Preparation technology for composite of epoxy resin nano silicon dioxide

A technology of nano-silica and epoxy resin, which is applied in the preparation process of epoxy resin composite materials, can solve problems such as complex processes, and achieve the effects of uniform mixing, increased dispersion and dispersion stability, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

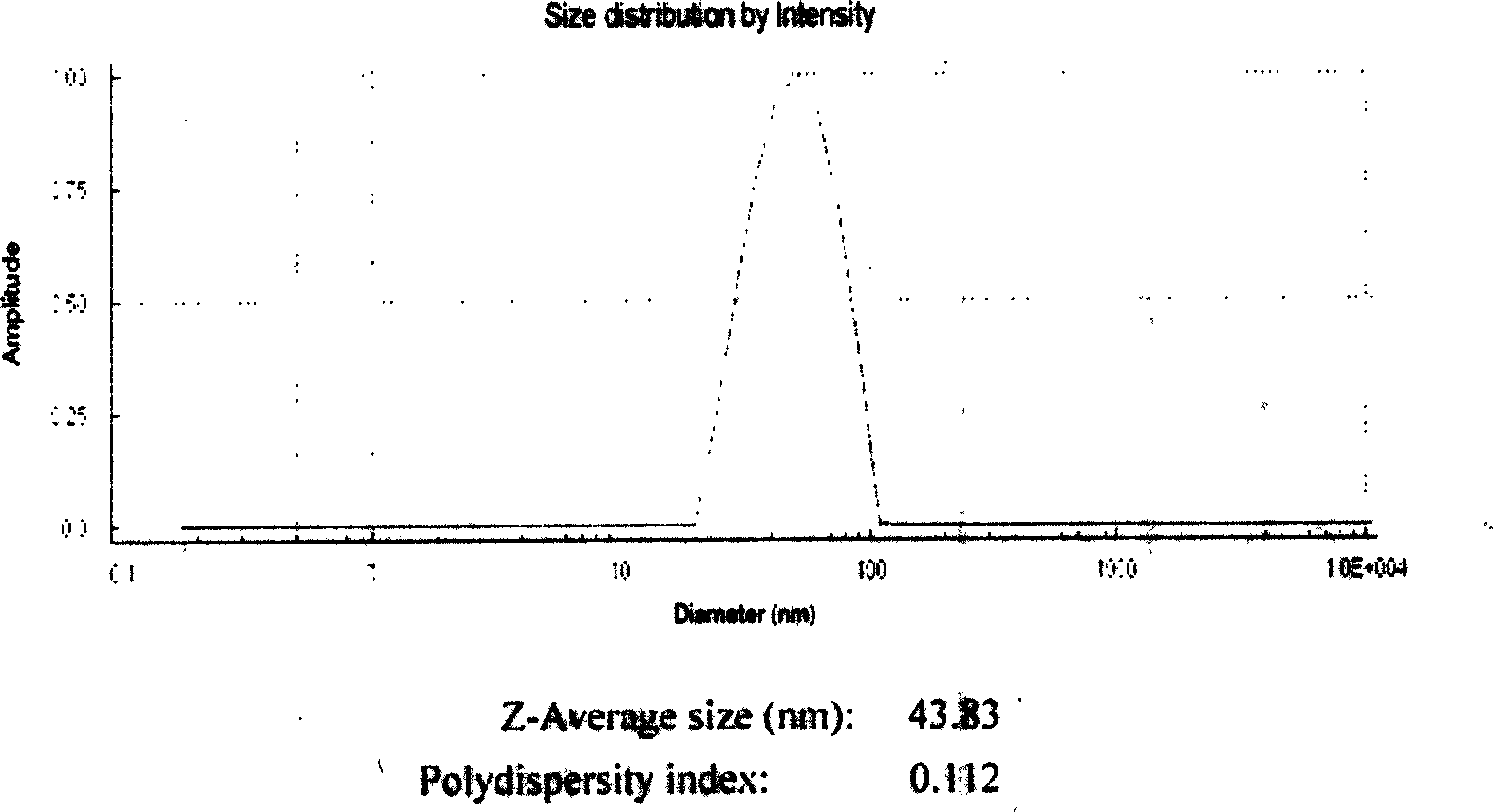

Embodiment 1

[0021] In the case of high-speed dispersion (5000-6000r / min), 0.1-5.0 parts by weight of nano silicon dioxide (SiO 2 ) particles are directly added to 95-105 parts by weight of liquid epoxy resin, and dispersed at high speed for 40 minutes; then add 40-60 parts by weight of water-based amine curing agent, mix evenly at a slow speed (100-200r / min), and mature for 20 minutes. The mixture was poured into a mold made of polytetrafluoroethylene, cured at constant temperature and humidity for 14 days (T=23±2° C., RH=55±5%), and the obtained polymer film was used for various performance tests.

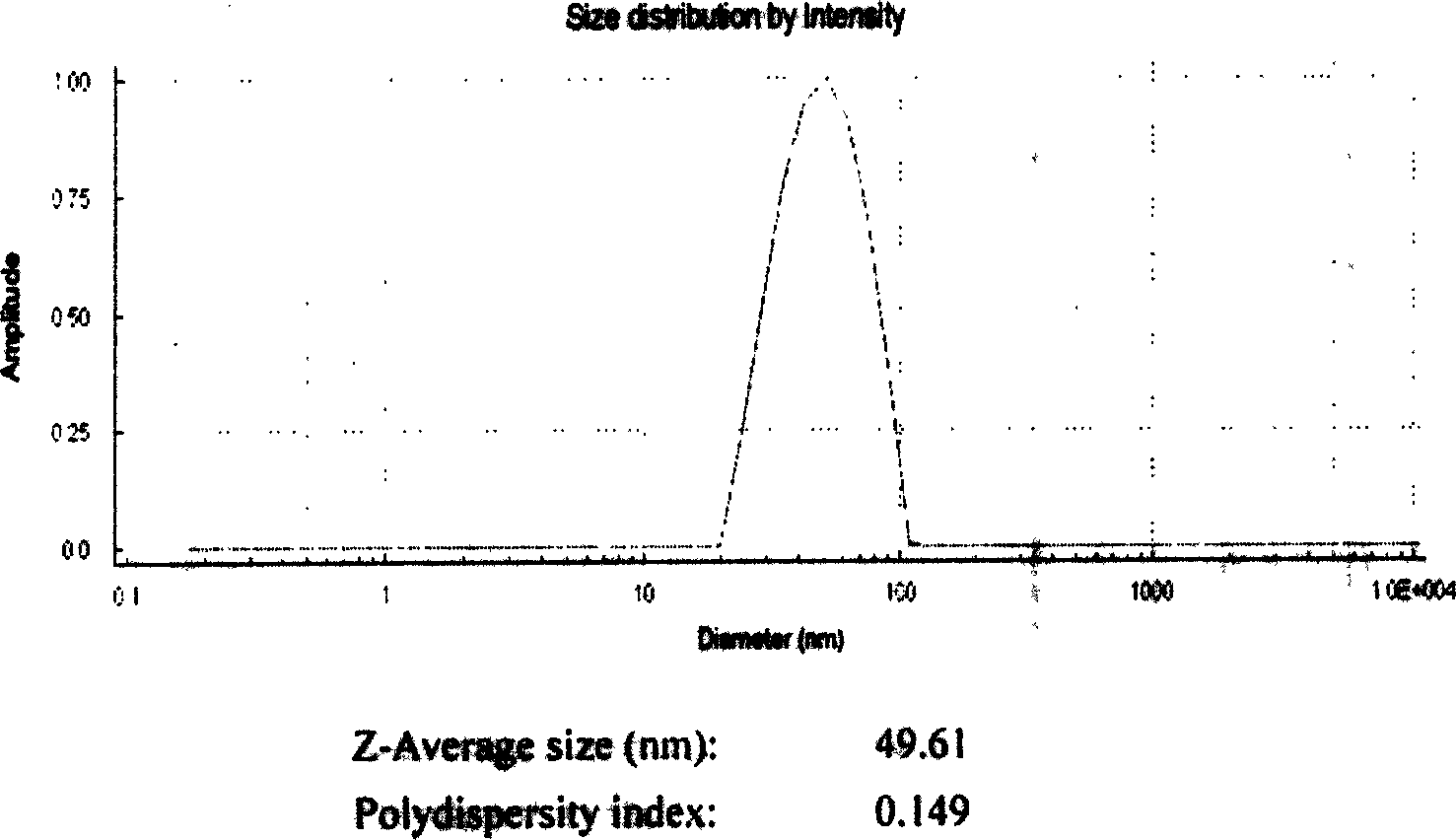

Embodiment 2

[0023] Under the action of ultrasonic waves, the nanoparticles are directly dispersed in the liquid epoxy resin. Others are the same as method 1.

Embodiment 3

[0025] Under the action of ultrasonic waves, the nano-silica particles are firstly dispersed in 10-60 parts by weight of epoxy active diluent, and then mixed evenly with epoxy resin under the action of a high-speed disperser. Others are the same as method 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com