High titanium-bearing heavy slag C50 self-compacting weakly expansive concrete-filled steel tube and preparation method thereof

A high-titanium heavy slag sand and concrete-filled steel tube technology, which is applied in the field of construction materials, can solve the problems of uncompacted pouring, easy voiding, and low air content of steel-filled steel tube concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In Examples 2 to 5, the preparation method of the described viscosity-increasing and plastic-retaining hyperdispersive additive comprises the following steps:

[0038] 1) Using methallyl alcohol, ammonia water and propylene oxide as raw materials, sodium methallylate or potassium methallylate as a catalyst, under the conditions of a pressure of 0.10-0.40MPaG and a temperature of 50-150°C , reacted for 3 to 7 hours to prepare a mixture of methallyl alcohol polyoxypropylene ether and triisopropanolamine, the molar ratio of the methallyl alcohol, ammonia and propylene oxide was 1:(0.2 to 0.5) : (5.0~78.0), the consumption of catalyst is 0.10~0.60% of methallyl alcohol quality;

[0039] 2) Take the mixture of methallyl alcohol polyoxypropylene ether and triisopropanolamine, sodium acrylate sulfonate, methacrylate and water prepared in step 1) as raw materials, add a reflux condenser, a thermometer and In the three-necked flask with dropping funnel, heat up to 60-90°C, add ...

Embodiment 1

[0043] In embodiment 1, the preparation method of thickening and plastic-retaining ultra-dispersion admixture is roughly the same as embodiment 2~5, and difference is: 1) the mol ratio of methallyl alcohol, ammoniacal liquor and propylene oxide is 1:0.4: 20. The amount of catalyst used is 0.4% of the mass of methallyl alcohol, the reaction pressure is 0.30MPaG, the temperature is 105°C, and the time is 5h; 2) the reaction between methallyl alcohol polyoxypropylene ether and triisopropanolamine Mixture 86%, sodium acrylate sulfonate 3%, methacrylate 8%, water 3%; 3) The molar ratio of methacrylic acid and polypropylene glycol monomethyl ether is 1.18:1, dipropylene glycol monobutyl ether and maleic anhydride The molar ratio is 1.5:1, the reaction temperature is 120°C, and the time is 4h; 4) Polypropylene glycol monomethyl ether methacrylate monomer 82%, diethylene glycol dipropylene glycol monobutyl ether monomer 3%, methyl 8% acrylic acid, 3% dimethylaminoethanol, 4% sodium me...

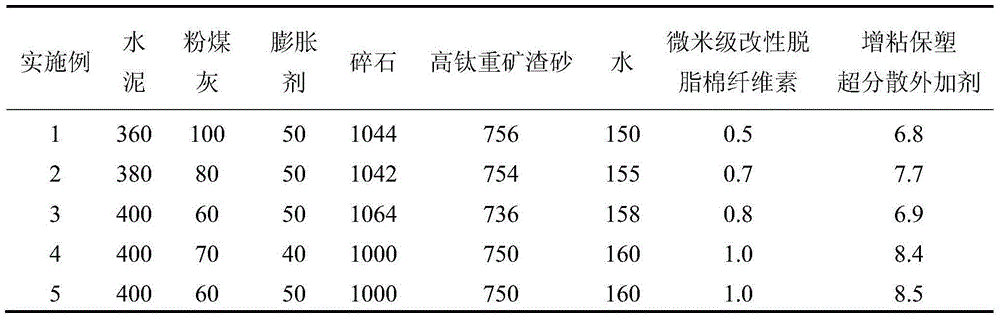

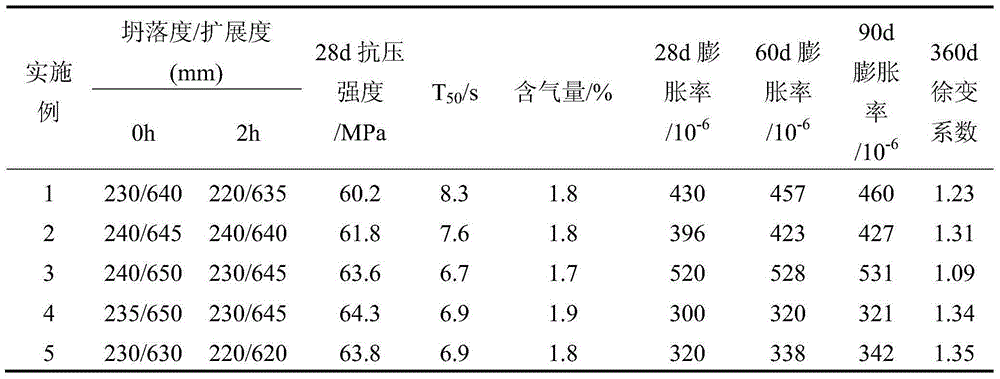

Embodiment 1~5

[0054] A kind of high-titanium heavy slag sand C50 self-compacting micro-expansion steel pipe concrete, with cement, fly ash, composite expansion agent, high-titanium heavy slag sand, gravel, thickening and plastic-retaining superdispersive admixture, micron-sized modified absorbent cotton fiber The raw material is prepared from element and water, and the preparation method comprises the following steps:

[0055] 1) take each raw material by each proportioning relation described in Table 1;

[0056] 2) Add the weighed cement, fly ash, composite expansion agent, gravel, and high-titanium heavy slag sand into the concrete mixer for dry mixing for 2 to 5 minutes; the high-titanium heavy slag sand should be soaked in water and pre-wetted for more than 20 hours before use. It reaches a saturated water absorption state, and the water absorption rate reaches 8-12%. During the dry mixing process, add the micron-sized modified absorbent cotton cellulose into the above-mentioned concret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com