Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Magnetic phase transition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It is shown that the magnetic phase transition occurs as a result of a signchange in the proper combination of the exchange parameters. The transition may be influenced by the variation of the pressure and the magnetic field.

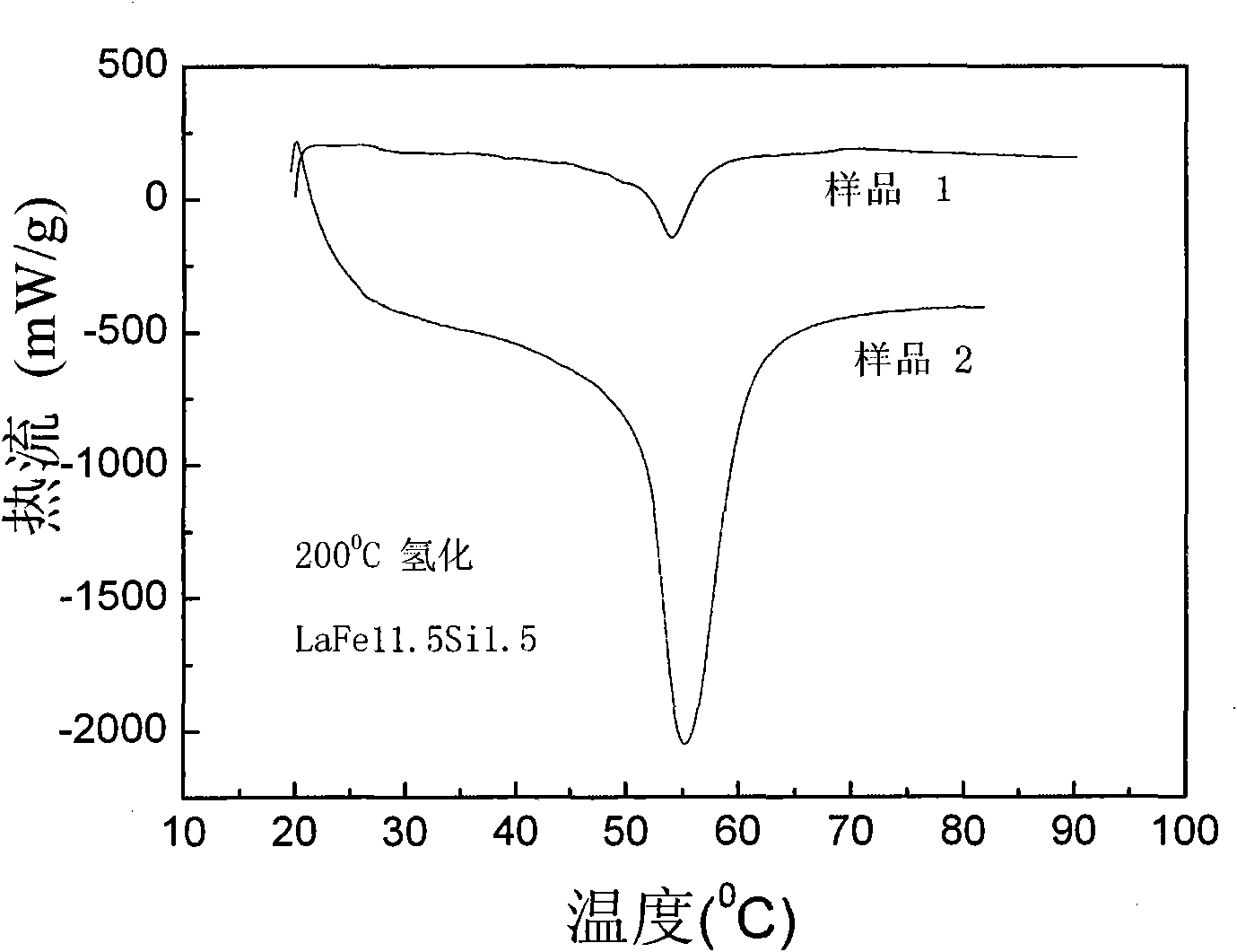

Magnetic material for magnetic refrigeration and method for producing thereof

ActiveUS7063754B2Stable magnetic refrigeration cycleLow costCompression machinesInorganic material magnetismHydrogenRoom temperature

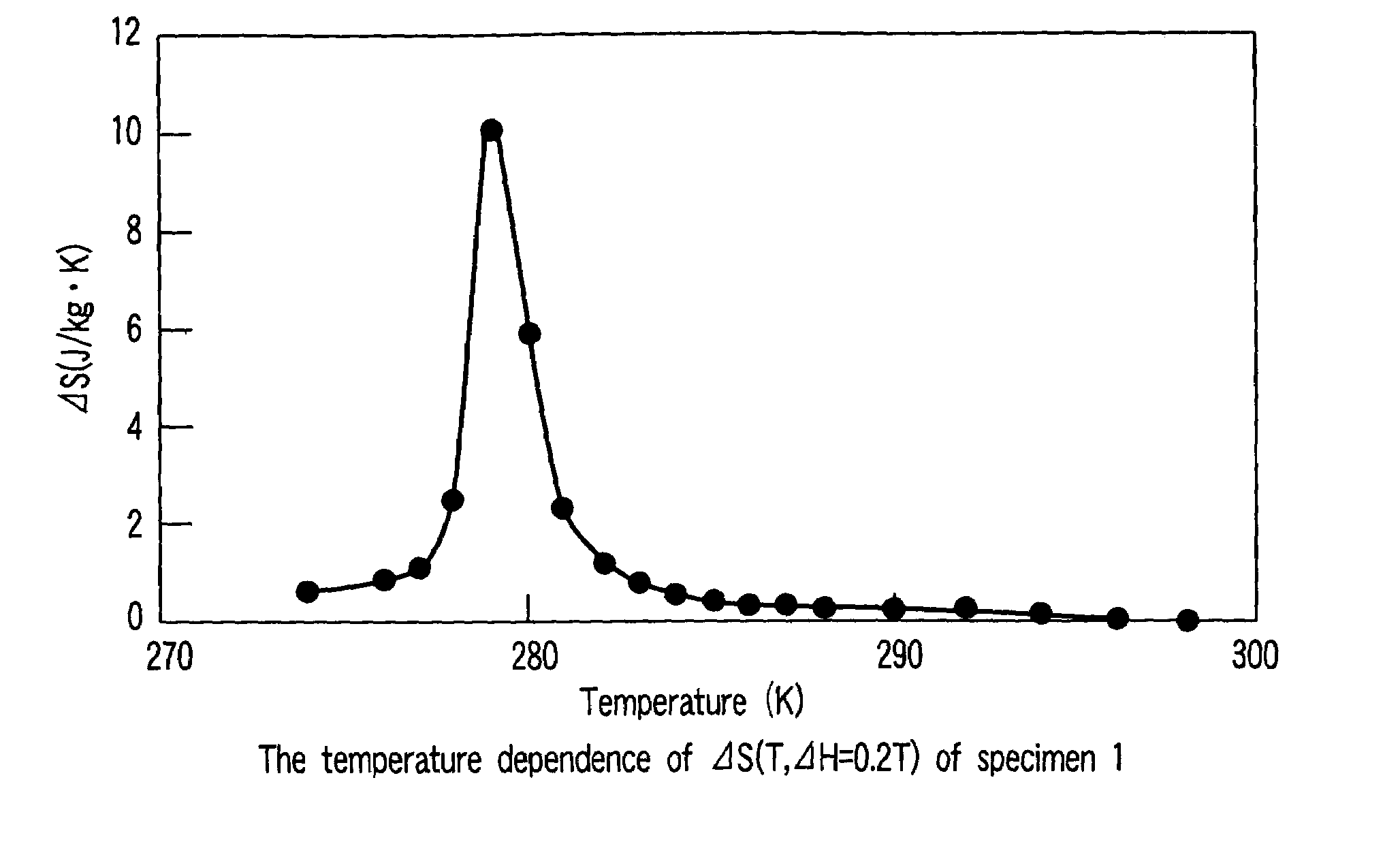

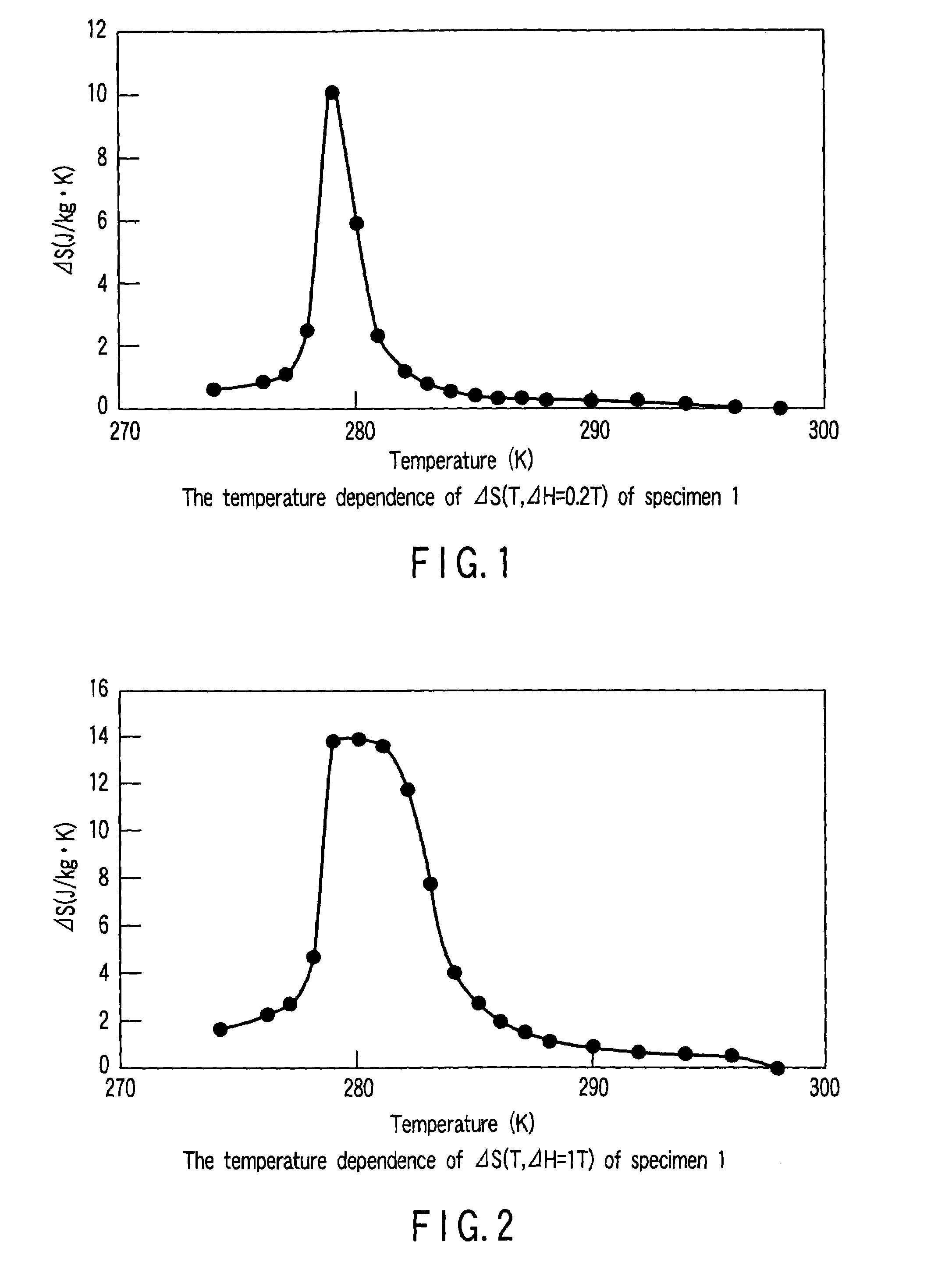

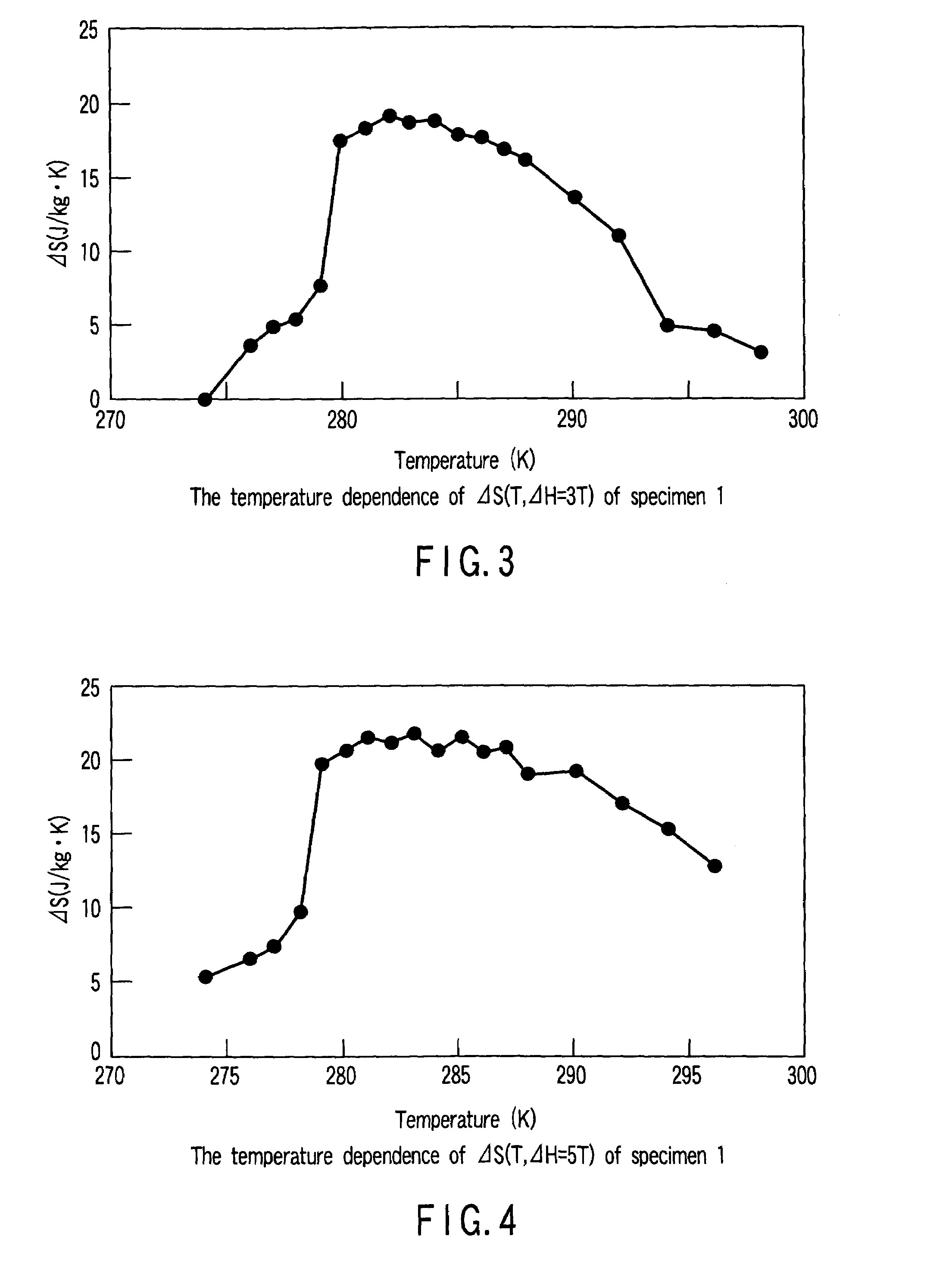

The magnetic material for magnetic refrigeration according to the present invention has an NaZn13-type crystalline structure and comprises iron (Fe) as a principal element (more specifically, Fe is substituted for the position of “Zn”) and hydrogen (H) in an amount of 2 to 18 atomic % based on all constitutional elements. Preferably, the magnetic material for magnetic refrigeration preferably contains 61 to 87 atomic % of Fe, 4 to 18 atomic % of a total amount of Si and Al, 5 to 7 atomic % of La. The magnetic material for magnetic refrigeration exhibits a large entropy change in a room temperature region and no thermal hysteresis in a magnetic phase transition. Therefore, when a magnetic refrigeration cycle is configured using the magnetic material for magnetic refrigeration, a stable operation can be performed.

Owner:KK TOSHIBA

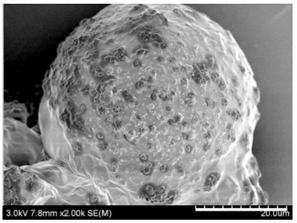

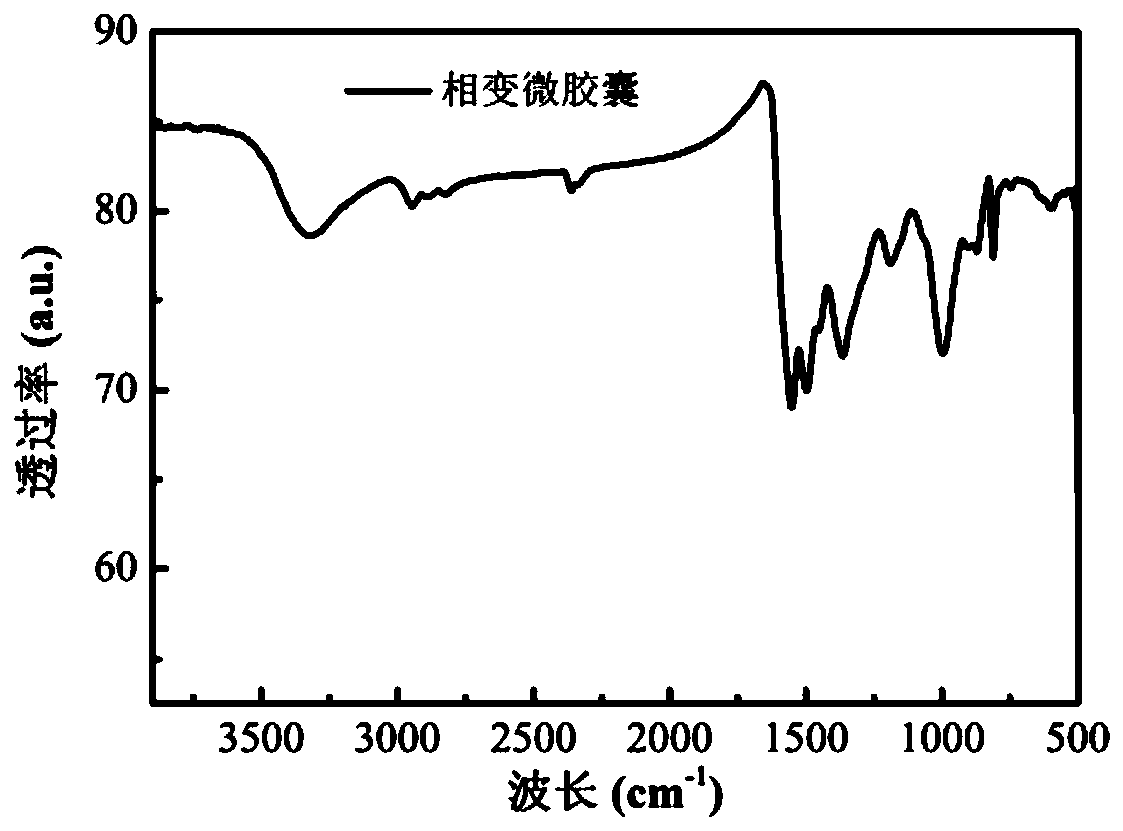

Magnetic phase transition microcapsule and preparation method thereof

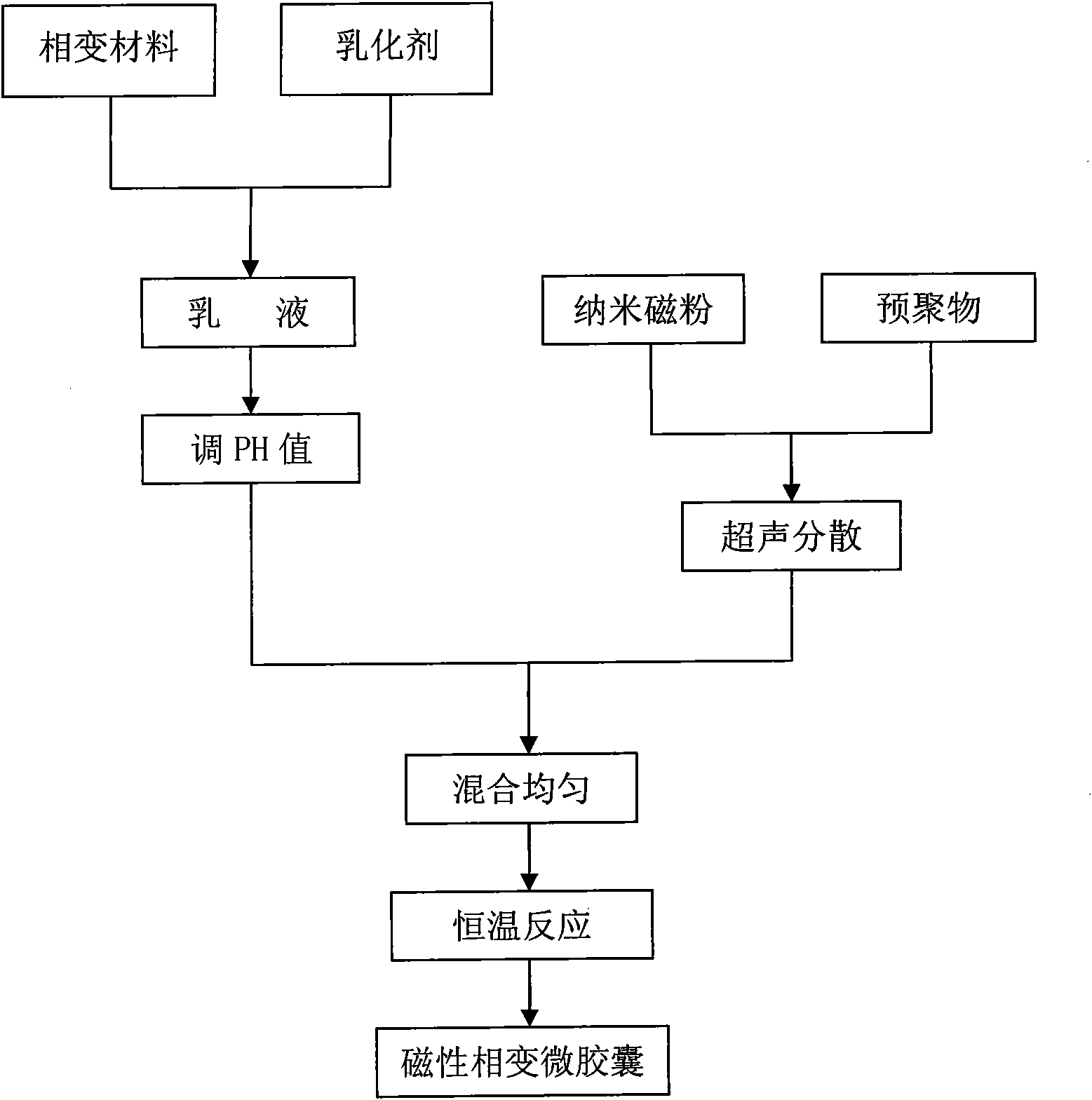

InactiveCN101574637AReduce consumptionEasy to controlHeat-exchange elementsMicroballoon preparationUltrasonic dispersionFORMALDEHYDE SOLUTION

The invention discloses a magnetic phase transition microcapsule and a preparation method thereof. Nanometer magnetic powder is filled in a microcapsule material to form a shell, and a core material is wrapped in the shell. The magnetic phase transition microcapsule is prepared by the following steps: firstly, adding urea to a formaldehyde solution to dissolve or adding melamine to the formaldehyde solution, or adding the urea to the formaldehyde solution and adding melamine after fully dissolving the urea; then, reacting under stirring at a constant temperature to obtain a prepolymer solution; adding the nanometer magnetic powder to the prepolymer solution and dispersing the solution under ultrasound; dissolving an emulsifying agent in the water, adding an organic phase transition material and cutting and emulsifying the organic phase transition material at a high speed to prepare an emulsion; and uniformly mixing the emulsion and the prepolymer solution after ultrasonic dispersion and reacting under stirring at the constant temperature to obtain the magnetic phase transition microcapsule. The magnetic phase transition microcapsule has magnetism and can reach specific parts under the guide of an external magnetic field while the magnetic phase transition microcapsule is applied to a latent heat type functional fluid so as to control the flow of the fluid.

Owner:NANJING UNIV OF SCI & TECH

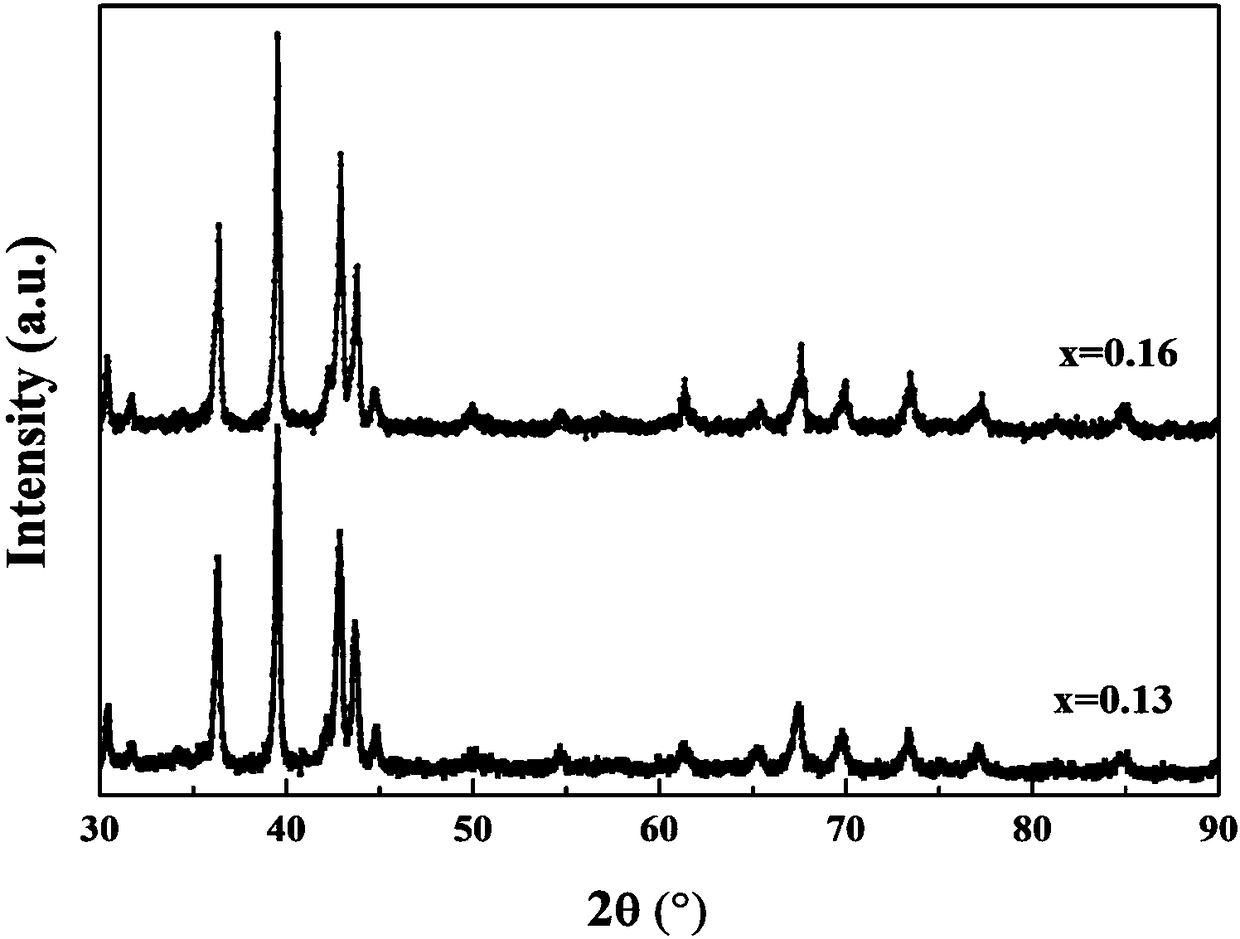

Magnetic material, and memory and sensor using same

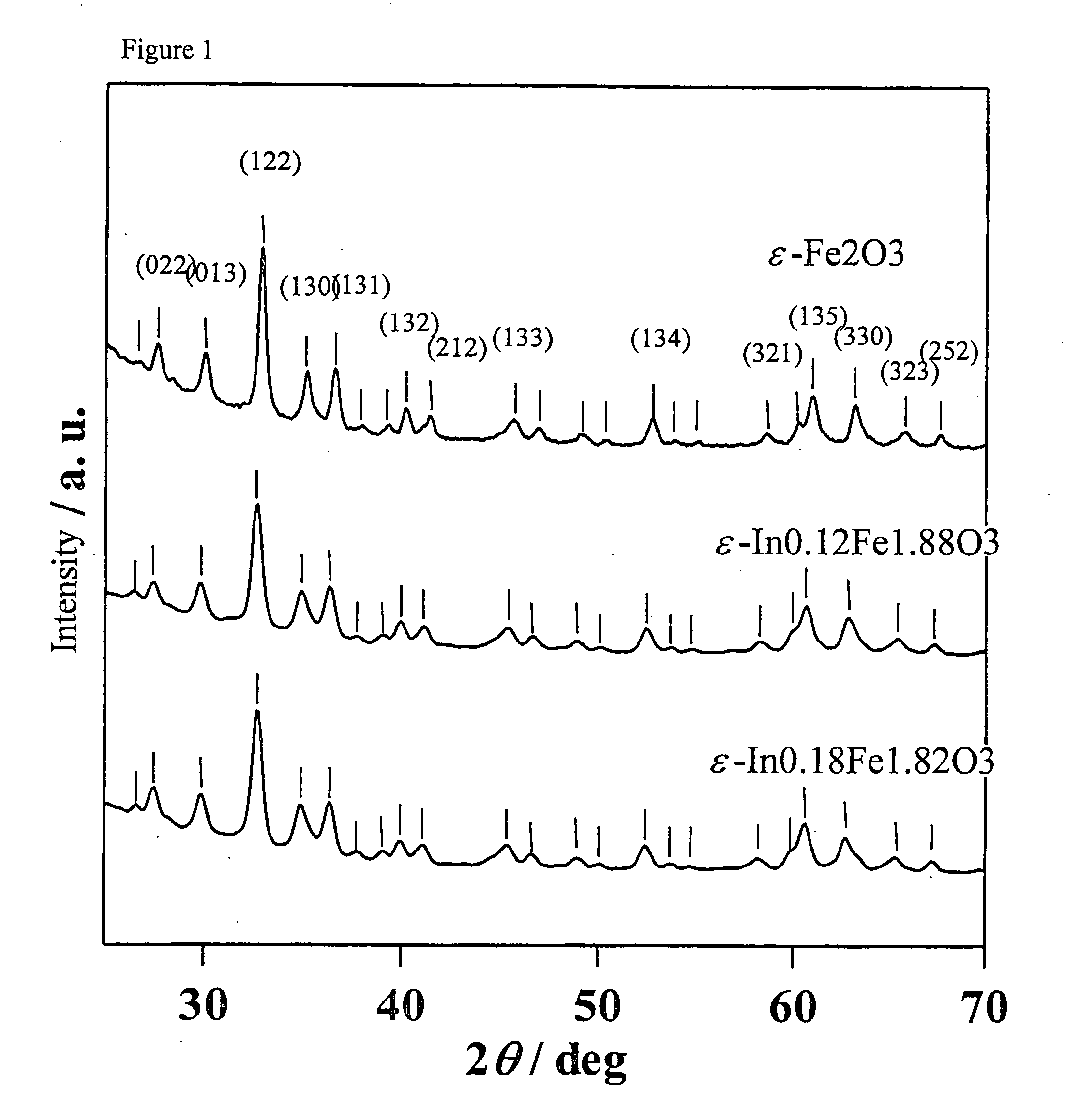

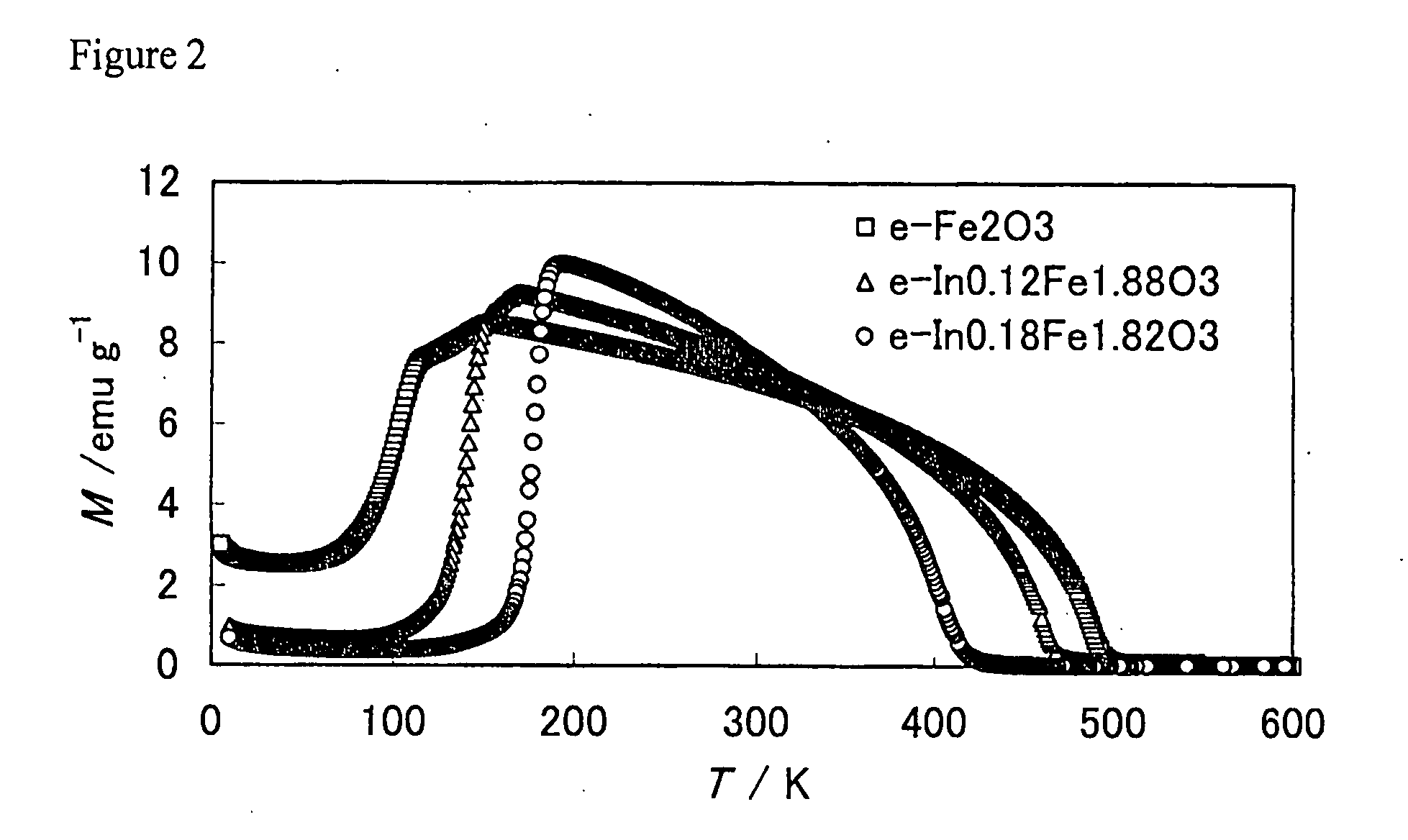

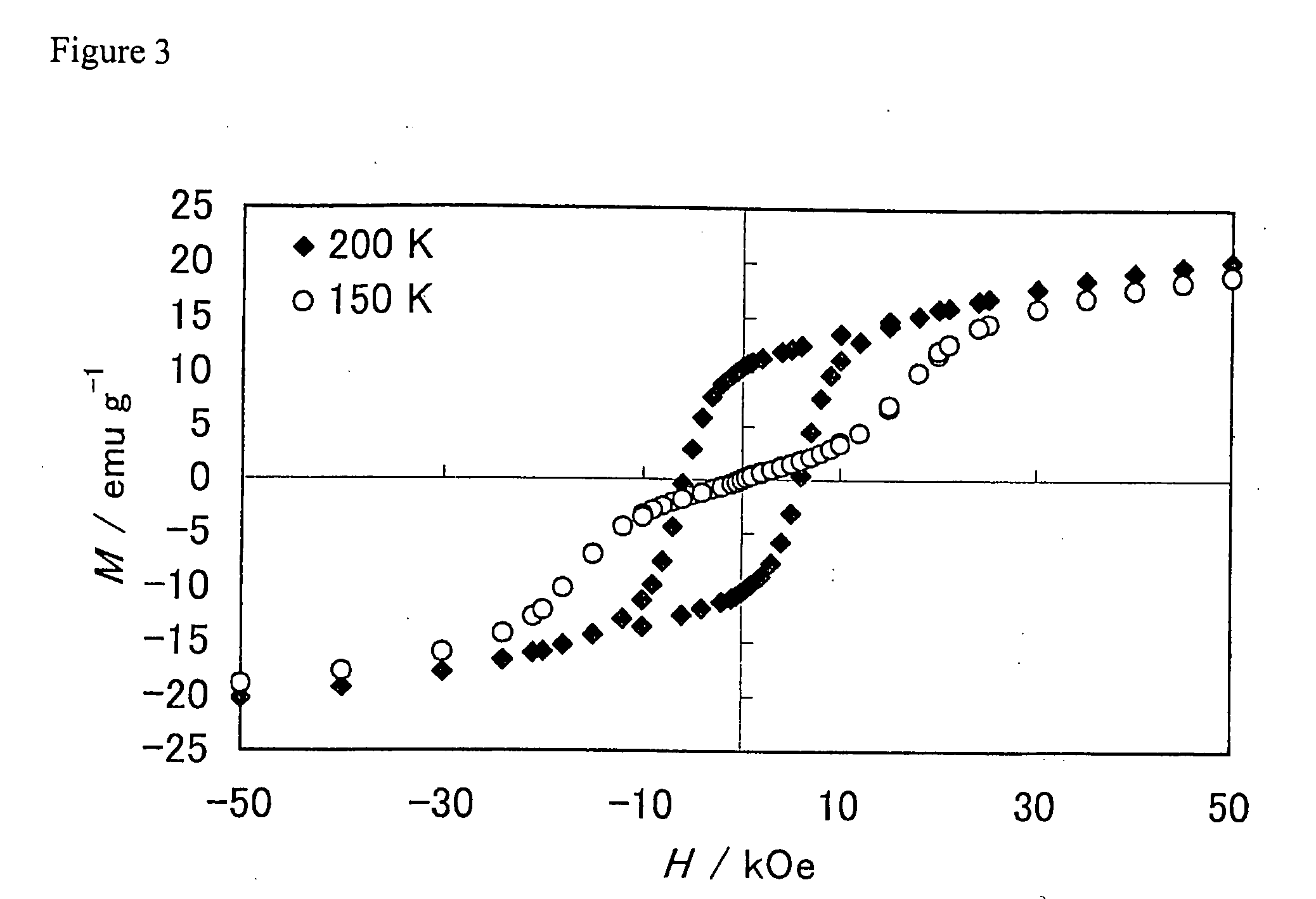

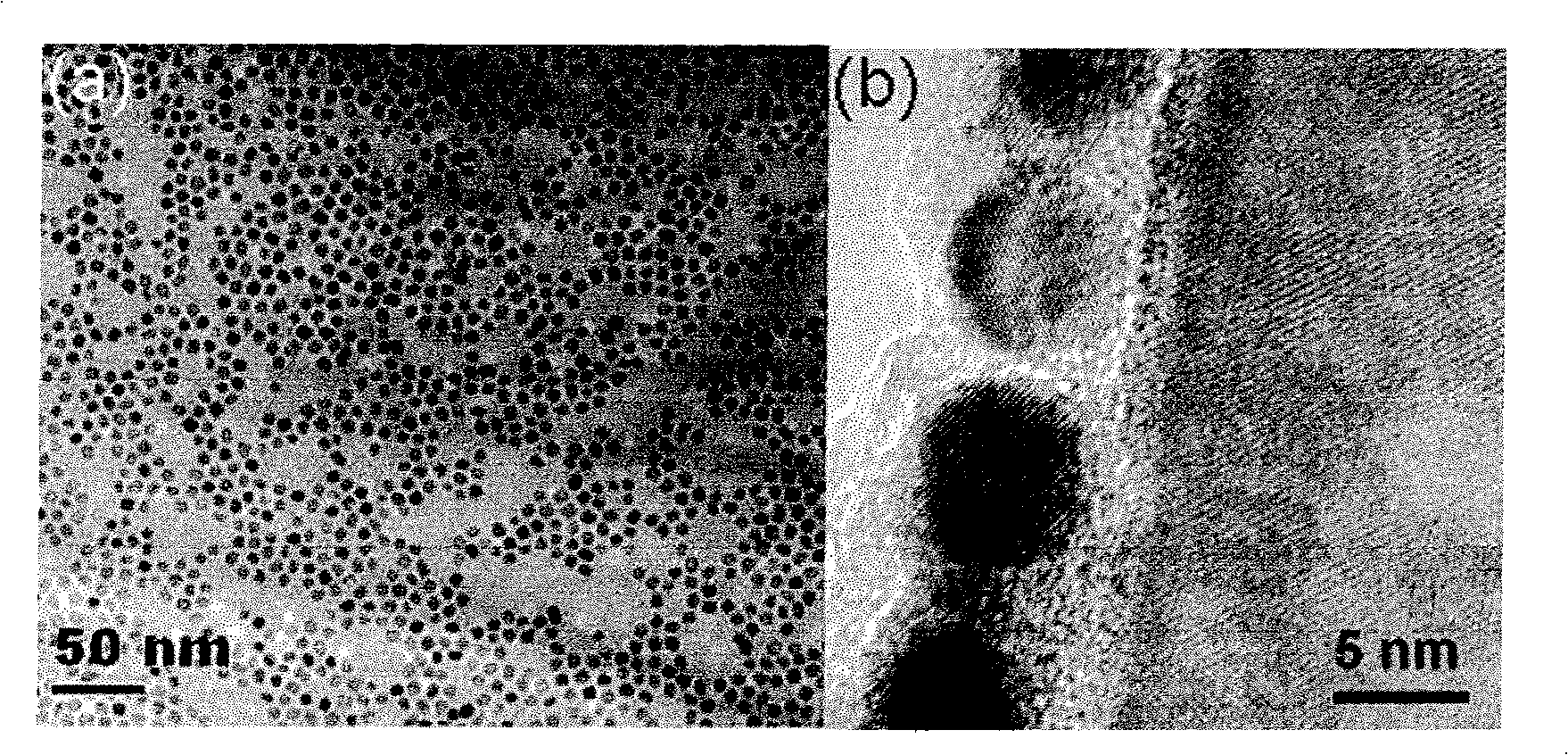

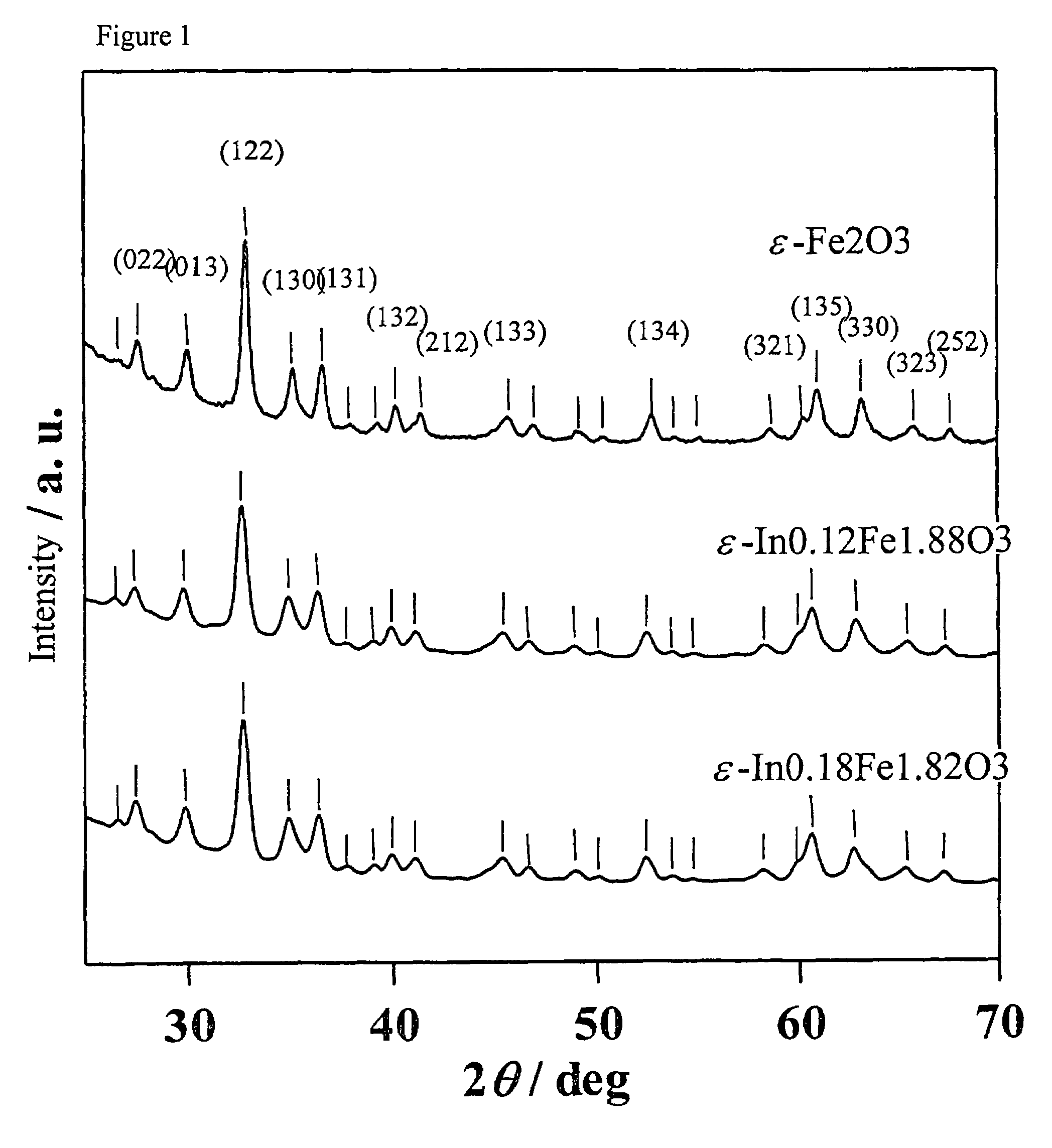

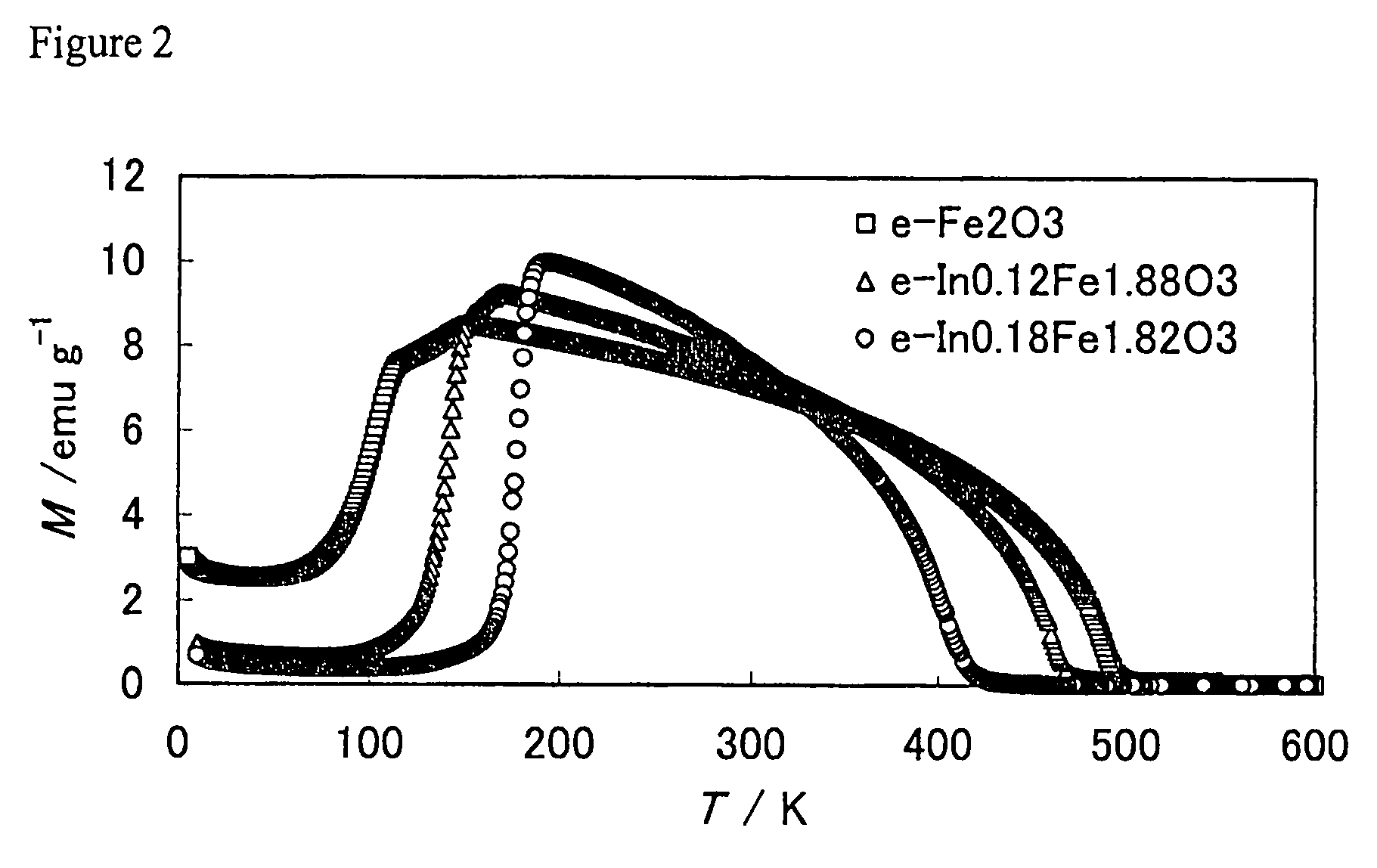

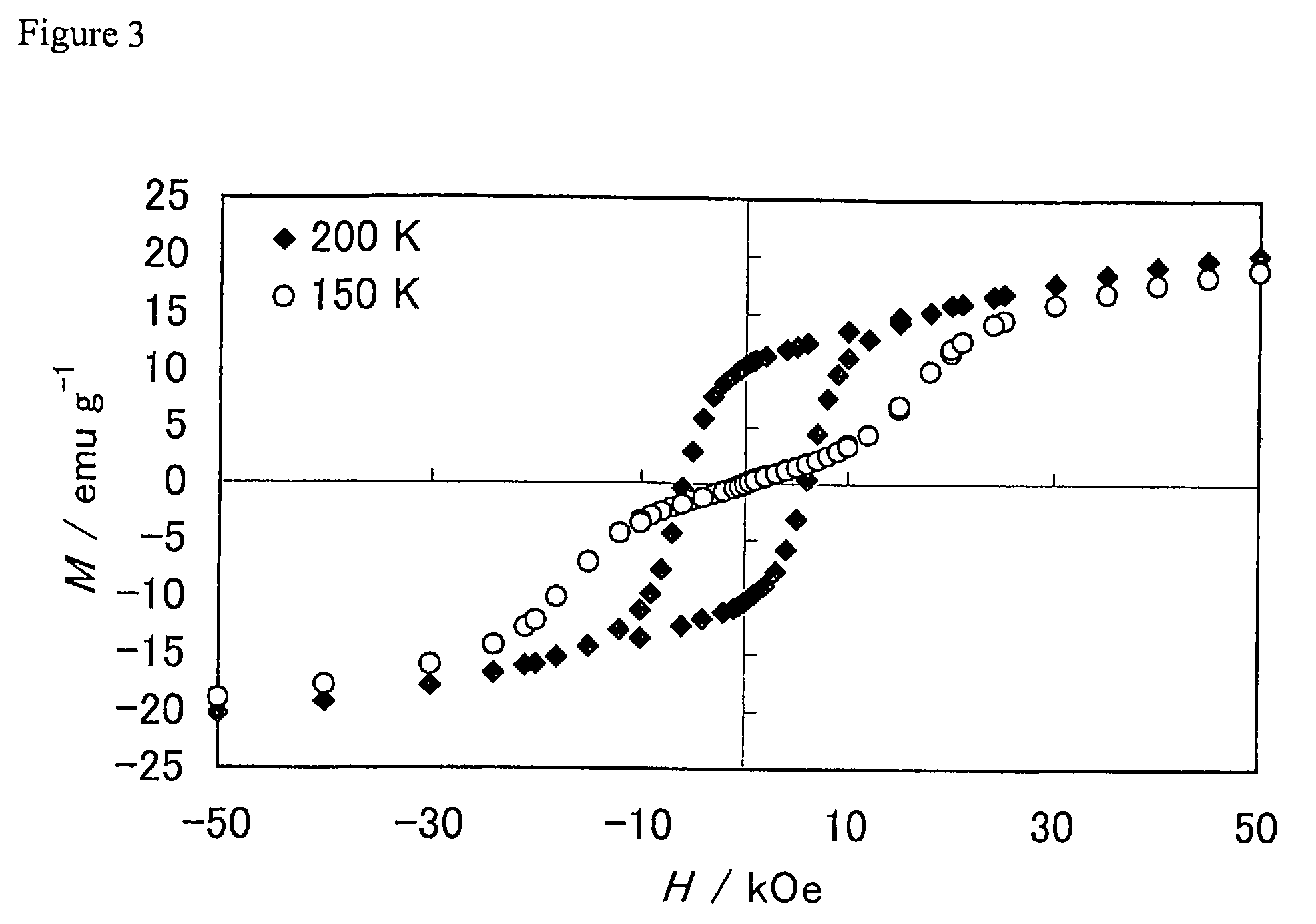

ActiveUS20070218319A1Easy to ultimately obtainLarge coercive forceNanomagnetismThermometers using electric/magnetic elementsDielectricCrystal structure

A magnetic material composed of ε-InxFe2-xO3 (wherein 0<x≦0.30) crystal in which In is substituted for a portion of the Fe sites of the ε-Fe2O3 crystal. The crystal exhibits an X-ray diffraction pattern similar to that of an ε-Fe2O3 crystal structure and has the same space group as that of an ε-Fe2O3. The In content imparts to the magnetic material a magnetic phase transition temperature that is lower than that of the ε-Fe2O3 and a spin reorientation temperature that is higher than that of the ε-Fe2O3. The In content can also give the magnetic material a peak temperature of the imaginary part of the complex dielectric constant that is higher than that of the ε-Fe2O3.

Owner:THE UNIV OF TOKYO +1

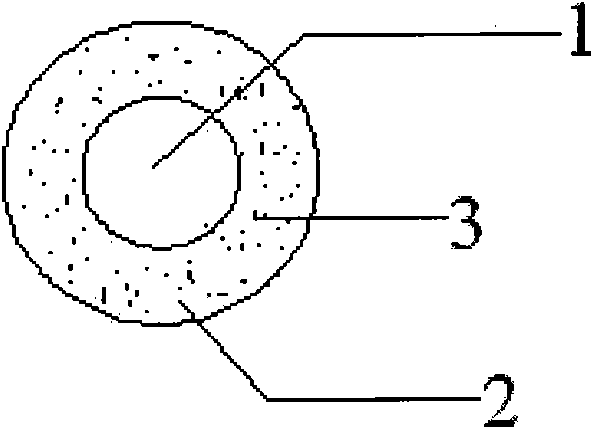

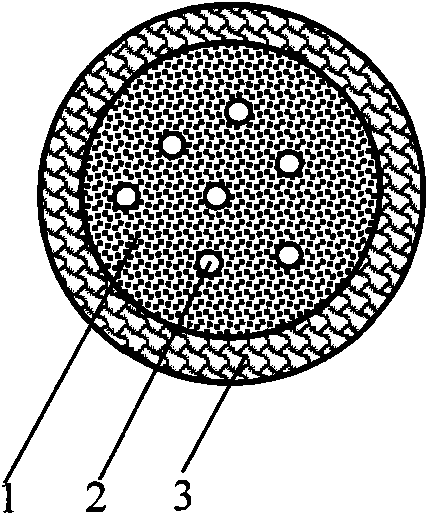

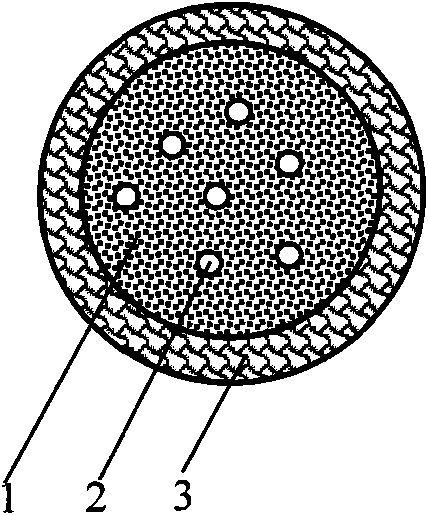

Magnetic phase-change microcapsule for performing thermal protection on normal structure in thermal physical therapy

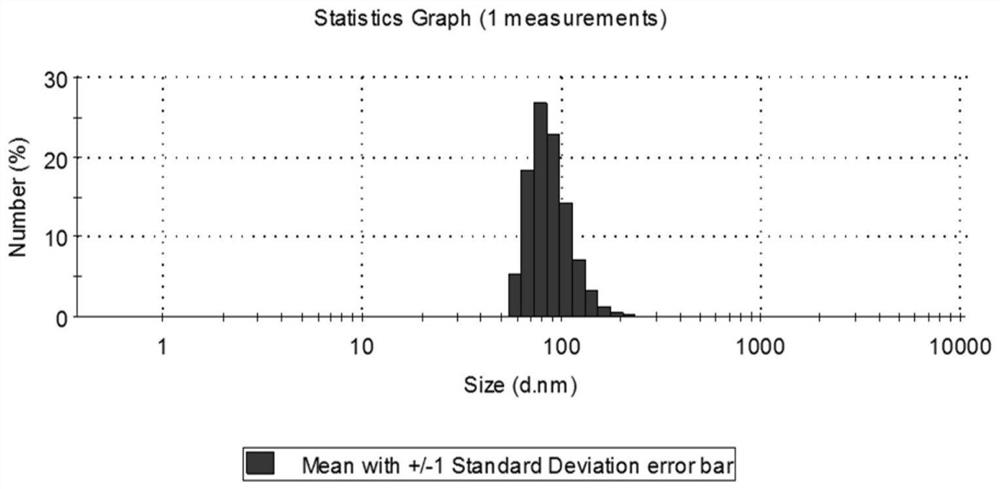

InactiveCN101836915AGood biocompatibilityLow toxicityUltrasound therapySurgical instrument detailsMean diameterMagnetic phase

The invention discloses a magnetic phase-change microcapsule for performing thermal protection on a normal structure in thermal physical therapy. The magnetic phase-change microcapsule is a spherical microcapsule which is composed of a phase-change material (1), magnetic particles (2) and a liposome shell (3), and the mean diameter thereof is 1nm-1mm. In the invention, the phase-change material (1) is solid-liquid or / and liquid-solid phase-change material with high phase change heat and the phase change temperature at -10-0 DEG C or 38-100 DEG C according to different thermal physical therapeutic processes such as thermal therapy, cold therapy, cryosurgery or cold-heat alternating therapy and the like; the magnetic particles (2) are magnetic micro / nano-particles or magnetotactic bacteria; and a liposome is taken as a capsule carrier for lowering toxicity of the material and protecting an encapsulated material. The invention provides a safe and effective thermal protection material with novel concept. In the invention, the magnetic phase-change microcapsule can be gathered into a target organ with blood circulation under the action of an applied magnetic field; phase-change latent heat and low thermal conductivity of the phase-change material are adopted to carry out thermal protection on the normal structure; and the material is widely applied to thermal physical therapy, and the application method thereof is simple, feasible and reliable.

Owner:CHONGQING UNIV

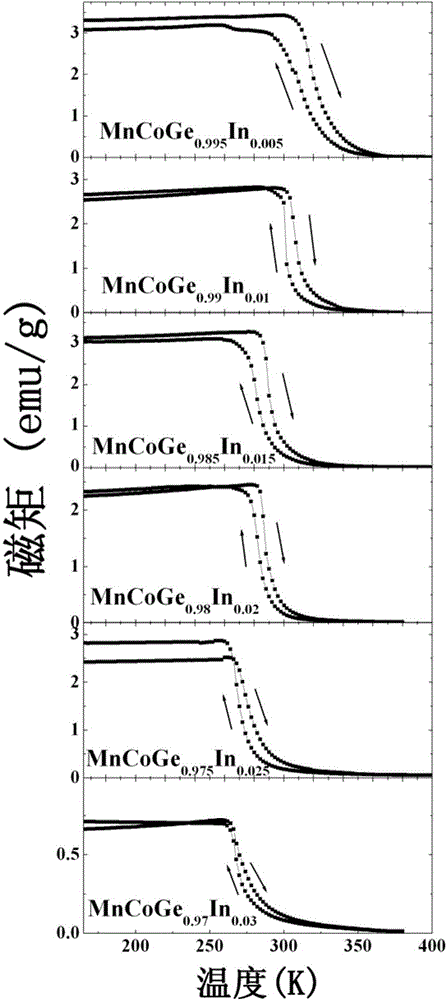

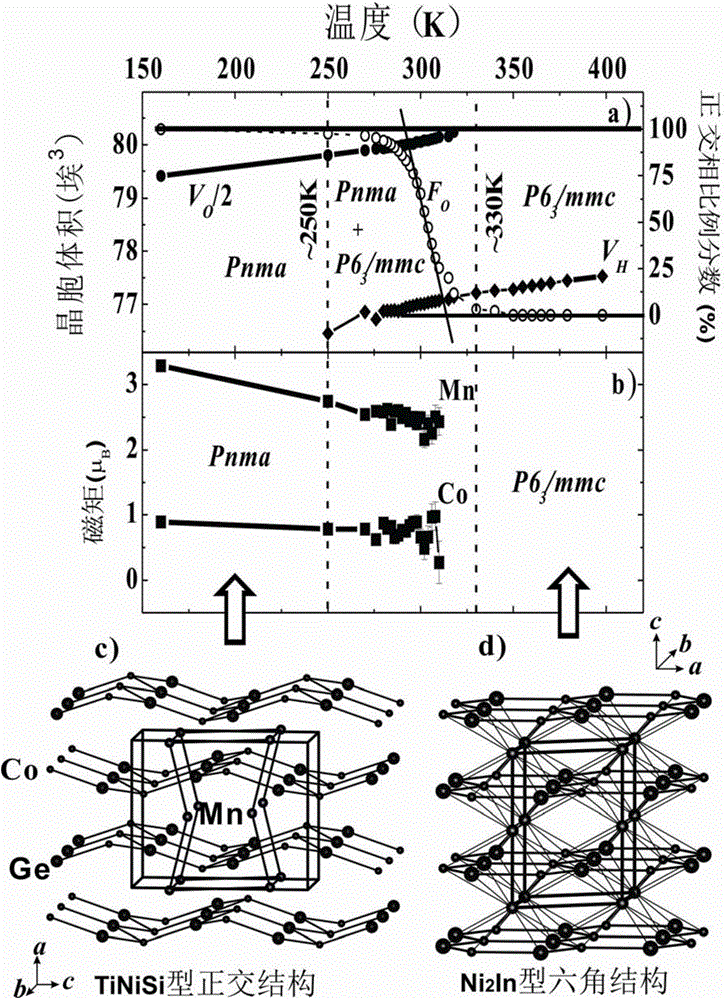

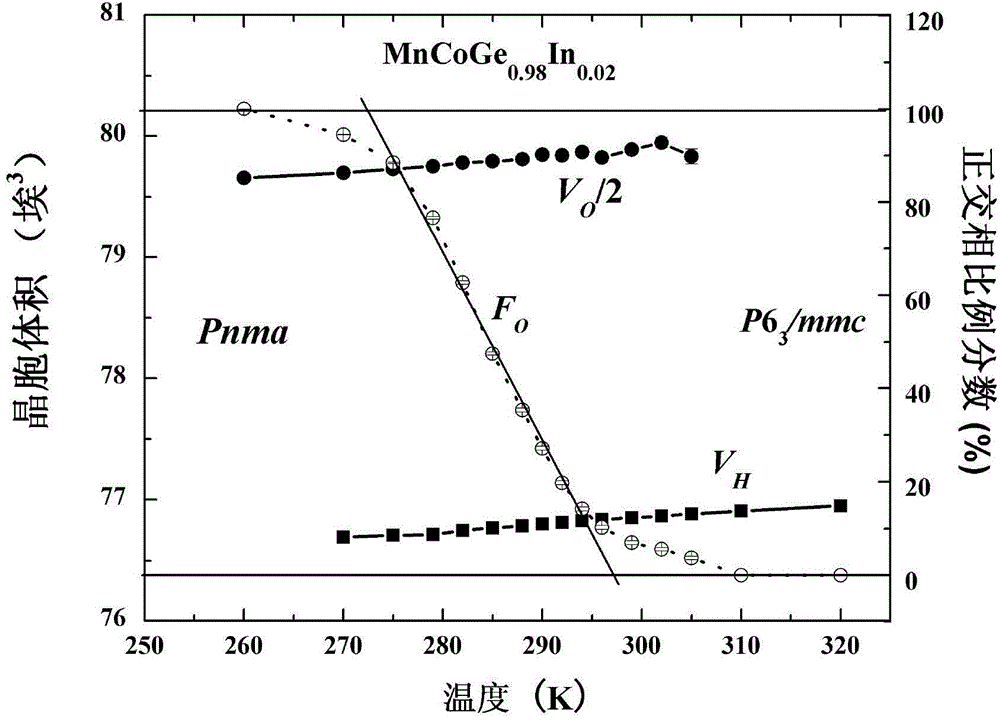

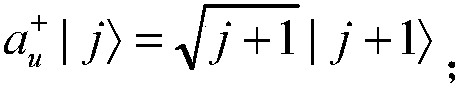

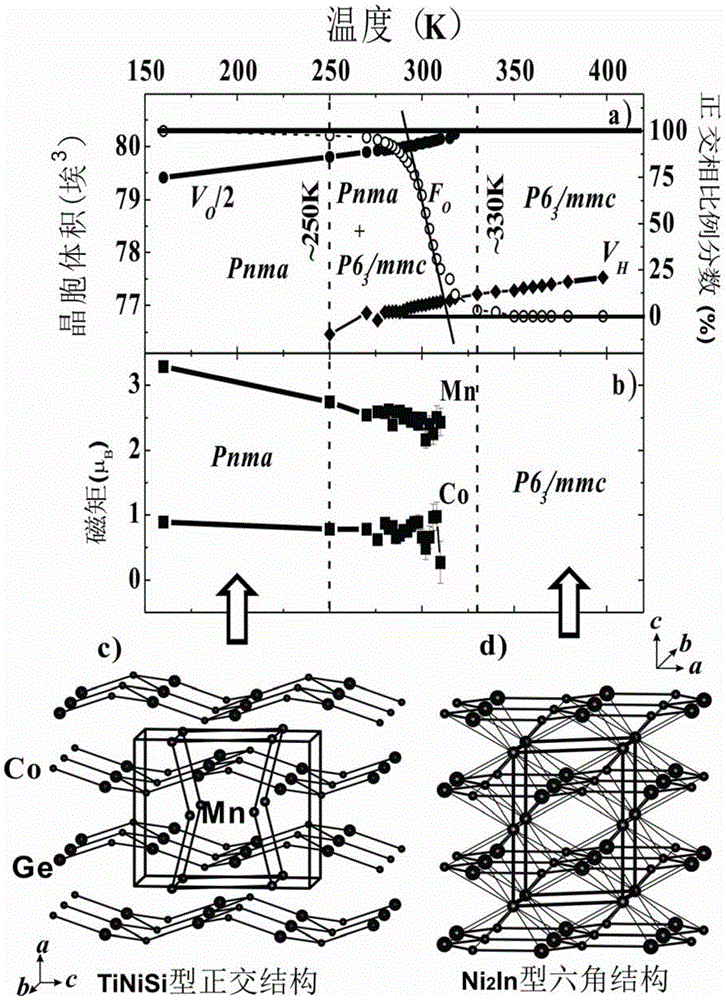

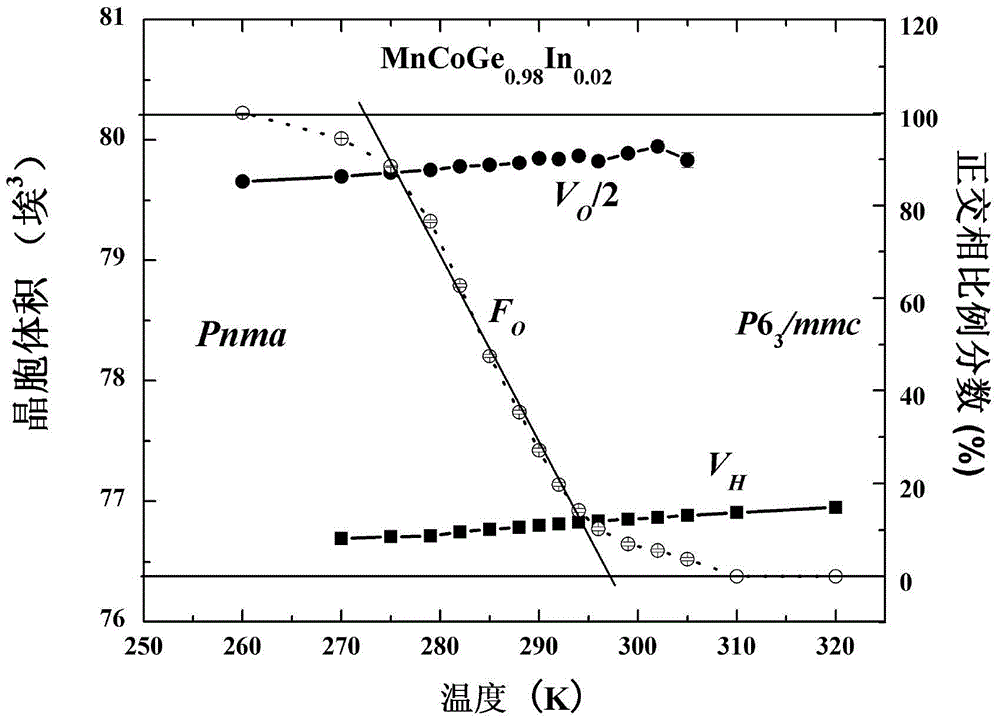

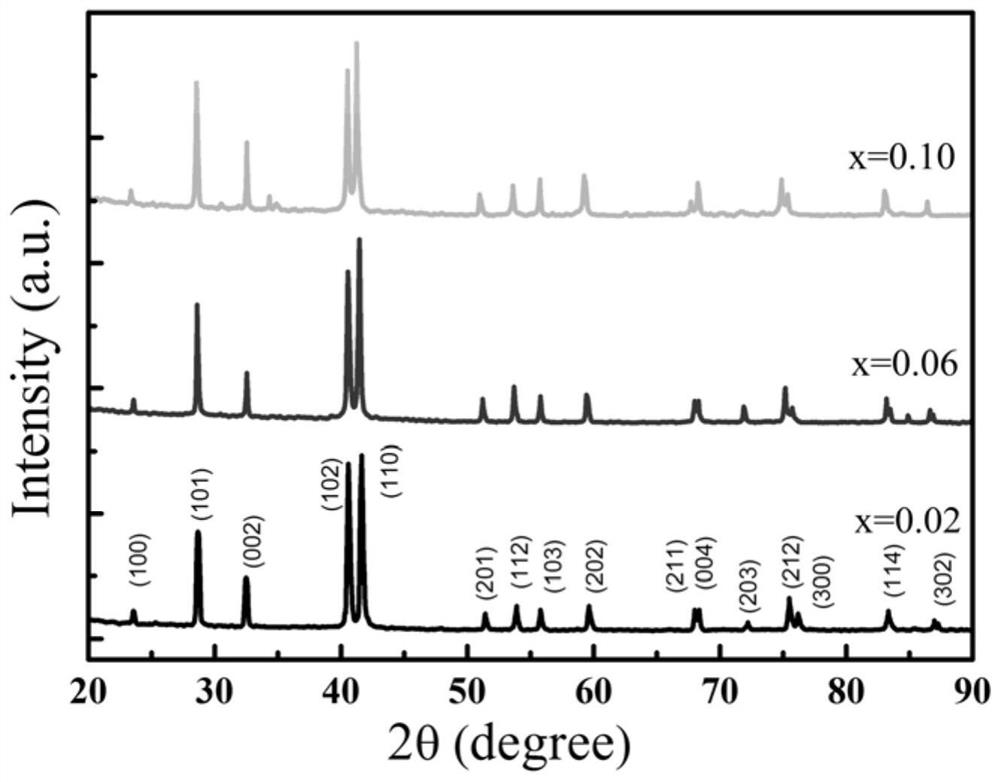

MnCoGe-based magnetic material with giant piezocaloric effect as well as preparation method and application thereof

ActiveCN104946954AReduce manufacturing costReduce dependenceMagnetic materialsThermoelectric devicesStructural phaseCoupling

The invention provides a MnCoGe-based magnetic material with a giant piezocaloric effect as well as a preparation method and application thereof. A chemical general formula of the MnCoGe-based magnetic material is MnCoGe1-xInx, wherein x is more than 0 and less than or equal to 0.03, and the MnCoGe-based magnetic material has a Ni2In type hexagonal structure. The MnCoGe-based magnetic material has the characteristic that martensitic structural phase transition and magnetic phase transition are coupled, and coupling is carried out at the temperature close to room temperature. The MnCoGe-based magnetic material shows an adverse piezocaloric effect under the action of pressure, the amplitude of entropy change under the action of pressure of 3kbar and at the temperature close to room temperature is at least 50J / (Kg.K). Along with change of In content, the magnetic structure coupling temperature Tmstru of the material is adjustable at a wide temperature region close to room temperature, so that the giant piezocaloric effect appears in the wide temperature region close to room temperature. The MnCoGe-based magnetic material has the advantages of simple preparation method, green and environmental-friendly raw materials, high efficiency and energy conservation.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

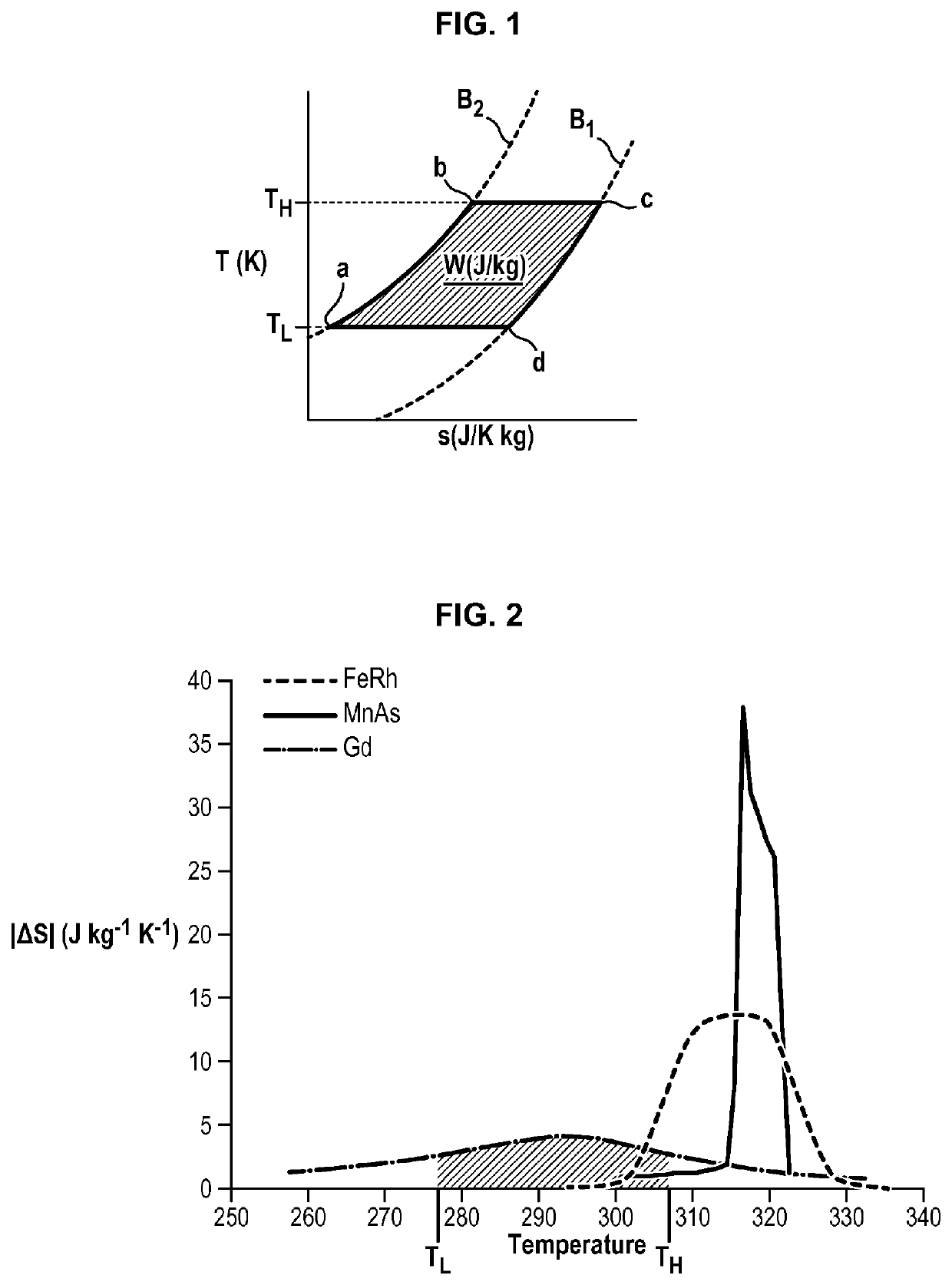

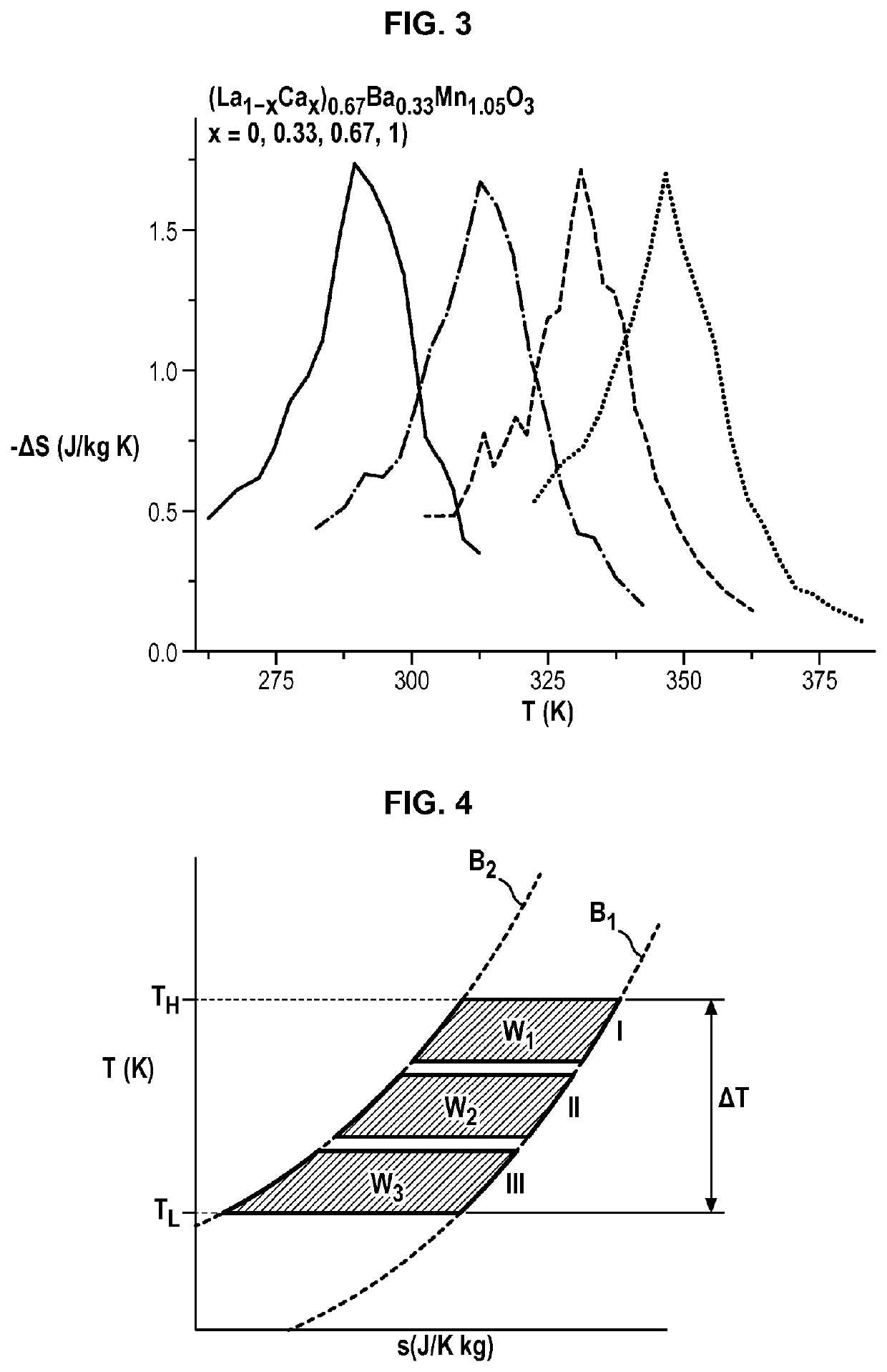

Magnetocaloric alloys useful for magnetic refrigeration applications

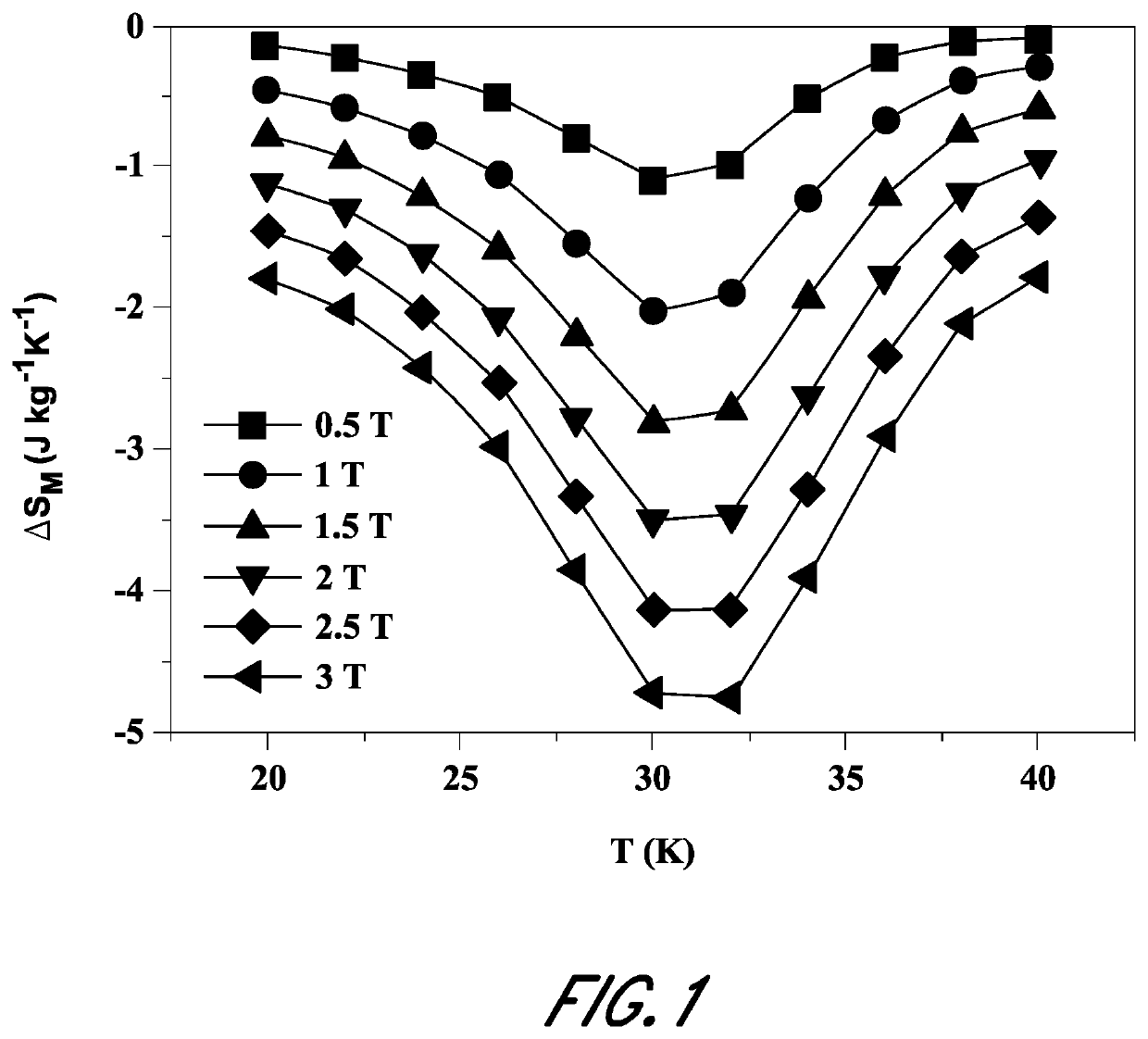

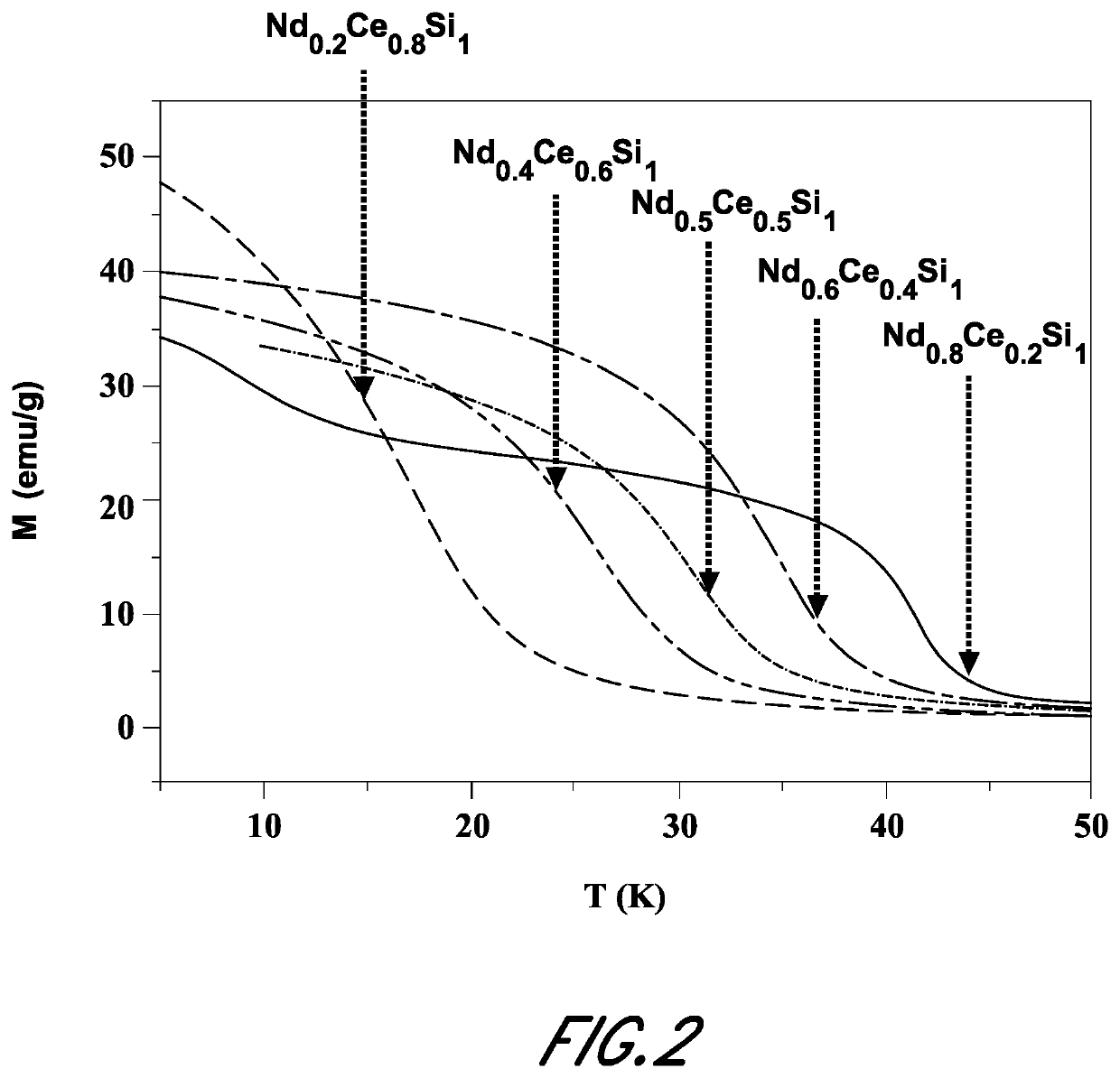

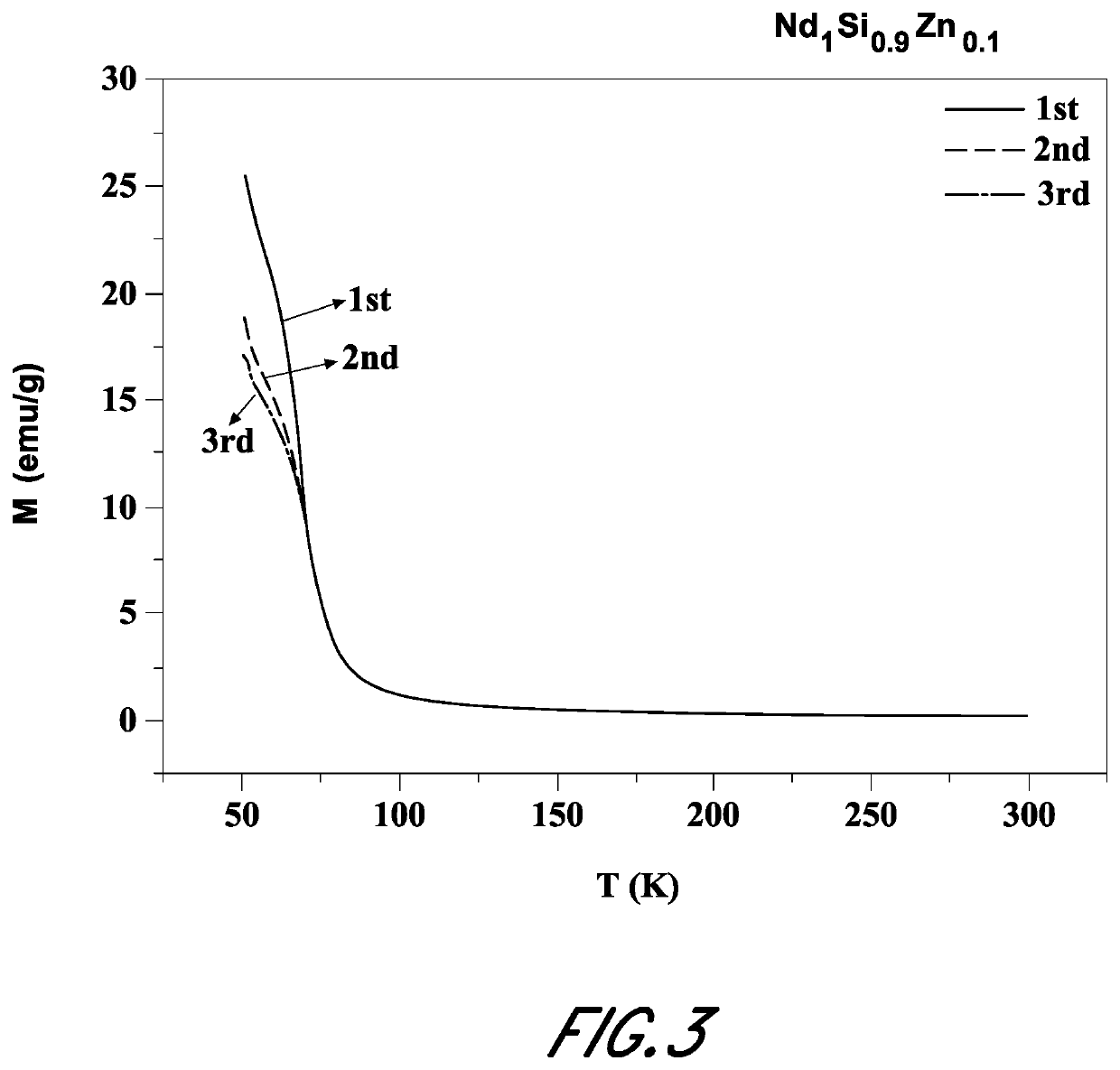

ActiveUS20190352747A1No thermal and structural hysteresis lossesTransportation and packagingMetal-working apparatusHysteresisMagnetic phase

This invention relates to magnetocaloric materials comprising ternary alloys useful for magnetic refrigeration applications. The disclosed ternary alloys are Cerium, Neodymium, and / or Gadolinium based compositions that are fairly inexpensive, and in some cases exhibit only 2nd order magnetic phase transitions near their curie temperature, thus there are no thermal and structural hysteresis losses. This makes these compositions attractive candidates for use in magnetic refrigeration applications. The performance of the disclosed materials is similar or better to many of the known expensive rare-earth based magnetocaloric materials.

Owner:RGT UNIV OF CALIFORNIA +1

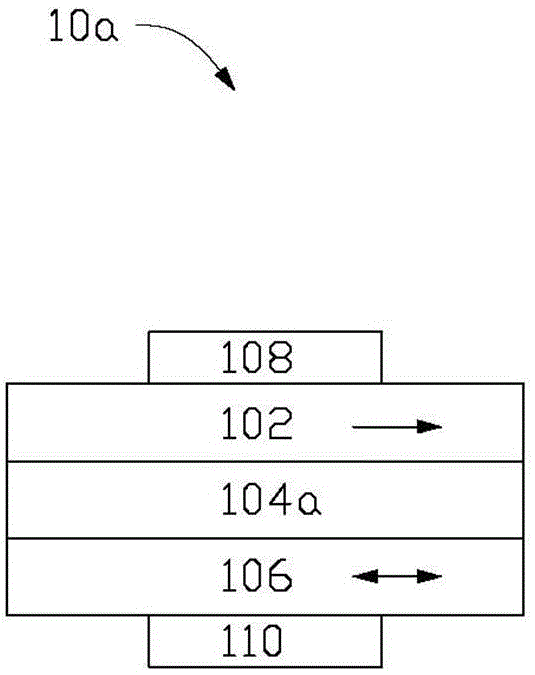

Phase-change spinning nonvolatile storage unit

ActiveCN105304812AReduce power consumptionReduce production processSolid-state devicesSemiconductor devicesMagnetic phaseEngineering

The invention provides a phase-change spinning nonvolatile storage unit, which comprises a magnetic fixing layer, a spacing layer, a magnetic free layer, a first electrode and a second electrode, wherein the magnetic fixing layer, the spacing layer and the magnetic free layer are overlapped and arranged sequentially; the first electrode is arranged on the magnetic fixing layer; the second electrode is arranged on the magnetic free layer; and the spacing layer is made of a phase-change material, or the magnetic fixing layer and the magnetic free layer are made of a dilution-type magnetic phase change material.

Owner:TSINGHUA UNIV

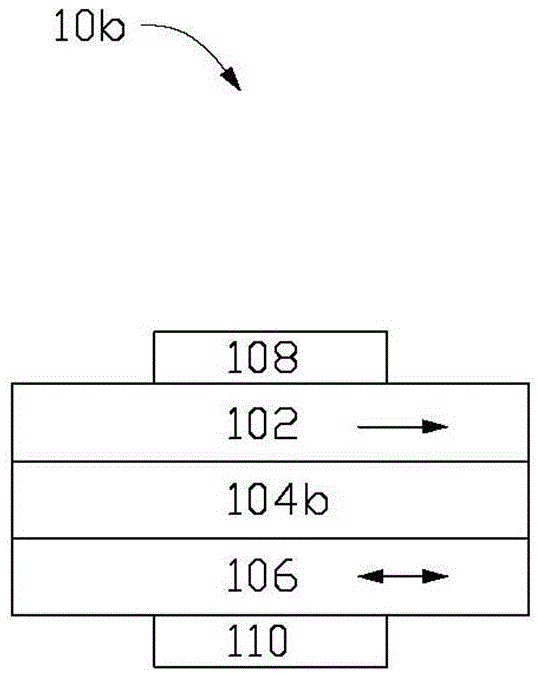

Six-element high-entropy alloy with first-order magnetic phase transition and preparation method thereof

InactiveCN103173674AReversibleLarge magnetic phase transition temperature rangePhotography auxillary processesMagnetic transitionsVitamin C

The invention relates to the technical field of high-entropy alloys and discloses a six-element high-entropy alloy with a first-order magnetic phase transition and a preparation method thereof. The six-element high-entropy alloy with the first-order magnetic phase transition has a general formula structure of MgaMnbFecCodNieGdf and is obtained by electrochemical reduction deposition, wherein an electrolyte in the electrochemical reduction deposition comprises the following components: dimethyl sulfoxide, tetraethylammonium hexafluorophosphate, vitamin C, GdCl3, FeCl2, CoCl2, NiCl2, MnCl2 and MgCl2. The prepared alloy is an amorphous alloy, the magnetic transition of the prepared alloy is the magnetic transition caused by strong electron correlation without being restrained by the crystal form transformation of a material, and therefore, the high-entropy alloy has the advantages of large temperature range of magnetic phase transition, controllable critical transition temperature and reversibility.

Owner:SUN YAT SEN UNIV

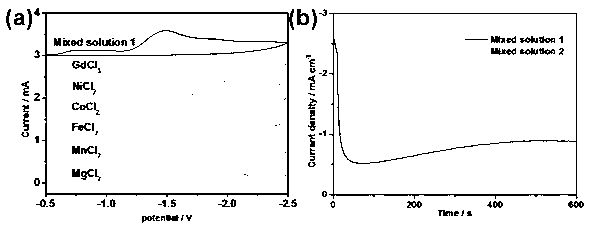

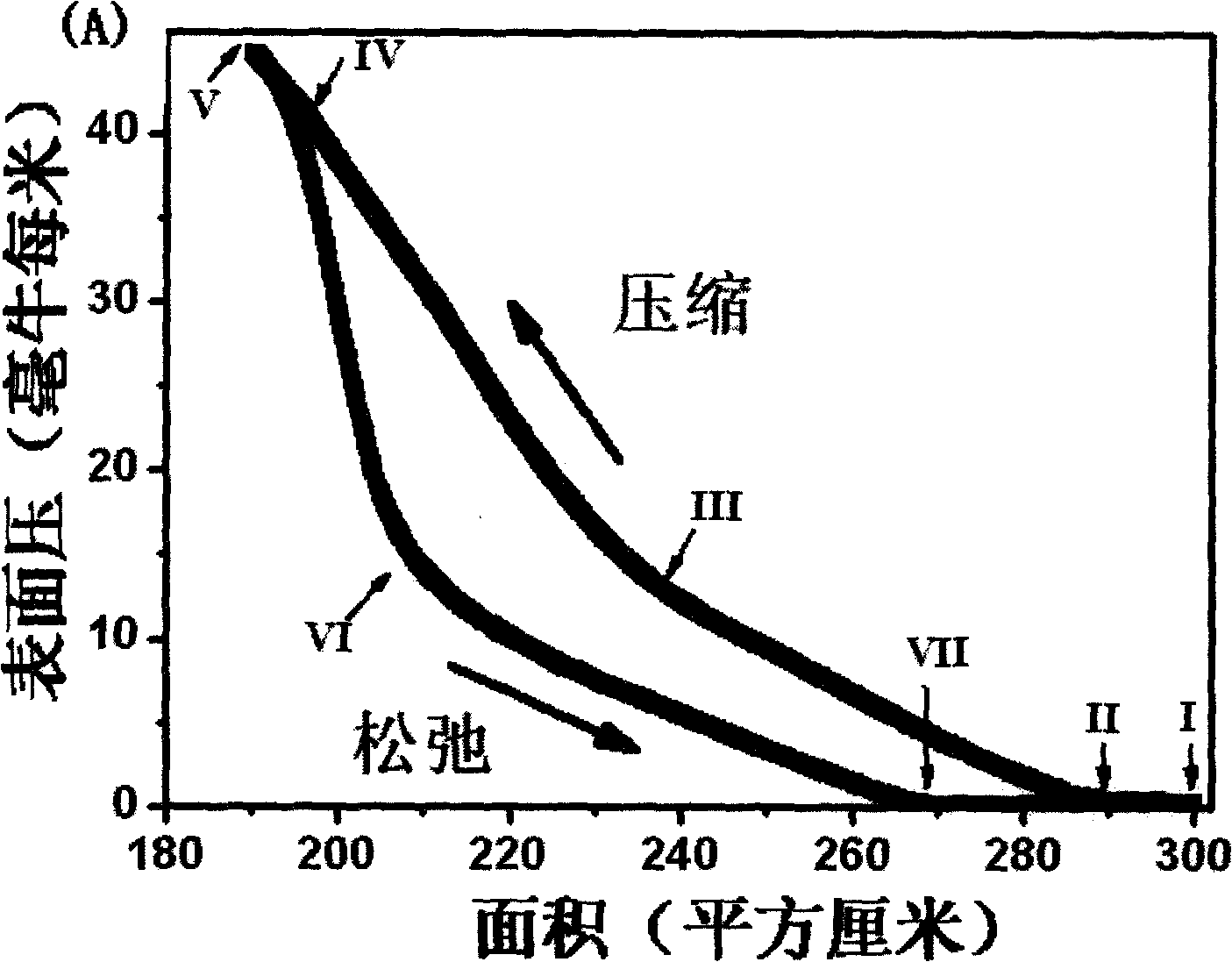

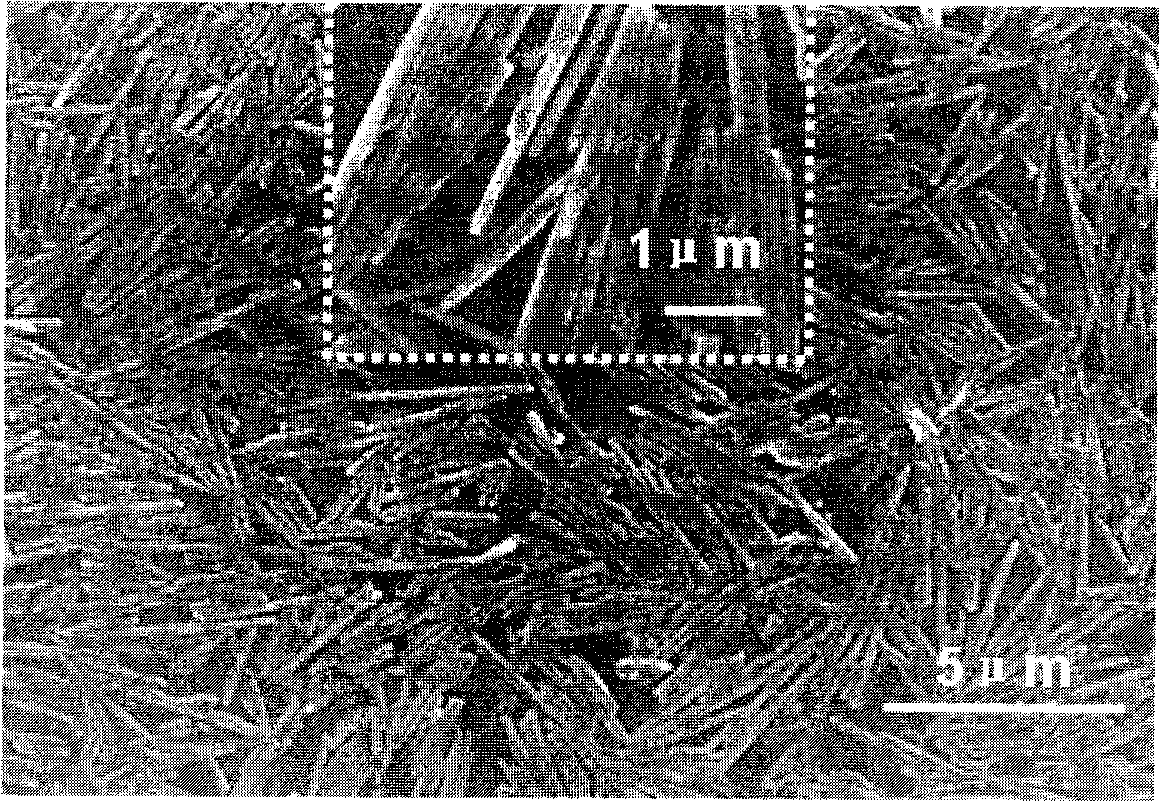

Method for realizing mono-disperse modification and optimal orientation array of hypovanadic oxide nano wire

InactiveCN101538066AGood dispersionMerit orientation is goodVanadium oxidesNano-deviceCrystal orientation

The invention relates to a method for realizing the mono-disperse modification and the optimal orientation array of a hypovanadic oxide nano wire. The method is as follows: two-step surface function treatment is carried out on a VO2 nano wire by stearic acid and hexadecyl trimethyl ammonium bromide, thus the VO2 nano wire achieves mono-disperse in chloroform and does not precipitate in case of one-month standing; the obtained VO2 nano wire LB film realizes (001) crystal orientation array and local region orientation array, and has quasi-persistent photoconductivity and typical magnetic phase transition and paramagnetic property. The method has simple process, low requirements for equipment, good reproducibility, high controllable degree, meets environmental requirements, and is applicable to the assembly, the integration and the application of sensing, photoelectric and biological novel nano devices.

Owner:武汉理工力强能源有限公司

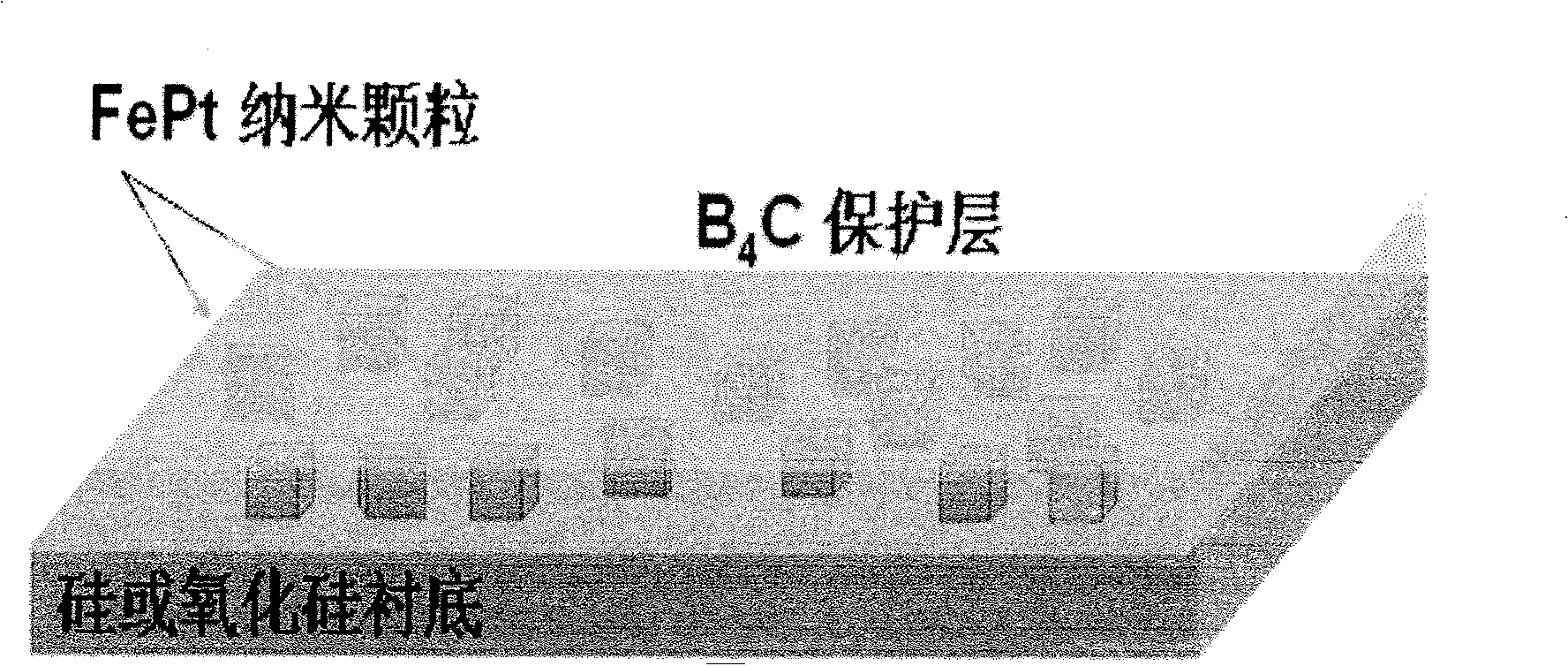

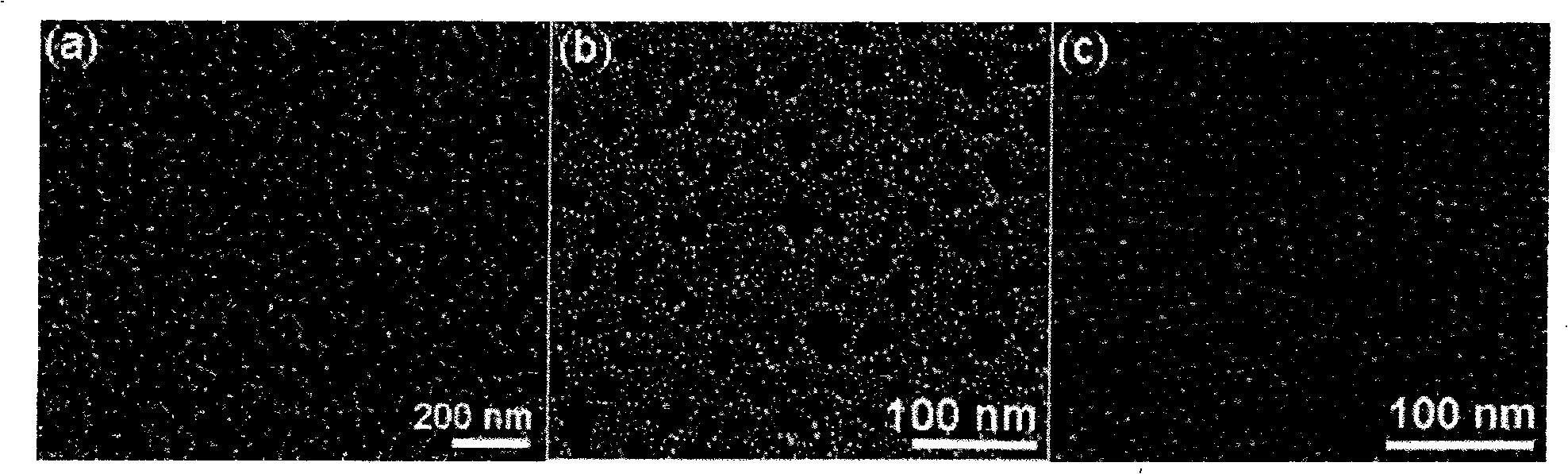

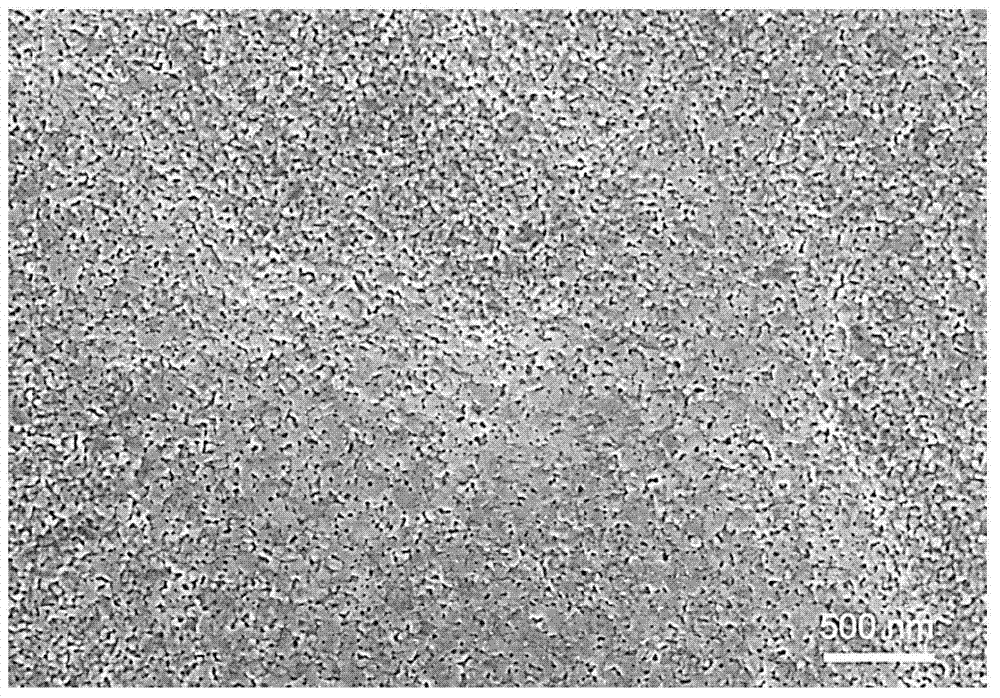

Magnetic memory material of compound structure of FePt nano-particle monolayer film and B4C and method of producing the same

InactiveCN101403098AImprove stabilityImprove coercive forceVacuum evaporation coatingSputtering coatingSputteringMagnetic memory

The invention provides a magnetic recording material compounded by iron-platinum nano-particle self-assembly monofilm and B4C and a preparation method thereof. The preparation method comprises the following steps: the mono-disperse nanometer FePt particles with adjustable grain diameters are spread on an inorganic material substrate to form a self-assembly monofilm structure, a B4C protective layer with thickness of 10-50 nanometers is sputtered on the monofilm by the magnetron sputtering technology, and the B4C protective layer covers and protects the iron-platinum nano-particle monofilm; after high temperature annealing, the complex film magnetic recording material formed by the FePt nano-particles with magnetic phase transition and stable self-assembly is formed. The material has the advantages of good stability, high coercive force, high integration, high repeatability, and the like, which can greatly improve recording density.

Owner:HUBEI UNIV

Magnetic material, and memory and sensor using same

ActiveUS7708902B2Easy to ultimately obtainLarge coercive forceNanomagnetismThermometers using electric/magnetic elementsDielectricX-ray

A magnetic material composed of ε-InxFe2-xO3 (wherein 0<x≦0.30) crystal in which In is substituted for a portion of the Fe sites of the ε-Fe2O3 crystal. The crystal exhibits an X-ray diffraction pattern similar to that of an ε-Fe2O3 crystal structure and has the same space group as that of an ε-Fe2O3. The In content imparts to the magnetic material a magnetic phase transition temperature that is lower than that of the ε-Fe2O3 and a spin reorientation temperature that is higher than that of the ε-Fe2O3. The In content can also give the magnetic material a peak temperature of the imaginary part of the complex dielectric constant that is higher than that of the ε-Fe2O3.

Owner:THE UNIV OF TOKYO +1

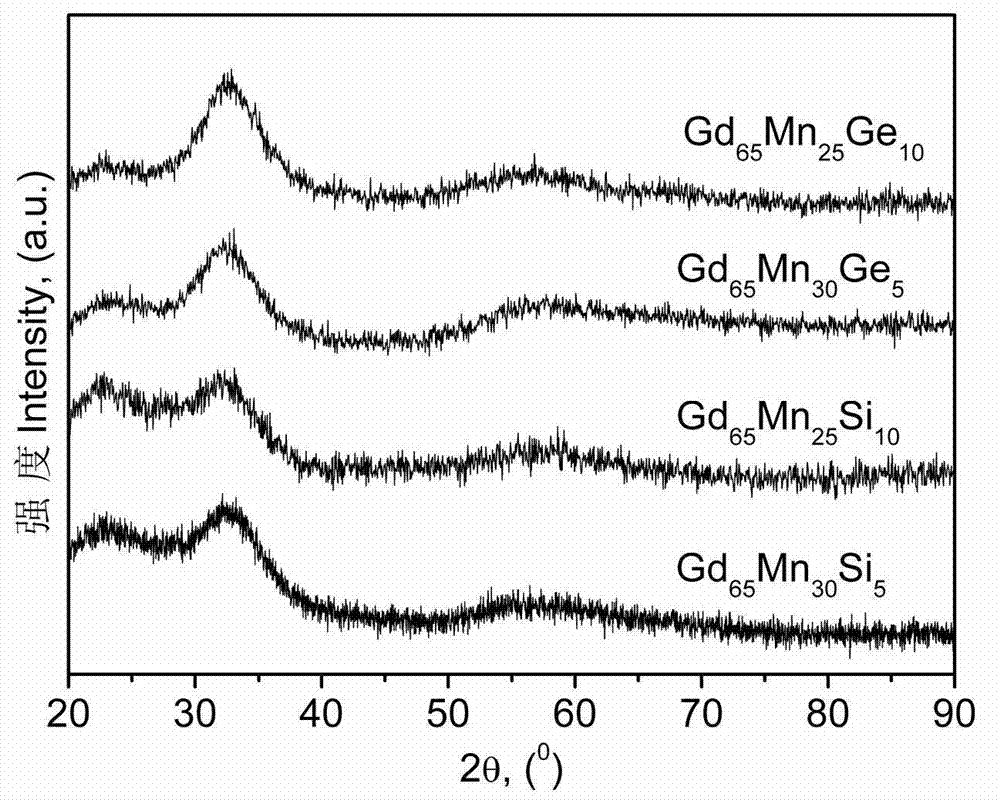

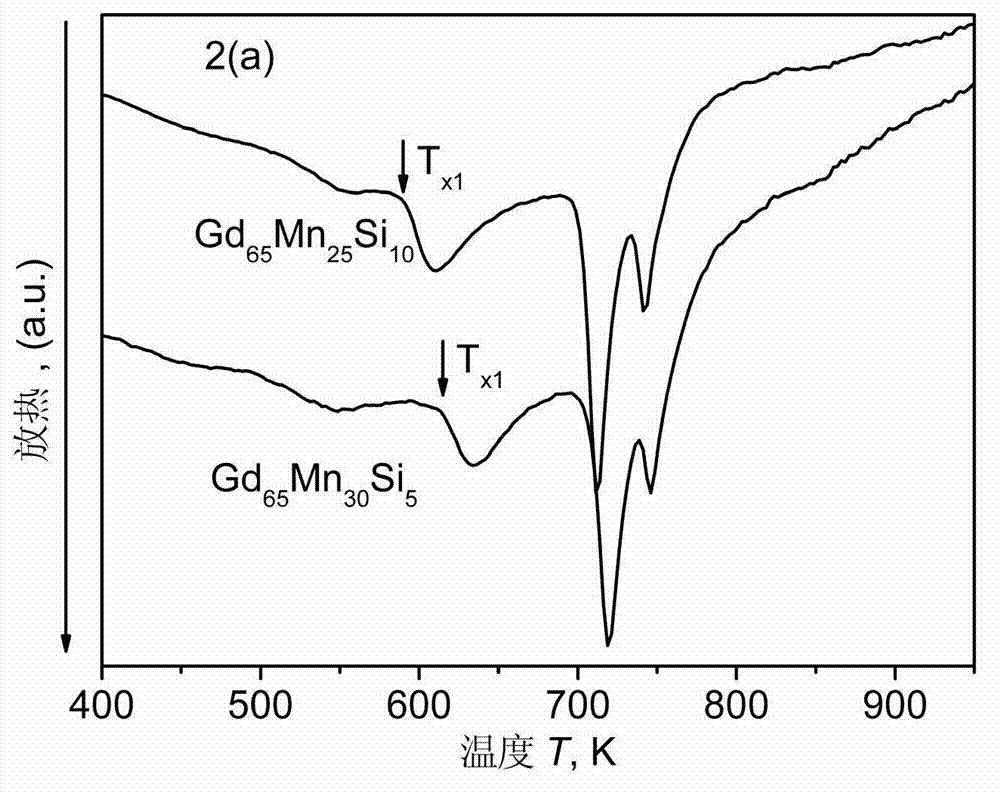

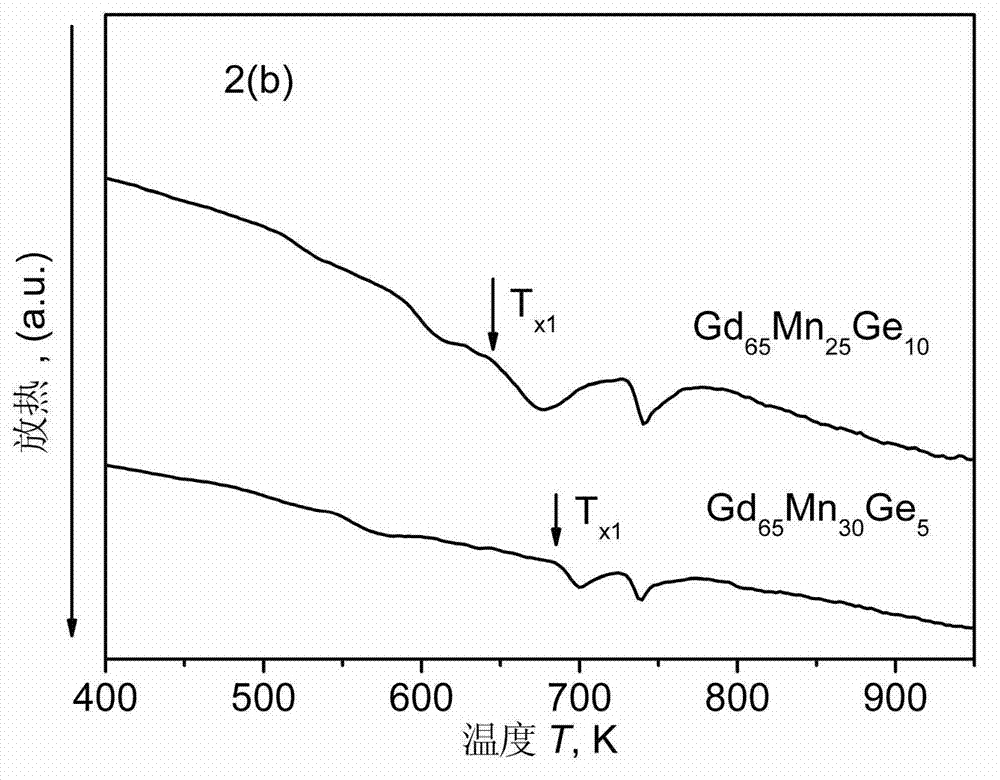

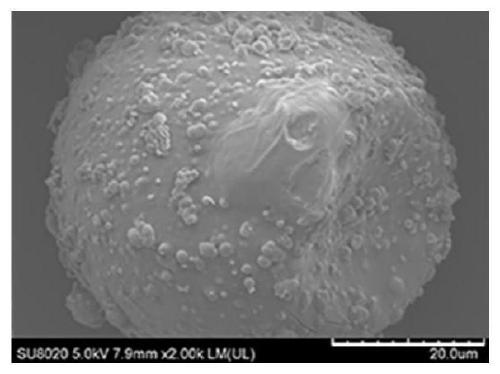

Gd-Mn-based amorphous magnetic refrigeration material and preparation method thereof

The invention relates to the field of magnetic materials and discloses a Gd-Mn-based amorphous magnetic refrigeration material and a preparation method thereof. The Gd-Mn-based amorphous magnetic refrigeration material has a chemical general formula of Gd65Mn35-xMx (x is greater than 0 and less than or equal to 10), wherein M represents Si or Ge. The preparation method comprises the following steps of 1, weighing pure elements according to a mass percentage of the elements shown in the chemical general formula and mixing, 2, repeatedly smelting the mixed elements to obtain a uniform alloy ingot, and 3, crushing the uniform alloy ingot into small blocks, and carrying out melt-spinning to obtain a stripe having the width of 1-2 millimeters and thickness of 30-50 micrometers, wherein the stripe is the Gd-Mn-based amorphous magnetic refrigeration material. The preparation method has simple processes, avoids long-term heat treatment, has a low cost and is suitable for industrial production. The Gd-Mn-based amorphous magnetic refrigeration material obtained by the preparation method can produce ferromagnetic-paramagnetic two-stage magnetic phase transition in magnetization, has a large refrigeration capacity and is suitable as a magnetic refrigeration material.

Owner:SOUTH CHINA UNIV OF TECH

Magnetic phase change microcapsule and preparation method thereof

ActiveCN110305636AWith transportationWith slow releaseHeat-exchange elementsMagnetic phaseIn situ polymerization

The invention relates to a magnetic phase change microcapsule and a preparation method thereof. The preparation method comprises the steps that an oil-in-water emulsion is prepared; a prepolymer solution is prepared; in-situ polymerization is carried out; and a magnetic additive is further added. According to the phase change microcapsule, a wall material of the phase change microcapsule can protect a core material well, and the phase change is enabled to play a better role; and magnetic materials such as Fe / Fe3O4 / CrO2 are doped into the wall material to enable the thermal conductivity of themicrocapsule to be increased and the latent heat of phase change to be increased, and the magnetic property is imparted to the magnetic phase change microcapsule, so that the functions of heat conduction, heat preservation and magnetic property are achieved.

Owner:三维印制(厦门)新材料有限公司

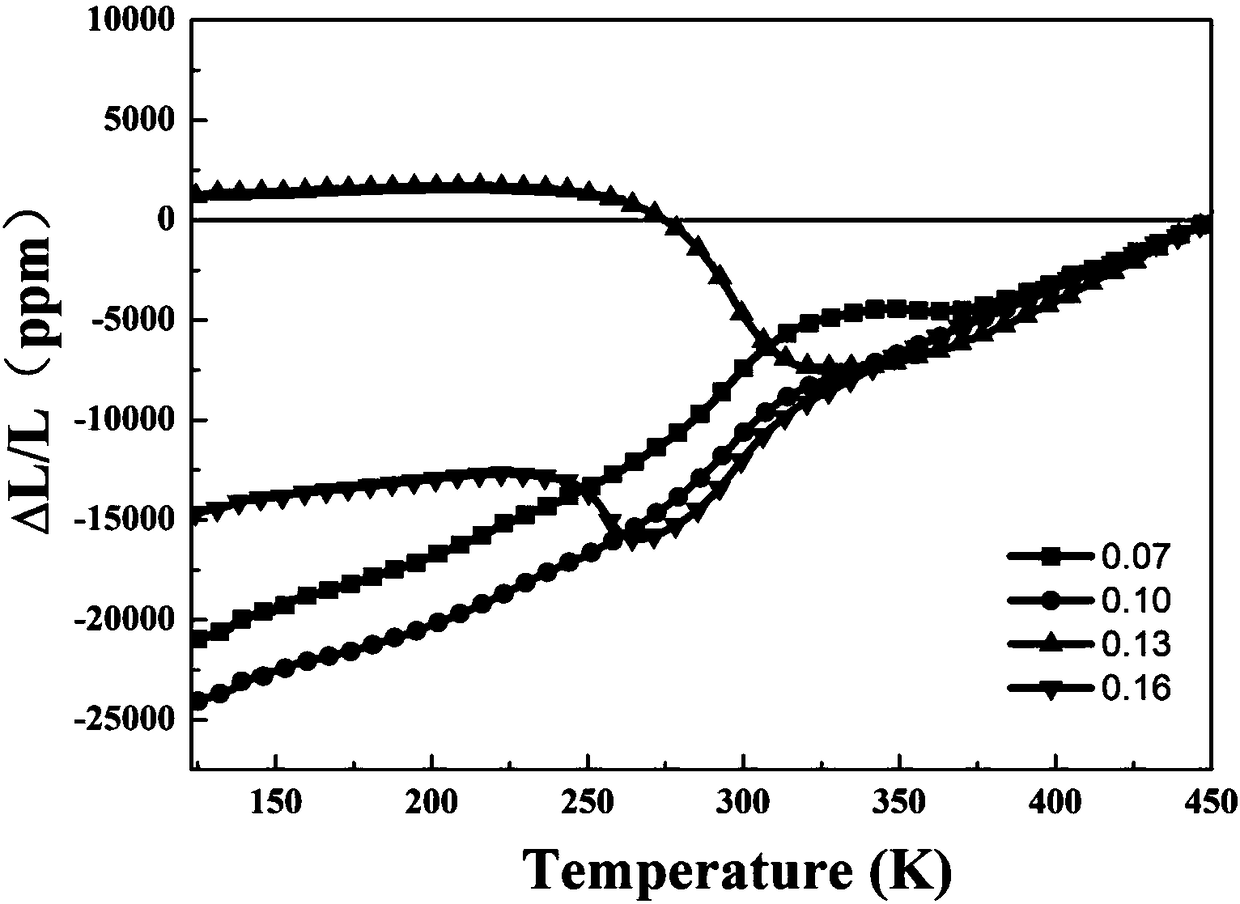

(Hf,Ta)Fe2 magnetic phase transition alloy with zero thermal expansion effect in wide temperature range and applications thereof

ActiveCN108517469ASmall coefficient of thermal expansionPractical application meetsInorganic material magnetismCompound aMagnetic phase

The invention discloses a (Hf,Ta)Fe2 magnetic phase transition alloy with a zero thermal expansion effect in a wide temperature range and applications thereof. The atomic expression of the magnetic phase transition alloy is Hf0.87Ta0.13Fe2, and the magnetic phase transition alloy has a zero thermal expansion effect in a temperature range of 15K-250K. Hf0.87Ta0.13Fe2 has an extremely low thermal expansion coefficient (alpha=1.5*10<-7>K<-1>) in a temperature range of 124-250K. In the prior art, an alloy with a zero thermal expansion effect is usually prepared by compounding a negative thermal expansion material and a positive thermal expansion material, the preparation technology is complicated, the equipment requirements are high, thus the cost is high, and the prepared alloy only has a zero thermal expansion effect in a narrow temperature range and a large thermal expansion coefficient, so the practical application of the alloy is very difficult. The provided (Hf,Ta)Fe2 magnetic phasetransition alloy has a zero thermal expansion effect in a wide temperature range and an extremely low thermal expansion coefficient and can effectively meet the use requirements therefore.

Owner:NANJING UNIV OF SCI & TECH +1

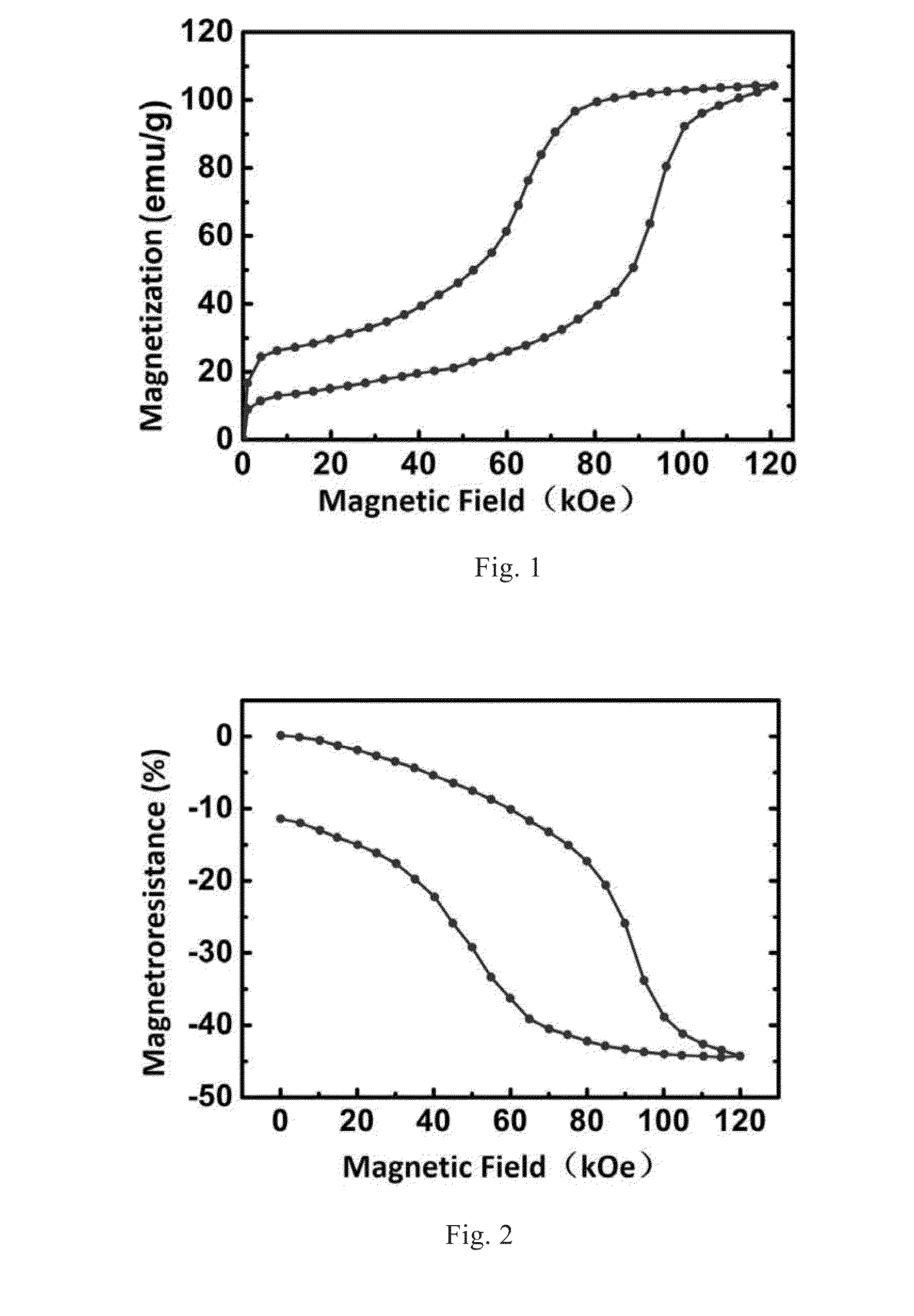

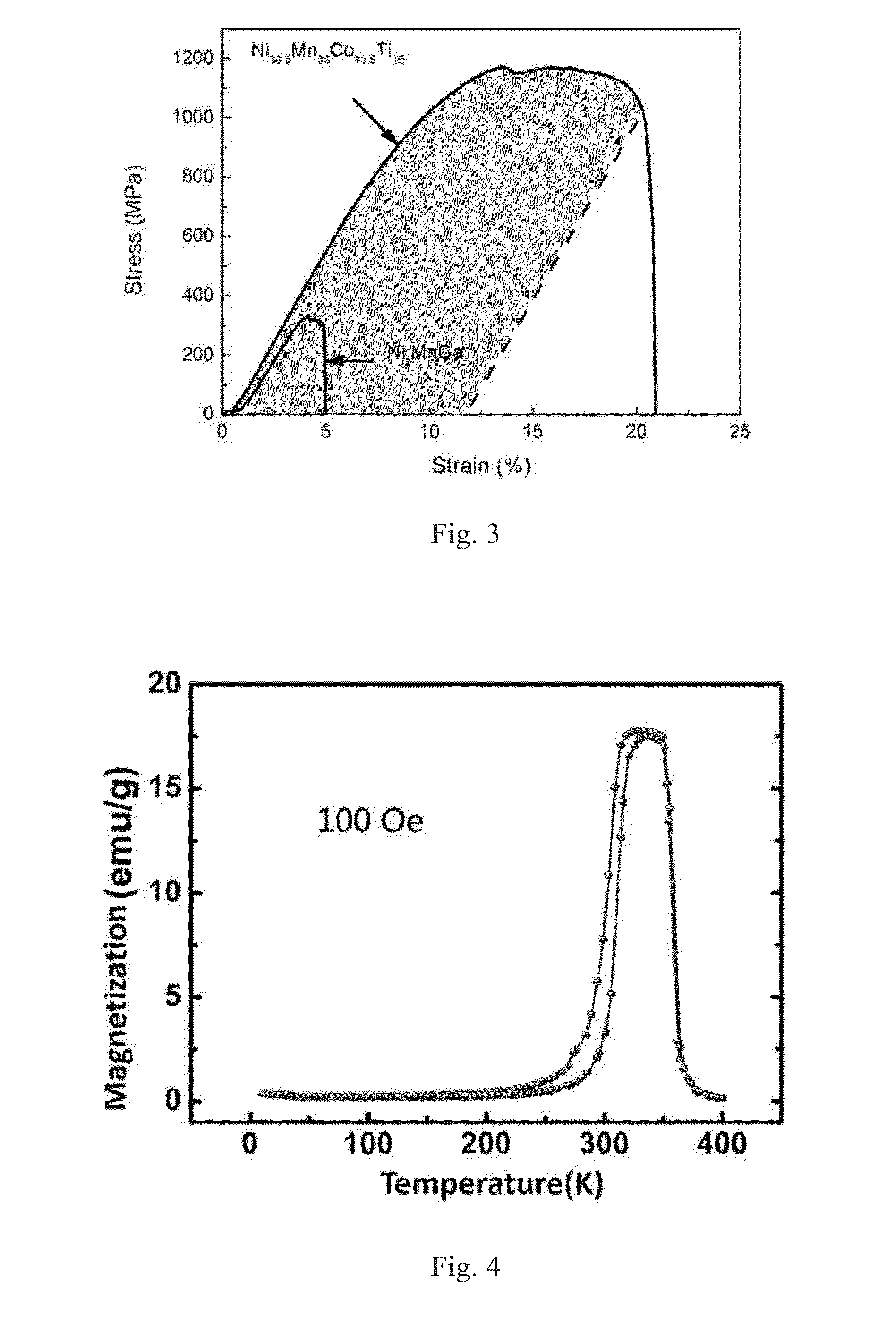

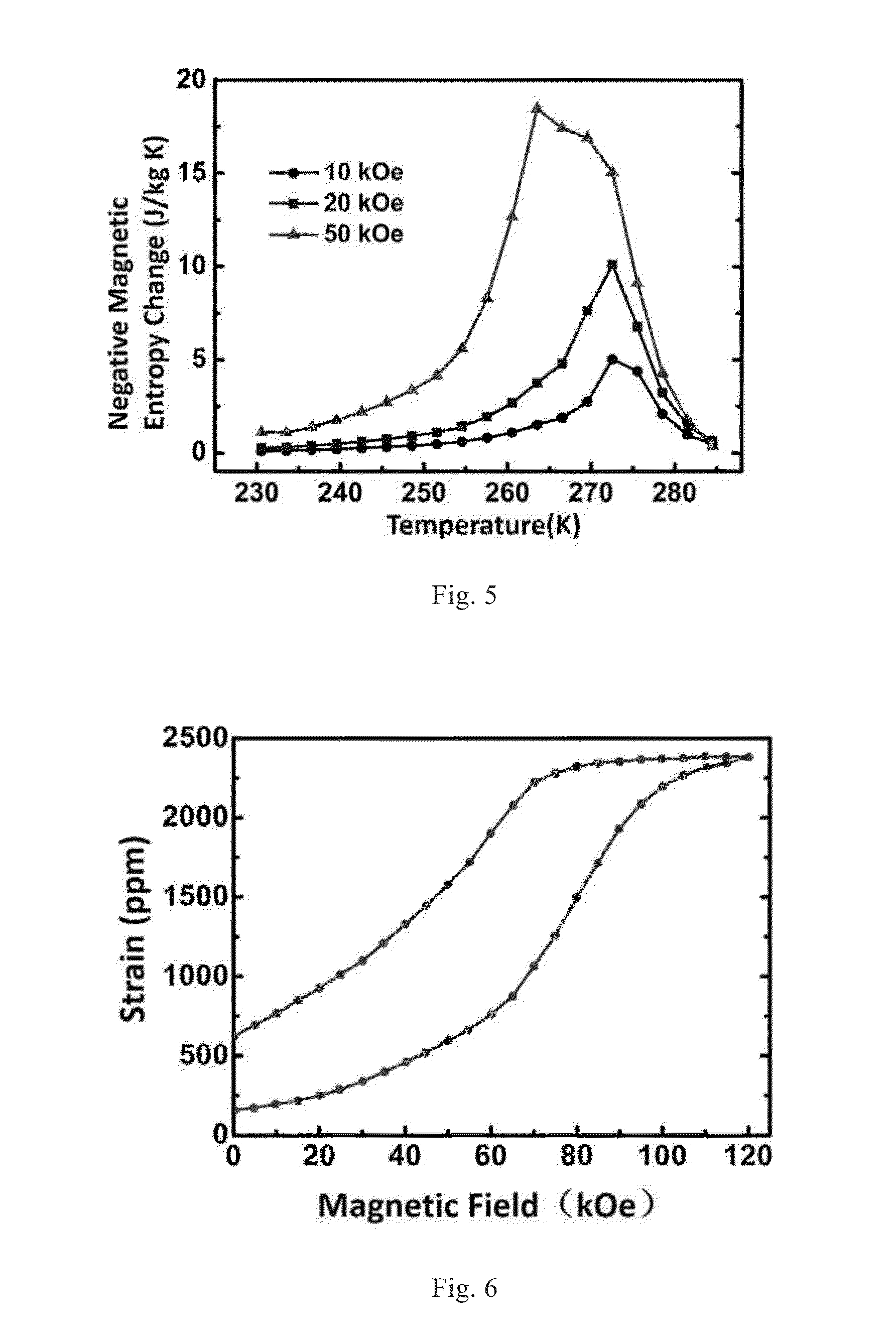

Magnetic phase-transformation material

ActiveUS20160256923A1Improve mechanical propertiesImprove toughnessMagnetic materialsMagnetic phaseMagnetic memory

A magnetic phase-transformation material with the formula Nia−mMnb−nCom+nTic is provided, wherein a+b+c=100, 20<a≦90, 5≦b<50, 5≦c≦30, 0≦m≦a, 0≦n≦b, 0<m+n<a+b, and wherein, any one or combination of a, b, c, m, n represent an atomic percentage content. The magnetic phase-transformation material has properties of high toughness, high deformation rate, ferromagnetism and magnetic field-driven martensitic phase transformation, which can be widely used in various fields including high-strength and high-toughness actuators, temperature and / or magnetic sensitive elements, magnetic refrigeration devices and equipments, magnetic heat pump devices, magnetic memories, micro-electromechanical devices and systems, and thermomagnetic power generators or transducers.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

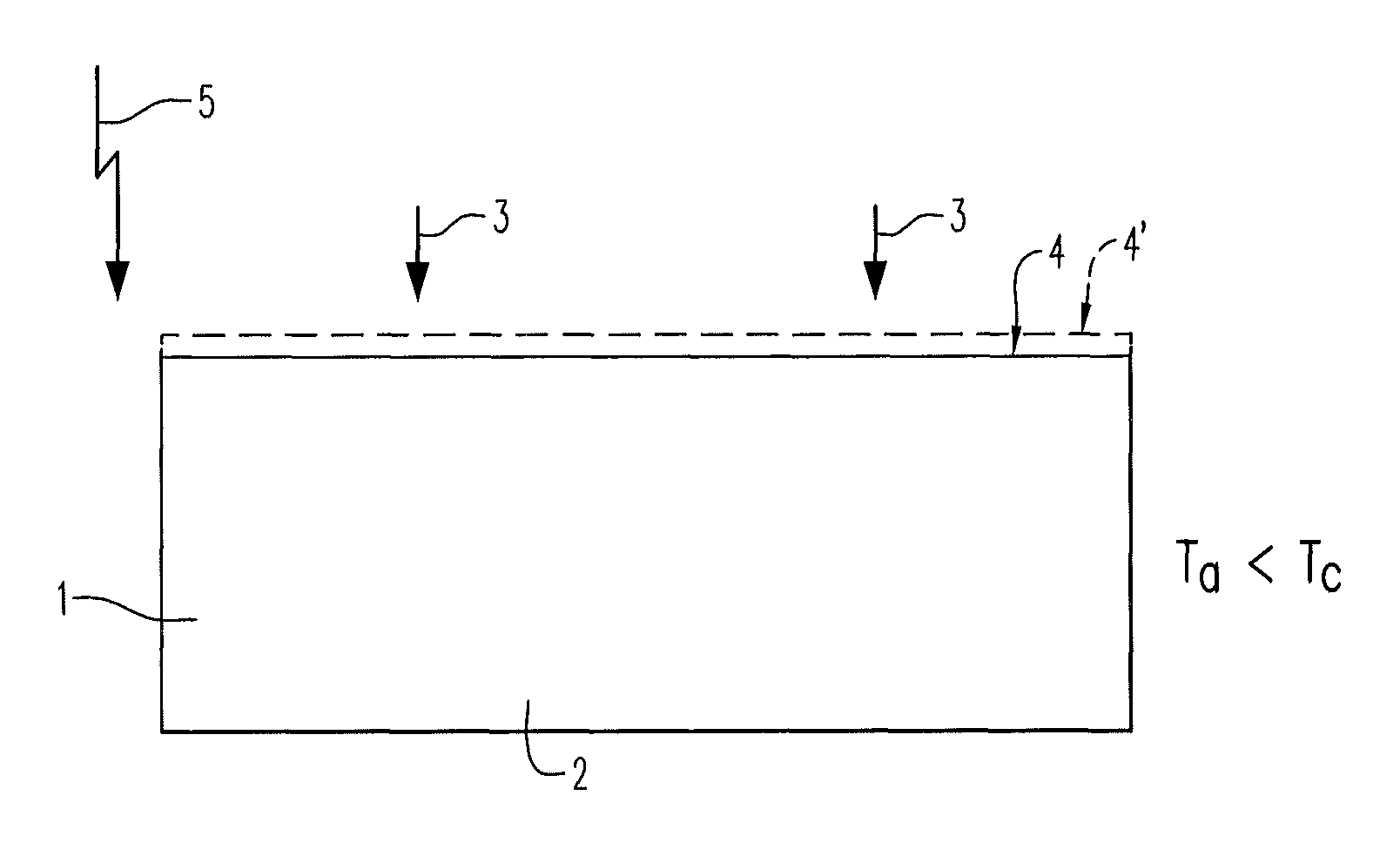

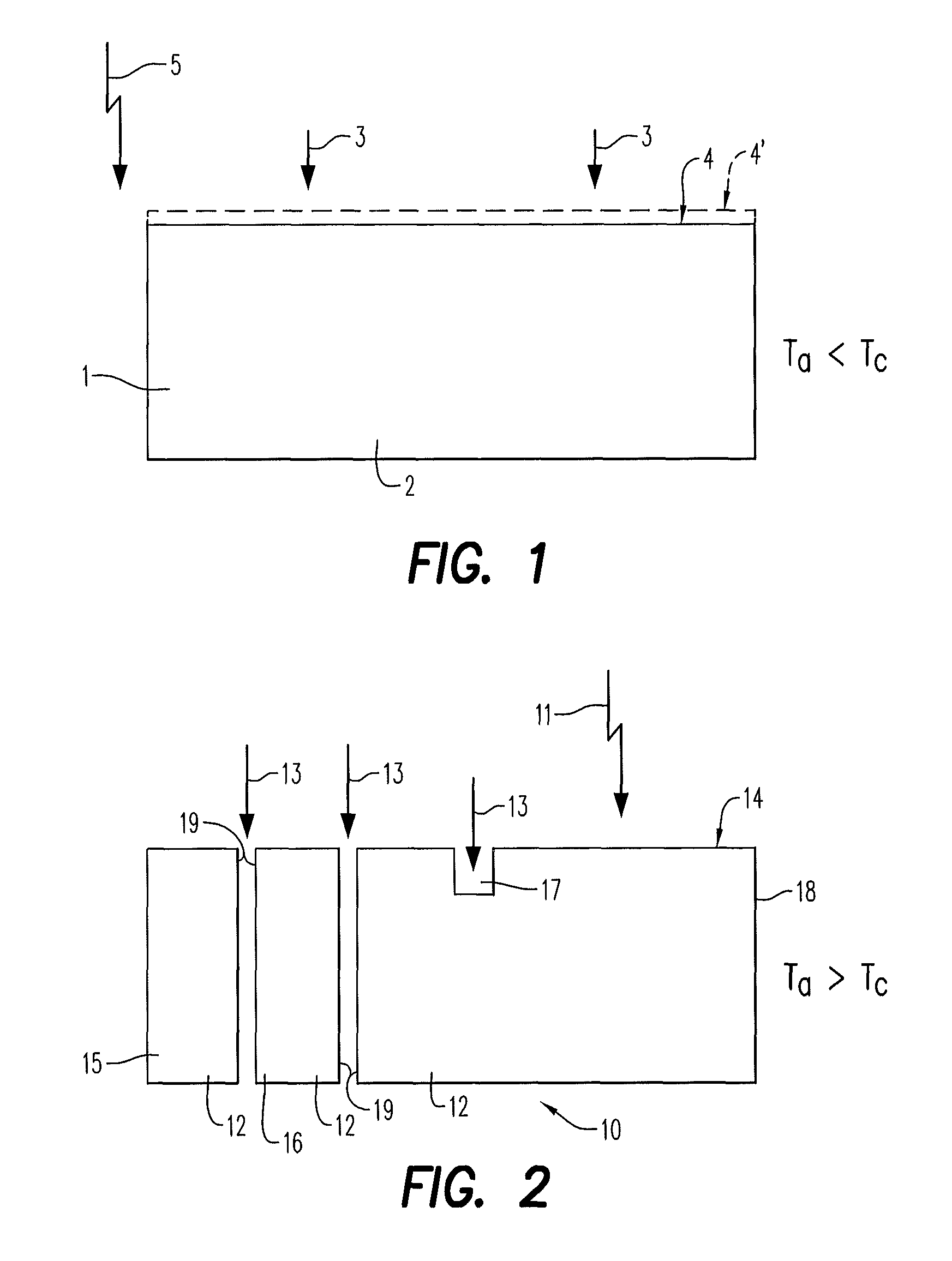

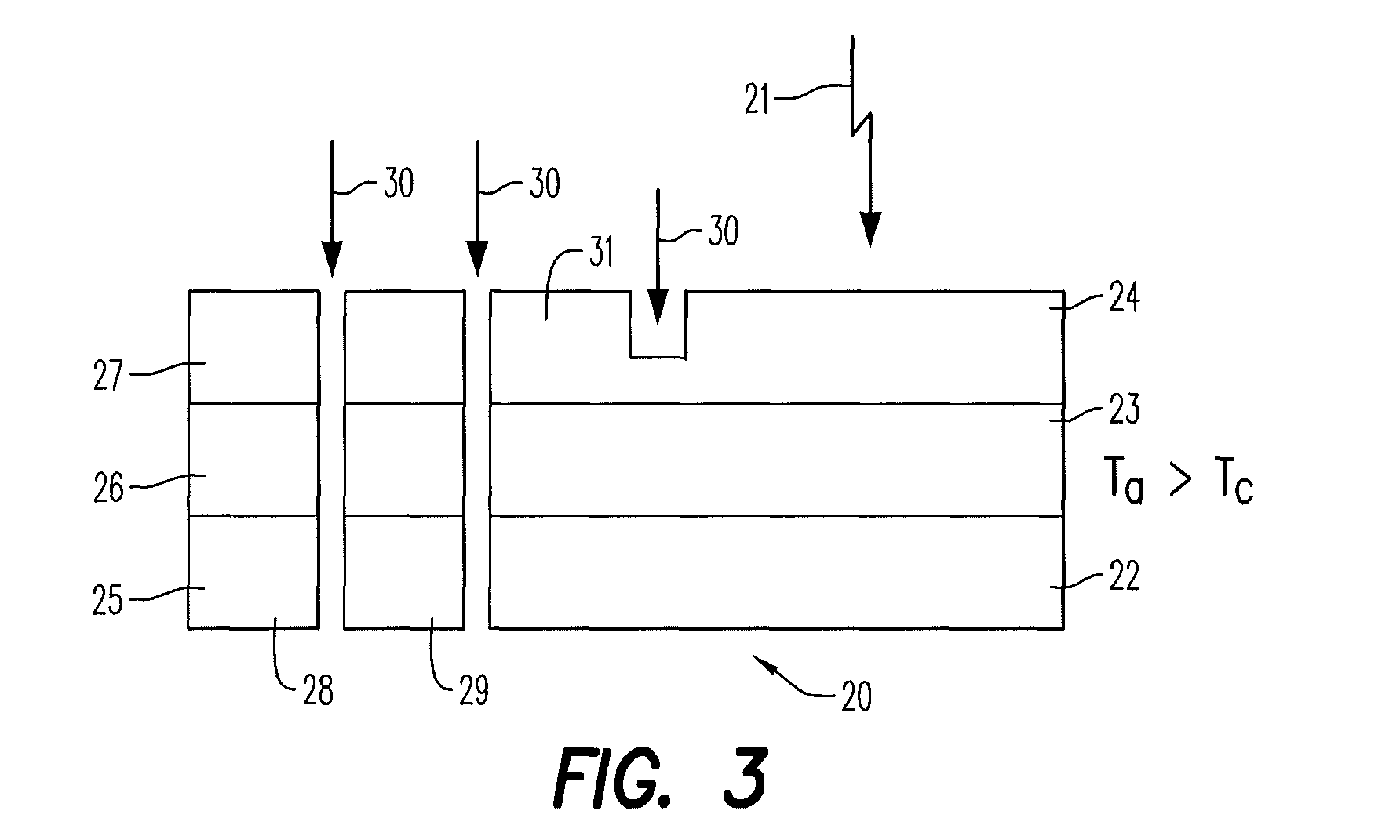

Article comprising at least one magnetocalorically active phase and method of working an article comprising at least one magnetocalorically active phase

ActiveUS8938872B2Cost-effective and reliableCost-effectiveSynthetic resin layered productsInorganic material magnetismActive phaseEngineering

A method of working an article includes providing an article containing at least one magnetocalorically active phase having a magnetic phase transition temperature Tc and removing at least one portion of the article while the article remains at a temperature above the magnetic phase transition temperature Tc or below the magnetic phase transition temperature Tc.

Owner:VACUUMSCHMELZE GMBH & CO KG

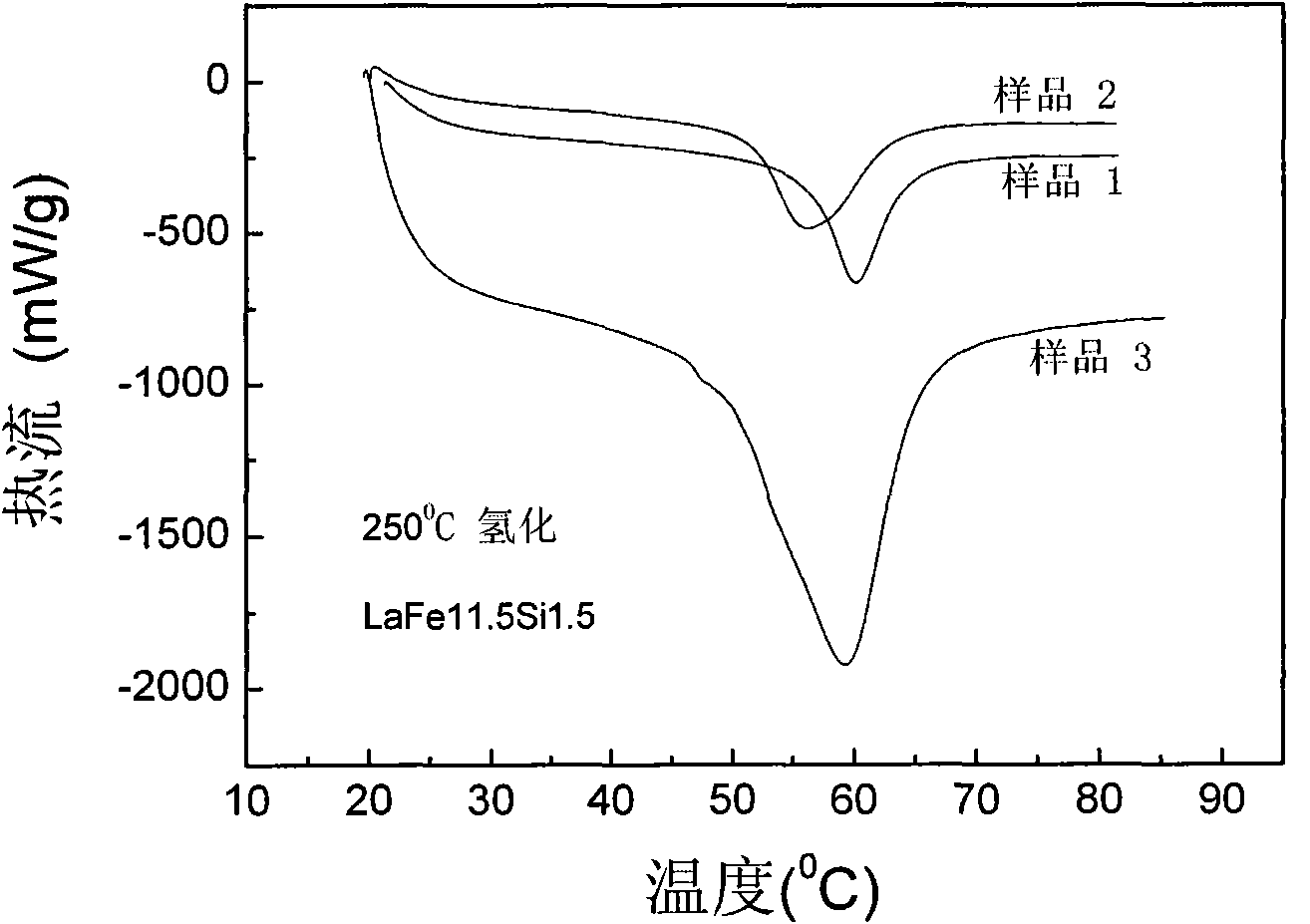

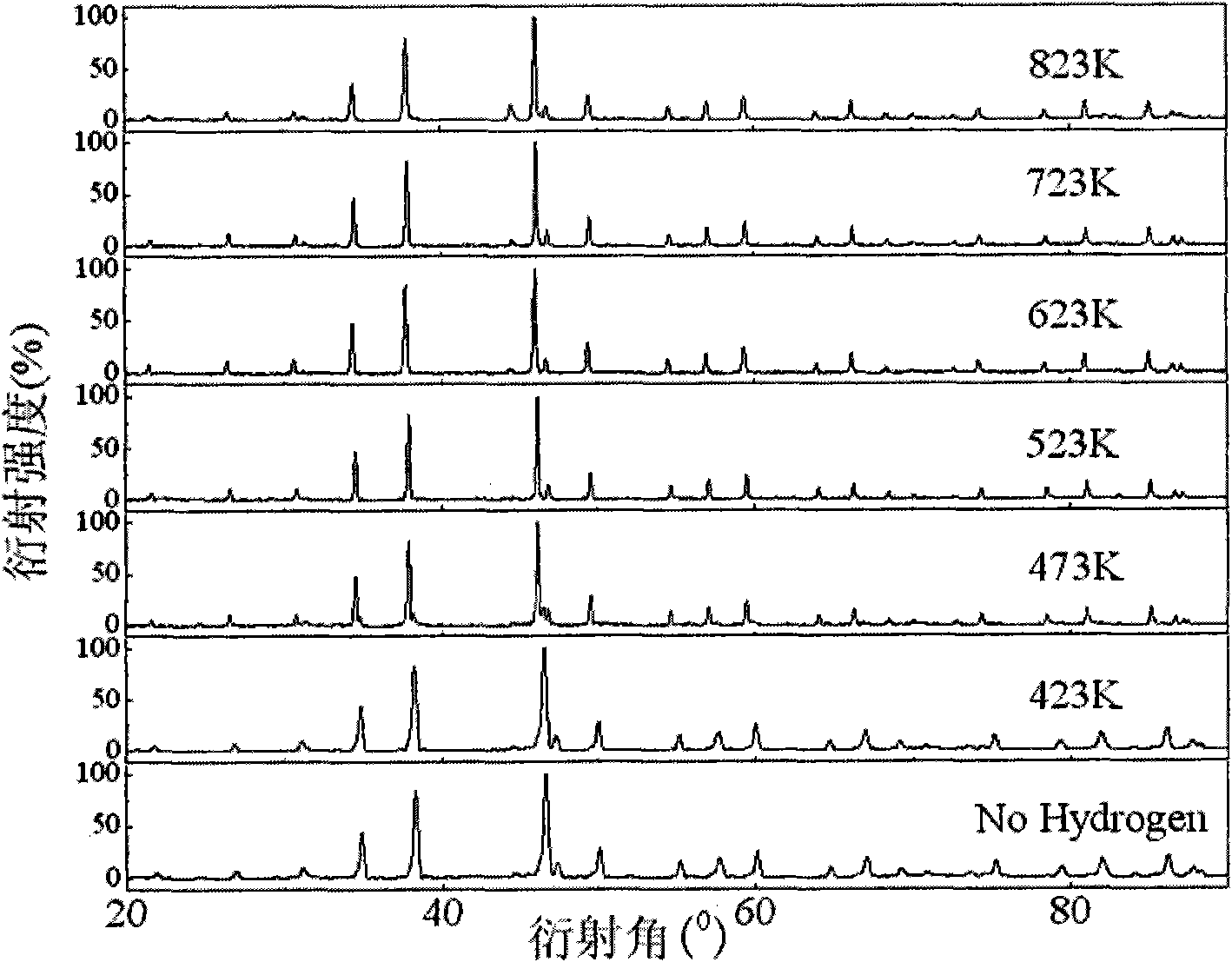

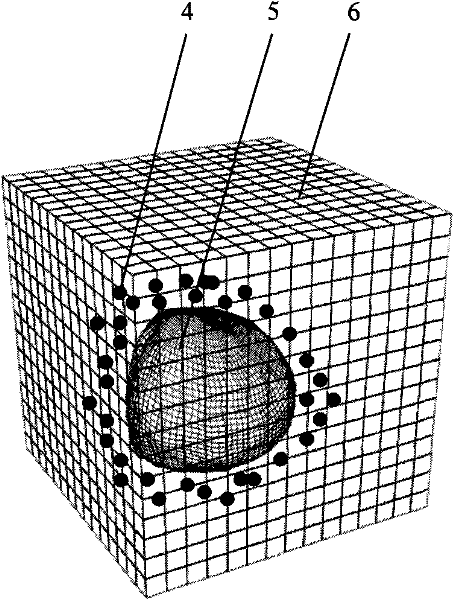

Method for even hydrogenation of NaZn13 structured rare earth-iron cobalt silicon material

InactiveCN101817078AShort hydrogenation timeHomogeneous hydrogenationInorganic material magnetismRare earthCrystal structure

The invention discloses a method for the even hydrogenation of NaZn13 structured rare earth-iron cobalt silicon material, which comprises the step: putting rare earth-iron cobalt silicon compound having NaZn13 structure in a hydrogenation furnace for hydrogenation thermal treatment for 2 to 4 hours at the temperature ranging from 400 to 600 DEG C. The method can also comprise the step of putting the rare earth-iron cobalt silicon compound having NaZn13 structure in the hydrogenation furnace for activation once or many times and then for hydrogenation thermal treatment at the temperature ranging from 80 to 600 DEG C for 2 to 4 hours so as to result in the finished product. The rare earth-iron cobalt silicon hybride obtained after hydrogenation according to the preparation method has a crystal structure taking the NaZn13 structure as main phase, which is identical to the crystal structure of original rare earth-iron cobalt silicon compound. The method has the advantages that: the hydrogenation time is short, the rare earth-iron cobalt silicon compound can be certainly subject to even hydrogenation, and all the hybrides of the resultant rare earth-iron cobalt silicon compound have only one magnetic phase transition temperature. Thus, outstanding refrigerating effect of the hybrides of the rare earth-iron cobalt silicon compound during the use thereof in a magnetic refrigerator can be ensured.

Owner:UNIV OF SCI & TECH BEIJING

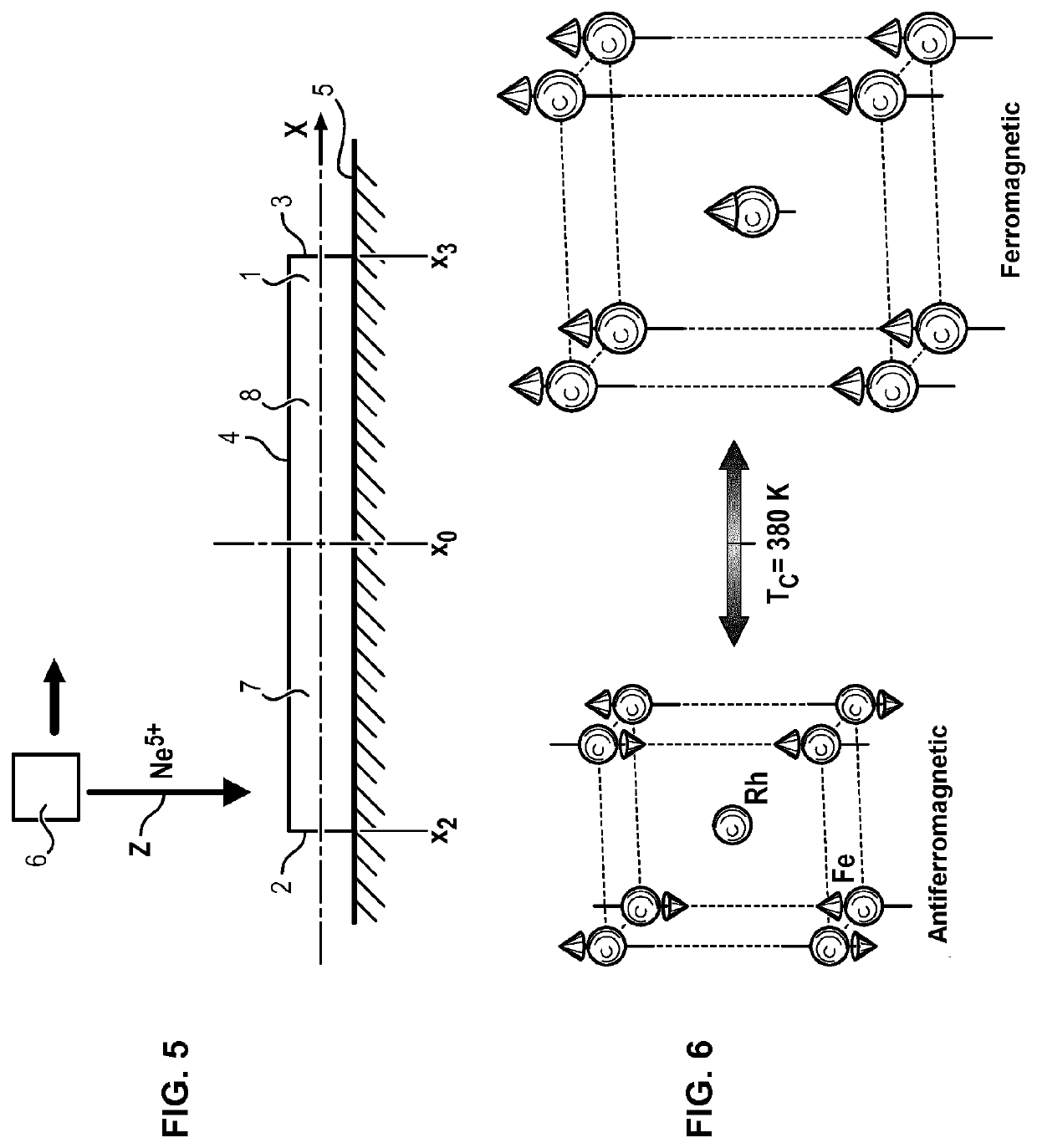

Method For Obtaining A Material With Giant Magnetocaloric Effect By Ion Irradiation

InactiveUS20200126697A1Increase cooling powerInorganic material magnetismMachines using electric/magnetic effectsParticle physicsIrradiation

The present invention concerns, in particular, a method for obtaining a product with magnetocaloric effect from a single piece of material having a magnetic phase transition, the method comprising irradiation of at least one part of the material with ions, the irradiation being carried out with a suitable flux so that, after the irradiation, the material has various magnetic phase transition temperatures in the various parts of the material.

Owner:CENT NAT DE LA RECHERCHE SCI +1

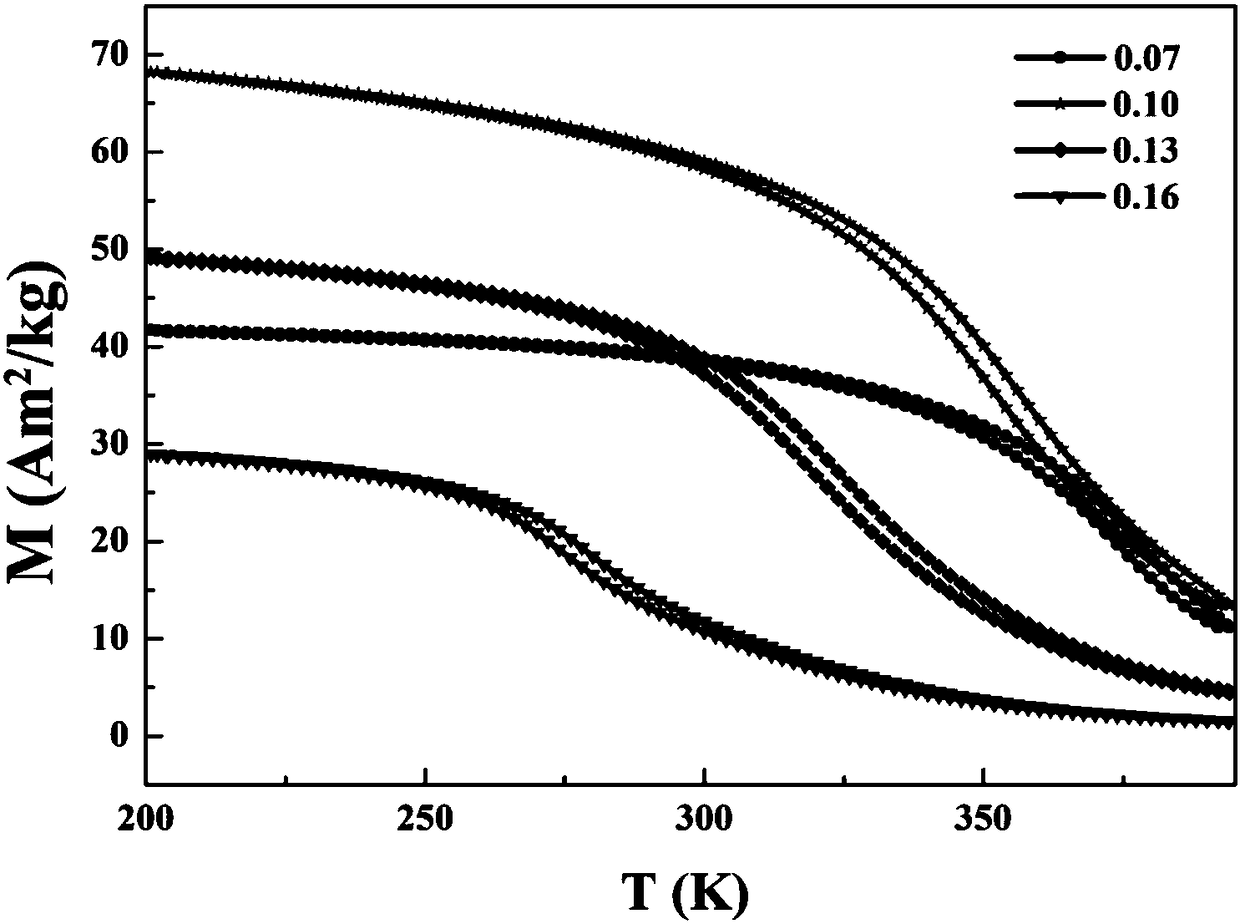

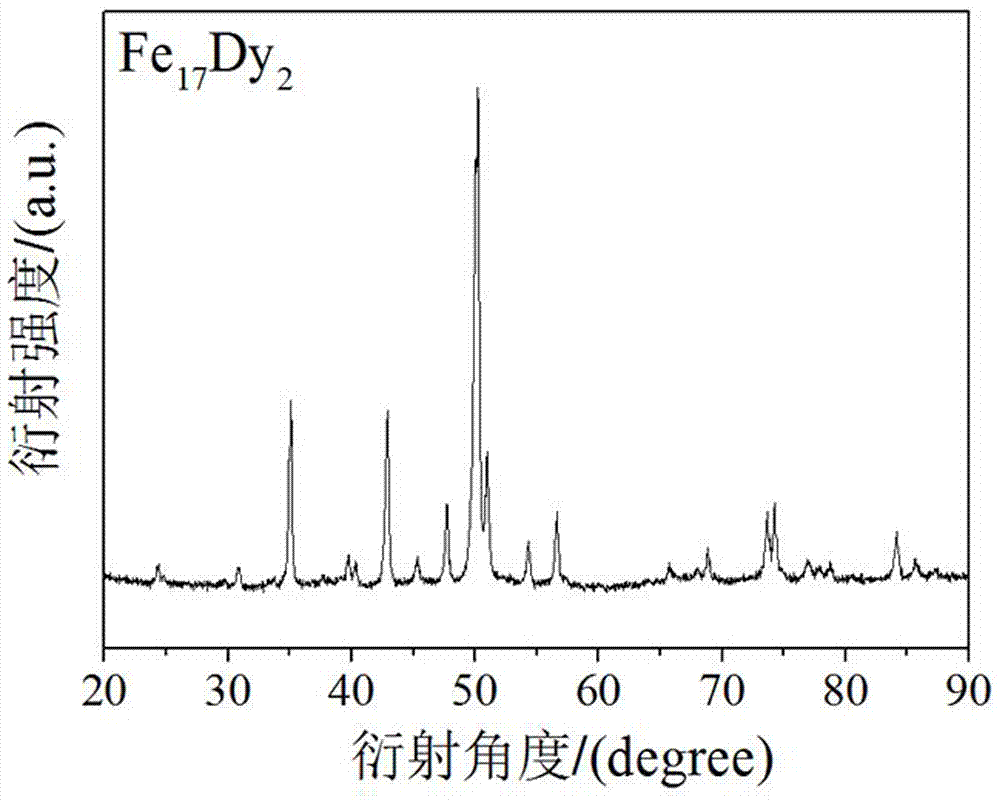

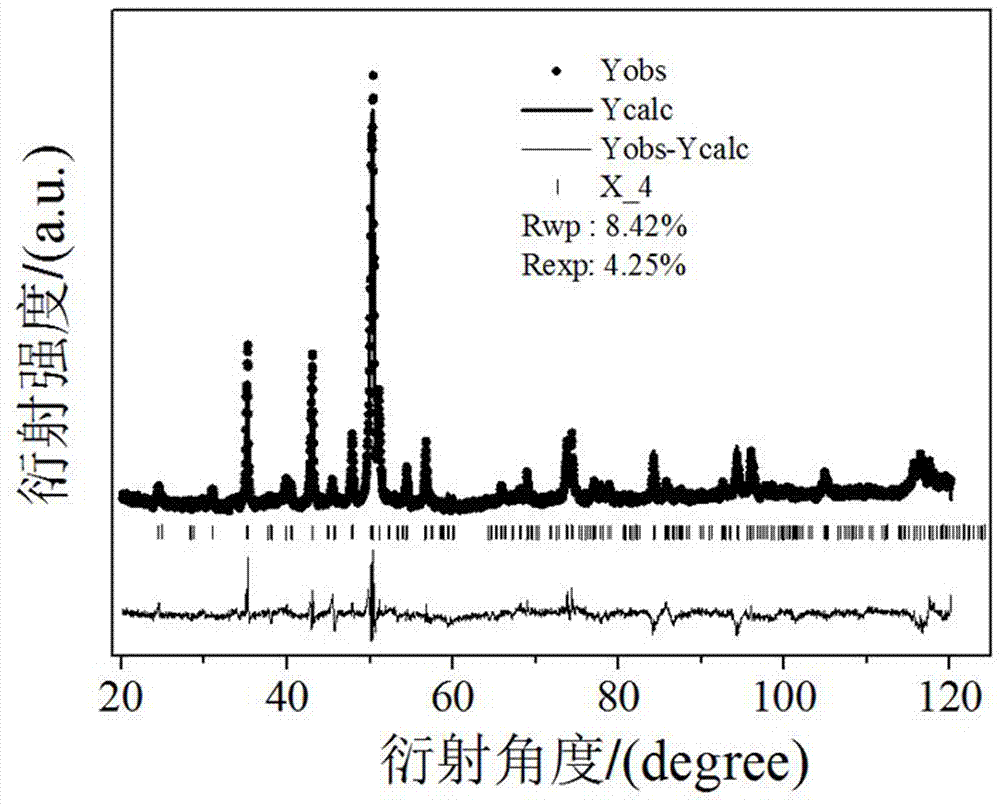

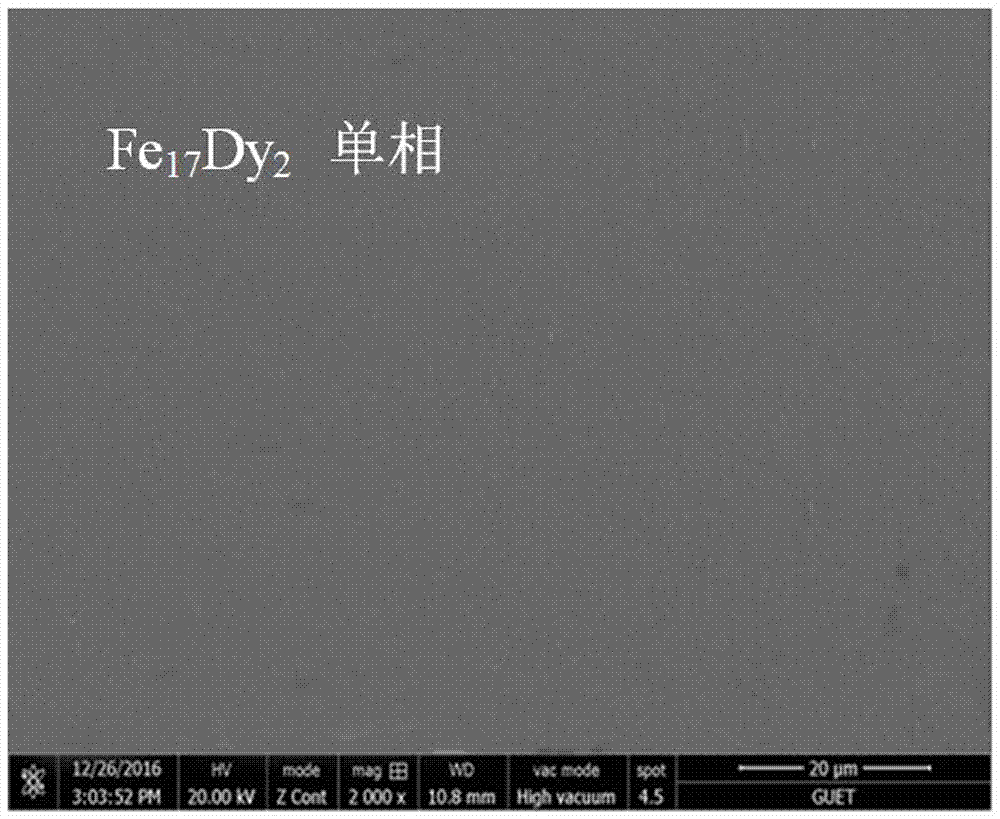

Ferro-magnetic Fe-Dy hydrogen storage material and preparation method thereof

ActiveCN107574363ALower working temperatureHigh hydrogen storage capacityWorking temperatureRare earth

The invention discloses a ferro-magnetic Fe-Dy hydrogen storage material. The Fe-Dy hydrogen storage material with the chemical formula being Fe17Dy2 is prepared from Fe and rare earth Dy serving as raw materials through electric arc melting and heat treatment, the ferro-magnetic material has a Th2Ni17 type hexagonal crystal structure, the saturated magnetization intensity is 62 to 100 Am<2> / kg, the Curie temperature is 90 to 100 DEG C, and the hydrogen storage performance is 0.1 to 0.2 percent by weight. The preparation method comprises eh following steps: 1) weighting Fe and Dy according tothe chemical formula and smelting to prepare Fe17Dy2 alloy; and 2) performing heat treatment on the prepared alloy to prepare the Fe-Dy hydrogen storage material. When serving as a hydrogen storage material, the ferro-magnetic Fe-Dy hydrogen storage material has magnetic phase transition characteristic, the hydrogen storage quantity is 0.11 to 0.14 percent by weight when the temperature is higherthan the Curie temperature, and the hydrogen storage quantity at the Curie temperature is increased to 0.18 to 0.2 percent by weight. The Curie temperature of the hydrogen storage material is low, andthe work temperature is near the Curie temperature.

Owner:GUILIN UNIV OF ELECTRONIC TECH

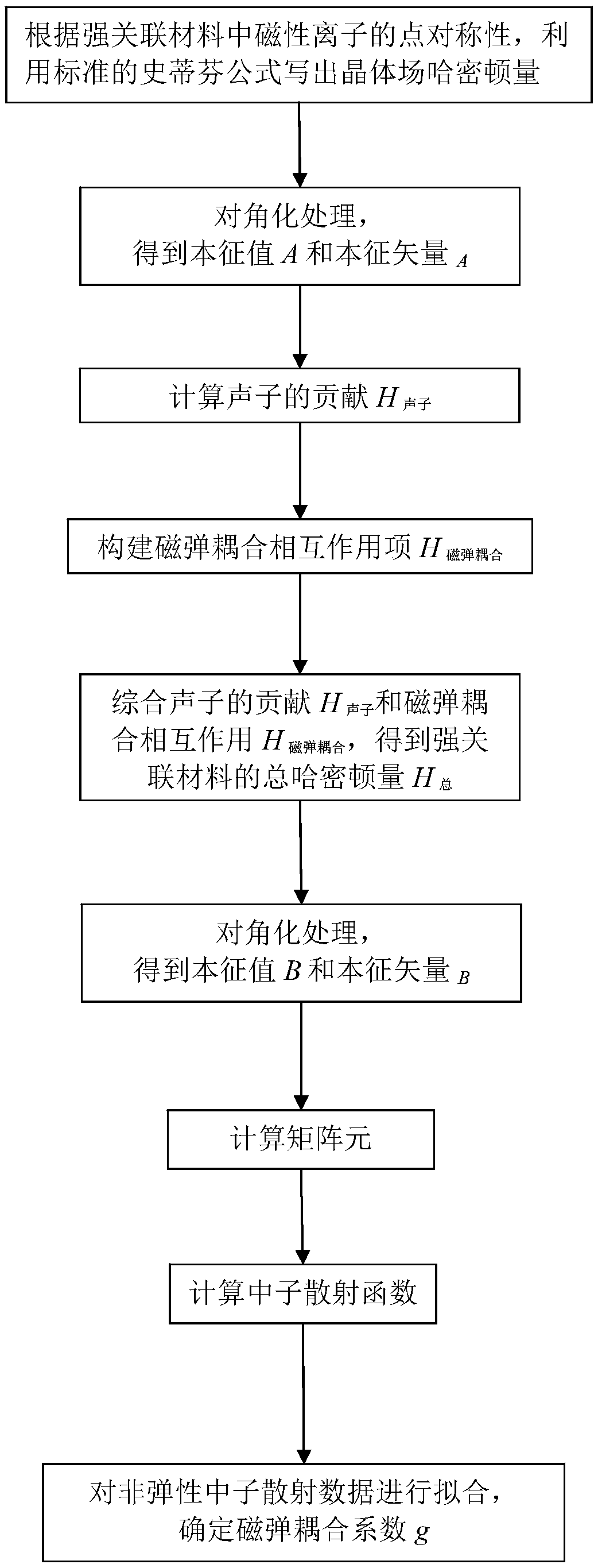

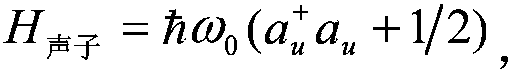

Inelastic neutron scattering data analysis method of strong correlation material

ActiveCN111324855AMaterial analysis using wave/particle radiationComplex mathematical operationsMagnetoelastic couplingScattering function

The invention provides an inelastic neutron scattering data analysis method for a strong correlation material, and the method comprises the following steps: (a) diagonalizing the Hamiltonian quantityof a conventional crystal field, and calculating an eigenvalue A and an eigenvector A; (b) diagonalizing the total Hamiltonian quantity by integrating phonon contribution and magnetoelastic coupling interaction factors, and calculating an eigenvalue B and an eigenvector B; (c) calculating a matrix element according to the eigenvector B obtained in the step (b); and (d) calculating a neutron scattering function according to the eigenvalue B obtained in the step (b) and the matrix element obtained in the step (c), and fitting neutron scattering experimental data to obtain a magnetoelastic coupling coefficient g. The method is suitable for fitting the non-elastic neutron scattering data observed above the magnetic phase transition temperature of the strongly correlated material, and can be used for analyzing the crystal field excitation and phonon coupling phenomenon in the material.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

A kind of mncoge-based magnetic material with giant barocaloric effect and its preparation method and application

ActiveCN104946954BMagnetic structure coupling temperature adjustableReduce manufacturing costMagnetic materialsThermoelectric devicesCondensed matter physicsMaterials science

The invention provides a MnCoGe-based magnetic material with giant pressure thermal effect and its preparation method and use. The general chemical formula of this magnetic material is: MnCoGe1‑xInx, where 0<x≤0.03, and it has a Ni2In type hexagonal structure. The material has the characteristics of coupling the Martens structure phase transition and the magnetic phase transition, and the coupling occurs near room temperature. The material exhibits a reverse pressure heating effect under pressure, and the entropy change amplitude near room temperature under the pressure of 3kbar is at least 50Jkg‑1K‑1. As the In content changes, the magnetic structure coupling temperature Tmstru of the material is adjustable in a wide temperature range near room temperature, so that the giant pressure heating effect appears in a wide temperature range near room temperature. The preparation method of the magnetic material is simple, the raw materials are green and environmentally friendly, and it has the advantages of high efficiency and energy saving.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

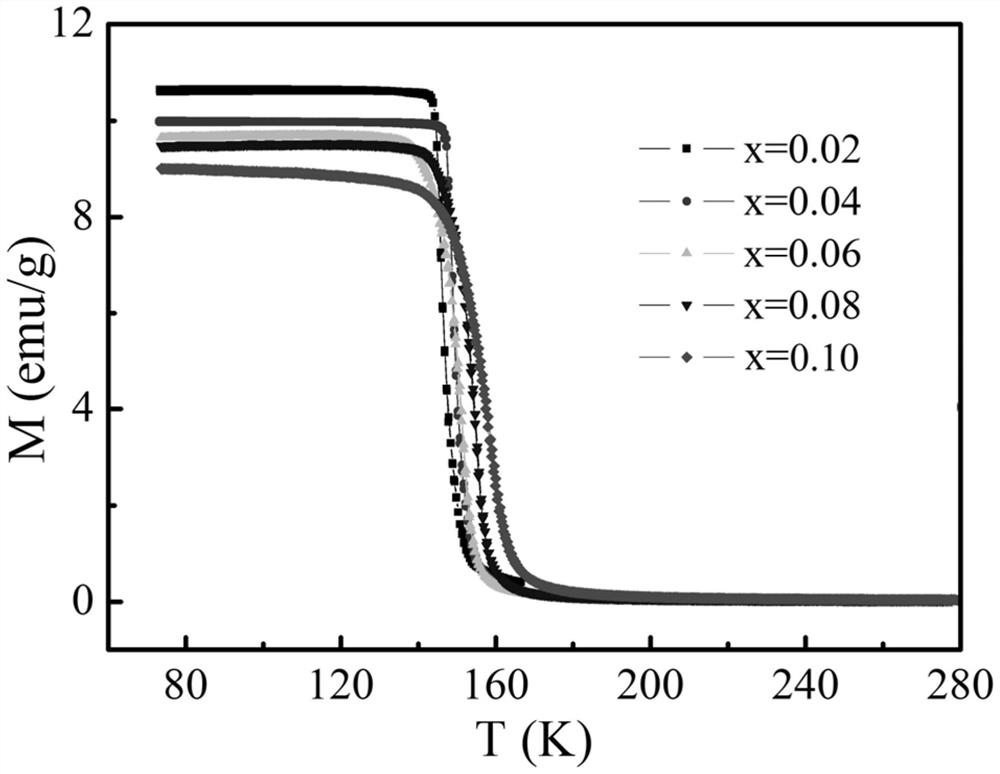

Cobalt-manganese-tin-based alloy material and preparation method thereof

The invention belongs to the field of magnetic refrigeration, and specifically relates to a cobalt-manganese-tin-based alloy material and a preparation method thereof. The molecular formula of the cobalt-manganese-tin-based alloy material is Co 1‑x mn 1+x Sn, where x=0.02‑0.10, its structure is hexagonal. The alloy material overcomes the shortcomings of the small magnetic entropy change half-peak width and large thermal hysteresis of the first-order magnetic phase transition. Its phase transition behavior is a second-order magnetic phase transition, which has a large magnetocaloric effect and avoids Large thermal hysteresis effect. Cobalt-manganese-tin alloy has low cost and broad application prospects, and can be applied to many important fields of the national economy involving refrigeration and cryogenic technology.

Owner:天津市京建建筑防水工程有限公司 +1

(hf,ta)fe with zero thermal expansion effect in wide temperature range 2 Magnetic Phase Change Alloys and Their Applications

ActiveCN108517469BSmall coefficient of thermal expansionPractical application meetsInorganic material magnetismThermal dilatationMagnetic phase

The invention discloses a (Hf,Ta)Fe2 magnetic phase transition alloy with a zero thermal expansion effect in a wide temperature range and applications thereof. The atomic expression of the magnetic phase transition alloy is Hf0.87Ta0.13Fe2, and the magnetic phase transition alloy has a zero thermal expansion effect in a temperature range of 15K-250K. Hf0.87Ta0.13Fe2 has an extremely low thermal expansion coefficient (alpha=1.5*10<-7>K<-1>) in a temperature range of 124-250K. In the prior art, an alloy with a zero thermal expansion effect is usually prepared by compounding a negative thermal expansion material and a positive thermal expansion material, the preparation technology is complicated, the equipment requirements are high, thus the cost is high, and the prepared alloy only has a zero thermal expansion effect in a narrow temperature range and a large thermal expansion coefficient, so the practical application of the alloy is very difficult. The provided (Hf,Ta)Fe2 magnetic phasetransition alloy has a zero thermal expansion effect in a wide temperature range and an extremely low thermal expansion coefficient and can effectively meet the use requirements therefore.

Owner:NANJING UNIV OF SCI & TECH +1

Magnetic phase-change microcapsule for performing thermal protection on normal structure in thermal physical therapy

InactiveCN101836915BGood biocompatibilityLow toxicityUltrasound therapySurgical instrument detailsMean diameterMagnetic phase

The invention discloses a magnetic phase-change microcapsule for performing thermal protection on a normal structure in thermal physical therapy. The magnetic phase-change microcapsule is a spherical microcapsule which is composed of a phase-change material (1), magnetic particles (2) and a liposome shell (3), and the mean diameter thereof is 1nm-1mm. In the invention, the phase-change material (1) is solid-liquid or / and liquid-solid phase-change material with high phase change heat and the phase change temperature at -10-0 DEG C or 38-100 DEG C according to different thermal physical therapeutic processes such as thermal therapy, cold therapy, cryosurgery or cold-heat alternating therapy and the like; the magnetic particles (2) are magnetic micro / nano-particles or magnetotactic bacteria;and a liposome is taken as a capsule carrier for lowering toxicity of the material and protecting an encapsulated material. The invention provides a safe and effective thermal protection material with novel concept. In the invention, the magnetic phase-change microcapsule can be gathered into a target organ with blood circulation under the action of an applied magnetic field; phase-change latent heat and low thermal conductivity of the phase-change material are adopted to carry out thermal protection on the normal structure; and the material is widely applied to thermal physical therapy, and the application method thereof is simple, feasible and reliable.

Owner:CHONGQING UNIV

Six-element high-entropy alloy with first-order magnetic phase transition and preparation method thereof

InactiveCN103173674BReversibleLarge magnetic phase transition temperature rangePhotography auxillary processesMagnetic transitionsHigh entropy alloys

The invention relates to the technical field of high-entropy alloys and discloses a six-element high-entropy alloy with a first-order magnetic phase transition and a preparation method thereof. The six-element high-entropy alloy with the first-order magnetic phase transition has a general formula structure of MgaMnbFecCodNieGdf and is obtained by electrochemical reduction deposition, wherein an electrolyte in the electrochemical reduction deposition comprises the following components: dimethyl sulfoxide, tetraethylammonium hexafluorophosphate, vitamin C, GdCl3, FeCl2, CoCl2, NiCl2, MnCl2 and MgCl2. The prepared alloy is an amorphous alloy, the magnetic transition of the prepared alloy is the magnetic transition caused by strong electron correlation without being restrained by the crystal form transformation of a material, and therefore, the high-entropy alloy has the advantages of large temperature range of magnetic phase transition, controllable critical transition temperature and reversibility.

Owner:SUN YAT SEN UNIV

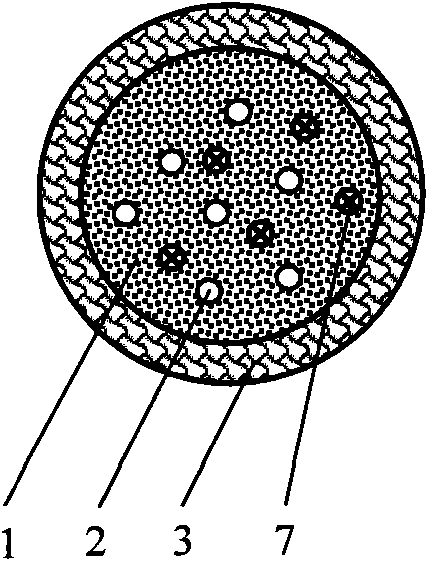

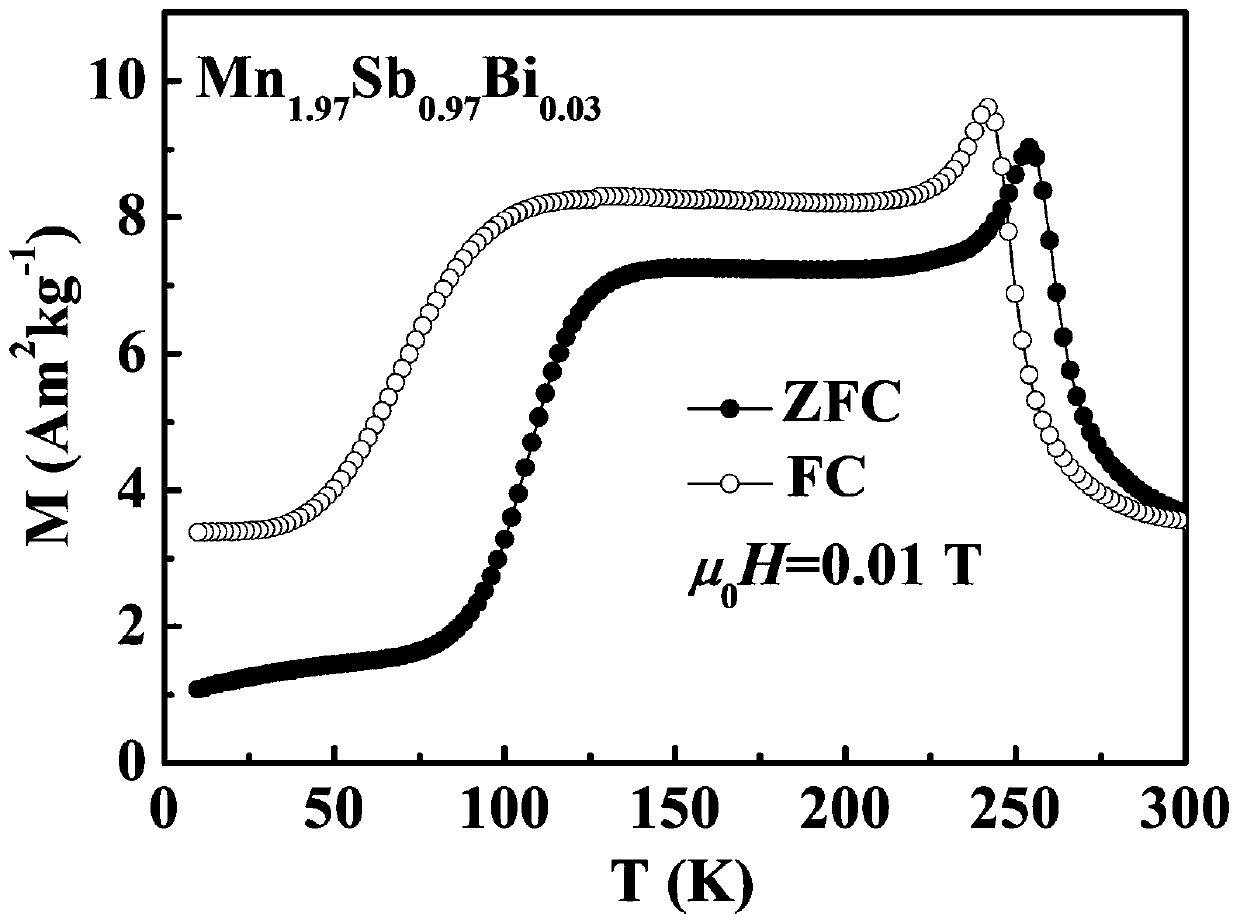

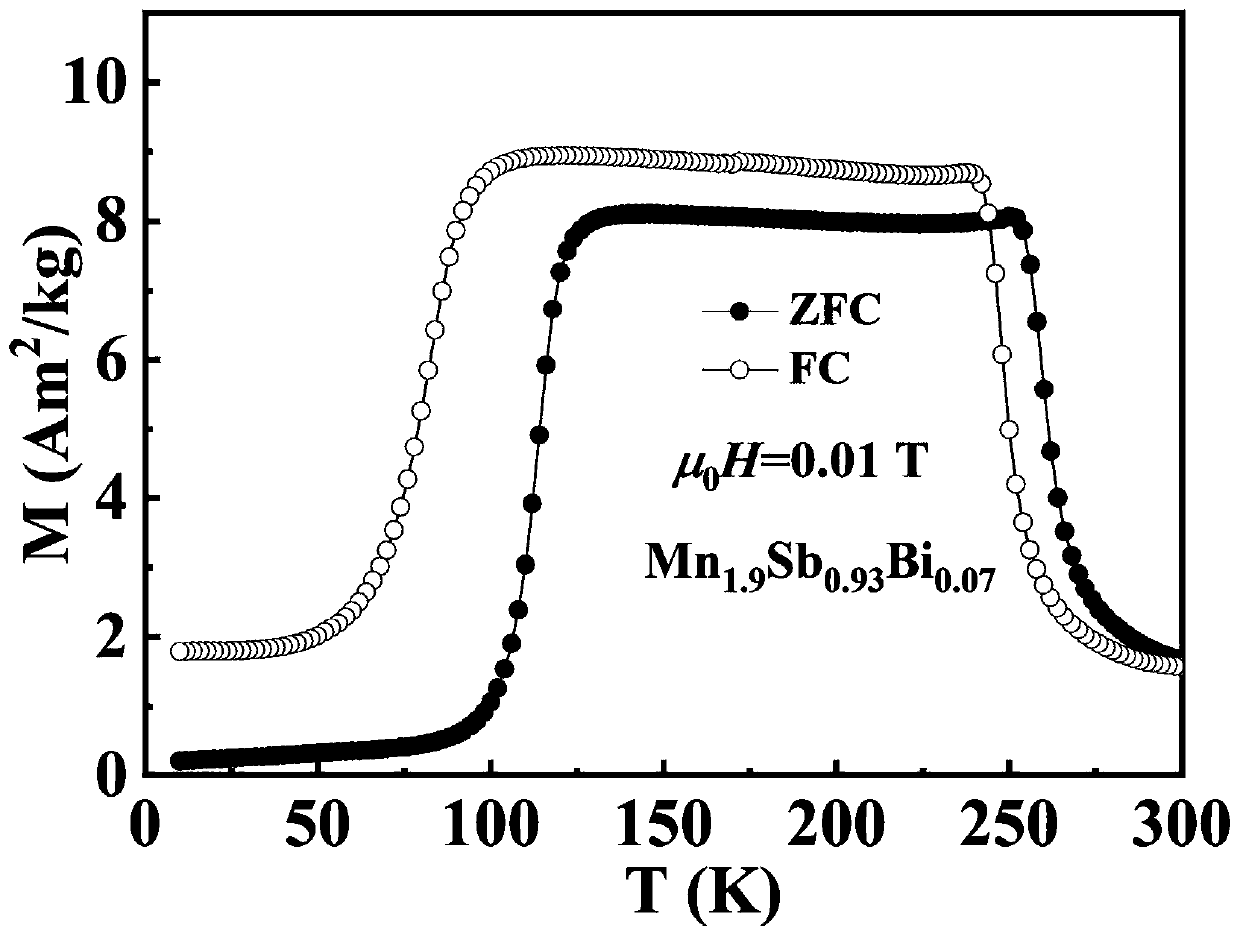

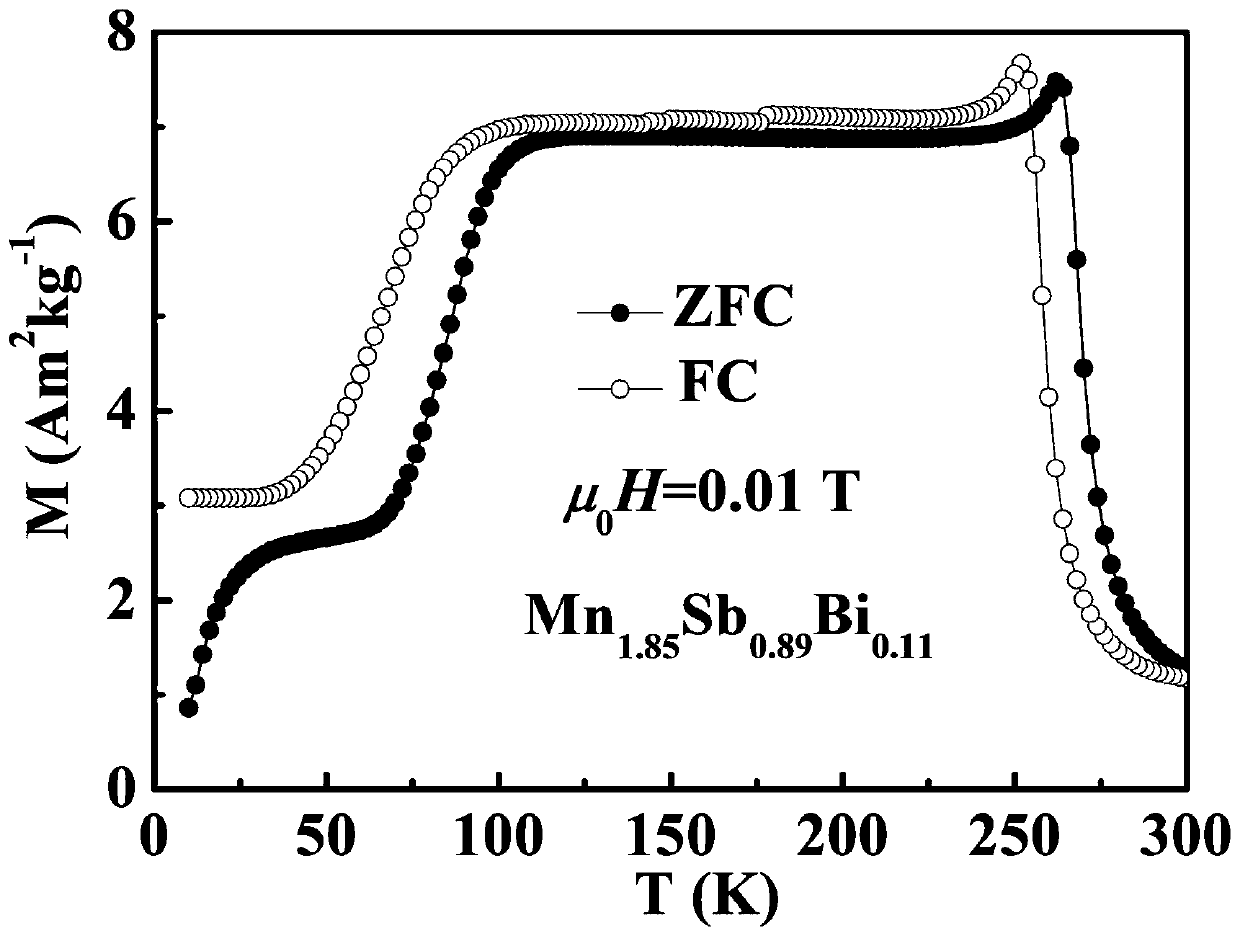

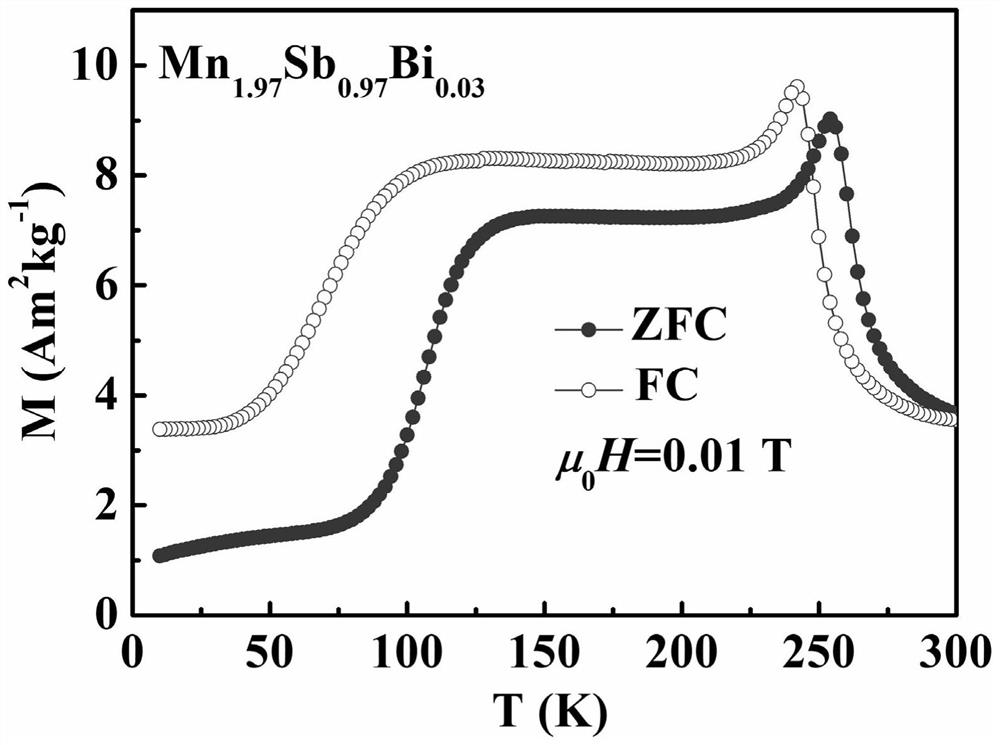

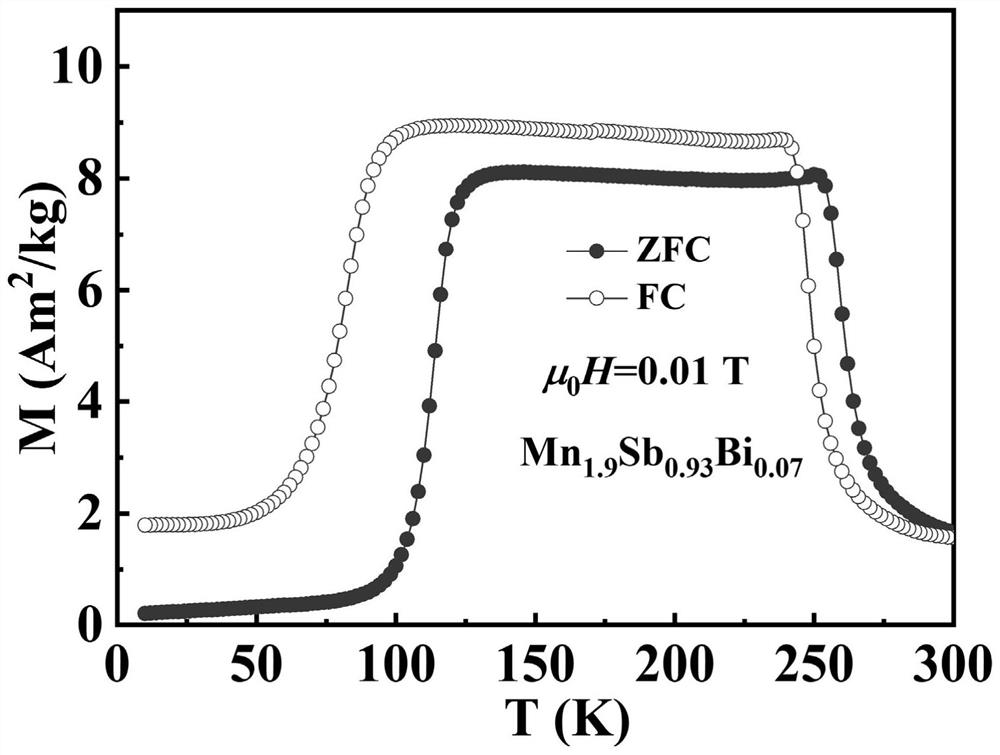

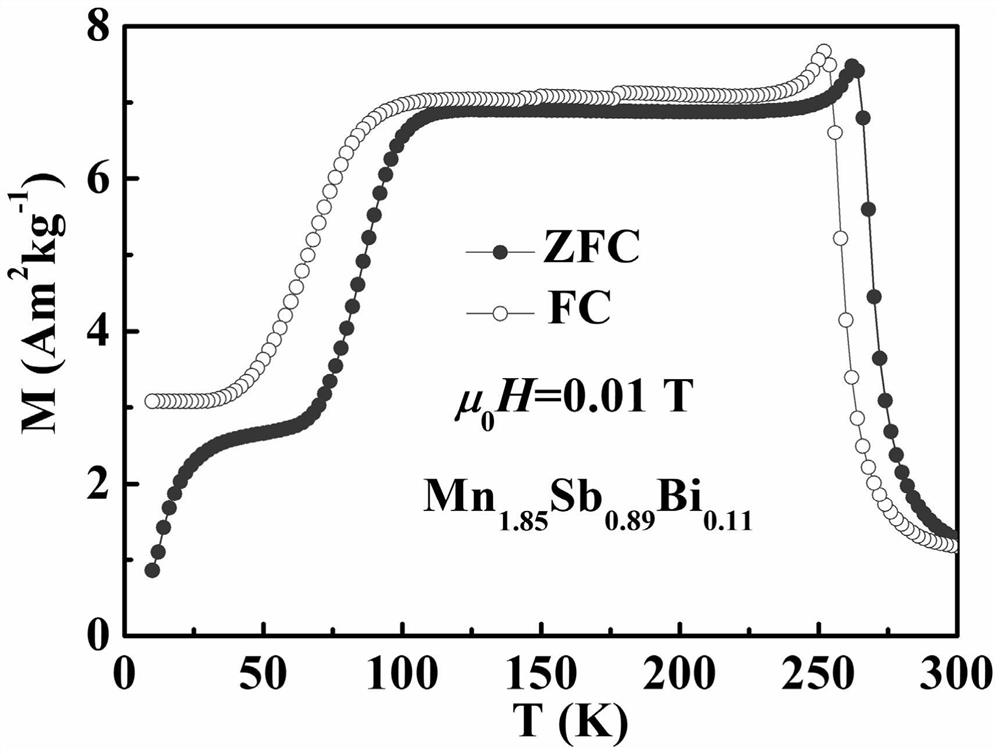

Bi substituted Mn absent Mn2Sb-based alloy and preparation method and application thereof

ActiveCN111575532AHas a first-order magnetoelastic phase transitionExcellent magnetic functional propertiesInorganic material magnetismMagnetic phaseMagneto elastic

The invention relates to the technical field of magnetic phase change materials, and discloses a Bi substituted Mn absent Mn2Sb-based alloy and a preparation method and application thereof. The chemical formula of the Bi substituted Mn absent Mn2Sb-based alloy is Mn2-ySb1-xBix, wherein y is the absence amount of Mn atoms, x is the substitution amount of Bi to Sb, y is larger than 0 and smaller than 1, and x is larger than 0 and smaller than or equal to 0.4. Firstly, primary magnetic phase change is adjusted and controlled and achieved through transition element absence, the Bi substituted Mn absent Mn2Sb-based alloy is prepared with a doping or element substitution method, primary magnetic elastic phase change is adjusted and controlled and achieved in the alloy, rich magnetic functional characters are obtained, the Bi substituted Mn absent Mn2Sb-based alloy can be widely applied to multiple fields such as magnetic refrigeration, magnetic storage, magnetic sensing, energy capture and energy conversion, and the preparation method is simple and convenient, low in energy consumption, low in preparation cost and suitable for industrial production.

Owner:JIANGXI UNIV OF SCI & TECH

A bi-substituted mn-deficient mn 2 Sb-based alloy and its preparation method and application

ActiveCN111575532BHas a first-order magnetoelastic phase transitionExcellent magnetic functional propertiesInorganic material magnetismMagnetic phaseMagneto elastic

Owner:JIANGXI UNIV OF SCI & TECH

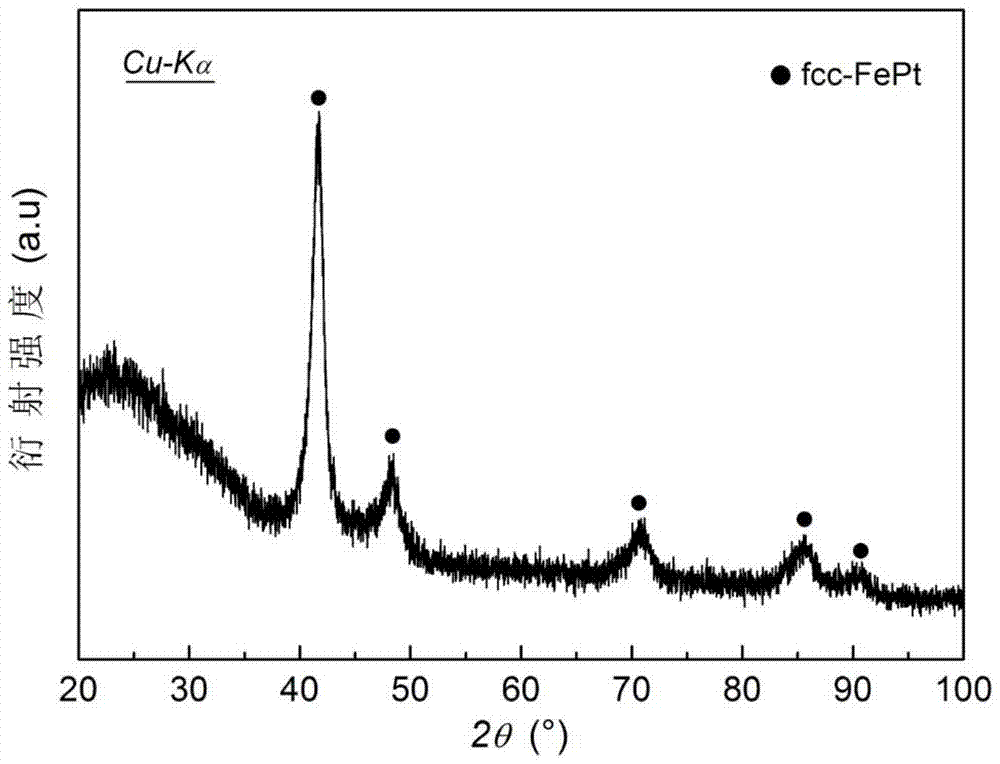

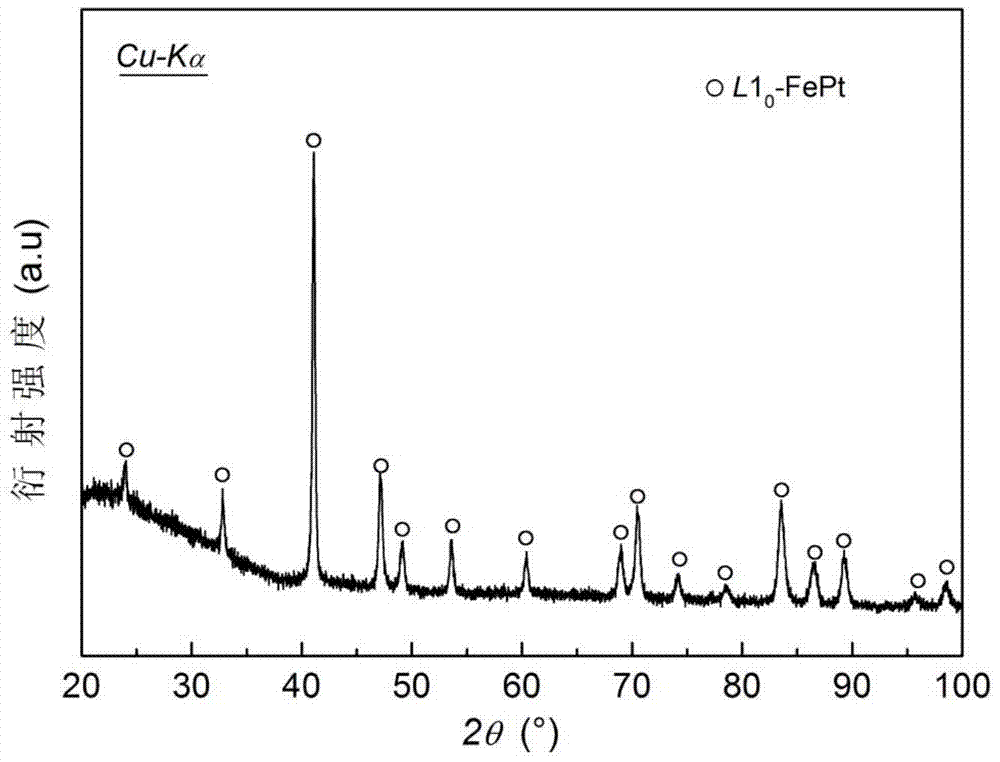

A kind of preparation method of high coercivity fe-pt alloy

The invention relates to a preparation method of a high-coercivity Fe-Pt alloy, which belongs to the technical field of new materials. Fe-Pt-B alloy strips with low Pt content were prepared by arc or induction melting and single-roller stripping as precursor alloys, and then prepared by dealloying the precursor alloy strips in a weakly acidic environment by electrochemical process The nanoporous Fe-Pt alloy with uniform pore size is then subjected to vacuum annealing treatment, and the hard magnetic L10-FePt phase is obtained through phase transformation, so that the alloy has high coercive force. The coercive force of the Fe-Pt alloy prepared by the method provided by the invention exceeds 6.12kOe under an external magnetic field of 18kOe, which is much higher than that of the Fe-Pt alloy prepared by the traditional method. The invention provides a new method for the preparation of the permanent magnetic material, and also opens up a new application field for the nanoporous metal material.

Owner:DALIAN UNIV OF TECH

Magnetic phase-change nano material and preparation method thereof

ActiveCN113980651AGive full play to the heat storage functionImprove thermal conductivityMagnetic liquidsInductances/transformers/magnets manufactureMagnetic phaseCross linker

The invention discloses a magnetic phase-change nano material and a preparation method thereof. The preparation method comprises the steps of dispersing magnetic graphene oxide in a solvent, then adding an epoxy cross-linking agent, and reacting at 25 DEG C for 1-48 hours to obtain epoxy group modified magnetic graphene oxide; and dispersing the epoxy group modified magnetic graphene oxide in a solvent, adding dihydric alcohol with ten carbon atoms or more, and reacting at 25-100 DEG C for 1-48 hours to obtain the magnetic nano material. According to the magnetic phase-change nano material, on the basis that the latent heat of the phase-change material is not reduced basically, the heat conductivity coefficient of the material is increased, and meanwhile, the magnetic phase-change nano material has a recovery and separation function under a magnetic field. The magnetic phase-change nano material prepared by the method can fully exert the heat storage function of the phase-change nano material and has magnetism.

Owner:XI AN JIAOTONG UNIV

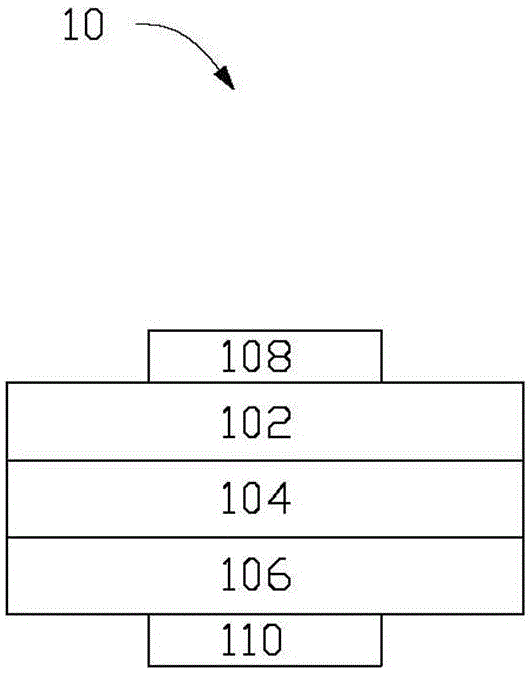

A Tunneling Magnetoresistance Device Driven by Magnetic Phase Transition

ActiveCN107591478BRealize the magnetoresistance effectReduce sizeMagnetic-field-controlled resistorsGalvano-magnetic material selectionMagnetic phaseAlloy

The invention discloses a tunnel magnetoresistance device driven by magnetic phase transition. The tunnel magnetoresistance device includes a substrate, a bottom electrode, a tunneling layer and a top electrode that are stacked in sequence; the bottom electrode has a ferromagnetic phase change; the material of the bottom electrode is Fe-Rh alloy or Fe-Ga alloy; The thickness of the bottom electrode is greater than 3 nm; an insertion layer is provided between the bottom electrode and the tunneling layer; the material of the insertion layer is paramagnetic metal. The present invention uses metal with ferromagnetic phase change on one side of the tunnel layer to prepare a tunnel magnetoresistance device. By utilizing the large changes in the density of metal states in the ferromagnetic phase change, the tunnel magnetoresistance device can achieve more than 10% of the energy at room temperature. Magnetoresistance effect; and the polarity and size of the device's magnetoresistance value can be controlled through the thickness of the interface insertion layer.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com