Ceramic spiral fiber reinforced silicone rubber light ablation resistance thermal insulation coating and application thereof

A heat-insulating coating and fiber-reinforced technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of inability to achieve room temperature drying and curing, poor workability, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

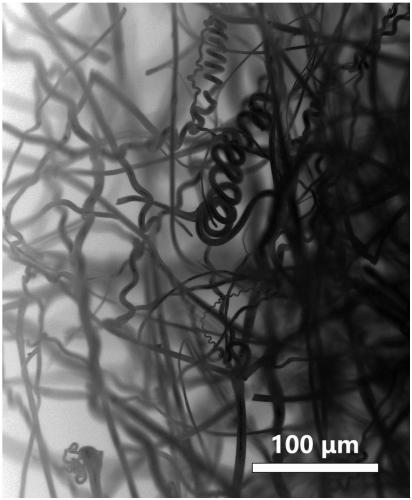

[0061] The ceramic helical fiber-reinforced lightweight silicone rubber ablation-resistant coating of the present invention is jointly used by two coatings, TI and TA, to achieve the ultimate high-temperature resistance and heat-proof performance.

[0062] (1) Preparation of TI thermal insulation coating

[0063] TI thermal insulation coating is composed of two components A and B according to a certain number of parts by mass. Component A consists of 30 parts of room temperature vulcanized silicone rubber, 25 parts of inorganic thermal insulation filler with low thermal conductivity, 1 part of coupling agent, 1 part of dispersant, and 43 parts of solvent.

[0064] Wherein, the preferred room temperature vulcanized silicone rubber of component A is dimethyl silicone rubber.

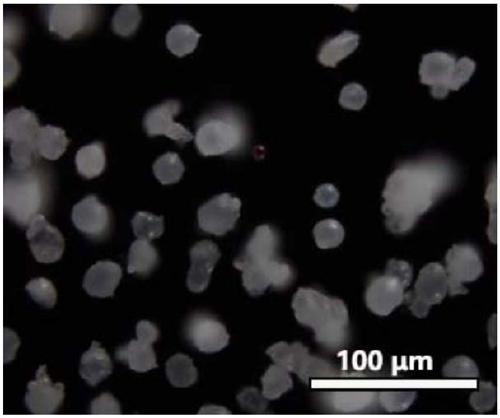

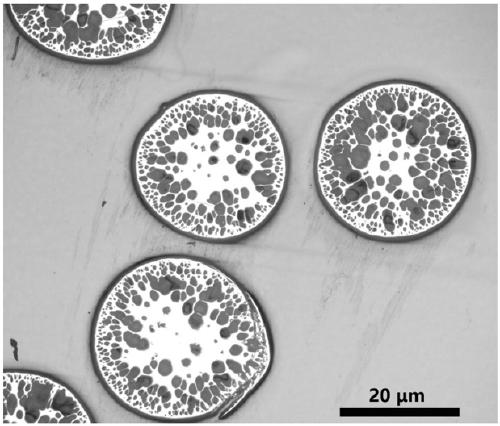

[0065] Wherein, the inorganic thermal insulation filler with low thermal conductivity is a combination of hollow glass microspheres and asymmetric hollow ceramic microspheres, and the ratio of parts by ma...

Embodiment 2

[0095]The ceramic helical fiber-reinforced lightweight silicone rubber ablation-resistant coating of the present invention is jointly used by two coatings, TI and TA, to achieve the ultimate high-temperature resistance and heat-proof performance.

[0096] (2) Preparation of TI thermal insulation coating

[0097] TI thermal insulation coating is composed of two components A and B according to a certain number of parts by mass. Component A consists of 30 parts of room temperature vulcanized silicone rubber, 25 parts of inorganic thermal insulation filler with low thermal conductivity, 1 part of coupling agent, 1 part of dispersant, and 43 parts of solvent.

[0098] Wherein, the preferred room temperature vulcanized silicone rubber of component A is dimethyl silicone rubber.

[0099] Wherein, the inorganic thermal insulation filler with low thermal conductivity is a combination of hollow glass microspheres and asymmetric hollow ceramic microspheres, and the ratio of parts by mas...

Embodiment 3

[0114] The ceramic helical fiber-reinforced lightweight silicone rubber ablation-resistant coating of the present invention is jointly used by two coatings, TI and TA, to achieve the ultimate high-temperature resistance and heat-proof performance.

[0115] (1) Preparation of TI thermal insulation coating

[0116] TI thermal insulation coating is composed of two components A and B according to a certain number of parts by mass. Component A consists of 30 parts of room temperature vulcanized silicone rubber, 25 parts of inorganic thermal insulation filler with low thermal conductivity, 1 part of coupling agent, 1 part of dispersant, and 43 parts of solvent.

[0117] Wherein, the preferred room temperature vulcanizing silicone rubber of component A is a combination of methyl vinyl silicone rubber and methyl phenyl vinyl silicone rubber, and the mass ratio is 1:1.

[0118] Wherein, the inorganic thermal insulation filler with low thermal conductivity is a combination of hollow gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com