Micro-crack self-repairing microcapsule and preparation method thereof

A technology for self-repairing microcapsules and microcracks, which is applied in microcapsule preparation, microsphere preparation, coating and other directions to achieve the effect of reducing tedious work and stable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

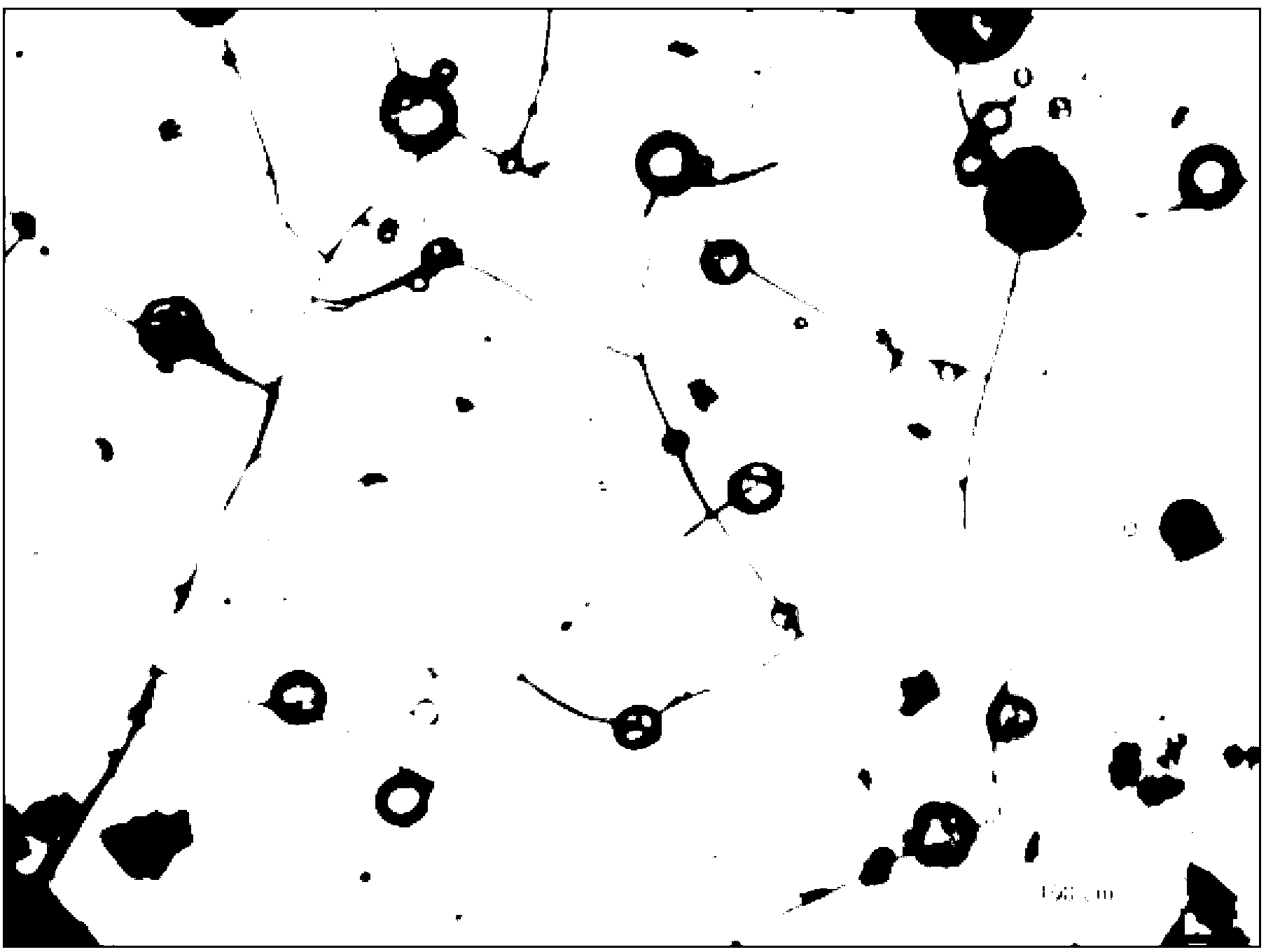

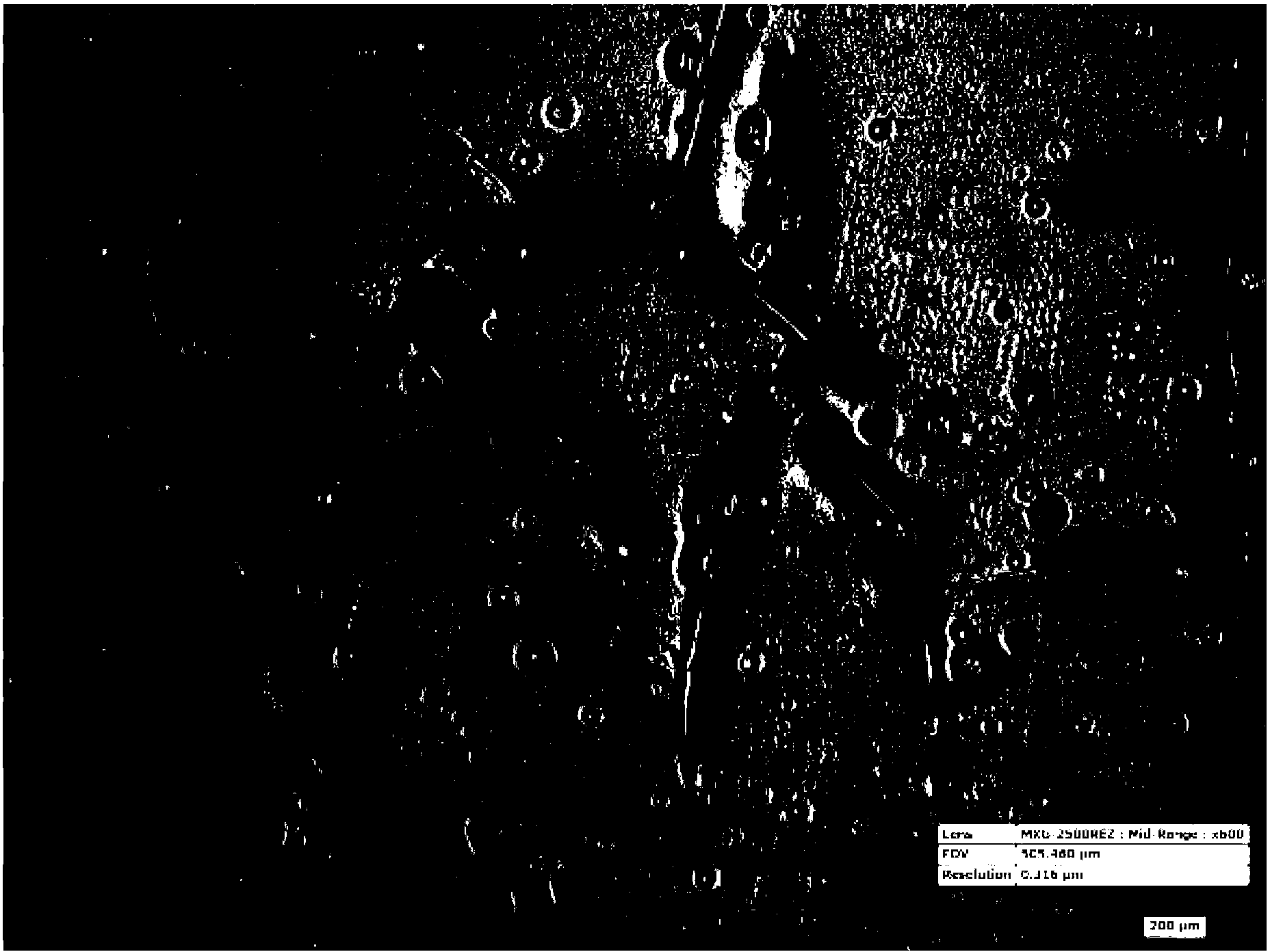

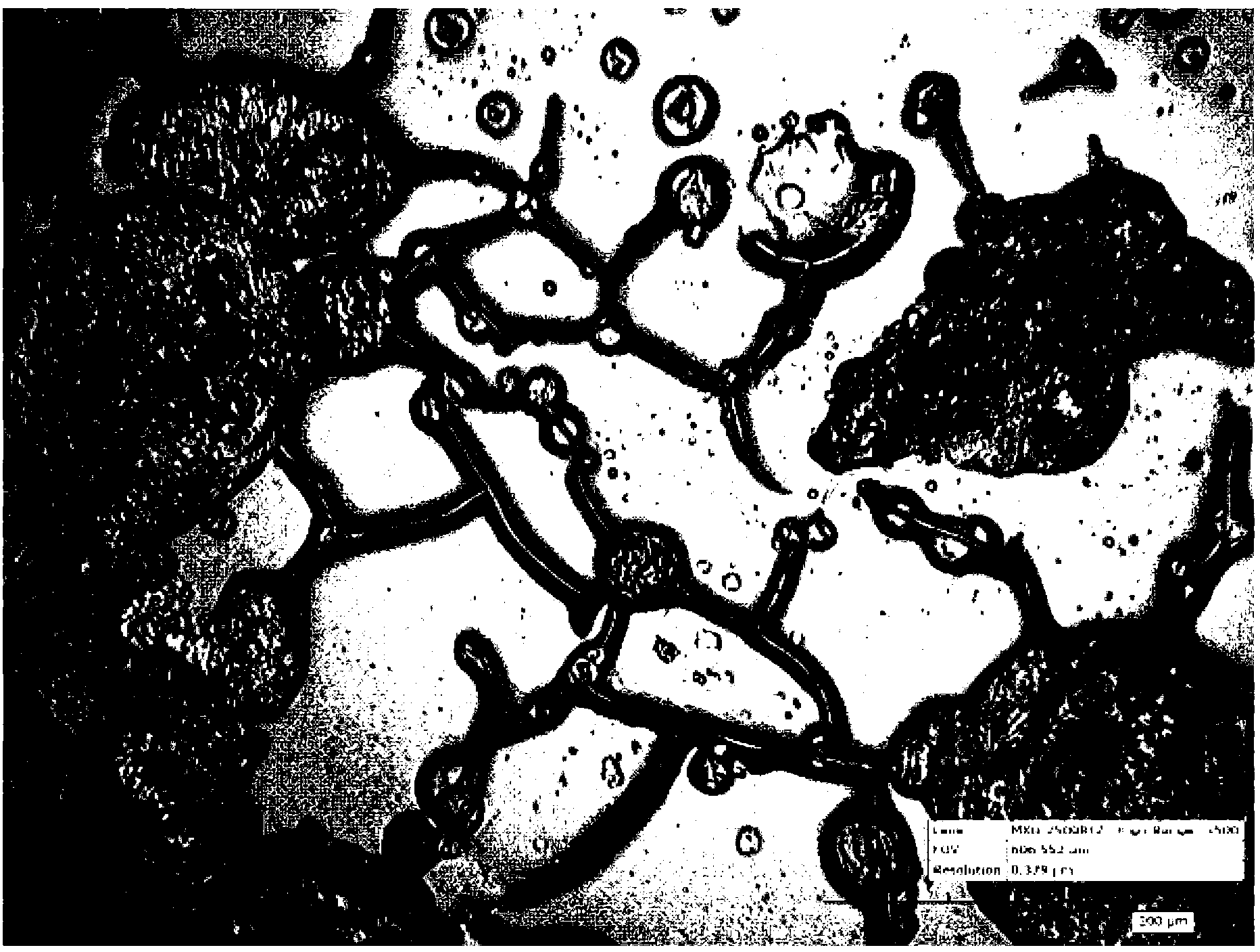

Image

Examples

Embodiment 1

[0045] In a 500ml container, dissolve 20g of 2,4-toluene diisocyanate in 60g of cyclohexanone, place the container in an oil bath, and stir magnetically at a speed of 400r / min. Add 18g of 1,4-butanediol to the reaction vessel at a speed of 20 hours. Afterwards, the reaction mixture was distilled at 100° C. for 6 hours to distill off excess cyclohexanone, water, and 2,4-toluene diisocyanate, leaving a light yellow, viscous prepolymer.

[0046] Take another 500ml container, add 5g surfactant to dissolve in water, stir and mix for 5 hours, take 40g prepolymer and dissolve it in chlorobenzene, add urea and formaldehyde mixed solution, slowly raise the temperature to 65°C, stir until the prepolymer Dissolve everything, add capsule core mixture (2,4-toluene diisocyanate 30g, benzyl alcohol 2g, cyclohexane 10g) and mix evenly, and emulsify with a high-speed emulsifier at a speed of 10000r / min for 20 minutes to form an O / W emulsion , add 1g defoamer. After reacting at 65°C for 4 hou...

Embodiment 2

[0050] In a 500ml container, dissolve 30 g of hexamethyl diisocyanate in 50 g of cyclohexanone, place the container in an oil bath, and stir magnetically at a speed of 1200 r / min. After reacting for 0.5 hours, 5 g of ethylene glycol was added to the reaction vessel at a rate of 5 mg / s, and the reaction continued for 40 hours. Afterwards, the reaction mixture was distilled at 100° C. for 5 hours to distill off excess cyclohexanone, water, and hexamethyl diisocyanate, leaving a light yellow, viscous prepolymer.

[0051] Take another 500ml container, add 1g of surfactant to dissolve in water, stir and mix for 3 hours, take 60g of prepolymer and dissolve in chlorobenzene, add urea and formaldehyde mixed solution, slowly raise the temperature to 65°C, stir until the prepolymer Dissolve everything, add capsule core mixture (20g hexamethyl diisocyanate, 5g ethyl phenylacetate, 6g cyclohexane) and mix evenly, and emulsify with a high-speed emulsifier at a speed of 30000r / min for 10 mi...

Embodiment 3

[0055] In a 500ml container, dissolve 30 g of p-toluene isocyanate in 70 g of cyclohexanone, place the container in an oil bath, and stir magnetically at a speed of 800 r / min. After reacting for 1.8 hours, 15 g of ethylenediamine was added to the reaction vessel at a rate of 8 mg / s, and the reaction was continued for 8 hours. Afterwards, the reaction mixture was distilled at 100° C. for 5.5 hours to distill off excess cyclohexanone, water, and p-toluene isocyanate, leaving a light yellow, viscous prepolymer.

[0056] Take another 500ml container, add 3g surfactant to dissolve in water, stir and mix for 4 hours, take 45g prepolymer and dissolve it in chlorobenzene, add urea and formaldehyde mixed solution, slowly raise the temperature to 65°C, stir until the prepolymer Dissolve everything, add capsule core mixture (30g p-toluene isocyanate, 3g ethyl phenylacetate, 8g chlorobenzene) and mix evenly, and emulsify with a high-speed emulsifier at a speed of 2300r / min for 15 minutes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com