Nonionic self-emulsifying water-based epoxy curing agent with Gemini surfactant structure and preparation method thereof

A surfactant and non-ionic technology, used in the field of non-ionic self-emulsifying water-based epoxy curing agent and its preparation, can solve the problems of poor compatibility of water-based epoxy systems, poor water resistance of coating films, and short pot life. Achieve excellent wettability, improve flexibility and increase hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

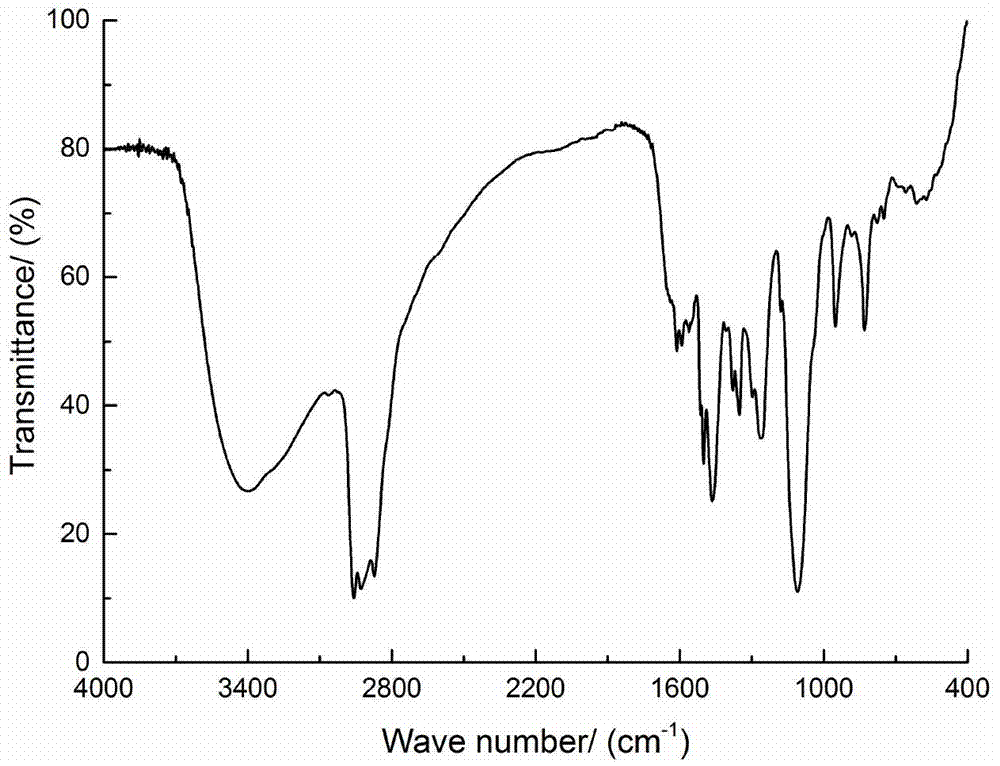

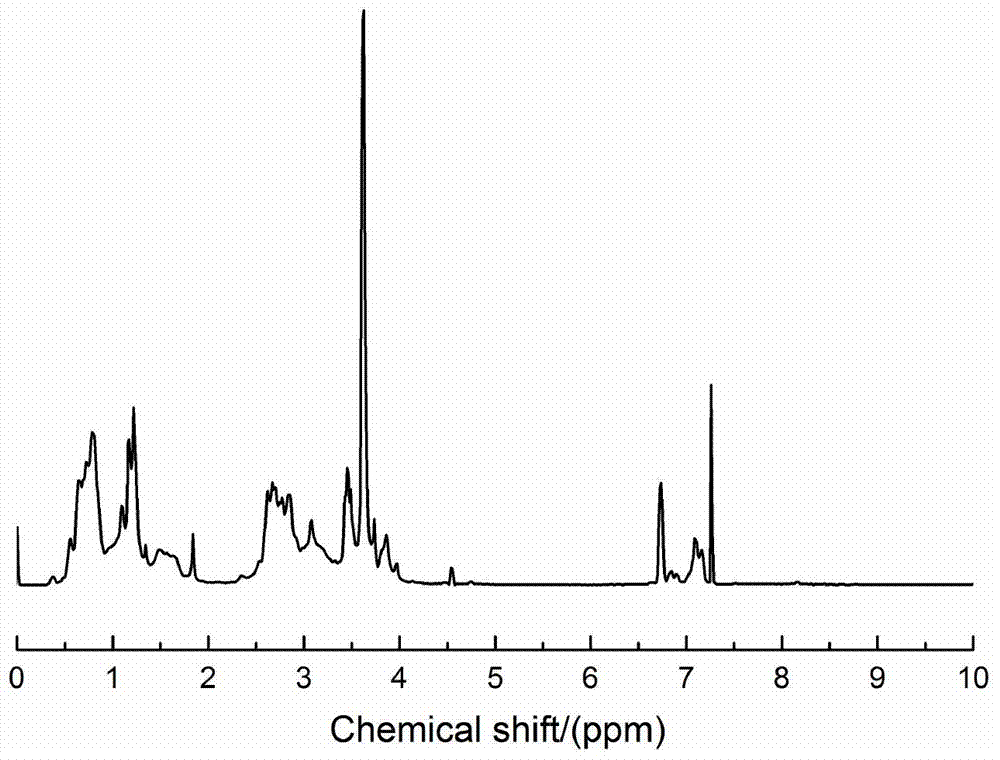

Image

Examples

preparation example Construction

[0039] A preparation method of a nonionic self-emulsifying water-based epoxy curing agent with a Gemini surfactant structure, the steps are as follows:

[0040] 1) Put the alkylphenol, polyamine, and formaldehyde solution in a solvent to carry out the Mannich reaction, and remove the solvent and by-products after the reaction to obtain the Mannich amine containing the primary amino group;

[0041] 2) Fully react the Mannich amine containing primary amino groups prepared above with diglycidyl ether, after the reaction is completed, lower the temperature, add water to fully disperse to form an emulsion, and obtain the product.

[0042] Preferably, the steps are as follows:

[0043] 1) Dissolve alkylphenols and polyamines in a solvent with a molar ratio of 1:1, mix them evenly and place them in a reactor, gradually raise the temperature to 70-90°C under stirring conditions, and then add dropwise an equimolar Formaldehyde solution (that is, the amount of formaldehyde in the forma...

Embodiment 1

[0053] Preparation of nonionic self-emulsifying waterborne epoxy curing agent with Gemini surfactant structure:

[0054] (1) 78.7g p-dodecyl-phenol (Suifenhe Wanfengyuan Economic and Trade Co., Ltd., Chinese name can also be called p-dodecylphenol, 4-dodecylphenol), 43.9g triethylene Tetramine was dissolved in 60ml ethanol solvent, placed in a three-necked flask equipped with a thermometer, agitator and condenser, and gradually heated up to 80°C under stirring conditions, and 23.4g of 38% mass fraction was added dropwise to it after the temperature was constant. Formaldehyde aqueous solution, keep the constant temperature reaction for 5 hours after the dropwise addition within 30 minutes, after the reaction is completed, the solvent ethanol, water and other volatile components are removed by distillation under reduced pressure at 50 ° C, and transparent Mannich amine containing primary amines is obtained;

[0055] (2) Slowly raise the temperature of the Mannich amine containin...

Embodiment 2

[0064] Preparation of nonionic self-emulsifying waterborne epoxy curing agent with Gemini surfactant structure:

[0065] (1) Dissolve 95.6g p-hexadecyl-phenol (Wuhan Fude Fine Chemical Co., Ltd., Chinese name can also be called p-hexadecylphenol, 4-hexadecylphenol), 18.0g ethylenediamine In 230ml of propylene glycol methyl ether solvent, place in a three-necked flask equipped with a thermometer, a stirrer and a condenser, gradually heat up to 90°C under stirring conditions, and dropwise add 23.4g of 38% Formaldehyde aqueous solution, keep the constant temperature reaction for 8 hours after the dropwise addition within 90 minutes, after the reaction is completed, distill off the solvent propylene glycol methyl ether, water and other volatile components at 90 ° C under reduced pressure to obtain transparent Mannich amine containing primary amine; ( 2) Slowly raise the temperature of the above-prepared Mannich amine containing primary amine to 80°C, and add 120.0g of polyethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com