Process for improving bearing capacity of formation

A technology of pressure bearing capacity and formation, applied in wellbore/well components, sealing/isolation, earth-moving drilling, etc., can solve the problem that the inert loss-stopping agent cannot be well cemented, the opening of formation cracks is very different, and the leakage The problem of low success rate, etc., can achieve the effect of accurate fracture opening, long plugging well section, and improving the success rate of lost circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

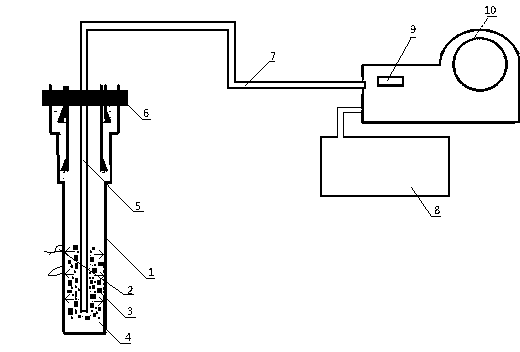

[0028] A technique for improving the pressure-bearing capacity of formations, characterized in that it comprises the steps of:

[0029] a. According to the data of formation pore size obtained by coring of exploratory wells in the block, the formation pore 2 size data of this well is obtained, and the plugging slurry is prepared with gel and plugging particles of corresponding size according to the formation pore 2 size;

[0030] b. Pump the prepared plugging slurry into the wellbore 1, and close the sealing device 6 after filling the wellbore 1;

[0031] c. Continue to pump the plugging slurry into the wellbore 1, so that the plugging slurry in the wellbore 1 is squeezed into the formation;

[0032] d. Rigid plugging particles 3 bridge the formation pores 2 to build a skeleton, and flexible plugging particles 4 fill in the rigid plugging particles 3 to fill the formation pores 2 near the wellbore 1 as much as possible, so that the casing pressure value of the sealer Continuo...

Embodiment 2

[0041] This embodiment is basically the same as the above-mentioned embodiment, the main difference is:

[0042]In the step a, the lost circulation slurry is prepared according to the relationship of 2.5 times the volume of the wellbore, and the lost circulation slurry is prepared according to the following mass percentages: 1% gel, 3% polyacrylamide, 5% rigid plugging particles, 20% flexible plugging Particles are leaked, and the balance is water.

[0043] In the present invention, the rigid plugging particles refer to sandstone materials with a size of 0.5 cm, and the flexible plugging particles refer to mica materials with a size of 0.1 cm.

[0044] In step c, Shanval pumps the lost circulation slurry into the wellbore at a displacement of 8L / S.

Embodiment 3

[0046] This embodiment is basically the same as the above-mentioned embodiment, the main difference is:

[0047] In the step a, the plugging slurry is prepared according to the relationship of 1 times the volume of the wellbore, and the plugging slurry is prepared according to the following mass percentages: 3% gel, 10% rigid plugging particles, 25% flexible plugging particles, and the balance is water.

[0048] The rigid plugging particles refer to nut shells, with a size of 2 cm, and the flexible plugging particles refer to mica materials, with a size of 1 cm.

[0049] In step c, Shanval pumps the lost circulation slurry into the wellbore at a displacement of 10L / S.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com