Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "BUTYL LACTATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Occupational exposure to n-butyl lactate may occur through inhalation and dermal contact with this compound at workplaces where n-butyl lactate is produced or used. Use data indicate that the general population may be exposed to n-butyl lactate via inhalation and dermal contact with consumer products containing n-butyl lactate(SRC).

Emulsifiable concentrate (EC) formulations for pesticides

Pesticidal emulsifiable concentrate compositions containing at least one EPA exempt plant essential oil compound as a pesticidally active ingredient and a carrier containing an EPA exempt solvent, such as butyl lactate, and methods for using same are disclosed.

Owner:GIBRALTAR BUSINESS CAPITAL LLC

Neutral blockage removing agent composition used for oilfield mechanical recovery well and preparation method thereof

ActiveCN104194757AGood compatibilityGood miscibilityDrilling compositionSodium acetateActivated attapulgite

The invention relates to a neutral blockage removing agent composition used for a mechanical recovery well in an oilfield. The neutral blockage removing agent composition is prepared from the following components in parts by weight: 16-20 parts of polyepoxysuccinic acid amine, 7-12 parts of hydroxyethylidene dipllosphate sodium, 21-25 parts of divinyl pentaacetic acid amine, 20-25 parts of hydroxyl ammonium acetate, 12-16 parts of activated attapulgite, 21-25 parts of ammonium persulfate, 9-12 parts ofdicyclohexyl sulfobutanedioate sodium, 7-9 parts of butyl lactate, 0.2-0.3 part of vanadium pentoxide, 5-8 parts of straight chain sodium dodecylbenzenesulfonate, 10-14 parts of nitrilotriacetic acid sodium salt, 4-7 parts of urotropin and 0.1-0.3 part of glycerin fatty acid ester. The neutral blockage removing agent composition is suitable for scale removal and blockage removal of an oil pumping unit well and a screw pump well, can effectively control the reaction speed of the blockage removing agent and the scale of the oil pumping unit well and the scaled screw pump well, and prevent the falling-off of big scale residues to result in the secondary blockage of the mechanical recovery well and an oil recovery pump thereof, has high blockage removal speed, is neutral and is free of corrosion; the waste liquid for blockage removal does not need to be discharged onto the ground to be subjected to sewage treatment, the blockage removal time does not exceed 24 hours, and the effect of safe and corrosion-free blockage removal is achieved.

Owner:GANSU HEIMA PETROCHEM ENG

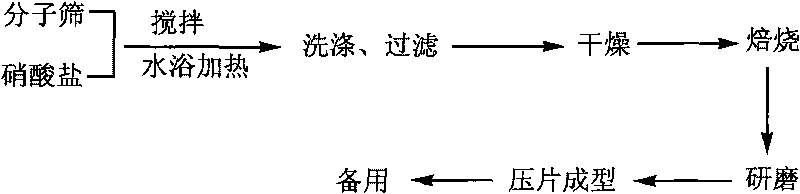

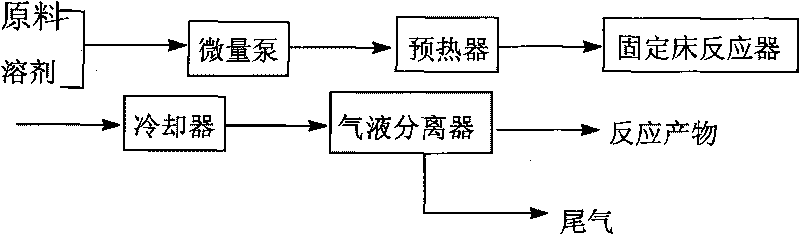

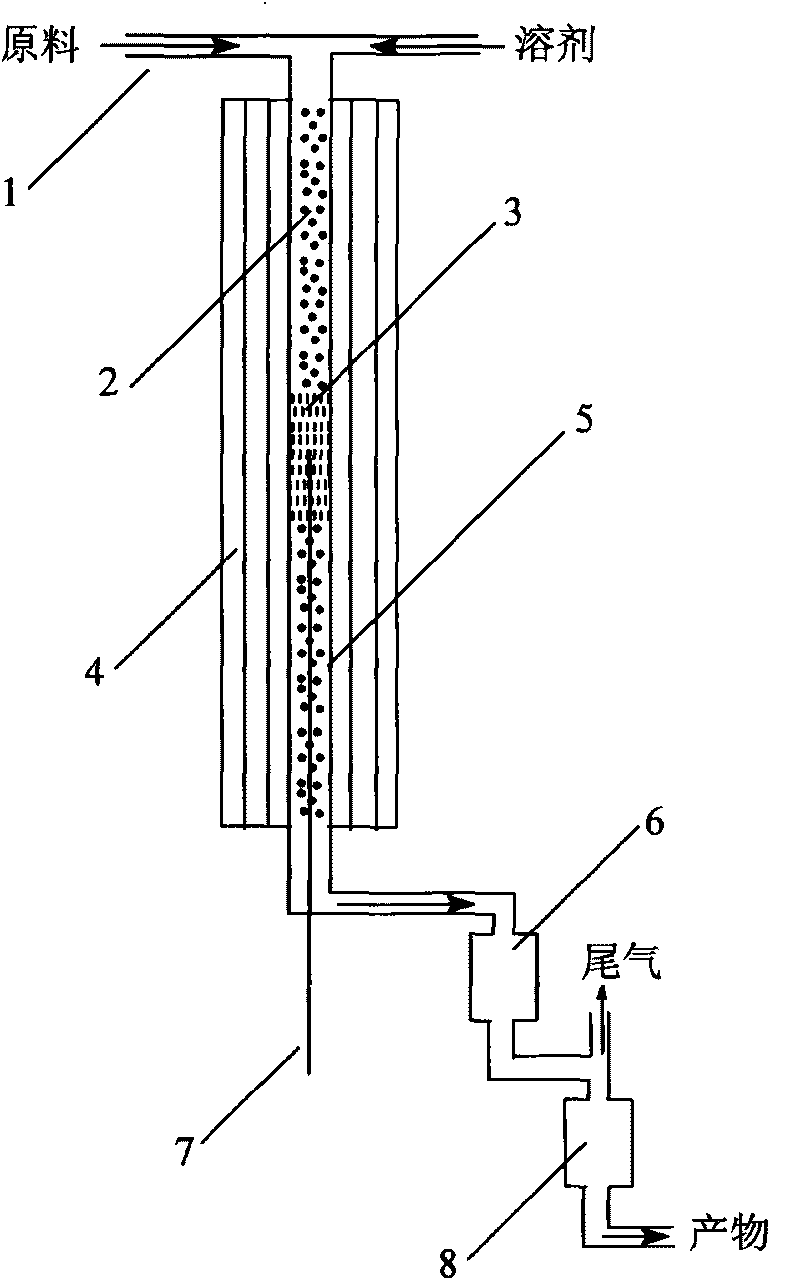

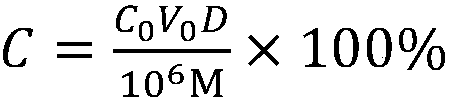

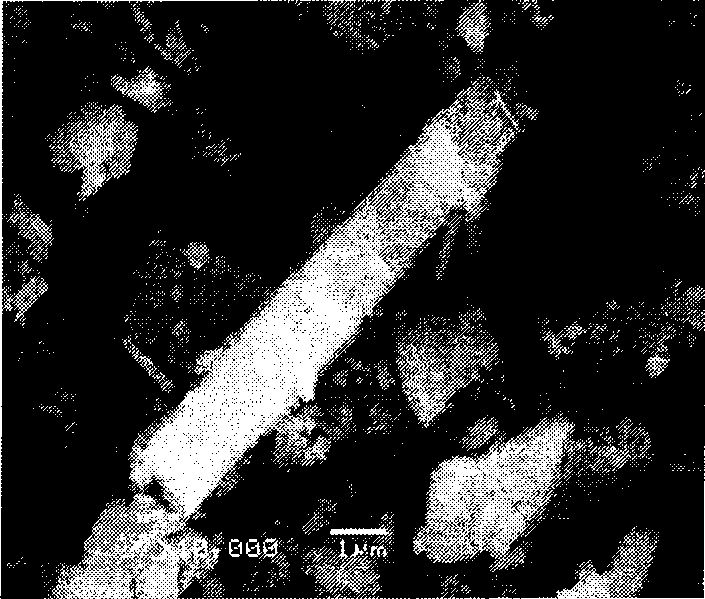

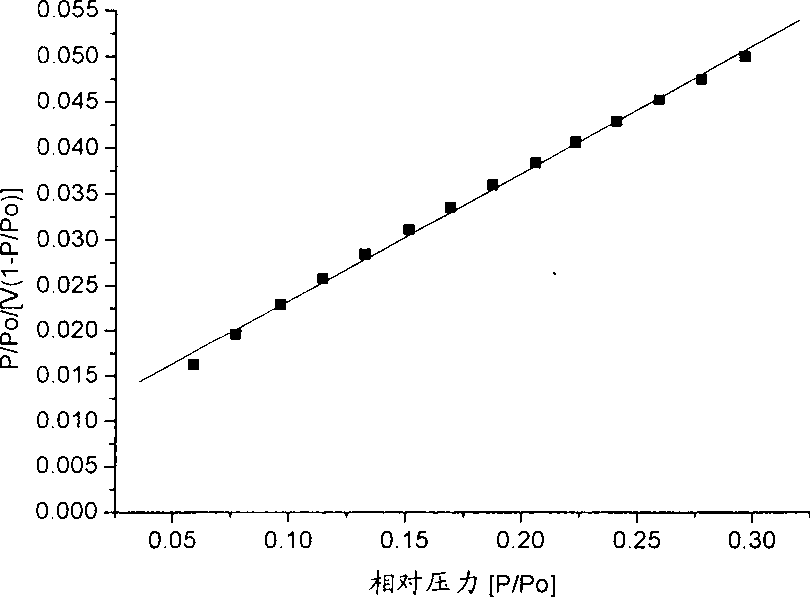

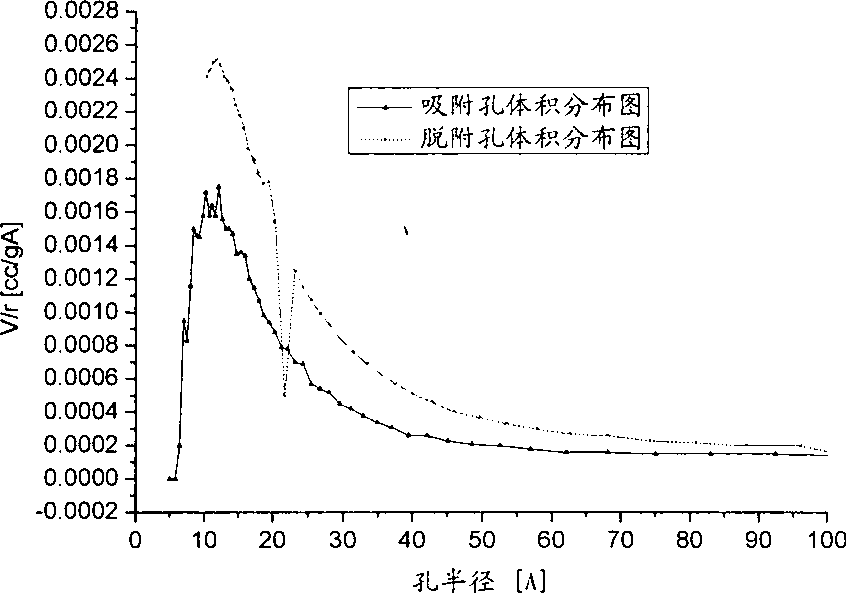

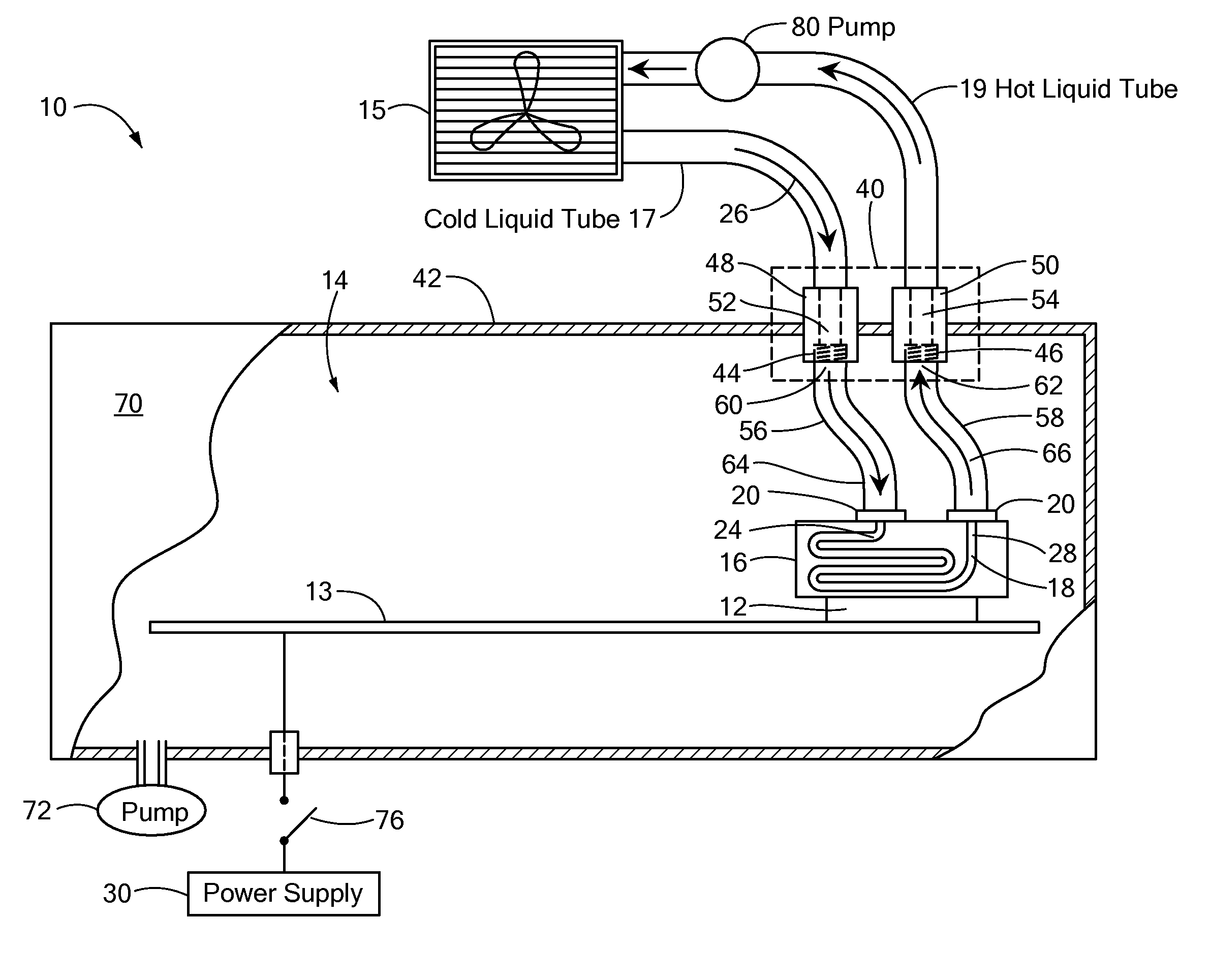

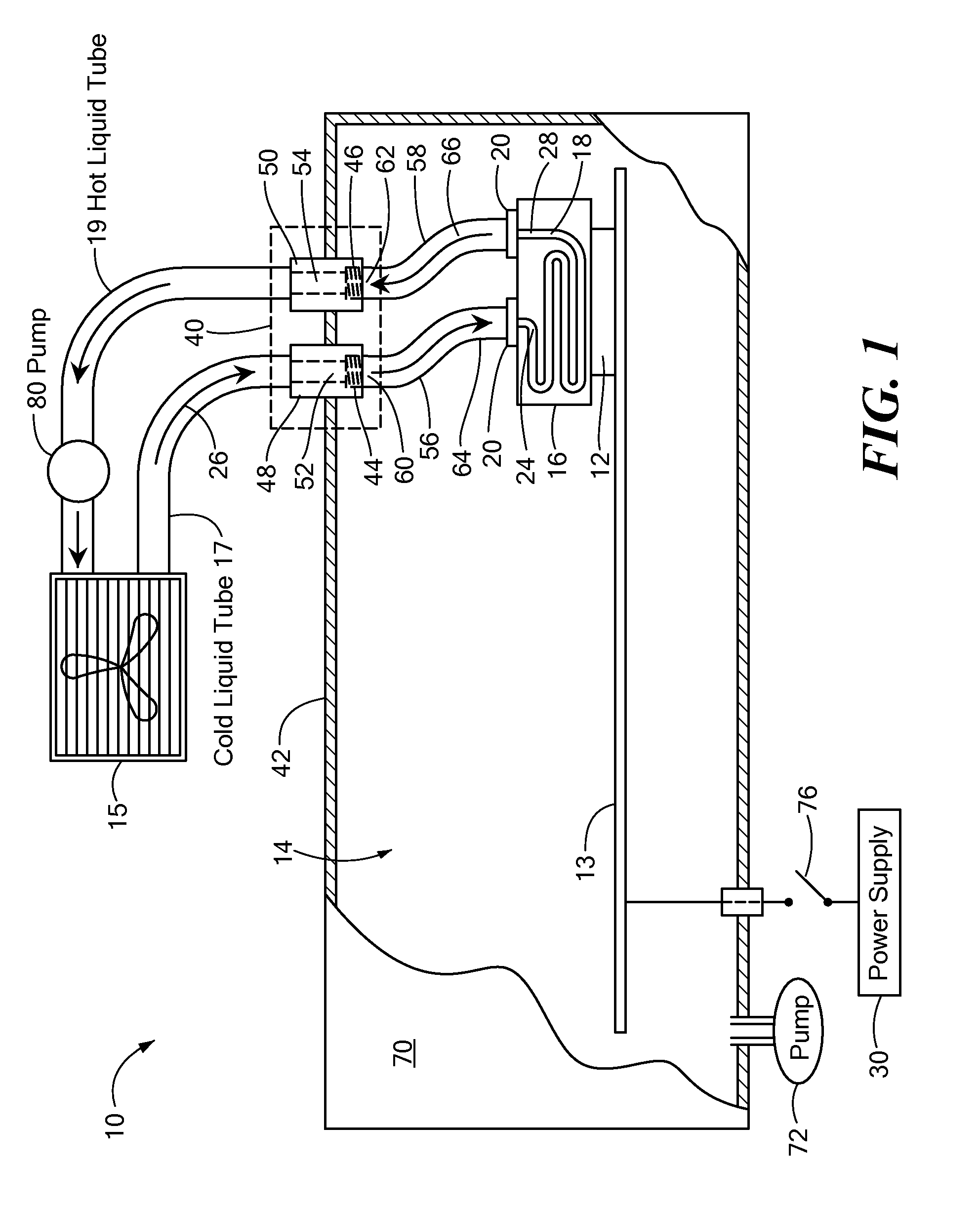

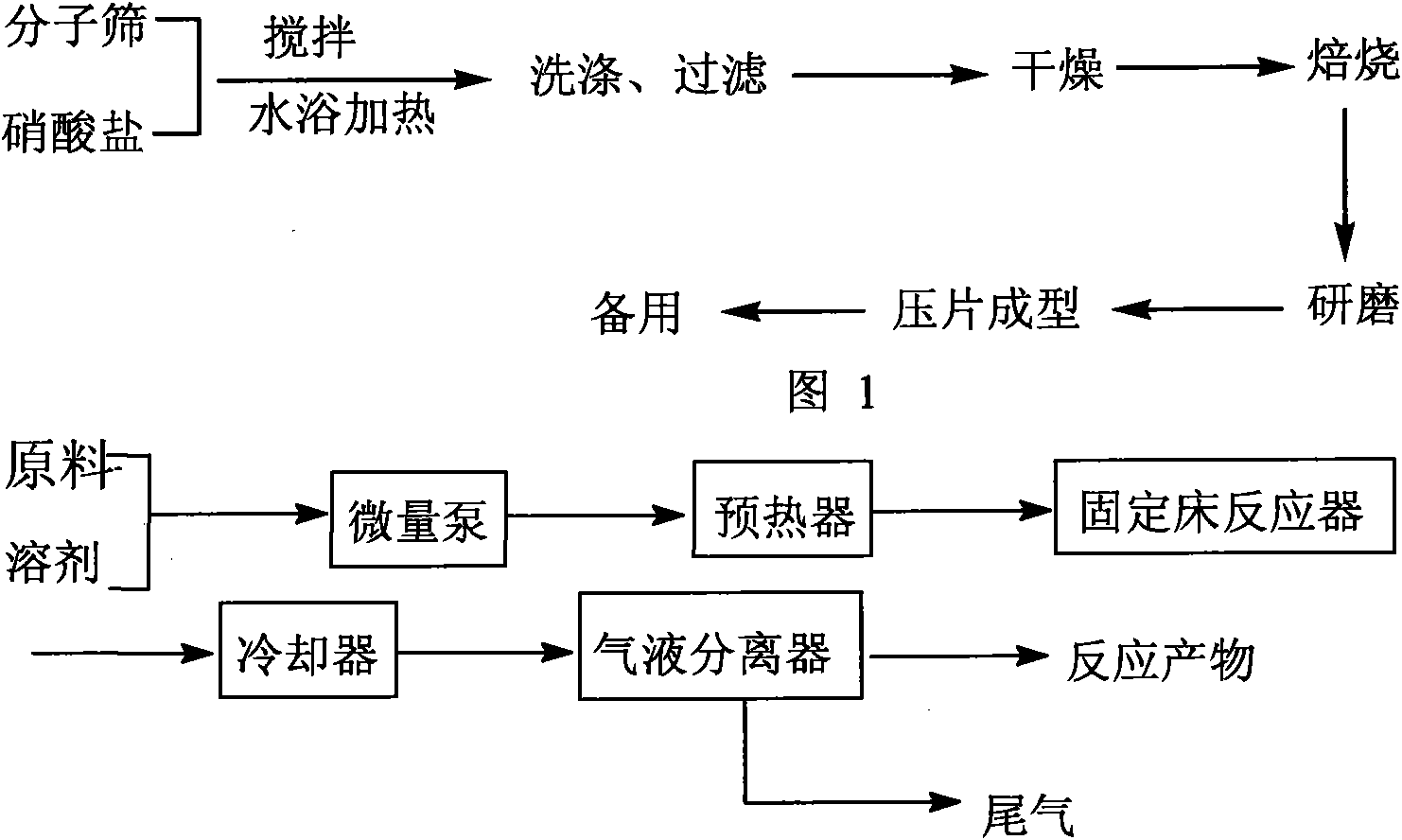

Molecular sieve modified catalyst, preparation method and application thereof to preparation of acrylic ester

ActiveCN101703944AStrong Acid StrengthLarge specific surface areaMolecular sieve catalystsOrganic compound preparationMuffle furnaceBUTYL LACTATE

The invention relates to a molecular sieve modified catalyst and a preparation method. The catalyst comprises a main catalyst A and an auxiliary catalyst B, wherein the main catalyst A comprises X-type, Y-type, ZSM-6type and ZSM-8-type molecular sieves, and the auxiliary catalyst B comprises nitrates of Ca (NO3)2, La (NO3)3, KNO3, Cu(NO3)2 and Co(NO3)2; the mass ratio of metal ions in the catalyst B to the catalyst A is 1%-5%. The preparation method comprises the following steps: weighting quantitative components A and B; adding a certain amount of deionized water; acutely stirring in a waterbath at 80 DEG C for 6h; soaking for 4h; drying a filter cake in an oven at 120 DEG C until free water is dried; baking the dried catalysts in a muffle furnace at 200-600 DEG C for 4-8h; and tabletting, grinding and sieving the cooled catalysts on a standard sieve to obtain a catalyst of 18-35 meshes. The method for preparing acrylic ester by catalyzing butyl lactate and methanol with the catalysts is carried out under the conditions that the mol ratio of raw materials is 0.5: (1-4):1, the temperature is 300-400 DEG C, the reaction pressure is normal pressure, and the airspeed is 1-4h-1. The specific surface area of the catalyst is increased by load metal ions, and the amplification of pore volumes is beneficial to the operation of the reaction.

Owner:溧阳常大技术转移中心有限公司

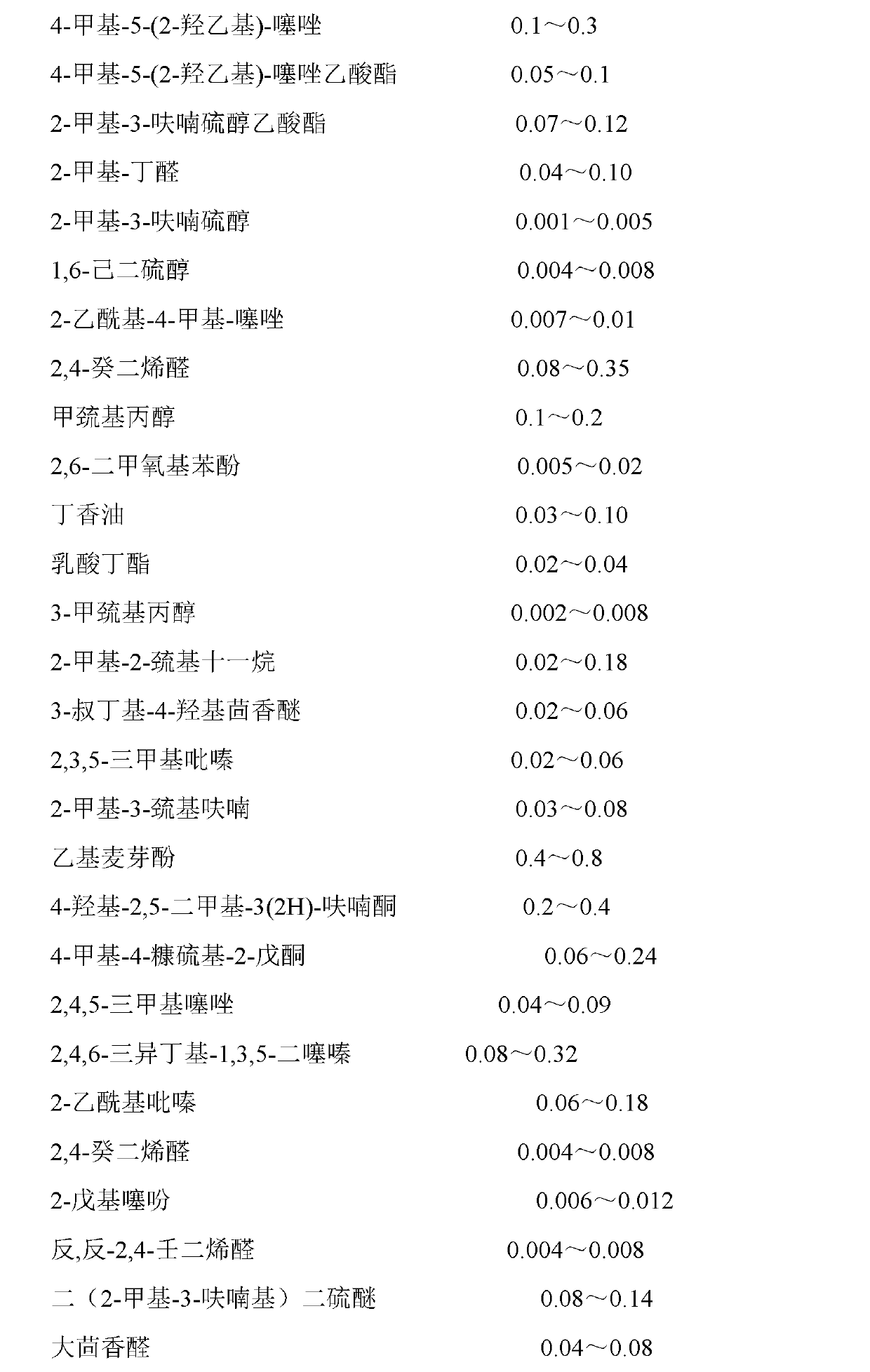

Meat flavor composition

The invention discloses a meat flavor composition which comprises 4-methyl-5-(2-hydroxyethyl)-thiazole, 4-methyl-5-(2-hydroxyethyl)-thiazole-acetate, 2-methyl-3-furanthiol-acetate, 2-methyl-butyraldehyde, 2-methyl-furanthiol, 1,6-ethanthiol, 2-acetyl-4-methyl-thiazole, 2,4-decadienal, methyl mercatopropanol, 2,6-dimethoxyphenol, clove oil, butyl lactate, 3-methyl mercatopropanol, 2-methyl-2-mercapto-undecane, 3-tert-butyl-4-hydroxyanisole, 2,3,5-trimethylpyrazine, 2-methyl-3-mercaptofuran, ethyl maltol and the like, with the balance being an oil-soluble solvent. The invention also provides a preparation method for the composition.

Owner:WUTONG AROMA CHEM CO LTD

Method for synthesizing high-recovery and high-optical purity L-butyl lactate

InactiveCN1450046AAvoid it happening againAvoid lostOrganic compound preparationCarboxylic acid esters preparationReaction temperatureN-Butyl Alcohol

The method for synthesizing L-butyl lactate with high yield and high optical purity uses concentrated sulfuric acid as catalyst, the added quantity of the concentrated sulfuric acid is 1.5% of lacticacid mass, the mole ratio of the n-butyl alcohol and lactic acid can be 0.5-4, reaction temp. is 50-150 deg.c, after the reaction is completed the solid anhydrous sodium acetate, solid anhydrous sodium carbonate, solid anhydrous sodium hydroxide or solid anhydrous sodium hydroxide can be directly added to neutralize sulfuric acid, then the above-mentioned material is filtered and separated so as to obtain the invented product. Its yield rate is up to above 90% and its optical purity is up to above 99.5%.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of high purity butyl lactate

ActiveCN103102269AImprove conversion rateHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfateSodium bisulfate

The invention relates to a preparation method of high purity butyl lactate. The method is characterized by: taking industrial lactic acid and n-butyl alcohol as raw materials, and adopting benzene as a water-carrying agent, subjecting them to an esterification reaction in the presence of a catalyst, then carrying out vacuum distillation and refining, thus obtaining the high purity butyl lactate. Specifically, the catalyst is a composite catalyst of potassium hydrogen sulfate and ferric trichloride, or a composite catalyst of p-toluenesulfonic acid and sodium hydrogen sulfate. The method provided in the invention shortens the esterification reaction time, increases the yield of butyl lactate, simplifies refining operation, and is easy to realize industrialization.

Owner:JIANGSU YIDA CHEM

Method for producing high-content and high-optical purity butyl lactate with two-step method

ActiveCN101914021AReduce moisture contentConfiguration flipPreparation by ester-hydroxy reactionOrganic-compounds/hydrides/coordination-complexes catalystsDepolymerizationLactide

The invention relates to a method for producing high-content and high-optical purity butyl lactate with a two-step method through the ester exchange reaction between lactide and butanol. The method comprises the steps of: adding a catalyst in lactic acid for condensation polymerization to obtain a lactic acid low polymer with the molecular weight of 1000-2500; adding the catalyst to the lactic acid low polymer for depolymerization to obtain a crude lactide product; and refining the crude lactide product, and carrying out total reflux reaction on the refined lactide and anhydrous butanol to obtain the butyl lactate. The invention has simple process, the synthesized butyl lactate has the content above 99.5 percent, and the optical purity reaches above 99 percent.

Owner:XIAOGAN ESUN NEW MATERIAL

Microemulsion detergent for resource treatment of oil-containing solid waste, and preparation method and application thereof

InactiveCN105236698AReduce interfacial tensionLow critical micelle concentrationSludge treatmentContaminated soil reclamationPropanoic acidSludge

A microemulsion detergent for resource treatment of oil-containing solid waste, and a preparation method and an application thereof are provided. The microemulsion detergent comprises the components by the mass percentage: 1.2%-4.0% of fatty alcohol polyoxyethylene ether sulfate, 2.0%-4.0% of butyl lactate, 0.5%-1.0% of amyl propionate, 0.3%-0.9% of sodium chloride, and 91.1%-96% of water. The microemulsion detergent can be mixed with the oil-containing solid waste at room temperature, can complete repair treatment and can recycle oil resources with high efficiency; cheap and easily accessible NaCl is used as an electrolyte, other components have less amount, treatment operation is simple, three-phase separation is facilitated, and subsequent treatment of sludge is facilitated; and an intermediate liquid phase namely a microemulsion phase can also continue to be recycled, so that the cost is lower.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

Preparation method of butyl lactate

InactiveCN102030644AOrganic compound preparationCarboxylic acid esters preparationEvaporationToluene

The invention relates to a preparation method of butyl lactate. The method comprises the following steps of: adding lactic acid, butanol, toluene and a catalyst into a flask according to a certain proportion; connecting a water konckout vessel; heating and performing a reflux reaction for a certain period of time; decompressing and evaporating so as to recycle toluene and butanol; after evaporation, cooling a reaction system to normal temperature; and removing the catalyst by filtering so as to obtain the butyl lactate, wherein the catalyst is an active argil supported catalyst. In the method, high-purity butyl lactate can be obtained; moreover, active argil has water absorbing and decoloring effects, so that the reaction is more complete and a product is attractive; simultaneously, a catalyst neutralizing step can be eliminated.

Owner:尹华芳

Plastic filler with high wear resistance and preparation method of plastic filler

The invention discloses plastic filler with high wear resistance. The plastic filler with high wear resistance is prepared from the following raw materials in parts by weight: 0.5-0.7 part of white oil, 0.3-0.5 part of resinous acid, 2-3 parts of zeolite molecular sieve powder, 1-1.5 parts of polyvinyl chloride paste resin, 1-2 parts of shea butter, 0.4-0.6 part of butyl lactate, 0.4-0.7 part of methyl methacrylate, 0.4-0.7 part of hydroxyethyl methylacrylate, 0.1-0.2 part of sodium persulfate, 2-3 parts of nano-iron-ore slag, 200-220 parts of light calcium carbonate, 5-9 parts of adjuvant and 20-30 parts of water. The corner angles of particles covered by using a modifying method disclosed by the invention are passivated and are close to be spherical, so that the particles are not easy to agglomerate and good in stability; due to the addition of high-polymer organic matters for modifying, the hydrophilicity of surfaces of the particles is changed into lipophilicity, the compatibility of the particles and plastics is good, and the strength and toughness of a plastic product are improved; and due to the addition of the nano-iron-ore slag, the impact resistance and wear resistance of the plastics can be enhanced. Due to the addition of the adjuvant, the dispersibility and self-lubrication property of the filler can be improved.

Owner:青阳县吉祥塑胶有限公司

Microemulsion and preparation method and application thereof and treatment method of oil-containing drill cuttings

ActiveCN108467797ASuper concentratedReduce interfacial tensionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsLauryl ether sulfateOil phase

The invention relates to the field of petroleum engineering drilling, and discloses a microemulsion and a preparation method and application thereof and a treatment method of oil-containing drill cuttings. The microemulsion comprises 15 to 25% by weight of an ionic surfactant, 5 to 20% by weight of a co-surfactant, 1 to 2.5% by weight of sodium chloride, 5 to 10% by weight of an oil phase and 55 to 65% by weight of water, the ionic surfactant is selected from at least one of sodium lauryl ether sulfate, fatty alcohol polyoxyethylene ether sulfate, and sodium lauryl sulfate; and the co-surfactant is at least one selected from the group consisting of butyl lactate, butyl acetate, propyl acetate, and amyl propionate. The microemulsion has ultra-low interfacial tension between drilling fluid base oil, and can effectively reduce the oil content of the drill cuttings. In addition, the microemulsion has the characteristics of superconcentration, and can save its own transportation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Purple yam essence, and preparation method and application thereof

ActiveCN104643004AAroma realism is highSoft and delicate aromaMilk preparationFrozen sweetsPyrazineIce Creams

The invention discloses purple yam essence, and a preparation method and application thereof. The purple yam essence is prepared from 2,3,5-trimethyl pyrazine, 2,3-dimethylpyrazine, dimethyl sulfide, butanedione, 3-hydroxy-2-butanone, 3-methylthiopropanal, 2-acetylpyrazine, 3-methylthio-propanol, butyryl butyl lactate, gamma-heptalactone, gamma-caprylolactone, ethyl maltol, maltol, anisic aldehyde, gamma-nonalactone, ethyl myristate, gamma-decalactone, delta-decalactone, mercaptan, delta-dodecalactone, ethyl vanillin, vanillin, trans-2-ethoxy-5-phenol and vanilla bean tincture are used as the main raw materials. the purple yam essence is prepared by adding all the raw materials into a container and uniformly agitating and mixing to obtain the purple yam essence. According to the purple yam essence, the raw materials are rich in source, so that the purple yam essence is coordinated and soft in aroma, has the natural featured aroma of prepared henry steudnera, and is rich in aroma, long in lasting time and stable. The purple yam essence can be used for adding the aroma of cakes, ice cream, milk products, drink and other products.

Owner:GUANGZHOU LEVON FLAVOUR & FRAGRANCE TECH

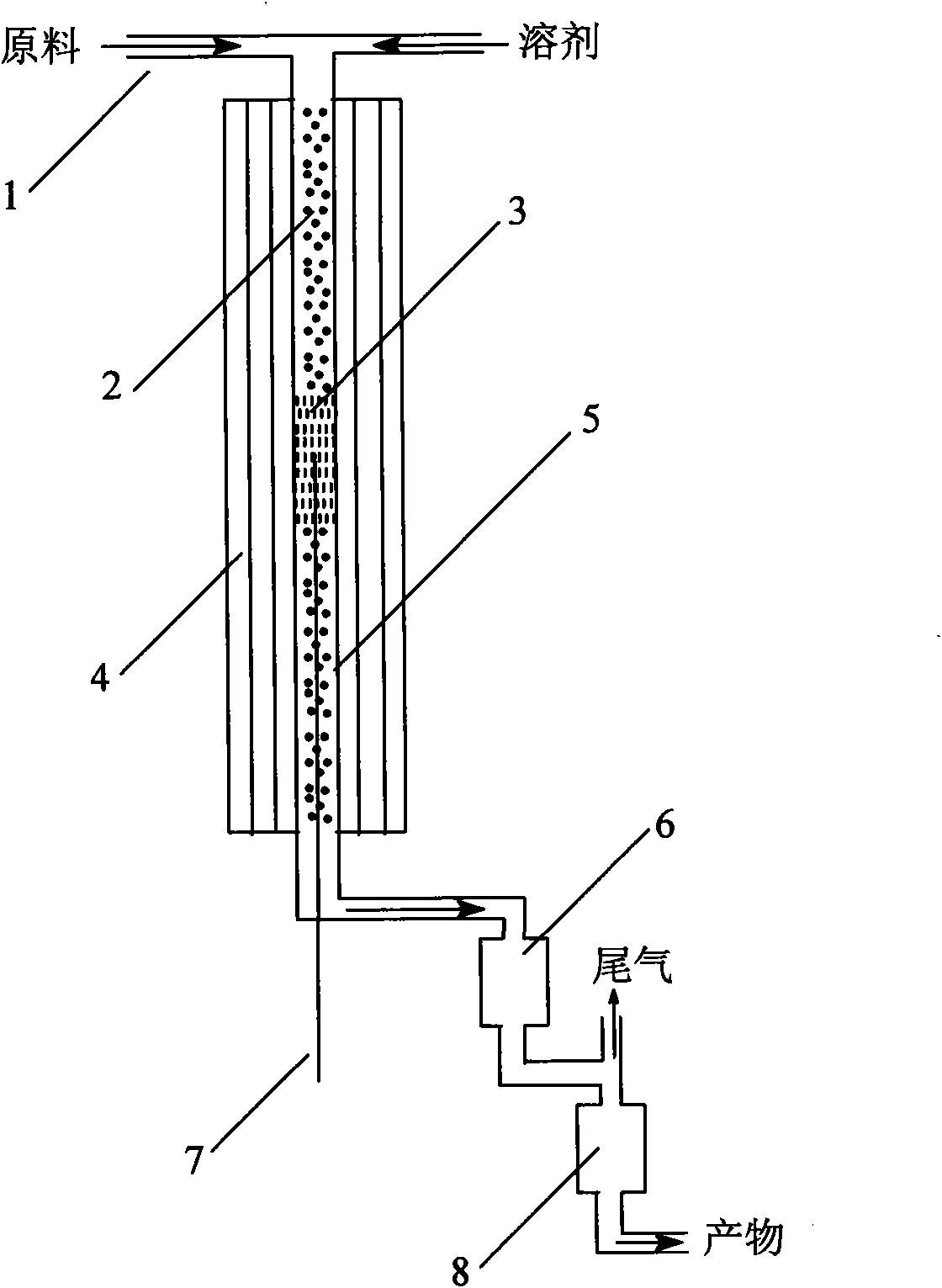

Catalyst for preparing acrylic acid and butyl ester using lactic acid method and preparation method thereof

ActiveCN101417232AImprove crystal structureHigh strengthPhysical/chemical process catalystsOrganic compound preparationSulphate IonBUTYL LACTATE

The invention discloses a catalyst used for preparing acrylic acid and butyl ester by the dehydration of butyl lactate and a preparation method thereof. The catalyst is a composite catalyst, comprising a main catalyst A and auxiliary catalysts B, C, D and E, wherein, A is calcium sulphate, B is sulphuric acid, C is phosphate, D is alkaline matter and E is promoter. The preparation method comprises the steps as follows: five compositions A, B, C, D and E are sufficiently mixed, baked for 2-10 hours at the temperature of 200-800DEG C and formed for standby. The catalyst has high catalytic activation; under the catalysis of the catalyst, the molar yield reaches 75.1 percent and the molar selectivity of the acrylic acid and butyl ester reaches 71.5 percent. The preparation method has the advantages that the crystal structure of the main catalyst can be improved so as to be beneficial for carrying out the reaction; and the introduction of different auxiliary catalysts and quantities is helpful to improve the conversion ratio of the raw material and the product selectivity and is beneficial for improving the strength of the catalyst.

Owner:溧阳常大技术转移中心有限公司

Varnish and color paste for making embossment, preparation method thereof, and use thereof

The invention discloses a varnish and color paste for making embossment, preparation methods thereof, and use thereof. The varnish comprises the following components in percentage by weight: 55 to 60 percent of aromatic solvent, 7 to 9 percent of di-2-ethylhexyl phthalate, 25 to 35 percent of n-butyl methacrylate-methyl methacrylate copolymer, 6 to 10 percent of butyl lactate and 1 to 2 percent of organic modified castor oil; and the total weight of the components is 100 percent. The color paste made by using the varnish of the invention and ceramic pigments has suitable viscosity and smoothness for point coating by a dispenser, avoiding blocking the pipe of the dispenser, preventing the point-coated semi-finished embossment from being unstable and deforming, and offers a desirable effect. The embossment can be made on a bone or ceramic material by the dispenser quickly and conveniently with less manpower and material cost.

Owner:SHENZHEN YONGFENGYUAN PORCELAIN

Essence with taste of butter

The invention relates to essence with taste of butter. The essence with the taste of butter comprises the following components in parts by mass: 50-70 parts of butter zymolyte, 1-1.5 parts of ethyl maltol, 0.5-0.6 part of undecalactone gamma, 0.8-1 part of gamma-nonanolactone, 0.1-0.3 part of 5.6-caproleic acid, 0.05-0.1 part of dimethyl sulfide, 0.7-1 part of ethyl caprylate, 0.2-0.4 part of methyl heptenone, 1-1.5 parts of butyric butyl lactate, 3-4 parts of 5-decanolide, 5-6 parts of delta-dodecalactone, 0.1-0.3 part of delta-tetradecalactone, 0.05-0.15 part of cis-4-heptene aldehyde, 3-4 parts of capric acid, 0.5-0.6 part of ethyl butyrate, 3-4 parts of palmitic acid, 0.05-0.1 part of 2-acetylpyrazine, 0.5-1 part of vanillin, and the balance being salad oil. The essence with the taste of butter disclosed by the invention has mellow, rich, comfortable and elegant fragrance in mouth feel, pure and natural milk taste, and plump and rich afteraste, and the temperature resistance of the essence can be permanent.

Owner:宁波威龙香精香料有限公司

Organic compound fuel oil additive

InactiveCN105567349APromote combustionImprove combustion efficiencyLiquid carbonaceous fuelsFuel additivesSulfonyl chlorideOil additive

The invention discloses an organic compound fuel oil additive. The additive comprises, by volume, 20-50 parts of diesel oil, 10-20 parts of butyl lactate, 20-40 parts of naphtha, 2-15 parts of turpentine, 20-40 parts of petroleum ether, 10-20 parts of dimethyl acetamide, 1-10 parts of ethyl acetate, 1-3 parts of cerium stearate, 1-2.5 parts of cerium naphthenate, 10-30 parts of acetone, 1-6 parts of butanone, 5-15 parts of ethanol, 20-40 parts of methanol, 10-20 parts of isopropanol, 10-30 parts of dimethyl ether, 10-30 parts of xylene, 10-30 parts of trimethylbenzene, 10-25 parts of 1,3-xylene and 1-5 parts of perfluorooctanoate sulfonyl chloride. The organic compound fuel oil additive has the advantages of high fuel oil efficiency, good fuel economy and small air pollution.

Owner:DONGGUAN HOUHE TECH CO LTD

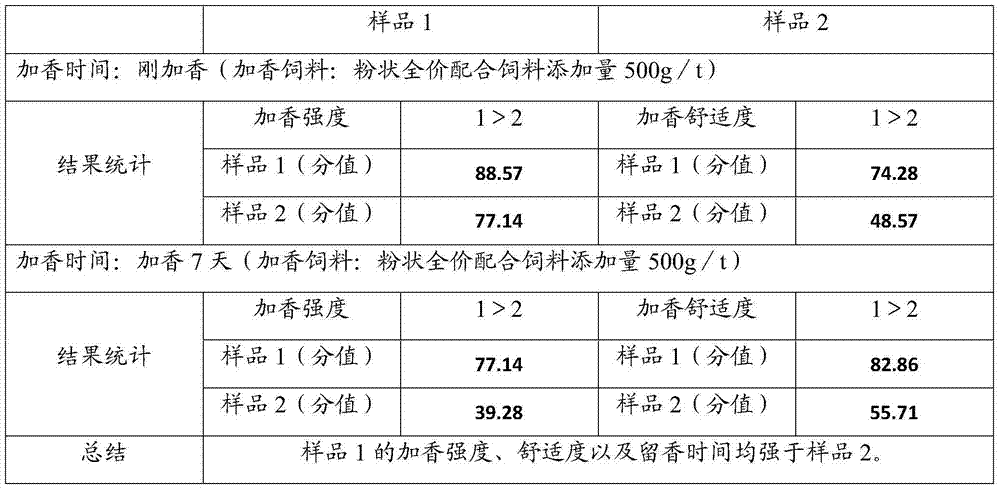

Toffee-flavored flavoring agent and preparation method thereof

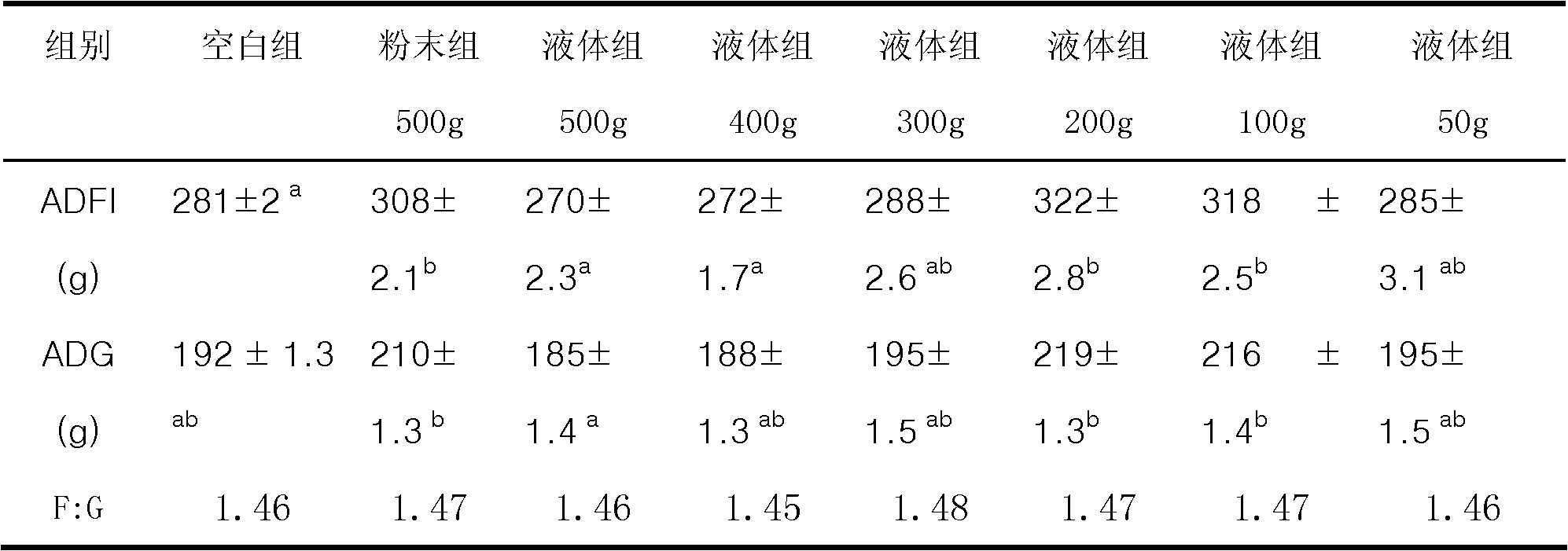

ActiveCN103636944AUnique flavorHighly recognizable aromaAnimal feeding stuffEthyl butyrateEthyl laurate

The invention relates to a toffee-flavored flavoring agent and a preparation method thereof. The flavoring agent consists of the following components in parts by weight, totaling 100 parts: 0.05-3 parts of butyric acid, 0.2-0.8 part of butyryl butyl lactate, 0.1-0.5 part of ethyl lactate, 0.05-0.5 part of ethyl butyrate, 0.5-3 parts of ethyl laurate, 0.8-2 parts of gamma-nonalactone, 0.1-1 part of gamma-decalactone, 0.2-3 parts of delta-decalactone, 0.5-5 parts of ethyl vanillin, 0.5-5 parts of lauric acid, 0.05-5 parts of linalool, 20-30 parts of an adsorbent, namely, silicon dioxide and 60-70 parts of a carrier. In comparison with the prior art, the flavoring agent is unique and unadulterated in toffee flavor, high and comfortable in aroma recognition degree, the food calling effect can be improved, the compatibility with feeds is good, the original bitterness of the feeds can be covered up, and the palatability of feeds is improved so as to promote ingestion of animals.

Owner:上海美农生物科技股份有限公司

Meat flavor composition

The invention discloses a meat flavor composition which comprises 4-methyl-5-(2-hydroxyethyl)-thiazole, 4-methyl-5-(2-hydroxyethyl)-thiazole-acetate, 2-methyl-3-furanthiol-acetate, 2-methyl-butyraldehyde, 2-methyl-furanthiol, 1,6-ethanthiol, 2-acetyl-4-methyl-thiazole, 2,4-decadienal, methyl mercatopropanol, 2,6-dimethoxyphenol, clove oil, butyl lactate, 3-methyl mercatopropanol, 2-methyl-2-mercapto-undecane, 3-tert-butyl-4-hydroxyanisole, 2,3,5-trimethylpyrazine, 2-methyl-3-mercaptofuran, ethyl maltol and the like, with the balance being an oil-soluble solvent. The invention also provides a preparation method for the composition.

Owner:WUTONG AROMA CHEM CO LTD

Water-blocking and oil-blocking fully degradable plastic film used for food packaging and preparation method thereof

InactiveCN105001459ASmall particle sizeExcellent gas barrier propertiesPolycaprolactoneBUTYL LACTATE

The invention discloses a water-blocking and oil-blocking fully degradable plastic film used for food packaging. The water-blocking and oil-blocking fully degradable plastic film is characterized by being prepared from, by weight, 60-65 parts of corn starch, 7-9 parts of nano-montmorillonite, 0.6-0.7 part of peanut oil, 1.2-1.4 parts of tetrabutyl titanate, 12-14 parts of ramie sticks, 30-35 parts of poval, 9-12 parts of polycaprolactone, 12-15 parts of trioctyl citrate, 2.5-3 parts of sodium alginate, 3-5 parts of calcium carbonate, 2-3 parts of butyl lactate and 1-1.5 parts of sodium trimetaphosphate. Poval of the appropriate amount is added to be matched with the starch-based material, then the trioctyl citrate and the butyl lactate are added to be blended, the melting point of the poval can be reduced, which is more beneficial for industrial production, the strength and flexibility are improved, and the prepared film is solid and durable; the plastic film can be applied to food packaging and cleaning bags and the like and be fully degraded and therefore is worthy of large-area popularization.

Owner:TONGLING FOUNDER PLASTICS TECH

Novel compound broad-spectrum herbicide

InactiveCN108651540ASignificant synergyFast weed killingBiocideAnimal repellantsCarpesium cernuumPendimethalin

The invention discloses a novel compound broad-spectrum herbicide which consists of the following raw materials in part by weight: 0.3-0.7 part of chlorantraniliprole, 0.1-0.5 part of sodium chlorate,3-8 parts of platanus orientalis leaves, 4-8 parts of pendimethalin emulsifiable concentrate, 0.3-0.7 part of quinclorac, 2-7 parts of carpesium cernuum extract, 1-5 parts of trifluralin emulsifiableconcentrate, 3-7 parts of JKCN, 4-9 parts of ragweed extract, 0.2-0.6 part of propisochlor, 0.1-0.5 part of cyhalofop butyl, 0.3-0.7 part of glyphosate isopropylamine, 0.3-0.7 part of pyrethroid, 0.4-0.7 part of quizalofop-p-ethyl, 4-9 parts of acetochlor emulsifiable concentrate, 2-5 parts of atrazine, 0.4-0.8 part of fomesafen, 0.3-0.7 part of Chinese prickly ash extract, 0.4-0.9 part of walnutquinone, 0.2-0.5 part of 2,4-D sodium butyl lactate, 0.3-0.7 part of isoproturon, 0.1-0.4 part of sodium dodecyl benzene sulfonate, 7-12 parts of camphor tree leaf, 2-6 parts of garlic extract, 0.3-0.7 part of bifenthrin, 2-5 parts of wettable powder and 0.2-0.6 part of mesotrione. The novel compound broad-spectrum herbicide disclosed by the invention has the advantages of being obvious in synergistic effect and grass killing speed improvement effect, board in herbicide control spectrum, low in medication cost and the like.

Owner:王奔

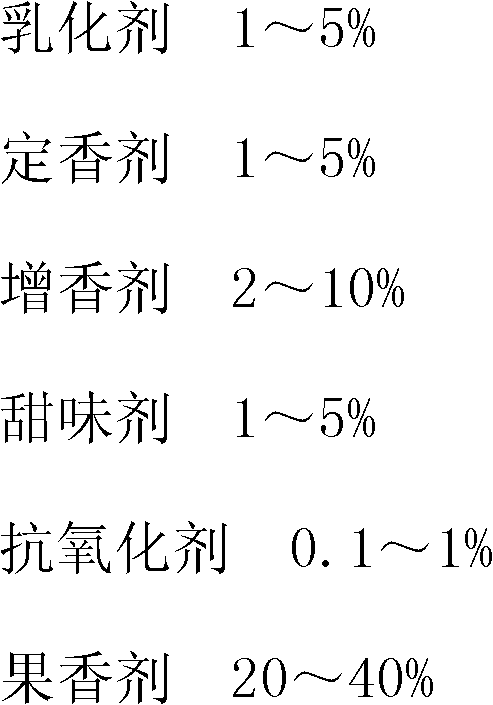

Anti-bacteria mildew-proof fruity type liquid flavoring agent and preparation technology thereof

InactiveCN102488092AAntibacterial and anti-mildew effect is remarkableGuarantee quality and safetyAnimal feeding stuffPropanoic acidAdditive ingredient

The invention relates to the field of animal feed, and particularly discloses an anti-bacteria mildew-proof fruity type liquid flavoring agent and a preparation technology thereof. The anti-bacteria mildew-proof fruity type liquid flavoring agent comprises, by mass percentage, emulsifier 1-5%, flavor fixing agent1-5%, flavor enhancer 2-10%, sweetener 1-5%, antioxidant 0.1-1%, fruit flavor agent 20-40%, anti-bacteria mildew-proof agent 15-25% and water 30-50%. The anti-bacteria mildew-proof agent is solution formed by mixing formic acid and propionic acid by mass ratio of 1:1-3. Furthermore, the fruit flavor agent is solution formed by mixing lemon oil butyric acid, water-soluble vanillin and butyl lactate by mass ratio of 6-4:4-2:1. The anti-bacteria mildew-proof fruity type liquid flavoring agent is efficient and remarkable in anti-bacteria and mildew-proof effects.

Owner:CHENGDU FENGLAN SCI & TECH

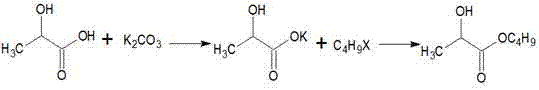

Method for synthesizing high-purity butyl lactate

InactiveCN107954867ALow priceLow costOrganic compound preparationCarboxylic acid esters preparationSodium bicarbonateDistillation

Provided is a method for synthesizing high-purity butyl lactate, and relates to the technical field of organic chemical synthesis. The method comprises the steps of: adopting lactic acid as a raw material, performing a reaction between the lactic acid and alkaline inorganic matter at a ratio in water to obtain lactate, performing distillation to remove water, performing a reaction between the lactate and n-butyl halide, and performing washing and rectification to obtain the high-purity butyl lactate, wherein the molar ratio of the lactic acid, alkaline inorganic matter and n-butyl halide is (1:0.5:1)-(1:1.1:1.5), the alkaline inorganic matter which is used for preparing the lactate includes one or a combination of more selected from sodium carbonate, potassium carbonate, sodium bicarbonate, potassium bicarbonate, sodium hydroxide and potassium hydroxide, and the n-butyl halide is one or a combination of more selected from n-butyl chloride and n-butyl bromide. The method has the advantages of low-cost raw materials, less equipment investment, mild reaction conditions and simple operation, and since water is adopted as a reaction solvent, the method is environmentally friendly and has low cost; the product can be purified easily, the purity can reach 99% or above, the yield can reach 95% or above, and therefore the method has a high economic value.

Owner:湖北华恒达化工有限公司

Fully-degradable plastic film with enhanced mechanical property and manufacturing method of fully-degradable plastic film

InactiveCN105968744ASolve poorly described problemsHigh strengthEnvironmental resistanceMechanical property

The invention discloses a fully-degradable plastic film with enhanced mechanical property. The plastic film is characterized by being made from the following raw materials, by weight part, 80-85 of polylactic acid, 25-30 of hemp fibers, 0.8-1 of a silane coupling agent kh-550, 20-25 of corn starch, 12-14 of glycerin, 1.6-2 of epichlorohydrin, a proper amount of a sodium hydroxide solution with the concentration being 1 mol / L, a proper amount of hydrochloric acid with the concentration being 1 mol / L, a proper amount of distilled water, 1-1.5 of epoxidized soybean oil, 5-7 of natural latex, 2-3 of butyl lactate and 3-5 of bamboo fibers. The manufactured fully-degradable plastic film is good in toughness and mechanical property, is easy to degrade in a natural condition, and is safe and eco-friendly. The manufacturing method is innovative in process and convenient for industrial control. The fully-degradable plastic film can be widely applied to packages for food and daily necessities. The plastic film is safe and eco-friendly, can be fully degraded, and is high in degradation speed.

Owner:ANHUI MENGNIU COLOR PRINTING&PACKAGING

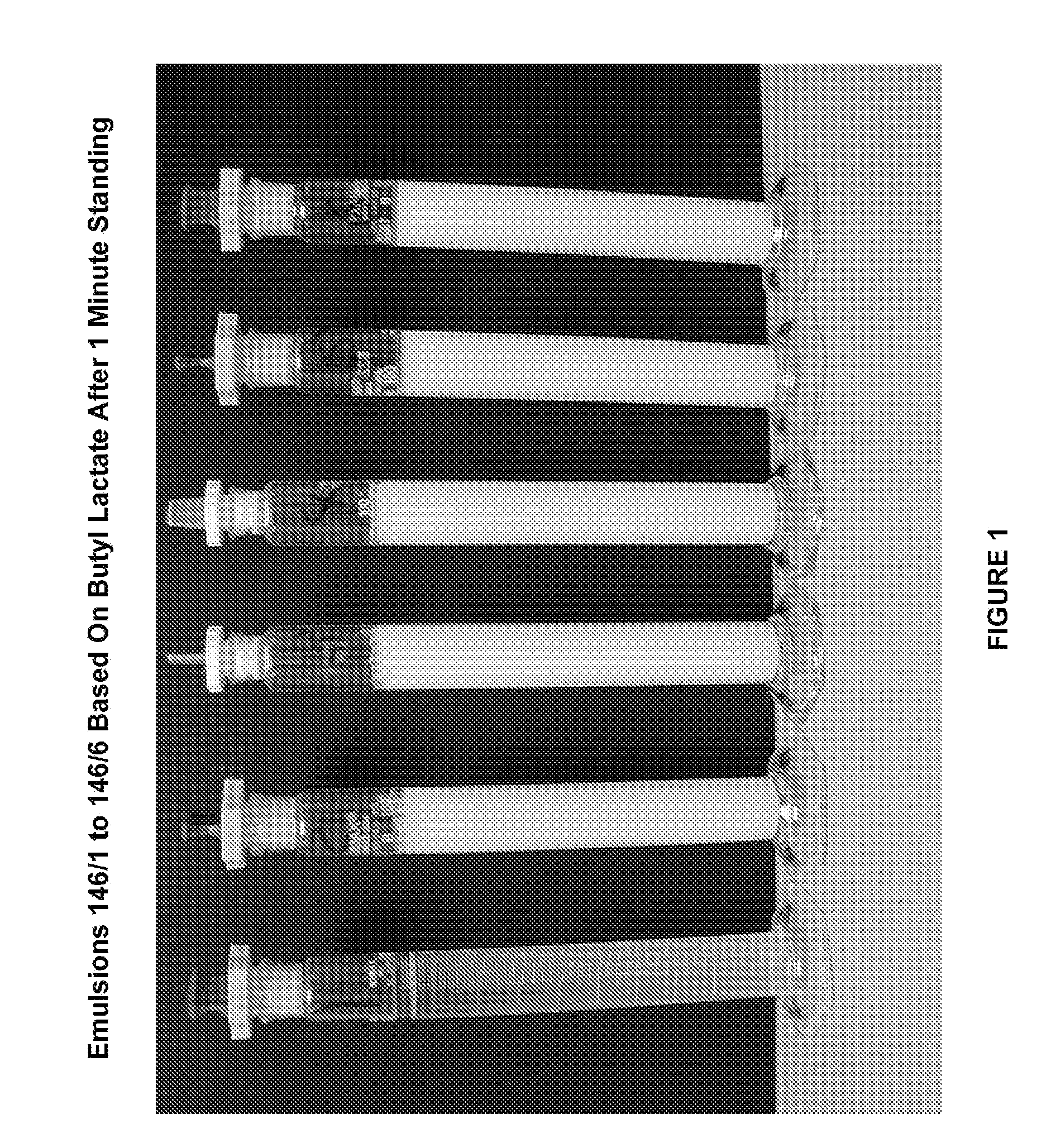

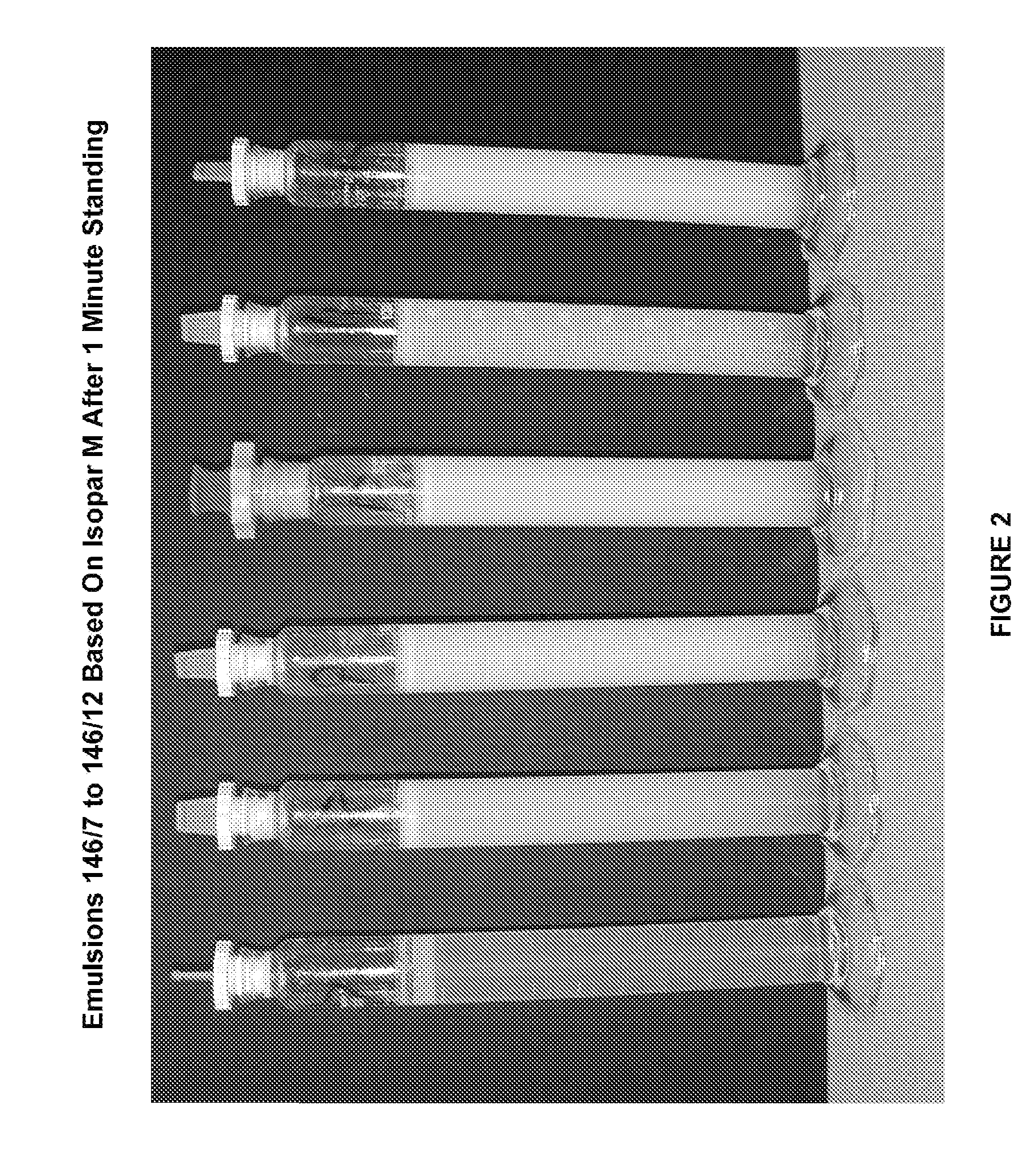

Butyl lactate emulsions for the precipitation of water-insoluble drug nanoparticles

Emulsions for use in precipitating water-insoluble drug nanoparticles. The continuous phase of the emulsions include water and an external surfactant. The discontinuous phase of the emulsions include butyl lactate, a co-solvent, an internal surfactant and a water-insoluble drug that is solubilized in the discontinuous phase. The emulsions allow for the precipitation of nanoparticles of water-insoluble drugs that are otherwise difficult or impossible to precipitate using conventional emulsion techniques.

Owner:FERRO CORP

Esterification technique of butyl lactate

InactiveCN106187757AHigh activityEfficientOrganic compound preparationCarboxylic acid esters preparationMass ratioDistillation

The invention relates to an esterification technique of butyl lactate. The technique comprises the following steps: by using lactic acid and butanol in a mass ratio of 1:1 as raw materials and dichromic acid as a catalyst (the mass ratio of the catalyst to the lactic acid is 1:200), proportioning, adding a novel catalyst, and carrying out esterification with stirring and water diversion while strictly controlling the esterification reaction temperature and esterification reaction time, thereby obtaining butyl lactate; and carrying out distillation and refinement. The technique has the characteristics of lower requirements for facility tool sets, simple preparation method, flexible reaction time and high product yield, does not need to add alkalis for neutralization since the catalyst has weak acidity, solves the problem of facility corrosion, and is safe and environment-friendly. The technique has the advantages of environment friendliness, high economy and high efficiency.

Owner:盐城华德(郸城)生物工程有限公司

Molecular sieve modified catalyst, preparation method and application thereof to preparation of acrylic ester

ActiveCN101703944BStrong Acid StrengthLarge specific surface areaMolecular sieve catalystsOrganic compound preparationMuffle furnaceBUTYL LACTATE

Owner:溧阳常大技术转移中心有限公司

Formula of shiitake-flavor essence

InactiveCN110643430AAdds Mushroom FlavorNatural Mushroom FlavorEssential-oils/perfumesFood scienceBiotechnologyFlavoring essences

The invention discloses a formula of a shiitake-flavor essence. The formula comprises, by weight, 5-10 parts of butyl butyrate, 10-15 parts of isoamyl butyrate, 2-8 parts of dimethyl sulfide, 3-9 parts of dimethyl disulfide, 2-10 parts of 1-octen-3-ol, 1-4 parts of 2-propionylthiazole, 3-8 parts of butyl lactate, 2-9 parts of oleic acid, 6-15 parts of medium-chain triglyceride, 2-9 parts of cis-4-heptenal, 5-14 parts of farnesene, 3-8 parts of ethyl hexanoate, 3-6 parts of phenethyl alcohol, 3-10 parts of tetradecanoic acid and 4-10 parts of bay leaf oil. The cis-4-heptenal, farnesene and ethyl hexanoate are added, the cis-4-heptenal has the fragrance of green grass and grease, and has the fragrance of cream after being diluted, so the shiitake fragrance of the shiitake essence is increased; the farnesene has fresh fragrance and floral fragrance, and can provide natural fragrance, so the shiitake fragrance of the shiitake essence is natural; and the ethyl hexanoate naturally exists infruits such as pineapples, and has the pineapple fragrance, so the fragrance richness of the shiitake essence is improved.

Owner:武穴格莱默生物科技有限公司

Preparation method for novel modified high molecular material

InactiveCN109181084AImprove skid resistanceImprove wear resistanceBulk chemical productionLiquid layerMalonate

The invention provides a preparation method for a novel modified high molecular material. The preparation method comprises the following steps: crushing artemisia vulgaris with a crusher to obtain artemisia vulgaris powder, adding the artemisia vulgaris powder into a supercritical carbon dioxide extraction pond to be extracted for 24 hours to obtain an extraction solution, secondarily extracting the extraction solution with ethyl ether, separating an artemisia vulgaris liquid layer and drying the artemisia vulgaris liquid layer with a blowing drier to obtain artemisia vulgaris extract for later use; inputting natural rubber and EVA510 into an open mill to carry out open milling, wherein the roller spacing of the open mill is 1-3 mm, and carrying out thin-passing for 8-12 times to obtain anopen mill substance; adding the open mill substance, percarbamide, zinc oxide and light calcium carbonate together into an internal mixer to be mixed at 75-85 DEG C for 7-12 minutes to obtain a mixture; and adding the artemisia vulgaris extract, the mixture, zinc stearate, L-butyl lactate, 8-12 parts of tert-butyl ethyl malonate and 3-5 parts of azodicarbonamide into the internal mixer to be mixed, mixing the mixture by setting temperatures of the front, middle and back sections of the internal mixer at a rotating speed of 60-80 rpm for 40-60 minutes, and cooling the mixture to obtain the novel modified high molecular material.

Owner:SUZHOU LUOTELAN NEW MATERIAL TECH

Essence formulation with blueberry fragrance

InactiveCN110540900AImprove heat resistanceImprove aroma qualityTobacco preparationEssential-oils/perfumesSucroseEthyl butyrate

The invention discloses an essence formulation with blueberry fragrance. The essence formulation is characterized by comprising the following components in parts by weight: 2-8 parts of blueberry essential oil, 1-3 parts of capric triglyceride, 3-10 parts of phenylacetaldehyde, 1-3 parts of alpha-damascenone, 1-5 parts of lactic acid, 5-10 parts of honey extract, 1-4 parts of ethyl vanillin, 2-5 parts of ethyl acetate, 1-3 parts of ethyl butyrate, 0.5-1.5 parts of butyl lactate, 1-4 parts of oleic acid, 5-10 parts of sucrose ester, 20-30 parts of glycerin, 3-8 parts of farnesene, 3-10 parts ofpectin, 5-10 parts of ethyl maltol, 3-9 parts of soya bean lecithin, 1-3 parts of leaf aldehyde, 3-5 parts of cinnamon oil, 1-5 parts of mint essential oil, 3-7 parts of chamomile oil, 1-4 parts of oleic acid and 20-30 parts of water. The blueberry essence formulation adopts the natural equivalent components species with strong affinity with the blueberry juice as the raw material, so that the juice taste of the blueberry juice, the fermented milk, the flavored milk and like beverage added with the essence is enhanced, and the juice has the fragrance and taste of the fresh blueberry.

Owner:武穴格莱默生物科技有限公司

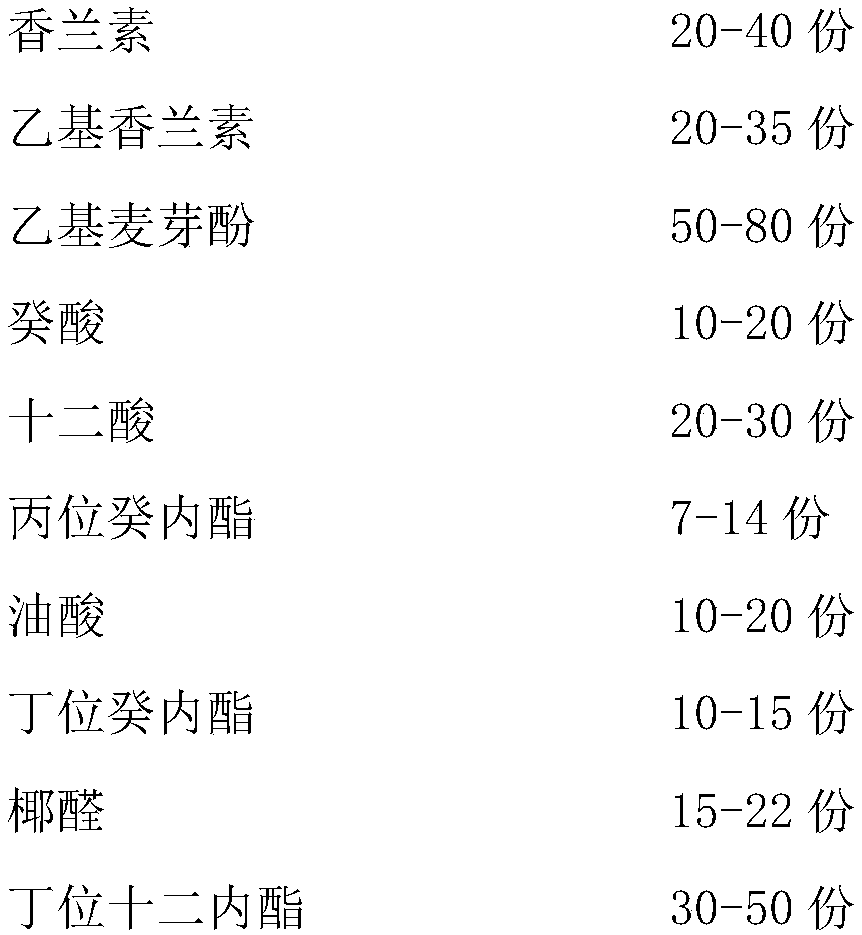

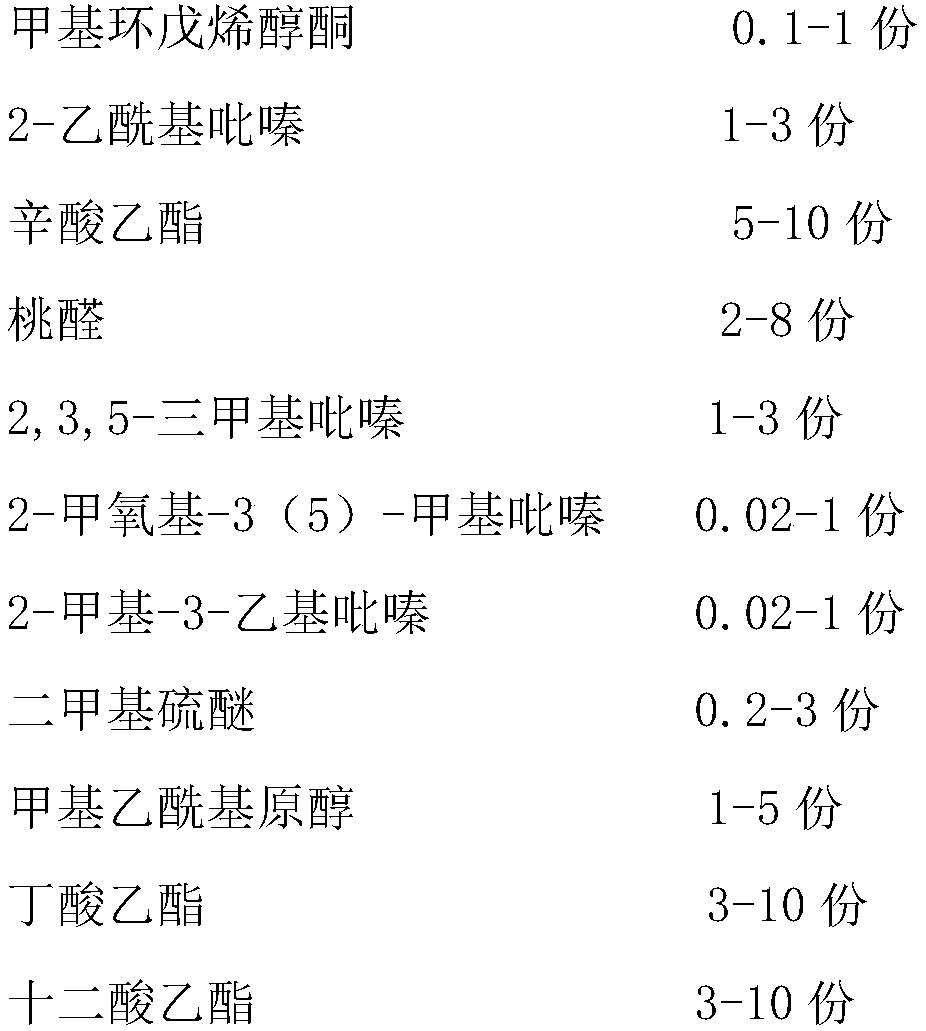

Condensed milk base, condensed milk essence and preparation method thereof

PendingCN108618095AAuthentic flavorSoft aromaLipidic food ingredientsFood ingredient as flavour affecting agentDigestionOleic Acid Triglyceride

The invention discloses a condensed milk base. The formula comprises the following components in parts by weight: 20 to 40 parts of vanillin, 20 to 35 parts of ethyl vanillin, 50 to 80 parts of ethylmaltol, 10 to 20 parts of capric acid, 20 to 30 parts of lauric acid, 7 to 14 parts of decalactone, 10 to 20 parts of oleic acid, 10 to 15 parts of butyl decanolate, 15 to 22 parts of cconut aldehyde,30 to 50 parts of dodecalactone, 15 to 20 parts of butyl butyl lactate, 20 to 30 parts of milk fat, 3 to 6 parts of 3-methylthiopropanal, 15 to 25 parts of butanedione, 2 to 10 parts of 3-methylthiopropanol, 10 to 20 parts of sulfurol, 20 to 30 parts of ethyl myristate, 500 to 600 parts of digestion butter and 1 to 2 parts of tert-butyl hydroquinone. The invention discloses condensed milk essenceprepared from the condensed milk base.

Owner:广州四季风食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com