Modified aliphatic high-efficiency water-reducing agent by utilizing lignosulfonate and preparation method thereof

A technology of lignosulfonate and high-efficiency water reducer, which is applied in the field of building materials, can solve problems such as environmental pollution and waste of resources, and achieve the effects of simple production process, short production cycle and reduced product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

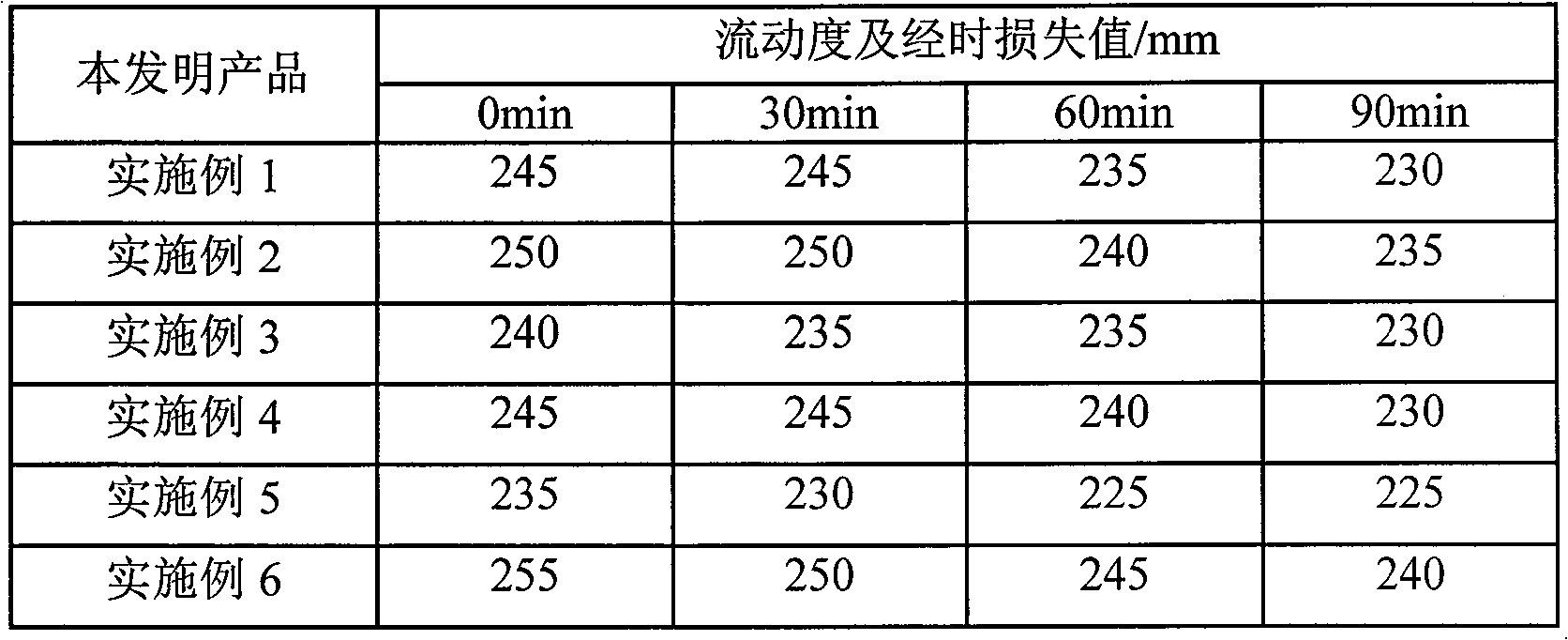

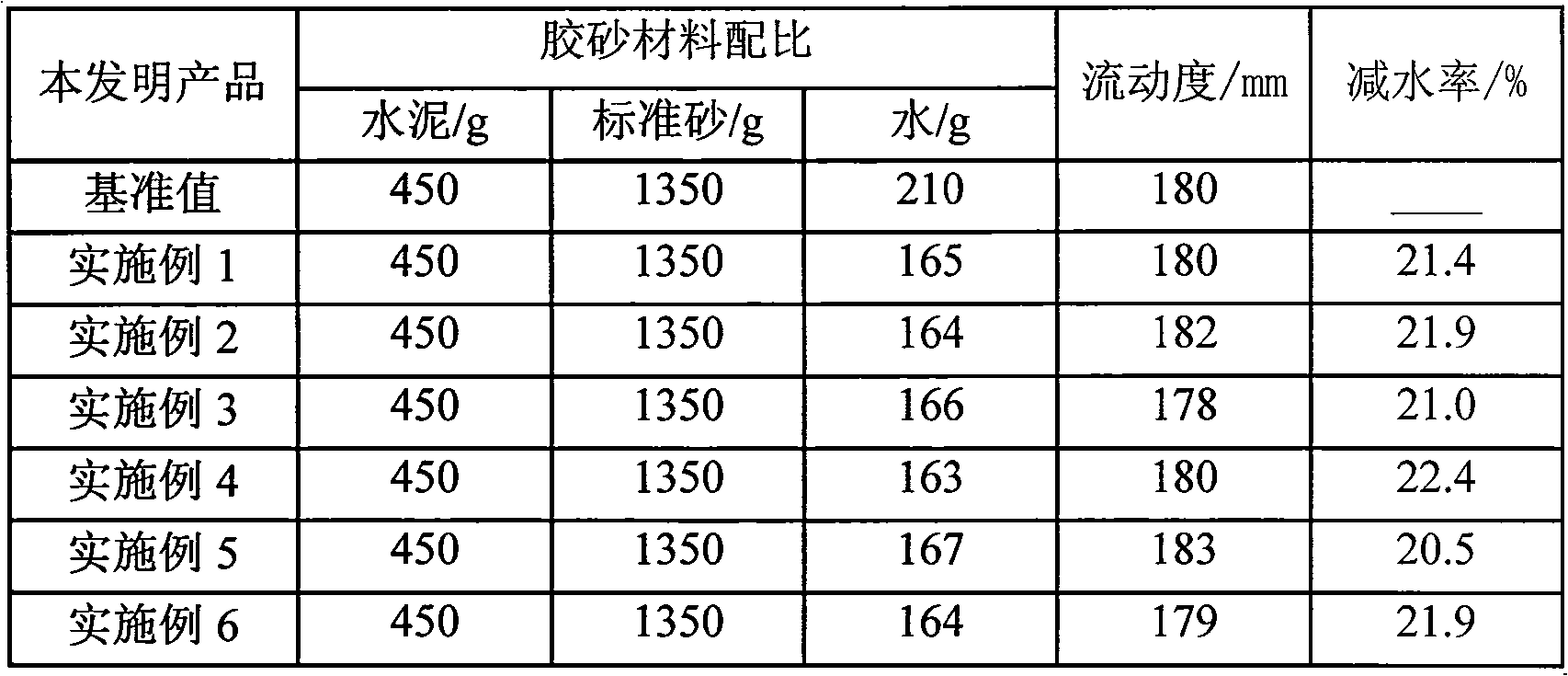

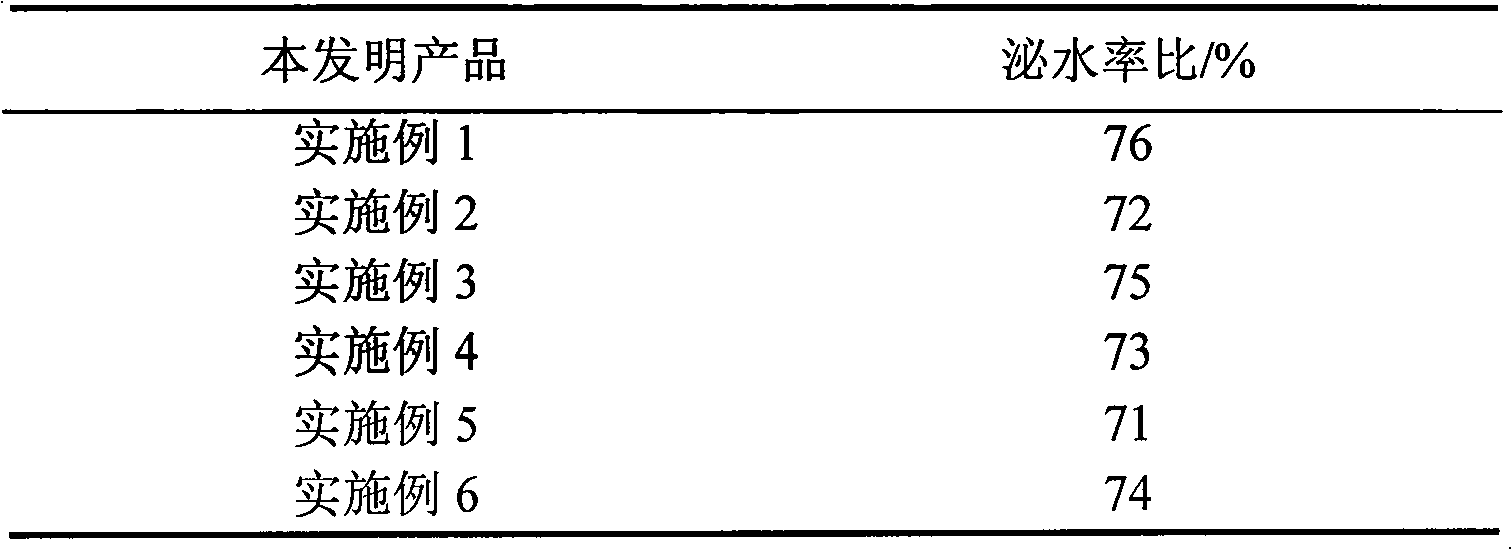

Examples

Embodiment 1

[0024] Example 1: first add 1 kg of acetone, 3 kg of sodium sulfite, 0.5 kg of sodium bisulfite and 13 kg of water into the reactor, stir evenly, heat up to 25 ° C for 1.5 h, then add dropwise 0.6 kg of formaldehyde solution for 1.75 h, then heat up to React at 95°C for 5 hours, then lower the temperature to 60°C, add 2.5kg of lignosulfonate and 0.4kg of formaldehyde solution into the reactor, adjust the pH value of the system to 8.0 with an alkaline regulator, and finally raise the temperature to 86°C for 1 hour of reaction Cool down and discharge to get the product.

Embodiment 2

[0025] Example 2: First add 1kg of acetone, 1.5kg of sodium sulfite, 0.5kg of sodium bisulfite, 1.2kg of sodium pyrosulfite and 14.5kg of water into the reactor, stir evenly, raise the temperature to 30°C for 1.2h, then add dropwise 1.05kg of formaldehyde solution for 2 hours, then heated up to 92°C for 4.5 hours, then cooled to 58°C, added 3.5kg lignosulfonate and 0.45kg formaldehyde solution into the reactor, adjusted the pH value of the system to 9.0 with an alkaline regulator, and finally Raise the temperature to 92°C and react for 2.5 hours, then cool down and discharge to obtain the product.

Embodiment 3

[0026] Example 3: first add 1 kg of acetone, 2 kg of sodium sulfite, 1 kg of sodium metabisulfite and 15.2 kg of water into the reactor, stir evenly, raise the temperature to 32 ° C for 1 h, then add 1.3 kg of formaldehyde solution dropwise for 0.25 h, then raise the temperature to 88 ° C for reaction 1h, then lower the temperature to 55°C, add 4kg lignosulfonate and 0.7kg formaldehyde solution into the reactor, adjust the pH value of the system to 13.0 with an alkaline regulator, and finally raise the temperature to 70°C for 1.5h, then cool down and discharge , that is, the product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com