Method for removing impurities by oxidation in process of zinc hydrometallurgy

A technology of hydrometallurgy and secondary zinc oxide, which is applied in the direction of improving process efficiency, etc., can solve the problems of electro-zinc impurity removal and high product quality, and achieve smooth production, high product quality and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

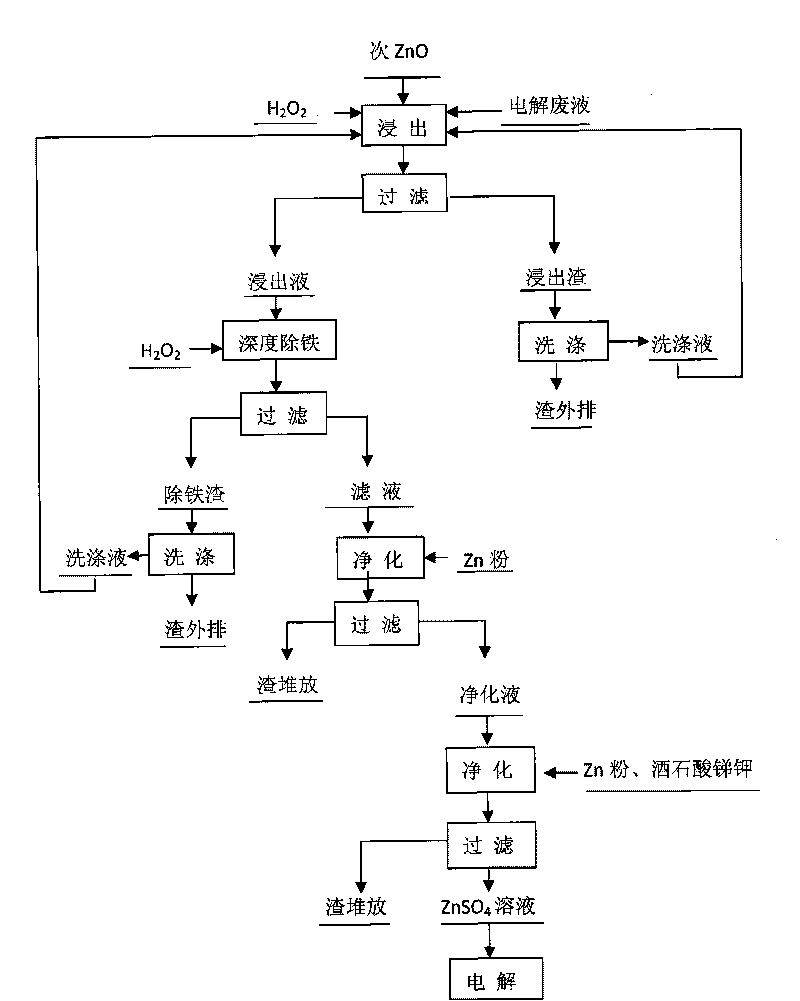

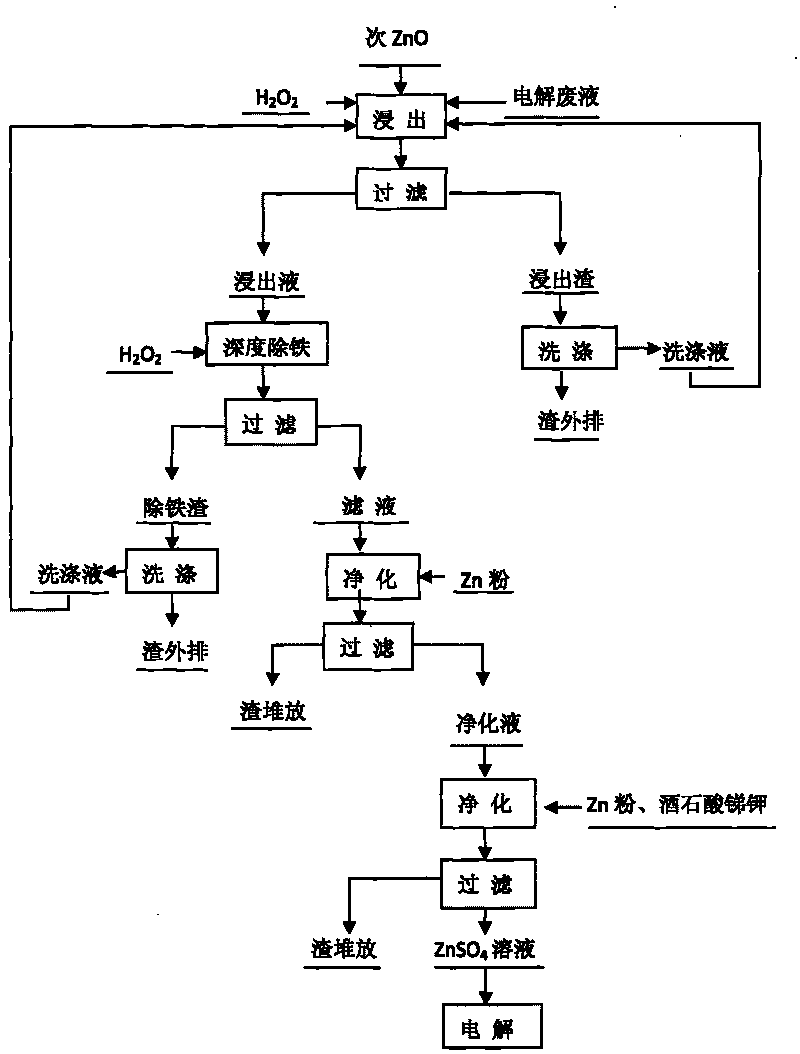

Method used

Image

Examples

Embodiment 1

[0022] Pumped 40m in the sub-zinc oxide leach tank 3 Electrolytic waste solution (see Table 1 for composition), drop into 10 tons of zinc oxide (see Table 2 for composition), stir for 50min, until the pH is 4.0, add H2O with a mass percentage of 27.5% 2 o 2 Solution 270kg, make the Fe in the solution 2+ <1g / L, then add 150kg of lime to adjust the pH to 5.2, stir for 60min;

[0023] Table 1

[0024] Element

Zn

h 2 SO 4

Fe

As

Sb

Ge

co

Cu

Cd

F

content,

g / L

38

150

0.015

0.00006

0.00006

0.00007

0.0008

0.0003

0.002

0.15

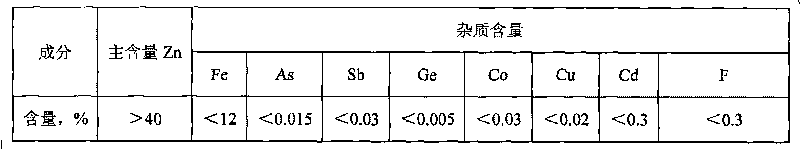

[0025] Table 2

[0026]

[0027] table 3

[0028] Element

Zn

Fe

As

Sb

Ge

co

Cu

Cd

F

Content, g / L

132

0.6

0.0003

0.0004

0.0003

0.005

0.025

0.21

0.18

[0029] Pump the filtered leaching solutio...

Embodiment 2

[0039] Pumped 39m in the sub-zinc oxide leach tank 3 Electrolyzed waste solution (see Table 7 for composition), drop into 10 tons of zinc oxide (see Table 8 for composition), stir for 50min, until pH is 4.5, adding mass percent is 27.5% H 2 o 2 Solution 300kg, make the Fe in the solution 2+ <1g / L, then add 120kg of lime to adjust the pH to 5.2, stir for 60min;

[0040] Table 7

[0041] Element

Zn

h 2 SO 4

Fe

As

Sb

Ge

co

Cu

Cd

F

Content, g / L

42

149

0.016

0.00007

0.00005

0.00006

0.0009

0.0002

0.001

0.13

[0042] Table 8

[0043]

[0044] Table 9

[0045] Element

Zn

Fe

As

Sb

Ge

co

Cu

Cd

F

Content, g / L

136

0.8

0.0002

0.0003

0.0002

0.005

0.029

0.21

0.16

[0046] Pump the filtered leaching solution into the deep iron removal reaction tank, maintain the te...

Embodiment 3

[0056] Pumped 43m in the sub-zinc oxide leach tank 3 Electrolyzed waste liquid (composition sees Table 13), drops into 11 tons of zinc oxide (composition sees Table 14), stirs 50min, until pH is 3.5, adding mass percentage is 27.5% H 2 o 2 Solution 270kg, make the Fe in the solution 2+ <1g / L, then add 200kg of lime to adjust the pH to 5.0, stir for 60min;

[0057] Table 13

[0058] Element

Zn

h 2 SO 4

Fe

As

Sb

Ge

co

Cu

Cd

F

content,

g / L

38

149

0.015

0.00007

0.00005

0.00006

0.001

0.0001

0.001

0.15

[0059] Table 14

[0060]

[0061] Table 15

[0062]

Element

Zn

Fe

As

Sb

Ge

co

Cu

Cd

F

Content, g / L

131

0.7

0.0002

0.0004

0.0003

0.007

0.023

0.22

0.15

[0063] P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com