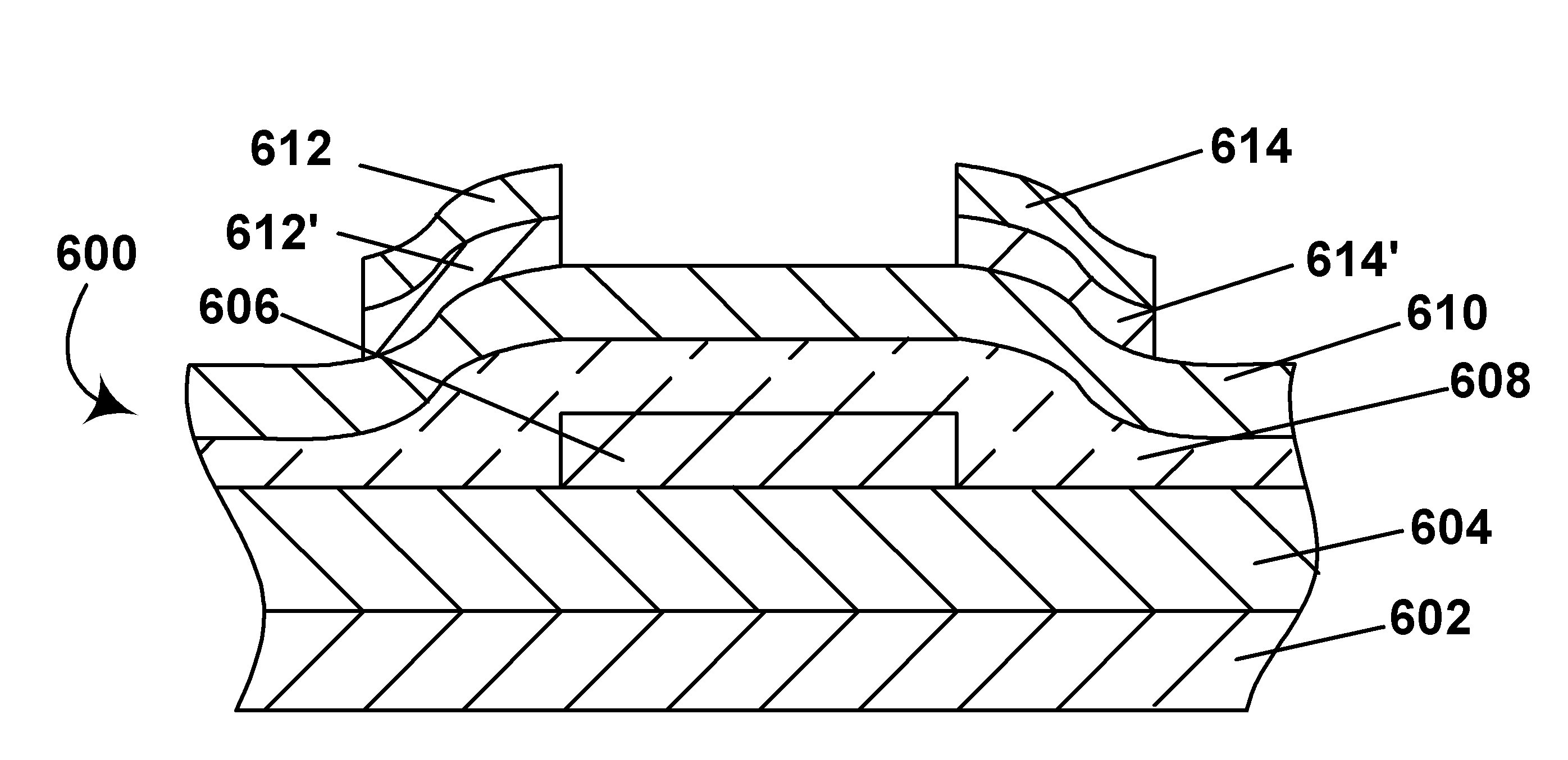

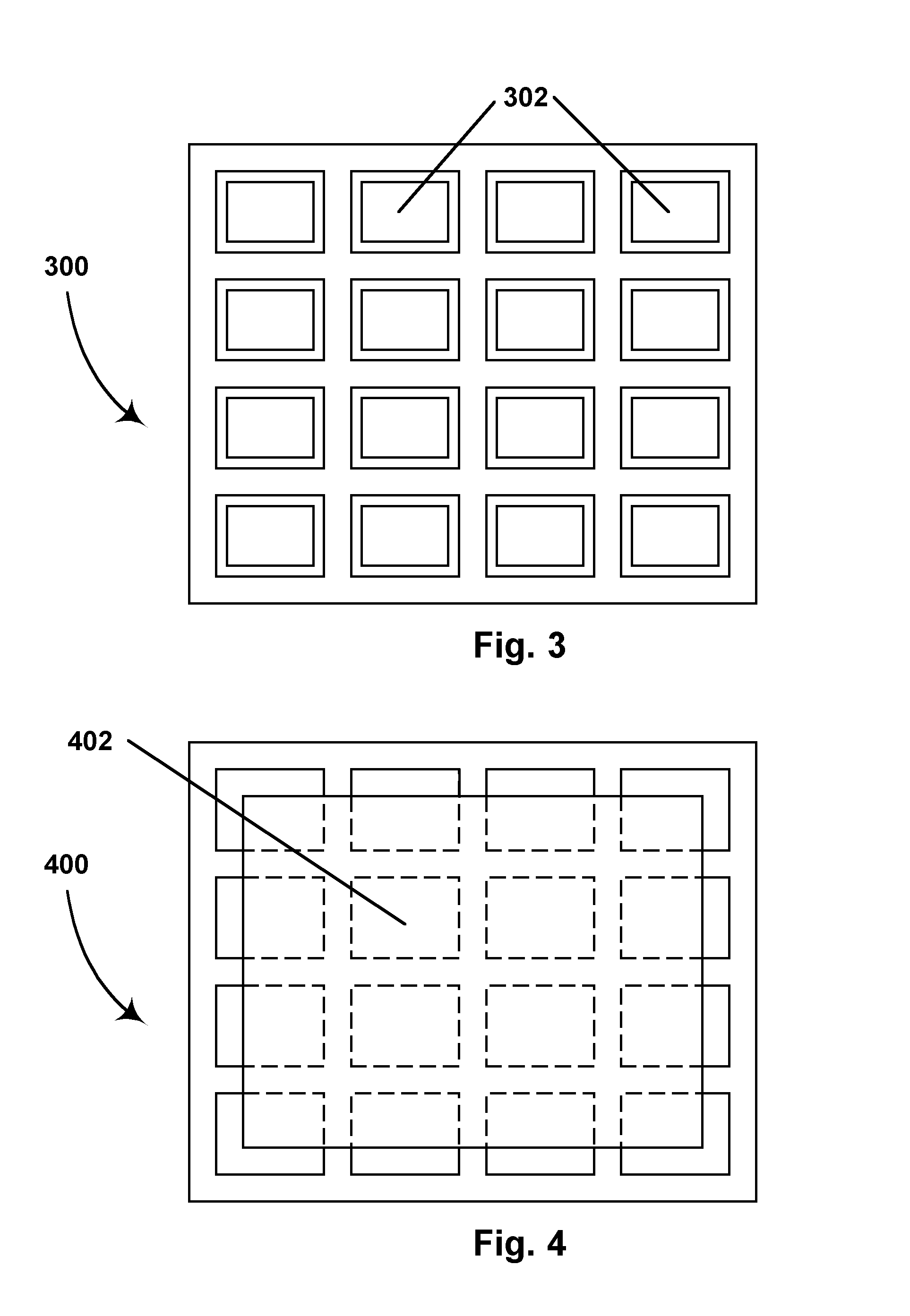

As indicated above, the present invention has several different aspects providing improvements in backplanes for electro-optic displays, and processes for the formation of such backplanes and displays. For ease of comprehension, the various different aspects of the invention will hereinafter be described separately, but it should be understood that a single backplane or display may make use of more than one aspect of the invention; for example, the 1D-curved processes of the invention may be carried out using a patterned metal foil backplane of the invention.

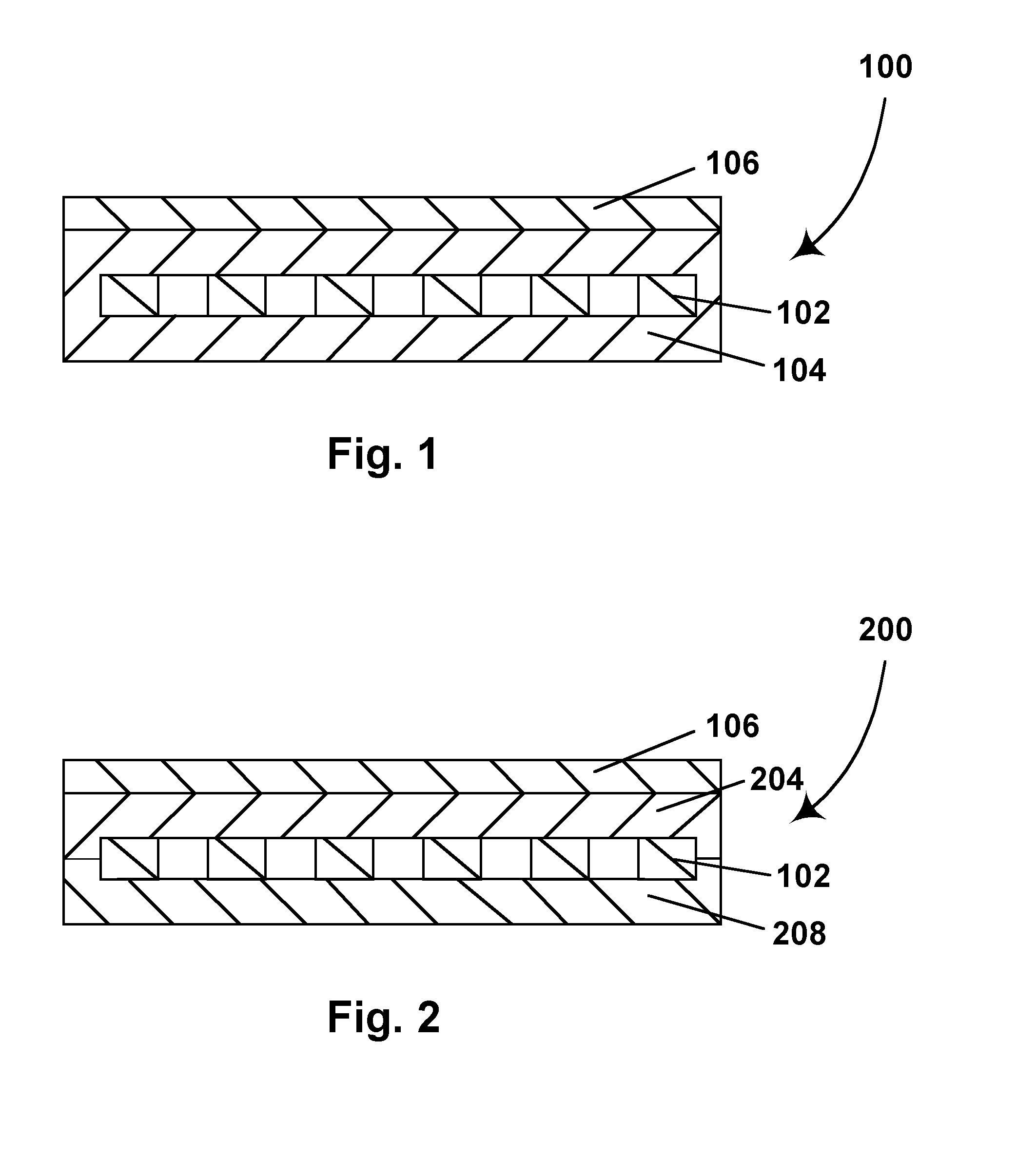

Patterned Metal Foil Backplane

As already mentioned, in one aspect this invention provides a backplane for use in an electro-optic display, this backplane comprising a patterned metal foil coated on one or both sides with an insulating polymeric material and having a plurality of thin film electronic devices provided on the insulating polymeric material. The resulting backplane is light in weight but substantially maintains the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| areas | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com