Toffee-flavored flavoring agent and preparation method thereof

A fragrance and formula technology, applied in animal feed, animal husbandry, application, etc., can solve the problems of inability to really improve animal feed intake, poor feed compatibility, and excessive aroma intensity, so as to improve the food-attracting effect, The effect of promoting food intake, pleasant aroma and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) First add 1 kg of butyric acid, 3 kg of butyryl lactate, 2 kg of ethyl lactate, 1 kg of ethyl butyrate, 15 kg of ethyl dodecanoate, 10 kg of γ-nonalactone, γ-decane Put 3 kg of lactone, 5 kg of δ-decalactone, 10 kg of ethyl vanillin, 10 kg of lauric acid, and 1 kg of linalool into the liquid aging tank in turn, stir and mix for 1 hour; wait until the mixing is completed After that, the aging is completed, and it can be put into production after passing the inspection by the production department;

[0021] (2) Start the mixer, feed 200 kg of the weighed silica, enter the mixer through the screen, and feed the prepared essence. After the feeding is completed, mix for 5 minutes;

[0022] (3) Put 700 kg of the remaining carrier (anhydrous saccharin sodium) into the mixer and mix evenly, then stop the machine, pass through the sieve, weigh and pack.

Embodiment 2

[0024] (1) First add 2 kg of butyric acid, 4 kg of butyryl lactate, 3 kg of ethyl lactate, 2 kg of ethyl butyrate, 18 kg of ethyl dodecanoate, 12 kg of γ-nonanolactone, and 12 kg of γ-decane Put 5 kg of lactone, 8 kg of δ-decalactone, 15 kg of ethyl vanillin, 15 kg of lauric acid, and 3 kg of linalool into the liquid aging tank, stir and mix for 2 hours; That is, the aging is completed, and it can be put into production after passing the inspection by the production department;

[0025] (2) Start the mixer, feed 250 kg of the weighed silica, enter the mixer through the screen, and feed the prepared essence. After the feeding is completed, mix for 4 minutes;

[0026] (3) Put 700 kg of the remaining carrier (heavy calcium carbonate) into the mixer and mix evenly, then stop the machine; weigh and pack after passing through the sieve.

Embodiment 3

[0028] (1) First add 2 kg of butyric acid, 5 kg of butyryl lactate, 4 kg of ethyl lactate, 1 kg of ethyl butyrate, 25 kg of ethyl dodecanoate, 15 kg of γ-nonanolactone, γ-decane Put 8 kg of lactone, 10 kg of δ-decalactone, 10 kg of ethyl vanillin, 25 kg of lauric acid, and 5 kg of linalool into the liquid aging tank, stir and mix for 1.5 hours; That is, the aging is completed, and it can be put into production after passing the inspection by the production department;

[0029] (2) Start the mixer, feed 300 kg of the weighed silica, enter the mixer through the screen, and feed the prepared essence. After the feeding is completed, mix for 5 minutes;

[0030] (3) Put 600 kg of the remaining carrier (anhydrous sodium sulfate) into the mixer and mix evenly, then stop the machine; weigh and pack after passing through the sieve.

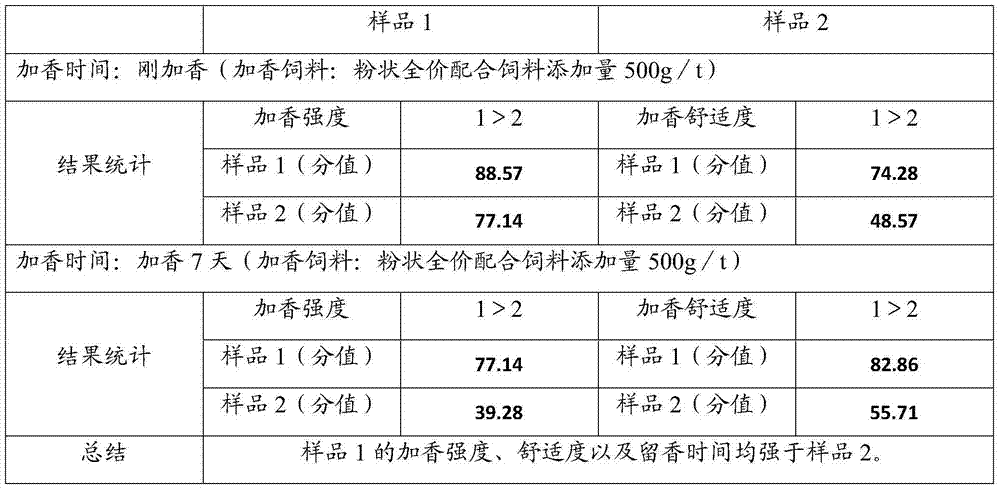

[0031] The beneficial effects of the present invention will be further illustrated below through effect examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com