Reversible thermochromic microcapsule pigment preparation method

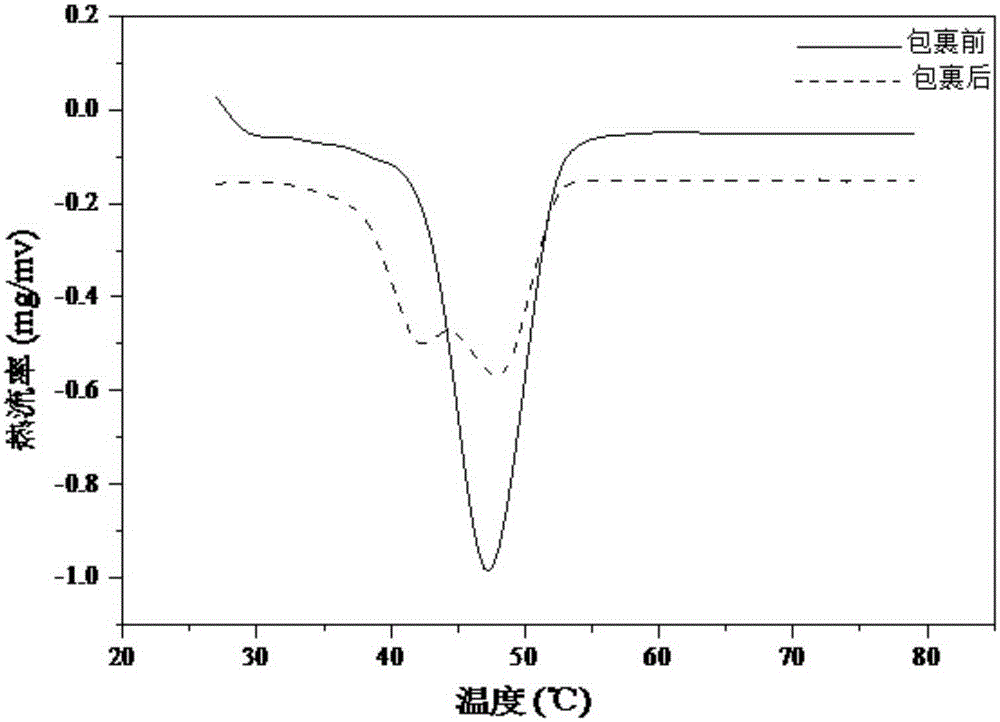

A thermochromic and microcapsule technology, applied in the directions of microcapsule preparation, microsphere preparation, color-changing fluorescent materials, etc., can solve the problems of high discoloration temperature and low discoloration sensitivity of thermochromic materials, and achieve the effect of improving the coating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

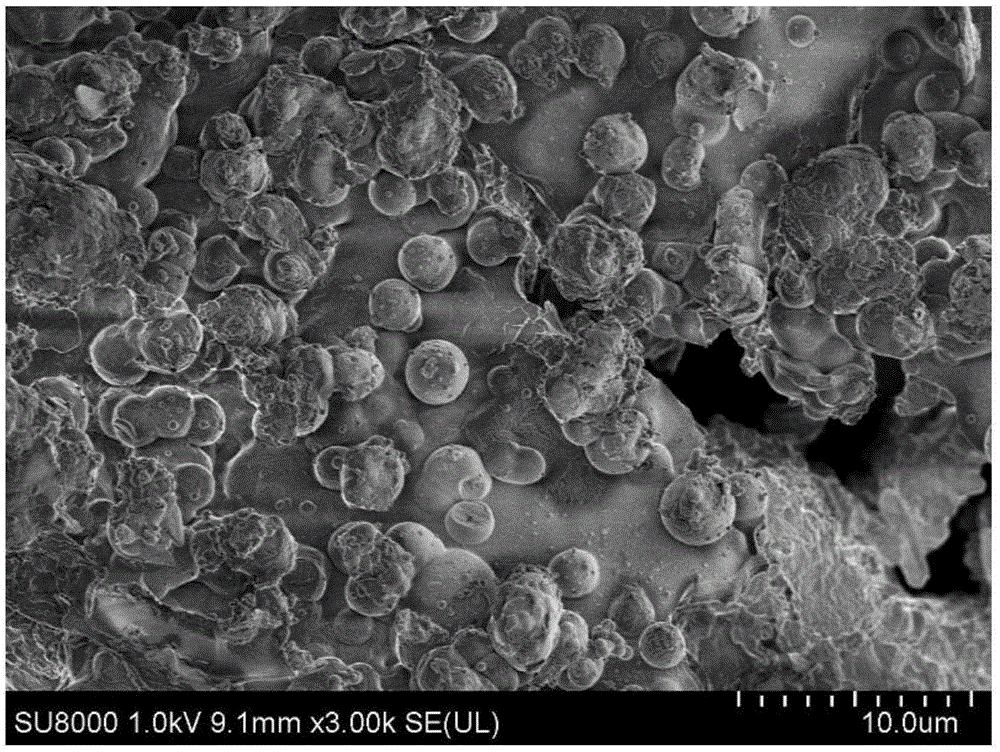

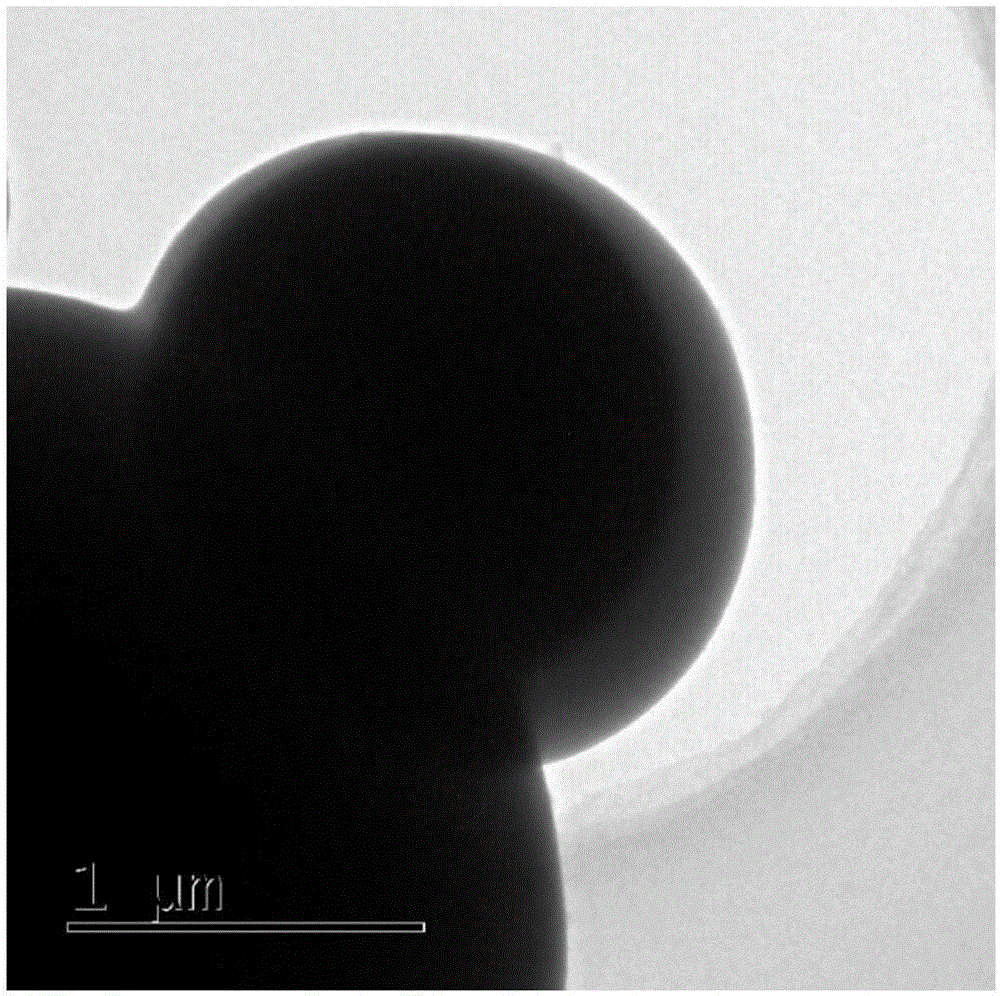

Embodiment 1

[0034]Weigh by mass percentage: 0.1% crystal violet lactone, 0.5% bisphenol A, 3.61% cetyl alcohol; 4% melamine, 4.2% formaldehyde solution with a mass concentration of 37%, 0.48% sodium dodecylbenzenesulfonate %, sodium lauryl sulfate at 0.11%, distilled water at 87%, the total content of the above components is 100%; heat the weighed cetyl alcohol until it is completely melted, then add the weighed bisphenol A and continue heating Until it melts, add crystal violet lactone and keep stirring, control the temperature at 60°C until it becomes a transparent liquid, and after natural cooling, a dark blue solid is obtained, which is compound A; mix 80% of the total amount of distilled water weighed, Sodium dodecylbenzenesulfonate and sodium dodecyl sulfate are mixed, and the glass rod is constantly stirred to make it fully emulsified. The emulsification stirring rate is 200r / min; then poured into a three-neck round bottom flask for water bath reaction, the water bath reaction time ...

Embodiment 2

[0036] Weigh by mass percentage: 0.08% crystal violet lactone, 0.4% bisphenol A, 3% cetyl alcohol; 2% melamine, 4.03% formaldehyde solution with a mass concentration of 37%, 0.4% sodium dodecylbenzenesulfonate %, sodium lauryl sulfate at 0.09%, distilled water at 90%, the total content of the above components is 100%; heat the weighed cetyl alcohol until it is completely melted, then add the weighed bisphenol A and continue heating Until it melts, add crystal violet lactone and keep stirring, control the temperature at 63°C until it becomes a transparent liquid, and after natural cooling, a dark blue solid is obtained, which is compound A; mix 80% of the total amount of distilled water weighed, Sodium dodecylbenzenesulfonate and sodium dodecyl sulfate are mixed, and the glass rod is constantly stirred to make it fully emulsified. The emulsification stirring rate is 220r / min; then poured into a three-neck round bottom flask for water bath reaction, the water bath reaction time i...

Embodiment 3

[0038] Weighing by mass percentage: 0.09% crystal violet lactone, 0.45% bisphenol A, 3% cetyl alcohol; 2.76% melamine, 5% formaldehyde solution with a mass concentration of 37%, 0.6 sodium dodecylbenzenesulfonate %, sodium lauryl sulfate at 0.1%, distilled water at 88%, the total content of the above components is 100%; heat the weighed cetyl alcohol until it is completely melted, then add the weighed bisphenol A and continue heating Until it melts, add crystal violet lactone and keep stirring, control the temperature at 67°C until it becomes a transparent liquid, and after natural cooling, a dark blue solid is obtained, which is compound A; mix 80% of the total amount of distilled water weighed, Sodium dodecylbenzenesulfonate and sodium dodecyl sulfate are mixed, and the glass rod is constantly stirred to make it fully emulsified. The emulsification stirring rate is 240r / min; The reaction temperature was 68°C to obtain emulsion A; then the obtained compound A was heated and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com