Urea resin wrapped dicyclopentadiene nanometer microcapsule, and synthetic method and application thereof

A technology of dicyclopentadiene and nano-microcapsules, which is applied in the preparation of microcapsule preparations and microspheres, can solve the problems of large particle size, and achieve the effects of uniform particle size distribution, easy operation, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

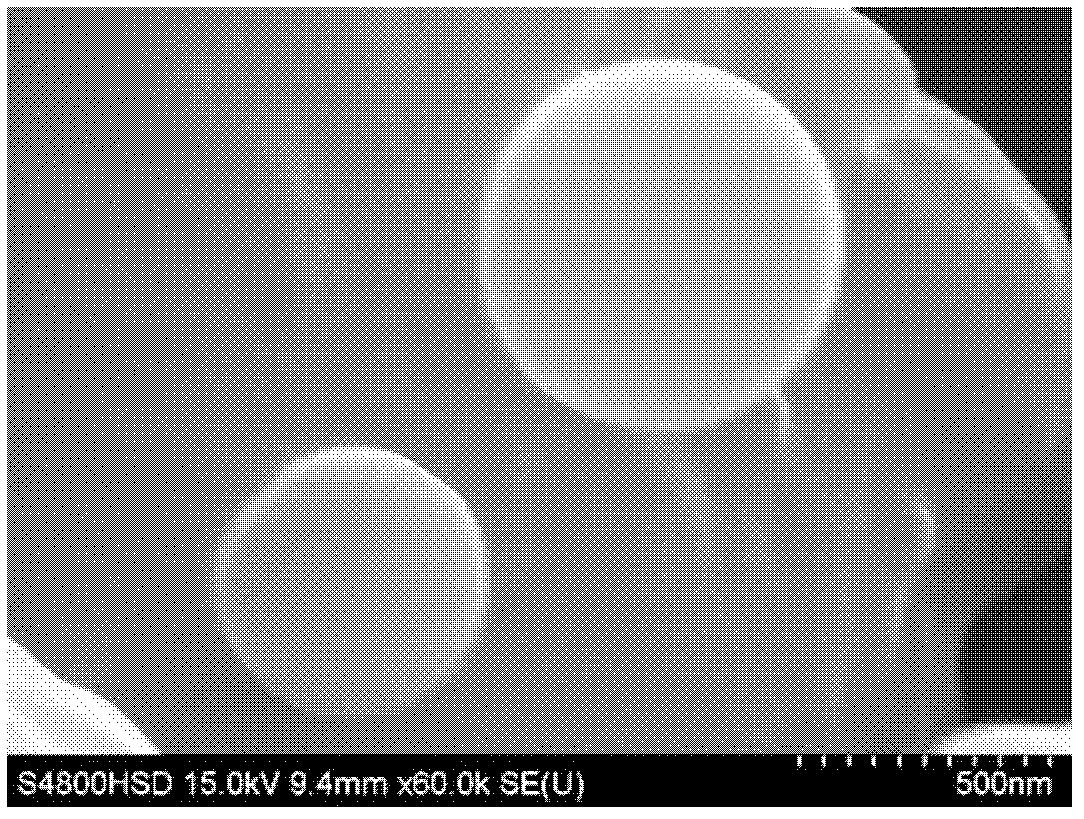

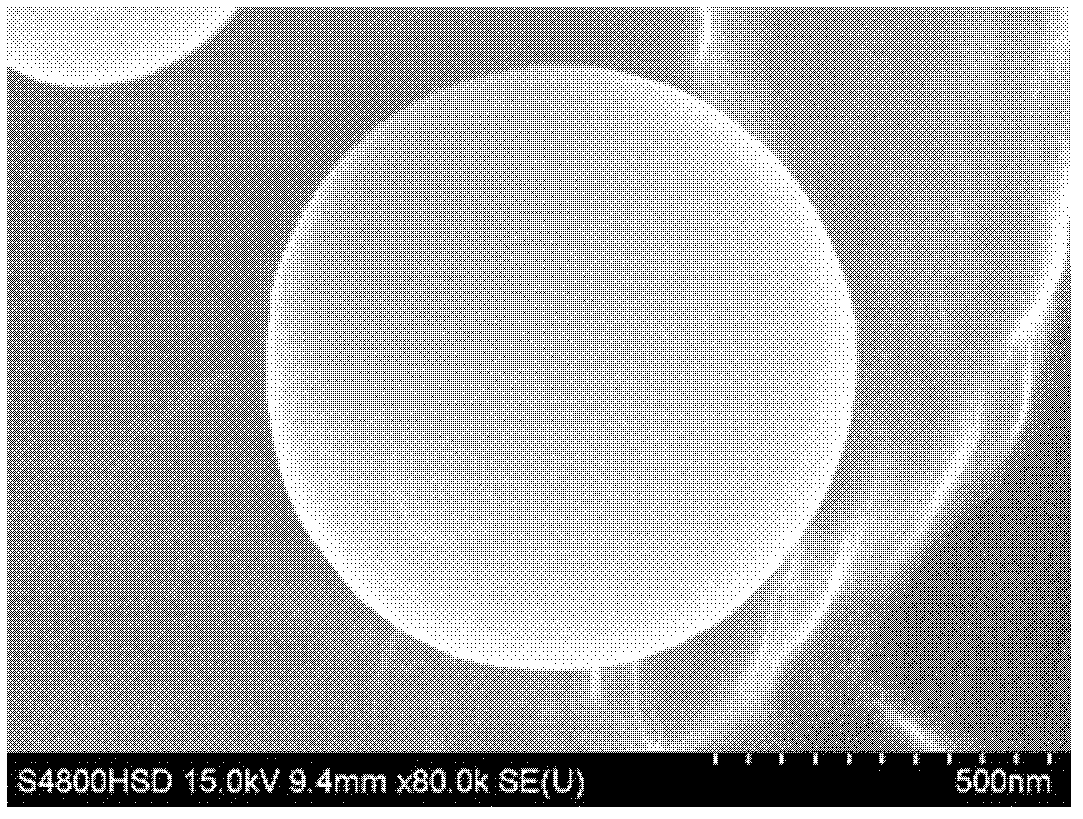

[0017] Embodiment 1: The urea-formaldehyde resin-coated dicyclopentadiene nano-microcapsules of this embodiment are spherical particles made of urea-formaldehyde resin as the wall shell and dicyclopentadiene as the core material, and the diameter of the spherical particles is 400nm~800nm .

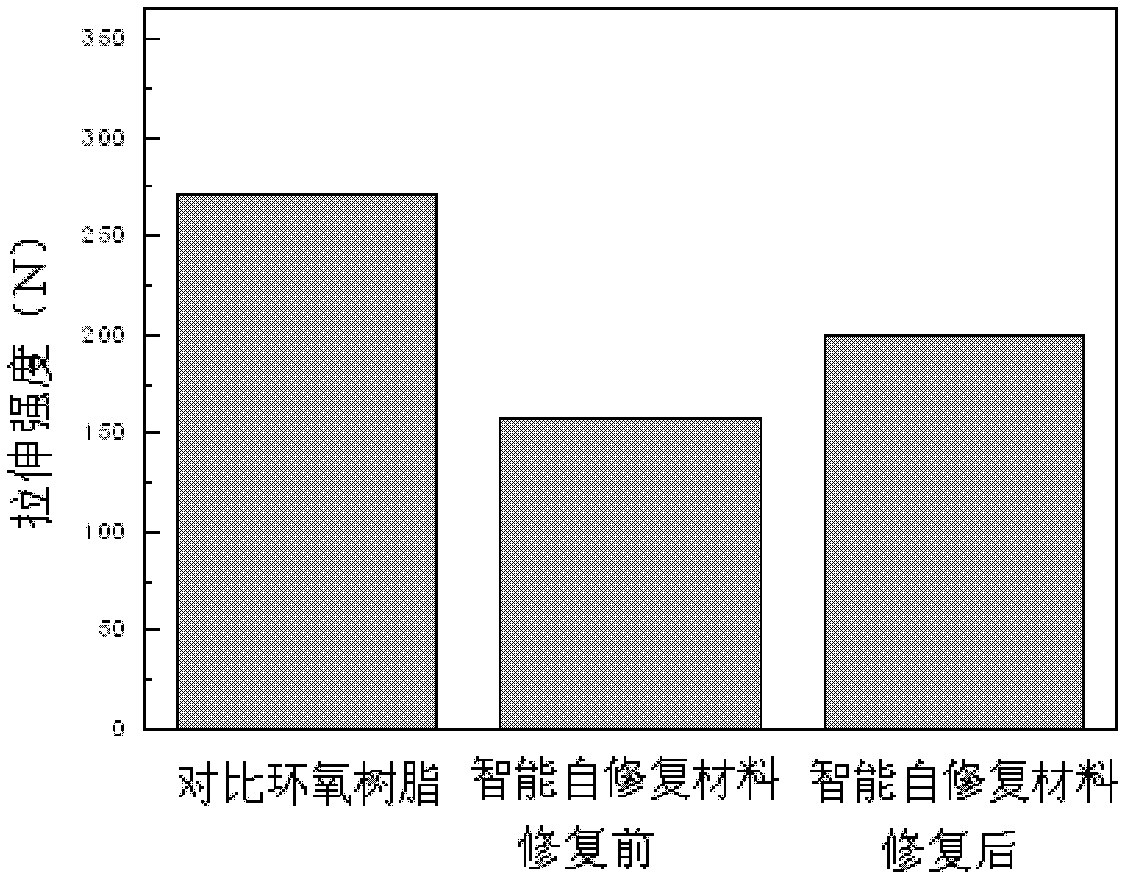

[0018] The urea-formaldehyde resin-coated dicyclopentadiene nano-microcapsules in this embodiment are in the form of powder, the surface is dense and smooth, and the size of the microcapsules is controllable, which can be well adhered to the matrix material. It is used as an intelligent repair material for composite materials , when the composite material is micro-damaged and cracks are generated, the crack propagation leads to the rupture of the microcapsules, which can release the core material as a repair agent to repair the composite material. The urea-formaldehyde resin-coated dicyclopentadiene nano-microcapsules realizes a self-repairing efficiency of more than 60%.

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that the diameter of the spherical particles is 500 nm to 700 nm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Specific embodiment three: the preparation method of the urea-formaldehyde resin-coated dicyclopentadiene nano-microcapsules of the present embodiment is carried out according to the following steps:

[0021] 1. The molar ratio of urea to formaldehyde in formaldehyde solution is 1:1.8~2.2, the mass ratio of urea to resorcinol is 1:0.03~0.07, urea to NH 4 The mass ratio of Cl is 1:0.03-0.07, and weigh urea, formaldehyde solution with a mass concentration of 35%-37%, resorcinol and NH 4 Cl;

[0022] 2. First add the urea weighed in step 1 and the formaldehyde solution with a mass concentration of 35% to 37% into the reactor, stir to dissolve the urea, and then add the resorcinol and NH 4 Cl, after stirring for 30min to 40min at a stirring rate of 800 to 1000 rpm, adjust the pH of the solution to 8 to 9 with triethanolamine; raise the temperature to 65°C to 75°C and keep it for 1h to 2h to obtain a prepolymer ;

[0023] Three, according to the volume ratio of prepolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com