Surface modification system before electroless plating and method for double modification of polymer substrate surface

A substrate surface, double modification technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of difficult direct chemical plating of polymer substrates, achieve excellent adhesion performance, simple process , the effect of scalability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

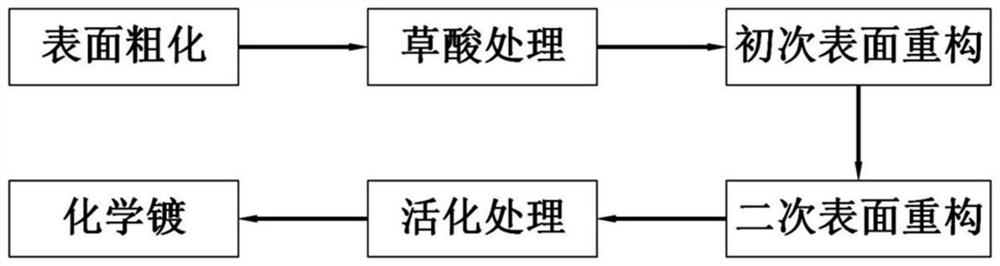

Method used

Image

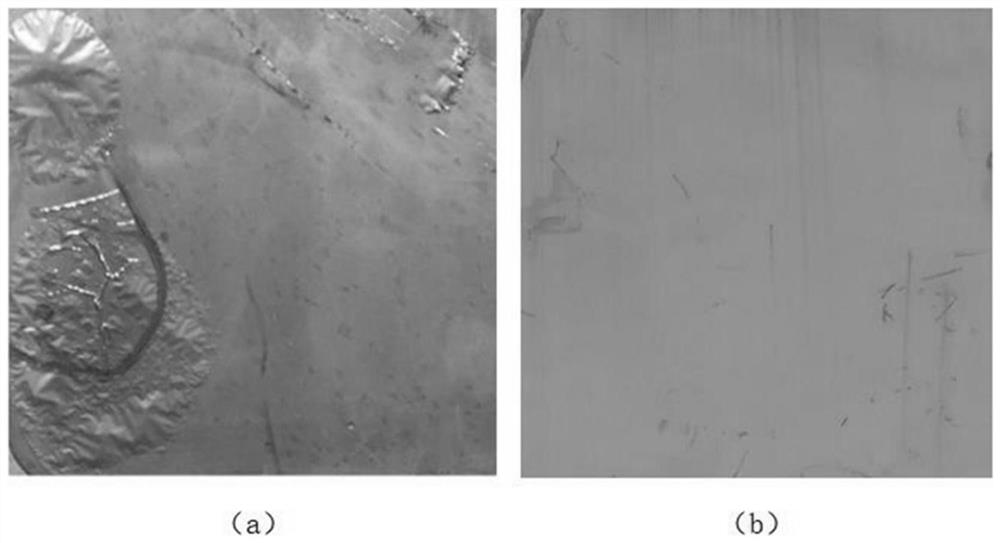

Examples

Embodiment

[0037] (1) Surface roughening: Add potassium permanganate and concentrated sulfuric acid (98% concentrated sulfuric acid) into deionized water in sequence, and stir thoroughly to obtain a roughened solution, in which the concentration of potassium permanganate is 10 g / L. The concentration of sulfuric acid was 25 ml / L. After the roughening solution was heated to 45 °C, the polyphenylene ether (PPO) substrate was immersed in the solution for 15 min. Then prepare an oxalic acid solution with a concentration of 3 g / L, wash the roughened substrate with deionized water and place it in it, and treat it at room temperature until the surface of the substrate fades to its original state (generally about 5~10 min) .

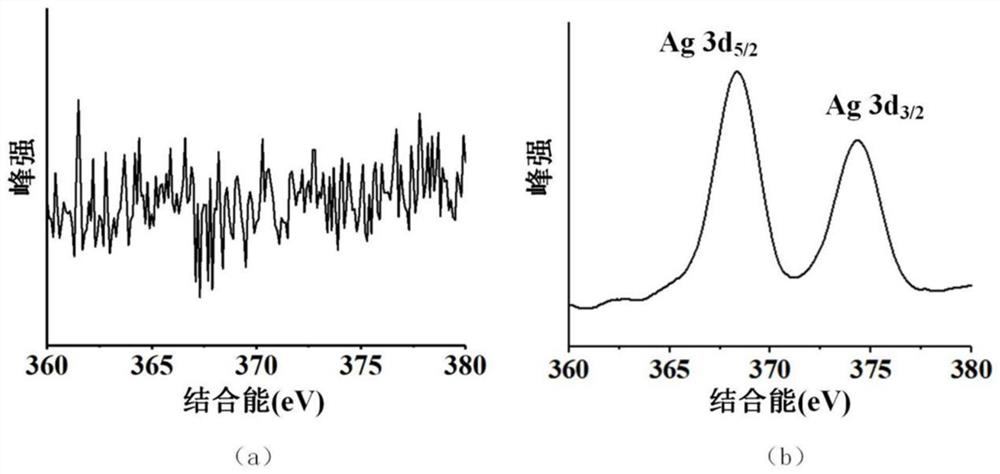

[0038](2) Primary surface reconstruction modification: Dissolve Tris (Tris) reagent in deionized water and use hydrochloric acid to adjust the pH value of the solution to about 8.5 to obtain a buffer solution, and then add norepinephrine to the buffer solution Thoroughly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com