Deformable plugging and anti-sloughing agent for drilling fluid

A technology of plugging and anti-collapse, drilling fluid, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of large leakage, pressure difference sticking, leakage, etc., to achieve increased compactness, shallow damage depth, The effect of convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 30 parts by weight of micron-scale non-deformable kapok staple fiber particles (purchased from Beijing Zhongke Risheng Technology Co., Ltd.), 20 parts by weight of nano-scale deformable redispersible ethylene / vinyl chloride / vinyl acetate copolymer (purchased From Tianjin Zhonghai Oil Service Chemical Co., Ltd.) and 10 weight parts of potassium humate (purchased from Beijing Zhongke Risheng Technology Co., Ltd.) mixed in a mixer for 80 minutes, and passed through a 200 mesh sieve to obtain the drilling fluid for drilling fluid of the present invention. Deformable plugging anti-collapse agent.

[0033] The core plugging flowback test was carried out on the obtained deformable plugging anti-slump agent, and the following test data as shown in Table 1 were obtained:

[0034] Table 1

[0035]

[0036] From the data in Table 1, it can be seen that the dynamic water loss rate is very low, forming an effective plug for the core. Through the flowback test, the permeability ...

Embodiment 2

[0038] 35 parts by weight of micron-scale non-deformable barite particles (purchased from Beijing Zhongke Risheng Technology Co., Ltd.), 40 parts by weight of nano-scale deformable and redispersible ethylene / vinyl chloride / vinyl laurosilicate three The meta-polymer (purchased from Tianjin Zhonghai Oil Service Chemical Co., Ltd.) and 25 parts by weight of sulfonated rubber (purchased from Beijing Zhongke Risheng Technology Co., Ltd.) were mixed in a mixer for 100 minutes, dried and ball milled through a 200-mesh sieve , to obtain the deformable plugging and anti-slump agent for drilling fluid of the present invention.

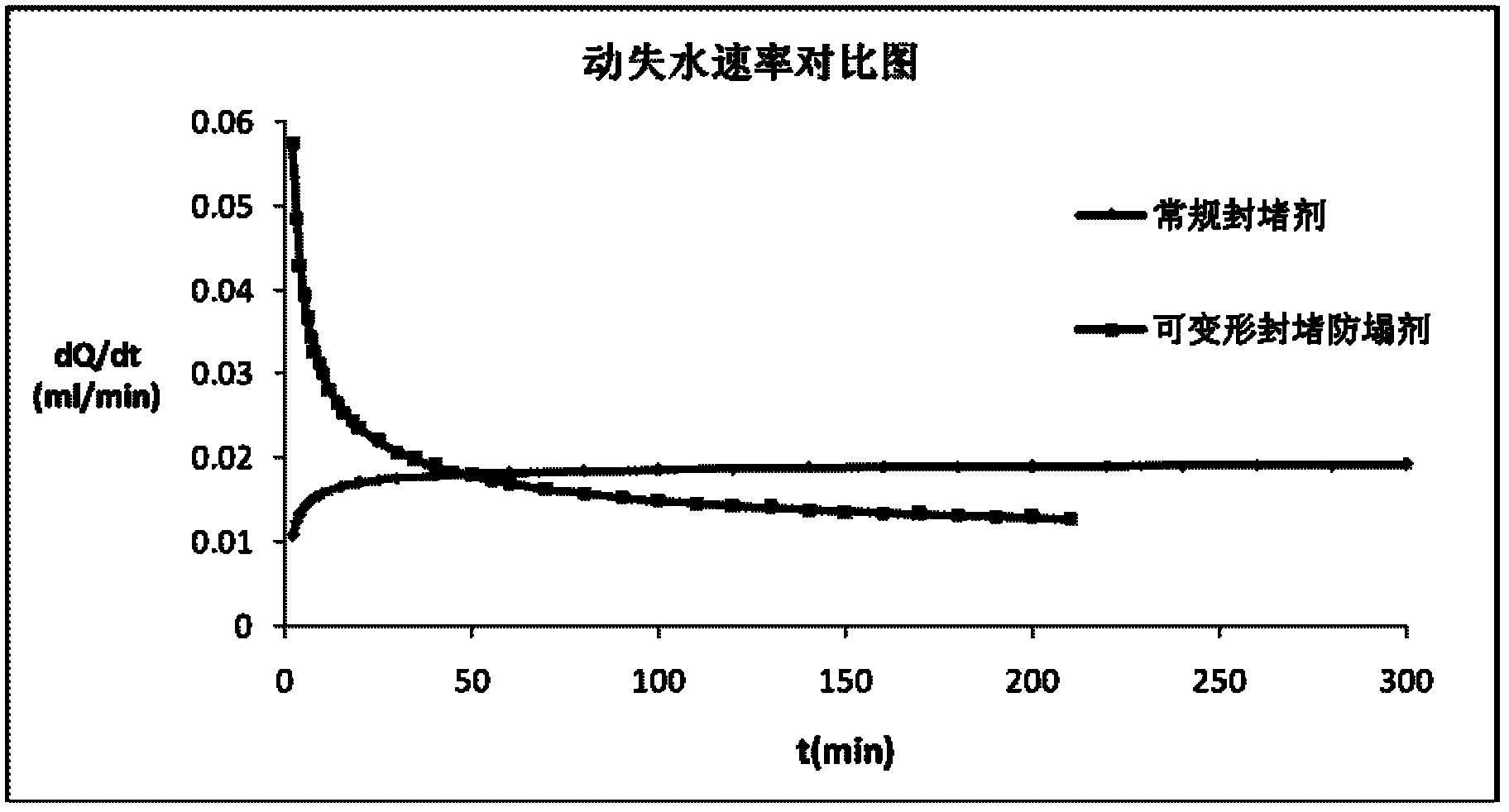

[0039] Through the core plugging flowback test, the dynamic water loss rate of the drilling fluid added with the deformable plugging anti-slump agent of the present invention and the drilling fluid added with the conventional plugging agent is tested. Depend on figure 1 It can be seen that after adding the deformable plugging and anti-slump agent of the present...

Embodiment 3

[0041] 40 parts by weight of micron-scale non-deformable cottonseed hull particles (purchased from Beijing Zhongke Risheng Technology Co., Ltd.), 30 parts by weight of nano-scale deformable and redispersible polyvinyl acetate copolymer (purchased from Tianjin COSL Chemical Co., Ltd.) and 15 parts by weight of carboxymethyl starch (purchased from Beijing Zhongke Risheng Technology Co., Ltd.) were mixed in a mixer for 120 minutes, and then passed through a 200-mesh sieve to obtain the deformable seal for drilling fluid of the present invention. Blocking anti-slump agent.

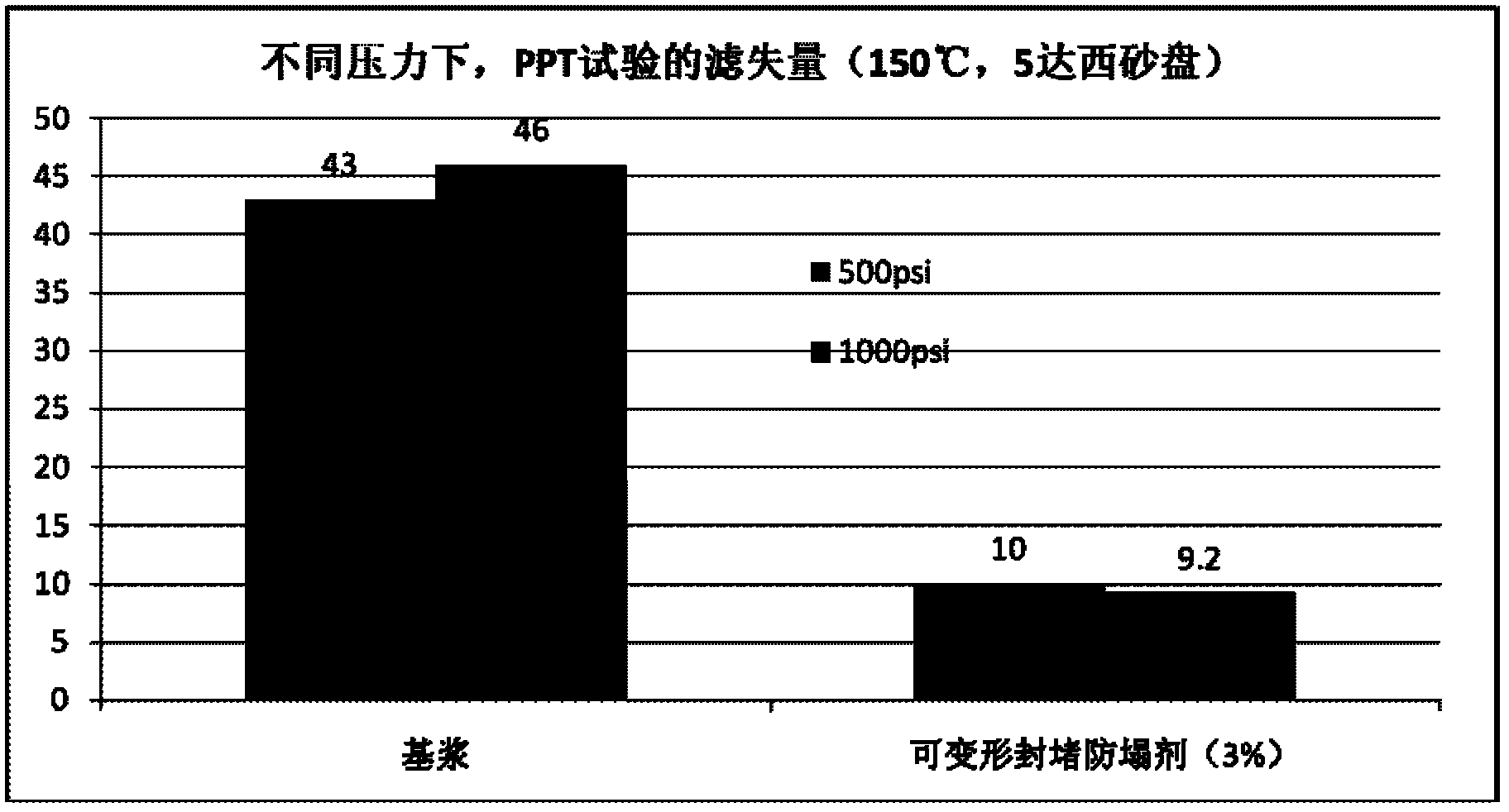

[0042]Use the permeability plugging tester (Permeability Plugging Tester, PPT) (OFI testing equipment company, the U.S.) and test the fluid loss of drilling fluid before and after adding the deformable plugging anti-slump agent of the present invention according to the steps of its product instruction manual The amount and quality of mud cake formed after drilling fluid loss.

[0043] Depend on figure 2 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com