Reinforcement laminate

a technology of reinforcement laminates and laminates, applied in the field of reinforcement laminates, can solve the problems of affecting the performance of the product, so as to improve the resistance of the substance to bending or flexing, improve the resistance of the substance to acoustic and other vibrations, and improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

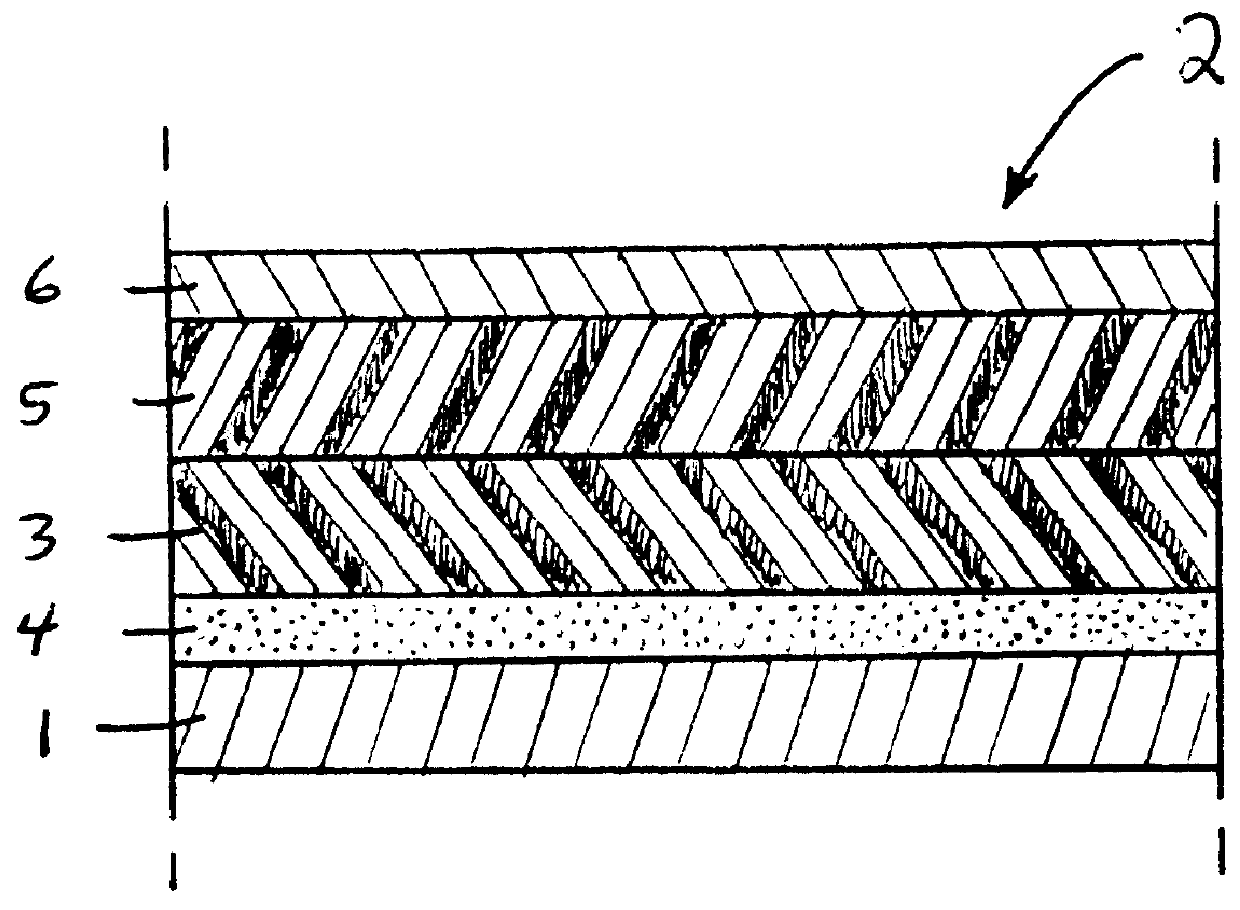

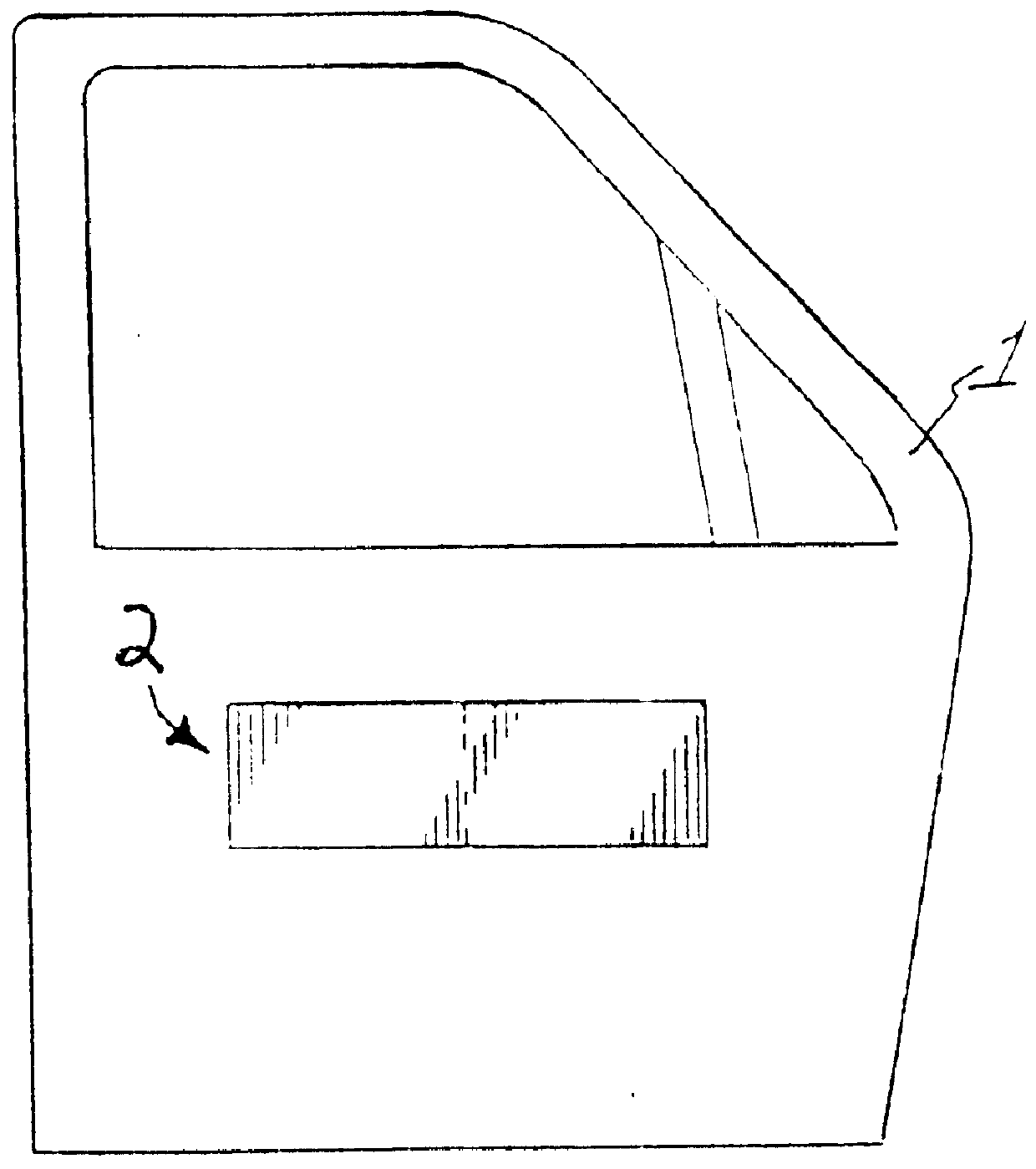

FIG. 1 illustrates a laminate 2 in accordance with this invention. As shown therein a compliant layer 3 is adhered to the substrate 1 through an adhesive layer 4. As will be subsequently explained in more detail, adhesion of the compliant layer to the substrate is significantly enhanced through the use of an epoxy resin / polyol / polyisocyanate-based adhesive in layer 4, particularly where the surface of the substrate is oily. A rigid layer 5 is applied against the compliant layer 3. FIG. 1 also illustrates a carrier layer 6 on the outer surface of rigid layer 5. This results in a laminated body panel stiffener 4.

When the thermosettable resin used to form rigid layer 5 cures, the compliant layer 3 helps to shield the shrinkage strains resulting from rigid layer 5 from the substrate 1 because it is not rigid after cure. Layer 5 is rigid after cure but its shrinkage strains are blocked from getting to the substrate by the compliant layer 3. Carrier layer 6 is used to provide additional s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com