Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

502 results about "Charoite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Charoite (K(Ca,Na)₂Si₄O₁₀(OH,F)·H₂O) is a rare silicate mineral, first described in 1978 and named for the Chara River. It has been reported only from the Sakha Republic, Siberia, Russia. It is found where a syenite of the Murunskii Massif has intruded into and altered limestone deposits producing a potassium feldspar metasomatite.

Preparation of iron-managanese compounded oxide/diatomite adsorbant, its using and regenerating method

ActiveCN101024160AImprove adsorption capacityGood arsenic removal effectOther chemical processesWater/sewage treatment by sorptionSorbentManganese oxide

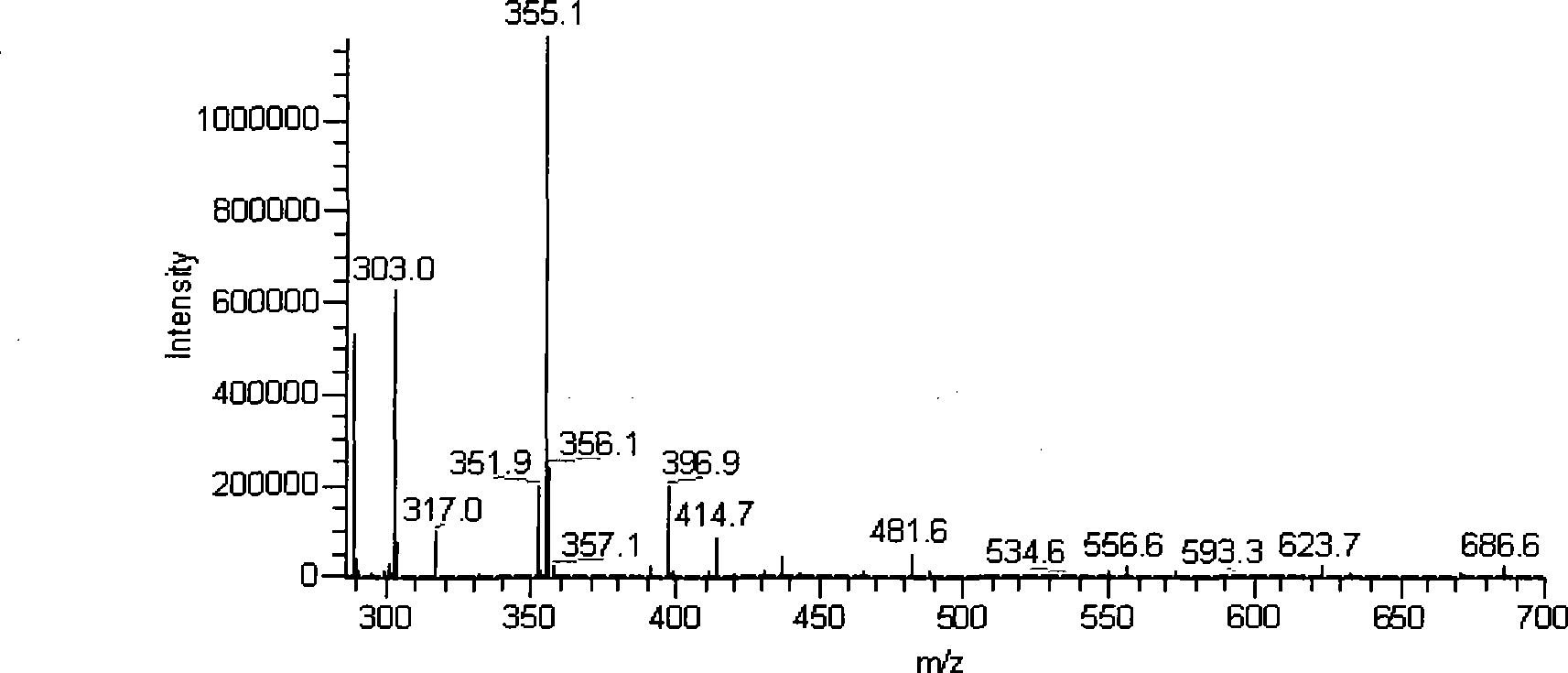

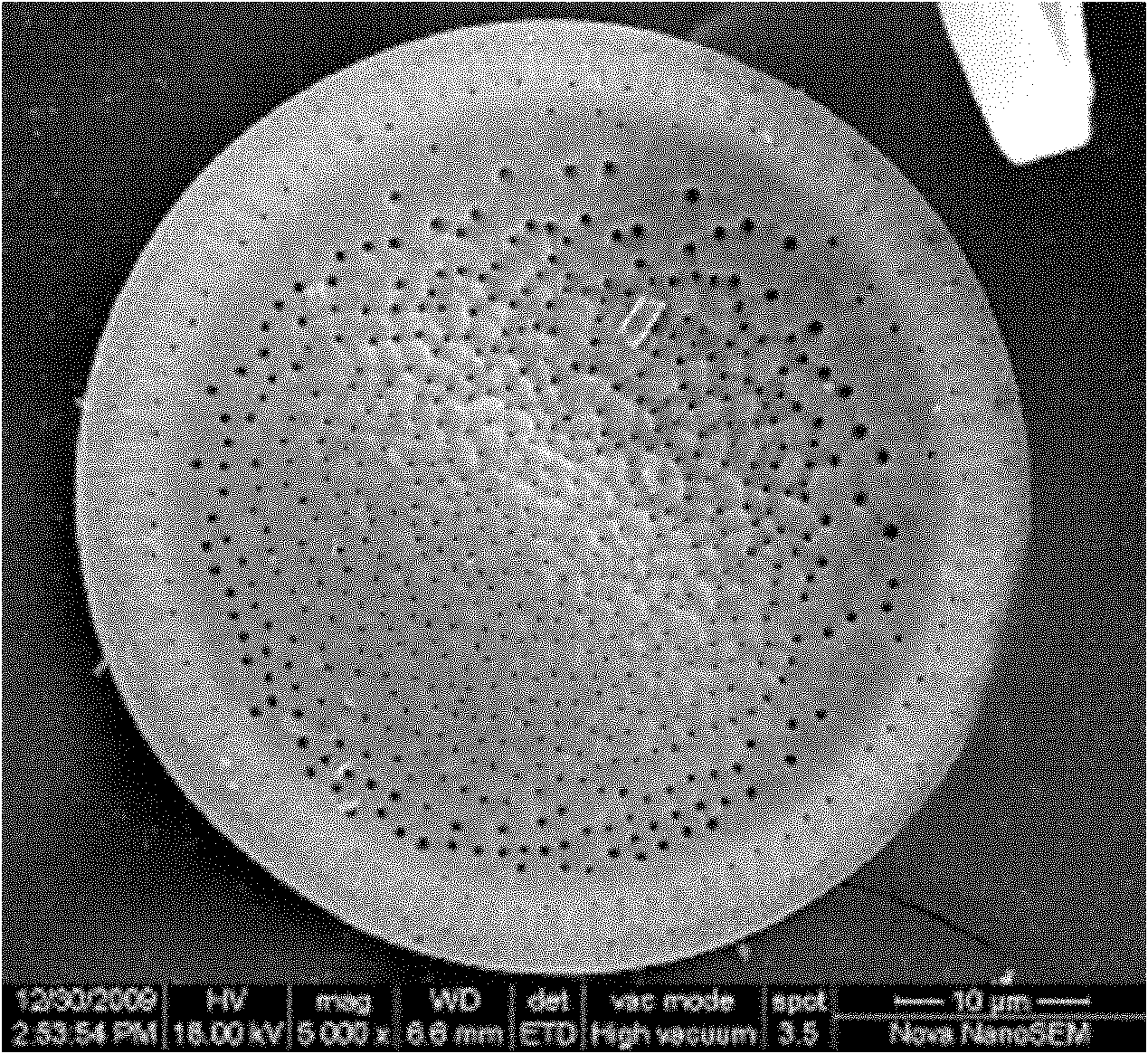

The invention supplies a new type adsorbent--mixed oxide of iron and manganese / diatomite preparation, use and regeneration method, belongs to the treatment of technology. The method used the soluble ferrous permanganate and salt as raw materials, respectively prepared the solutions, after adequate lye into permanganate solution, mixed two salt solutions, by adding diatomite particles, full oscillation, standing aging, neutralize, washing and drying to get the manganese oxide / silicon algae absorbent. The adsorbent is larger than the surface area and good adsorption properties can be used to remove arsenic in water pollutants (especially tervalence arsenic), and the adsorption surface activity of the saturated absorption of pollutants can be directly passed to load manganese oxide compound to regeneration.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Preparation method of novel diatom mud environment-friendly interior wall coatings

The invention relates to a preparation method of diatom mud environment-friendly interior wall coatings. The preparation method comprises the following steps of: firstly preparing the following materials in parts by weight: 20 of diatomite (325 meshes), 8 of adhesive powder, 0.6 of methyl cellulose, 7 of talc powder (700 to 900 meshes), 15 of calcium carbonate powder (400 to 600 meshes), 10of quartz sand (20 to 90 meshes), 10 of kaolin (750 to 850 meshes), 2 of attapulgite powder (550 to 750 meshes), 2 of titanium dioxide powder, 10 of ash calcium powder (550 to 650 meshes), 14.7 of r heavy calcium carbonate (1200 to 1300 meshes), 0.4 of wood fibers and 0.3 of staple fibers; loading the above materials into a horizontal high-speed dispersion machine according to the given ratio; and dispersing uniformly. The preparation method provided by the invention can produce novel interior wall coatings which are free of VOC (volatile organic compounds), temperature-resistant, fire-proof and wear-resistant and have stable performances, and a long useful service life.

Owner:HUNAN LANTIDEN ENVIRONMENTAL BUILDING MATERIAL LTD

High-quality strawberry planting dedicated slow-release compound fertilizer

InactiveCN104030800AImprove the phenomenon of single fixationGood release effectFertilizer mixturesMicrobial agentGluconates

The invention relates to the compound fertilizer field, and particularly relates to a high-quality strawberry planting dedicated slow-release compound fertilizer. The fertilizer is prepared from the following raw materials in parts by weight: 10-15 parts of a 1250-2000 mesh diatomite, 4-5 parts of borax, 2-3 parts of ammonium molybdate heptahydrate, 10-12 parts of sodium humate, 20-25 parts of urea, 18-22 parts of potassium nitrate, 25-28 parts of organic compost, 2-4 parts of fish meal, 1-3 parts of sesame leaves, 8-10 parts of alfalfa meal, 15-18 parts of corn distiller grains, 2-4 parts of brine, 8-10 parts of an erythromycin fungi residue, 1-2 parts of an EM microbial agent, 4-6 parts of a fern root residue, 1-3 parts of nano silver, 1-2 parts of a semen ginkgo powder, 4-6 parts of 1,6-hexanediol diacrylate, 10-12 parts of an acrylic resin dispersion liquid, 1-2 parts of isocyanate, 1-2 parts of calcium stearoyl lactate, 2-4 parts of zinc gluconate, 6-8 parts of table vinegar, and 4-5 parts of an auxiliary agent. The compound fertilizer has multiple nutrients, is low in production cost and good in slow-release effect, allows double coating to be formed on the nutrients by utilizing diatomite and a coating agent in the process, also contains various trace elements, has no toxicity and no pollution, and is excellent in quality of planted strawberry and obvious in yield and income increasing effects.

Owner:ANHUI SUNSON CHEM

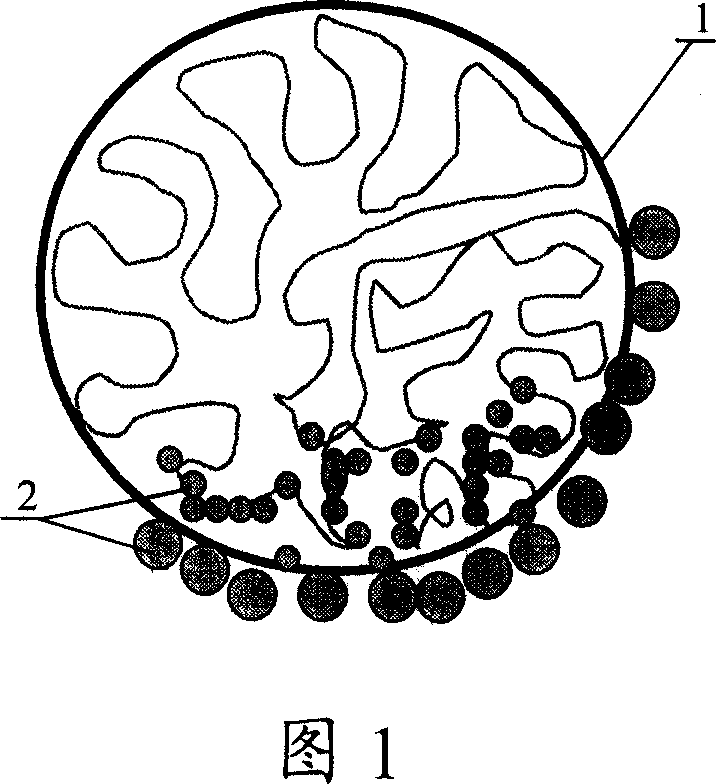

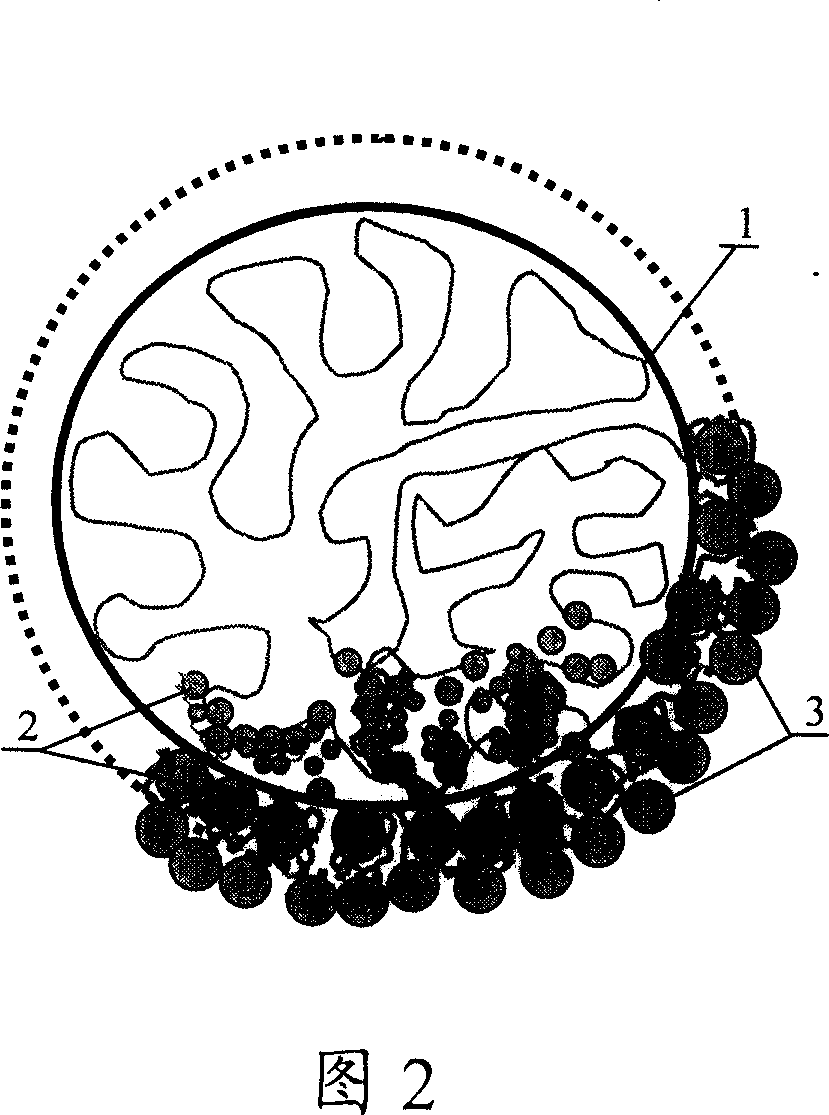

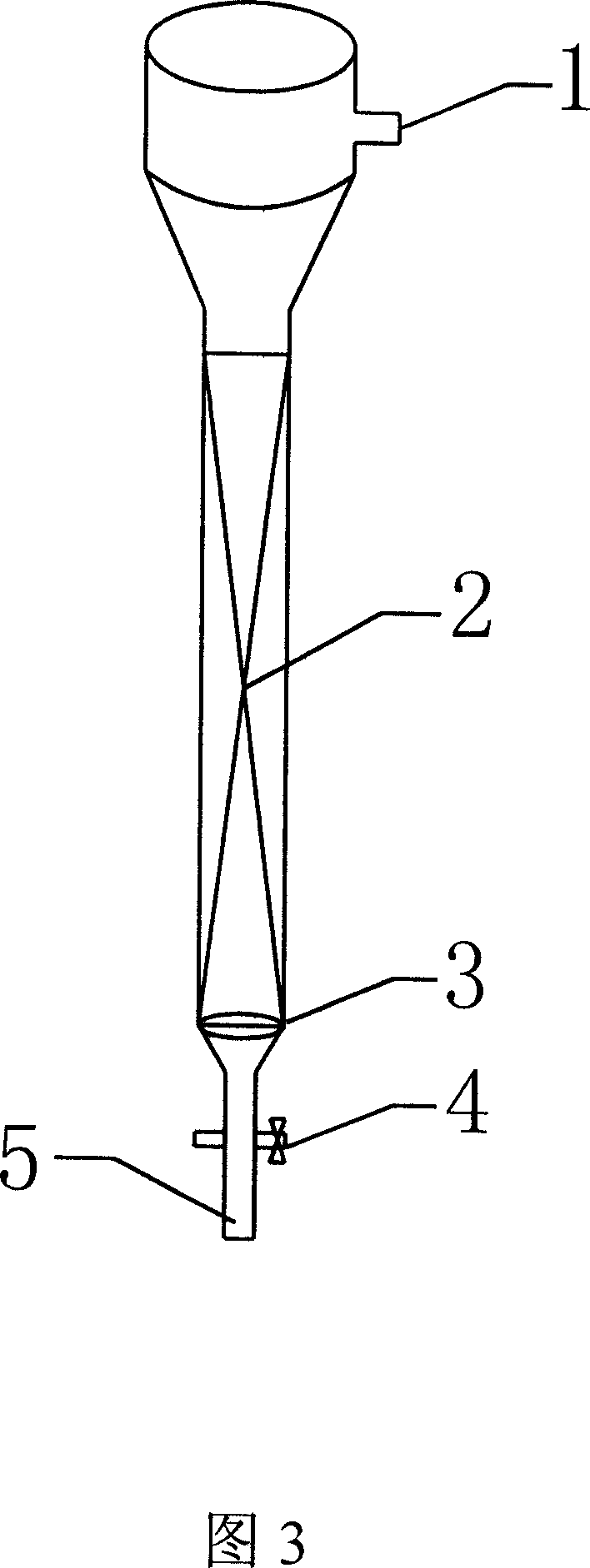

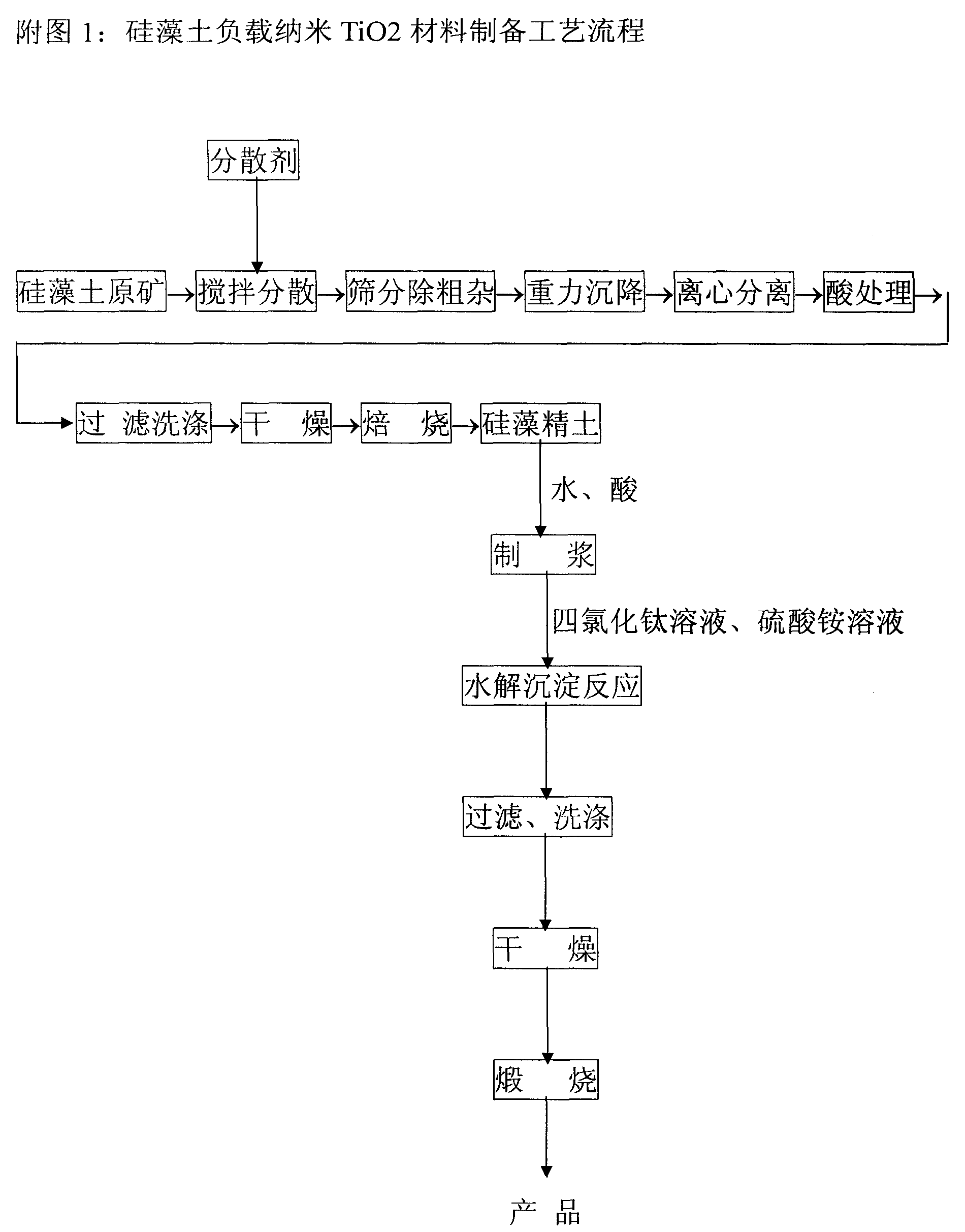

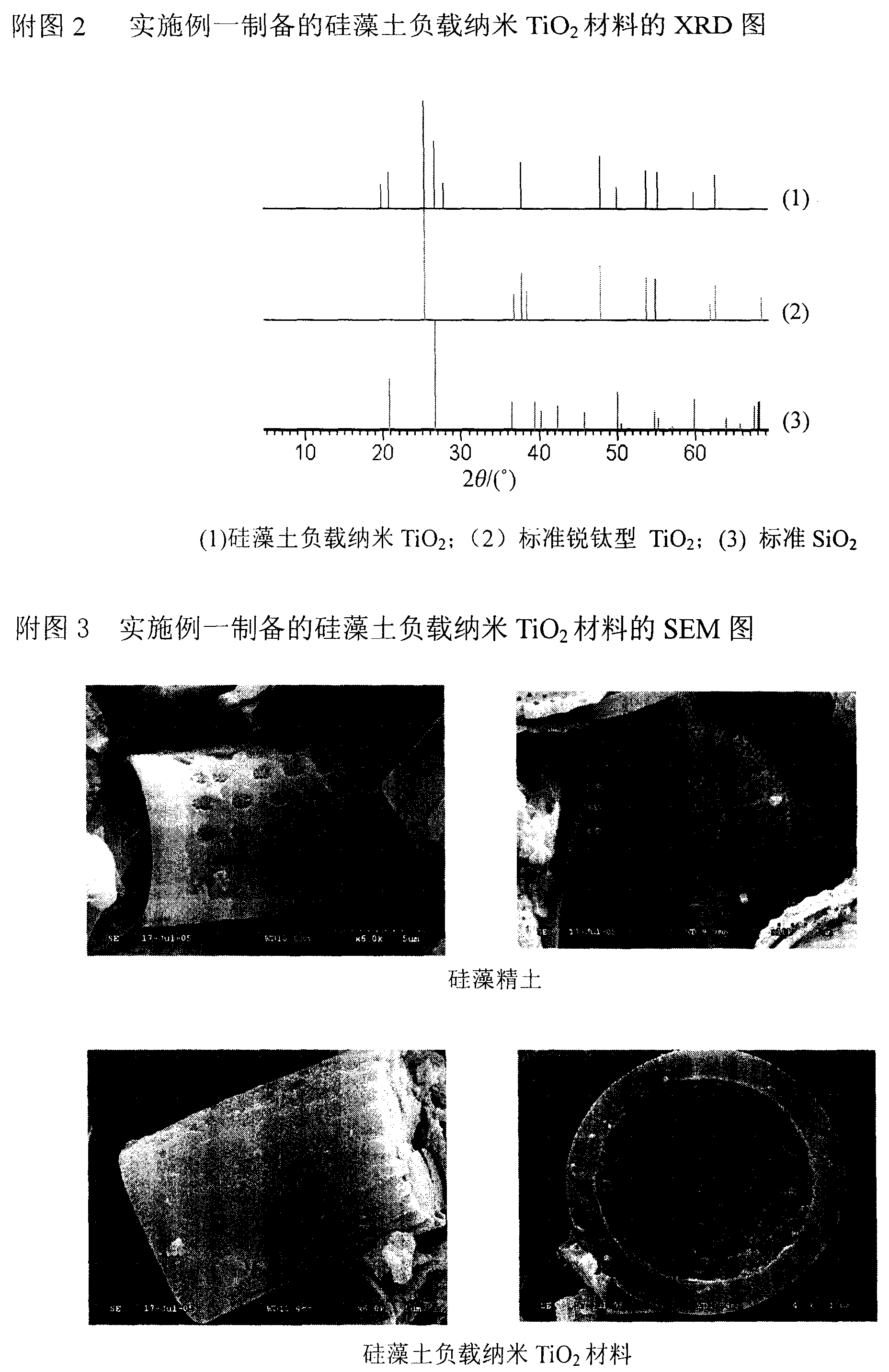

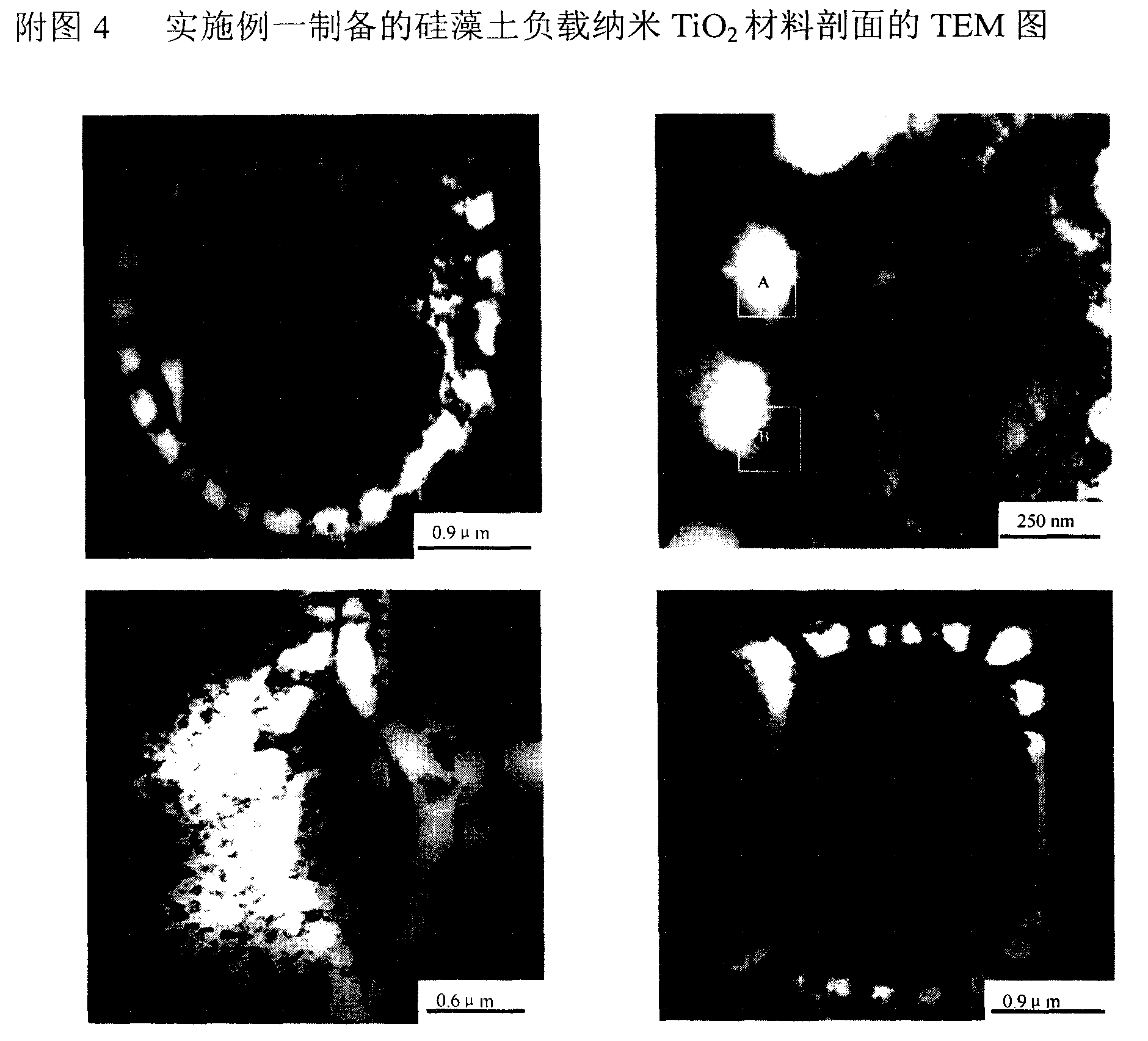

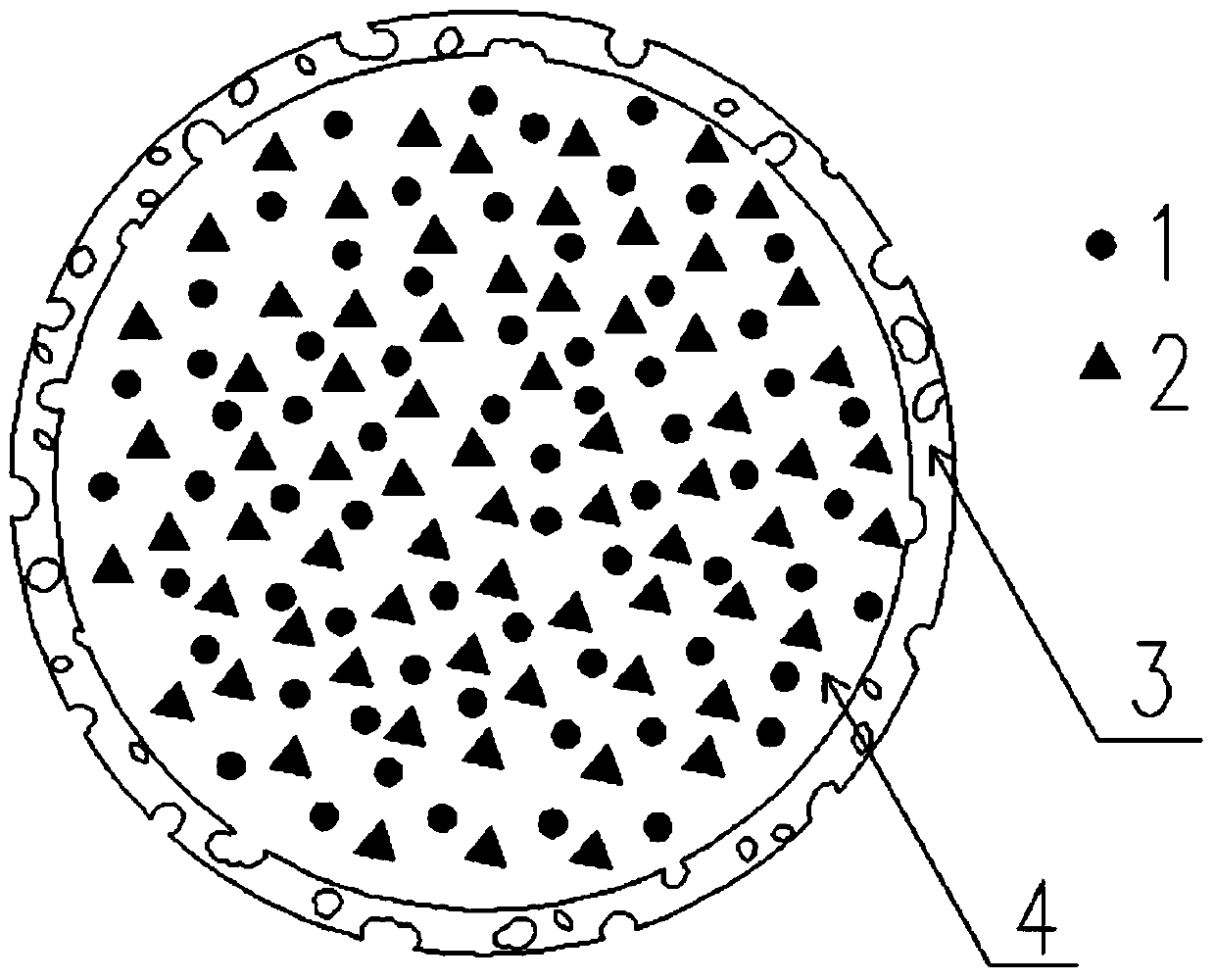

Method for producing tripolite loading nano-TIO2 material capable of being used for water and air purification

InactiveCN101195086AReduce manufacturing costGood photocatalytic effectPhysical/chemical process catalystsForeign matterDecomposition

The invention relates to a process for preparing diatom earth loading nanometer Ti2O material for purifying water and air, which belongs to the field of material process and environmental treatment. Diatom earth raw ore is filled with water and is churned and scattered, is screened, is sunken by gravity, and is eccentrically sunken, sulfuric acid is adopted to dissolve clay-type foreign matters which are left in pore passages after ores which mutually grow with diatom earth like quartz, feldspar, mica, and clay and the like and organic matters which are mixed such as grass roots and barks and the like are removed, and diatom fine soil is attained. Further, diatom fine soil is filtered, dried, and baked, and diatom fine soil after baked is filled with water, and is churned, and is filled with acid to regulate the PH value, and is filled TiCl4 solution, and is filled with ammonia sulfate solution to proceed hydrolytic decomposition deposition reaction, and product yield after the reaction is filtered, washed, dried, and baked to attain the nanometer Ti2O material.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

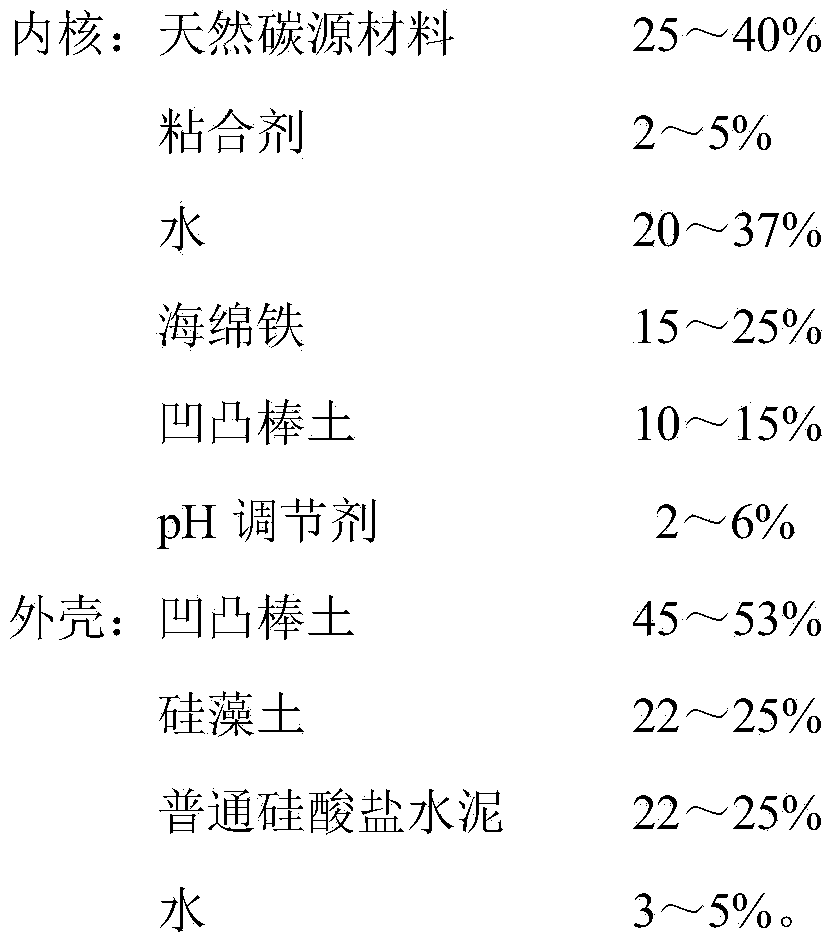

Carbon-iron microbattery slow-release carbon source filler and preparation method thereof

InactiveCN103723824AEliminate ChromaImprove biodegradabilityTreatment with anaerobic digestion processesAdhesivePortland cement

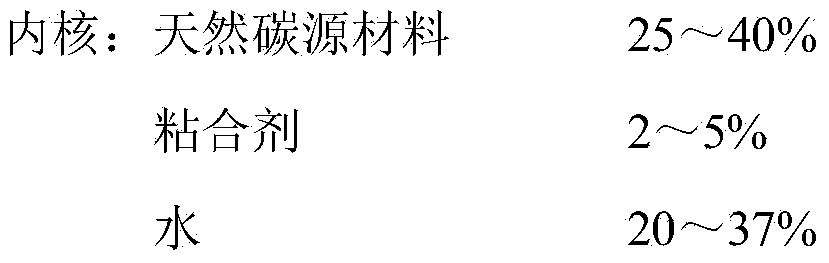

The invention discloses a carbon-iron microbattery slow-release carbon source filler and a preparation method thereof, belonging to the field of restoration of underground water pollution. The carbon-iron microbattery slow-release carbon source filler is composed of an inner core and an outer shell, wherein the inner core is made from organic carbon source mixed materials, and the outer shell is prepared from cement and high-permeability raw materials. The inner core is prepared from the following components in percentage by mass: 25-40% of natural carbon source material, 2-5% of adhesive, 20-37% of water, 15-25% of spongy iron, 10-15% of attapulgite and 2-6% of pH regulator; and the outer shell is prepared from the following components in percentage by mass: 45-53% of attapulgite, 22-25% of kieselguhr, 22-25% of ordinary Portland cement and 3-5% of water. By using the filler and method, the particle strength of the inner core can be enhanced to 70-105N / particle, and the thickness of the slow-release outer shell is lowered to 1-1.5 mm, so that the carbon-iron can be uniformly distributed in the material.

Owner:NANJING UNIV

Composite porous activated carbon flue gas adsorbent and preparation method thereof

InactiveCN104437371AImprove toughnessHigh strengthOther chemical processesDispersed particle separationPorositySodium metasilicate

The invention discloses a composite porous activated carbon flue gas adsorbent which is characterized by comprising the following raw materials in parts by weight: 98-105 parts of shell activated carbon, 36-40 parts of diatomite, 2-3 parts of sodium metasilicate, 2-3 parts of rosin, 2-3 parts of VAE emulsion, 2-3 parts of polyvinyl alcohol, 1-2 parts of sodium alcohol ether sulphate, 1-2 parts of sodium citrate, 1-2 parts of gypsum residue, 2.5-3.5 parts of pulverized fuel ash, 4-5 parts of edible corn starch, 2-3 parts of lanthanum nitrate, 9-12 parts of glass fiber powder, 4-6 parts of adsorption aids and a proper amount of water. The composite porous activated carbon flue gas adsorbent disclosed by the invention is reasonable in formula, viscous matters such as polyvinyl alcohol and edible corn starch are added, the toughness and strength of the activated carbon are improved, and the service life is prolonged; and due to the addition of the adsorption aids, the adsorbent has special porosity, the contact time between gas and the adsorbent is prolonged, and the effects of inhibiting bacteria and purifying the air are achieved. Therefore, the adsorption efficiency is high, the production process is simple, and the adsorbent is suitable for industrial dry desulfurization, automobile exhaust desulfurization and daily air purification.

Owner:ANHUI TOPTECHSCR ENVIRONMENTAL SCI & TECH

Process for the preparation of high activity carbon monoxide hydrogenation catalysts; the catalyst compositions, use of the catalysts for conducting such reactions, and the products of such reactions

InactiveUS20020028745A1High viscosity indexReduce pointsHydrocarbon from carbon oxidesOrganic compound preparationMagnesium saltHigh activity

A process for the preparation of a catalyst useful for conducting carbon monoxide hydrogenation reactions, particularly Fischer-Tropsch reactions; the catalyst compositions, use of the catalyst compositions for conducting such reactions, and the products of these reactions. The steps of the process for producing the catalyst comprise mixing together in solution (a) a compound, or salt of a Group VIII metal, e.g., Co(NO3)2; (b) a compound, or salt of magnesium, e.g., Mg(NO3)2; (c) a compound, salt, or powdered oxide of a Group IVB metal, e.g., zirconia; (d) a refractory inorganic oxide, e.g., kieselguhr; and (e) an ammonium or alkali metal salt precipitating agent, e.g., Na2CO3, to produce a precipitated solids mass, or catalyst precursor, and then reducing the precipitated solids mass, or catalyst precursor, to form a catalyst, e.g., (100 Co:6 MgO:10 ZrO2:200 kieselguhr). The precipitated solids mass, or catalyst precursor, is shaped and brought to a critical level of moisture, and reduced. A catalyst formed from the precursor in this manner has greater activity, and selectivity in the production of high melting waxes in conducting Fischer-Tropsch reactions, and gas make is lower, than in the use of catalysts made conventionally, i.e., from precursors of similar composition at differing moisture levels.

Owner:EXXON RES & ENG CO

Kieselguhr wall material, preparation technology and construction technology thereof

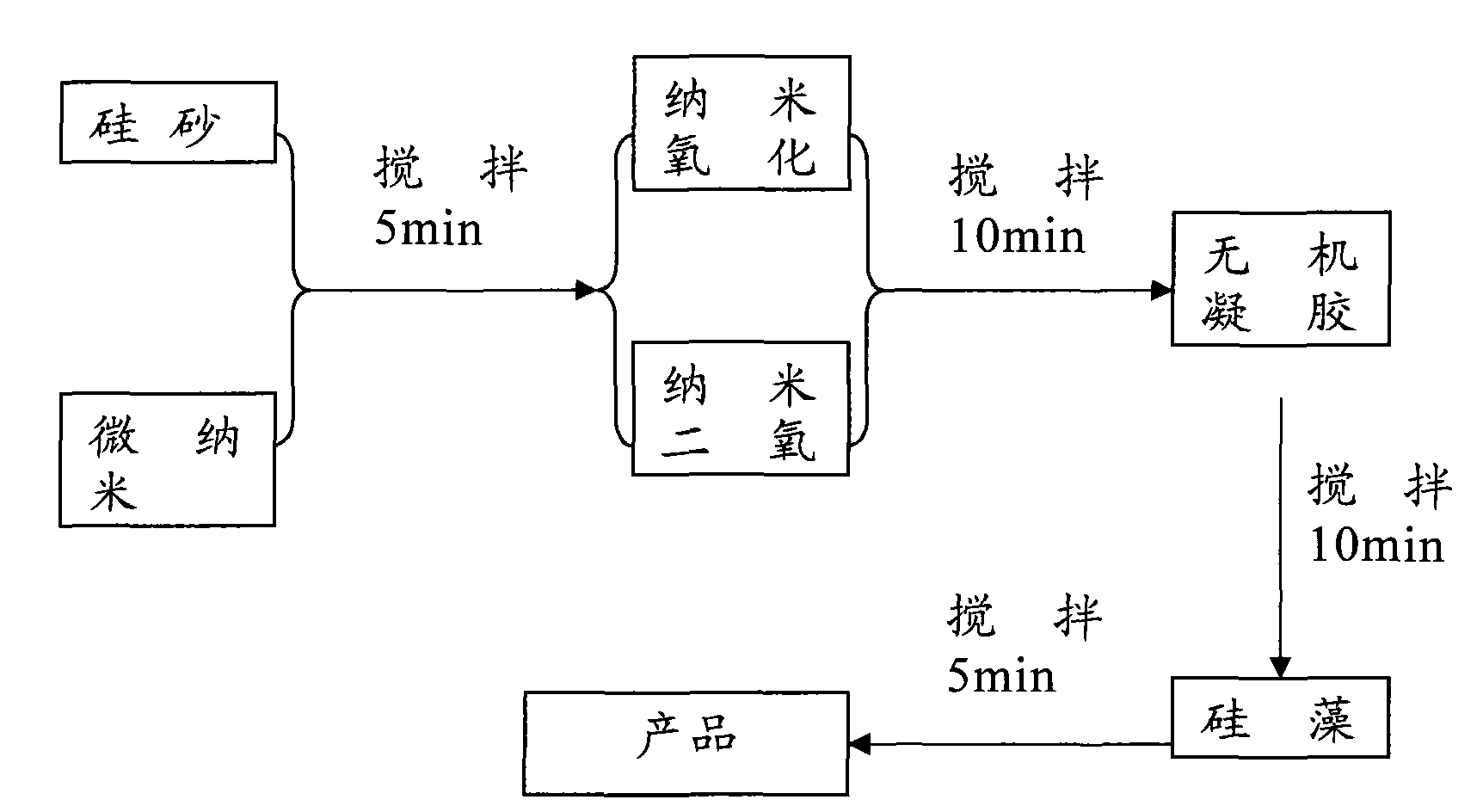

InactiveCN101618958ALarge specific surface areaImprove adsorption capacityCovering/liningsSilicon compoundsMicro nanoLevels zinc

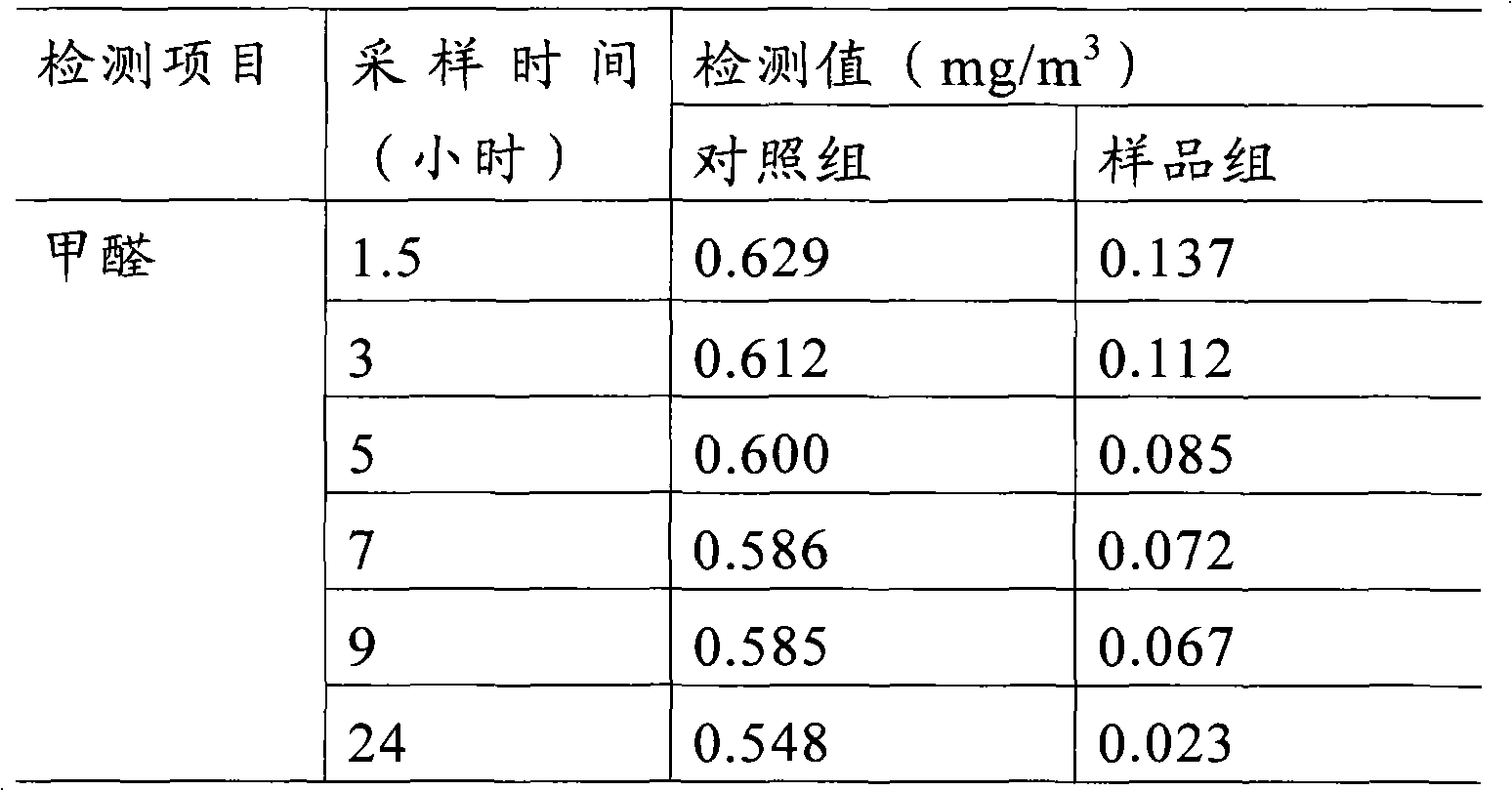

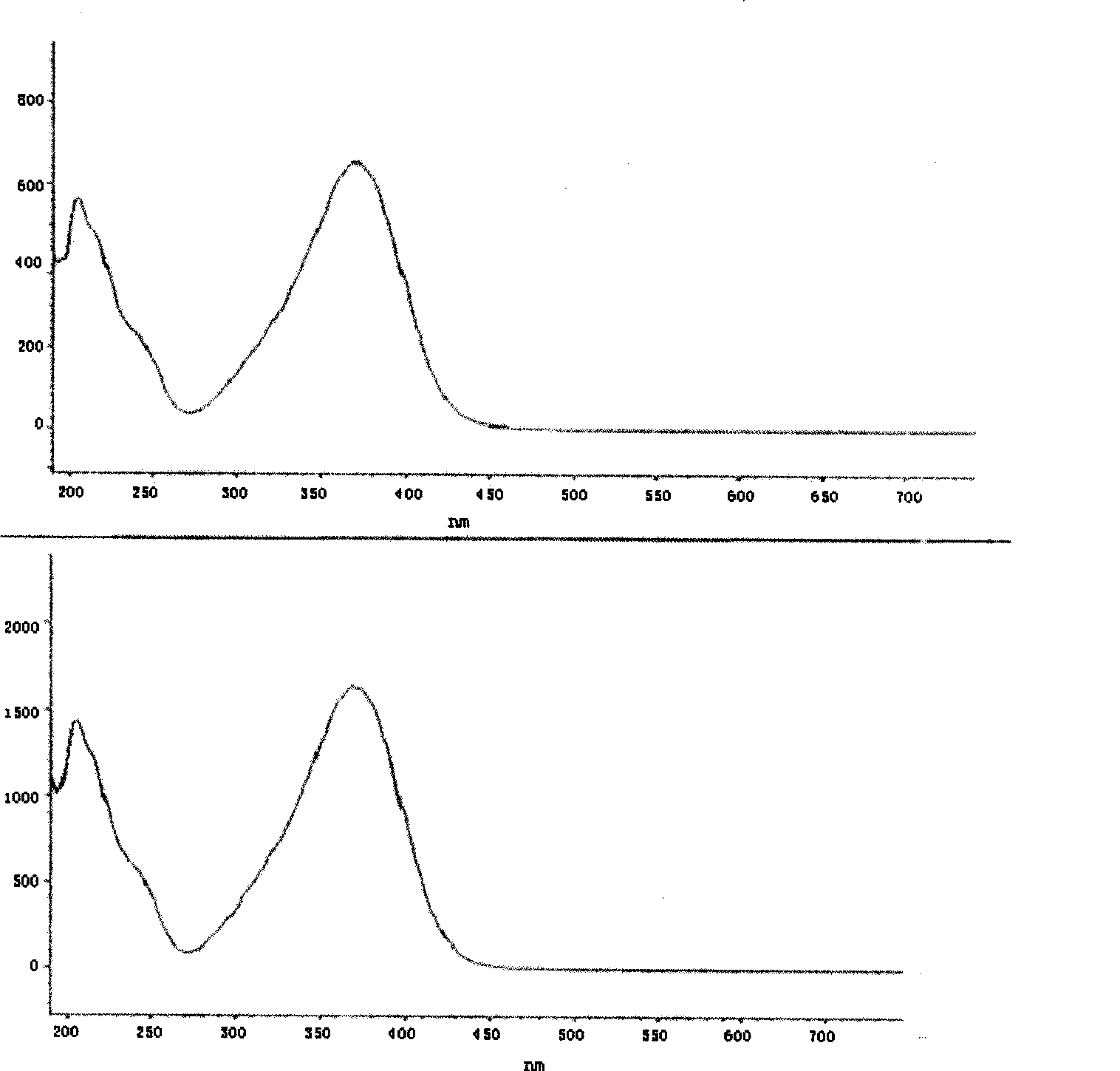

The invention discloses a kieselguhr wall material respectively comprising the following components according to parts by weight: 25-35 parts of kieselguhr, 10-15 parts of micro-nano level tourmaline, 5-10 parts of nano level titanium oxide, 6-11 parts of nano level zinc oxide, 18-25 parts of inorganic gel powder and 28-38 parts of siliceous sand. The invention also discloses a preparation method of the kieselguhr wall material and a construction technology thereof. The kieselguhr wall material is prepared by adopting and mixing various inorganic building materials, such as the kieselguhr and the like, has larger specific surface area and very strong adsorption capability, combines various mixed nano materials, enables the wall material to regulate the air humidity, greatly reduces indoor air pollution substances, decomposes harmful chemical substances such as formaldehyde, benzene, ammonia, VOC and the like and improves the indoor environment actively.

Owner:长白朝鲜族自治县川一硅藻土有限公司

Preparation method of kieselguhr load type compound photocatalyst with iron ions doped titanium dioxide

InactiveCN101628236ASignificant purification and decolorizationAbundant resourcesWater/sewage treatment by irradiationOther chemical processesWater bathsIron salts

The invention discloses a preparation method of a kieselguhr load type compound photocatalyst with iron ions doped with titanium dioxide, comprising the following steps: (1) mixing titanic acid esters or titanium salt with an alcoholic solvent, and then adding kieselguhr into the alcoholic solvent and stirring so as to form slurry; (2) dissolving iron salt into water to form an iron salt solution, and in a water bath with the temperature of 10-95 DEG C, dropping the iron salt solution into the slurry and stirring so that the titanic acid esters or the titanium salt inside the slurry is hydrolyzed to obtain colloidal sols; (3) aging the colloidal sols under room temperature to obtain dried gel; and (4) baking the dried gel for 0.5-5 hours under the temperature of 200-800 DEG C to obtain the kieselguhr load type compound photocatalyst with the iron ions doped with the titanium dioxide. The compound photocatalyst prepared by the method can effectively process waste water.

Owner:ZHEJIANG SCI-TECH UNIV

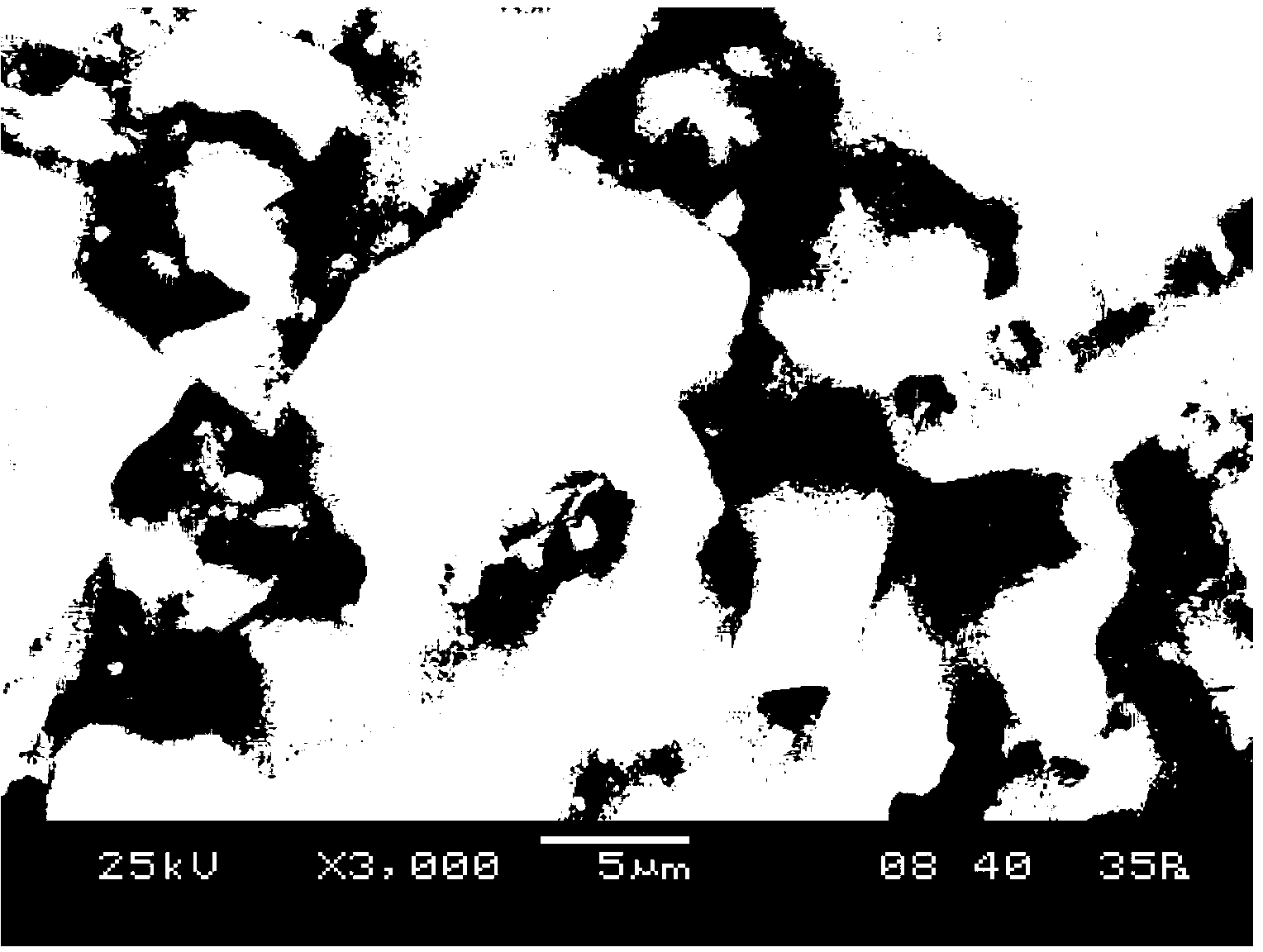

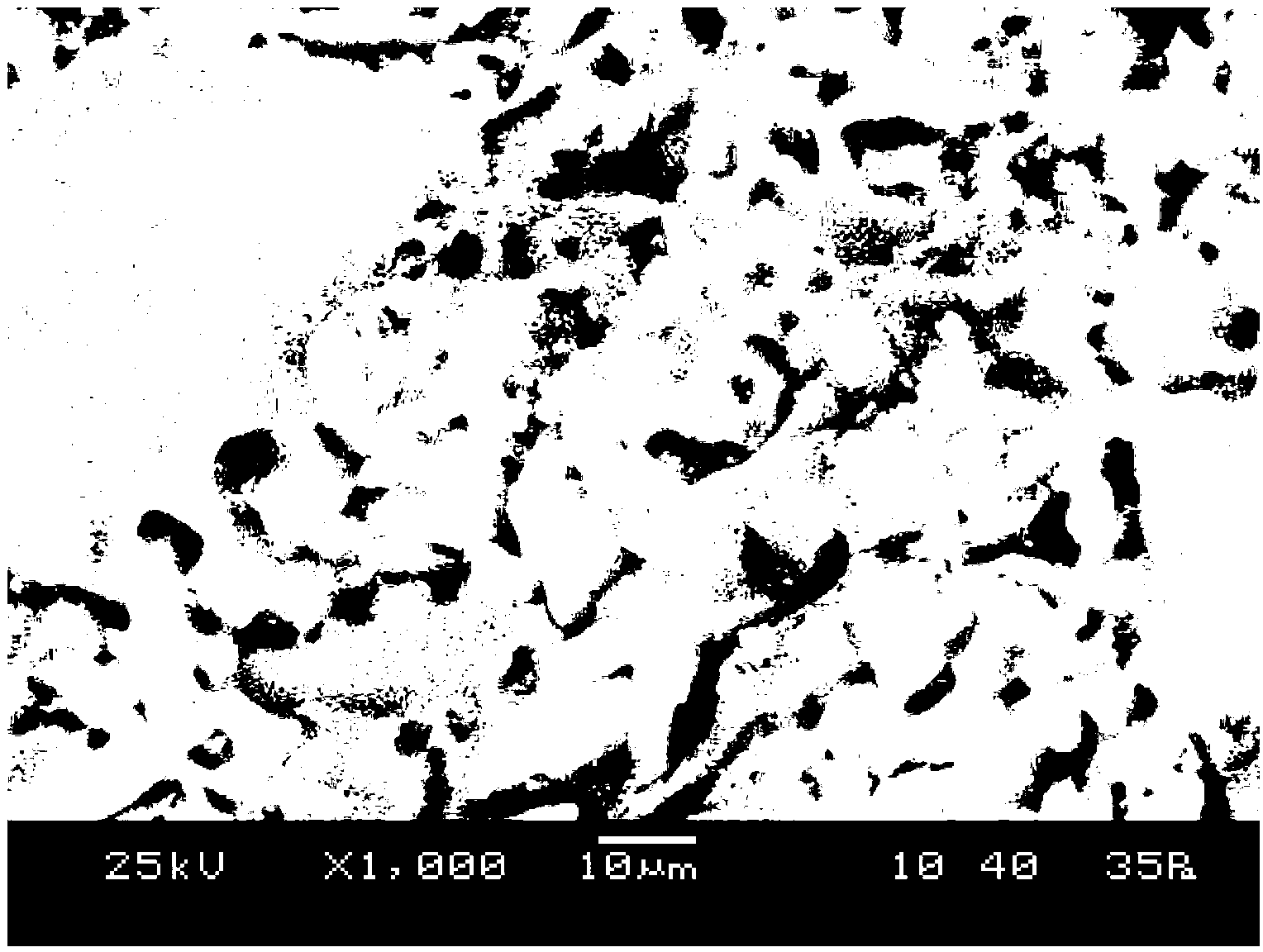

Microorganism composite carrier and application thereof

ActiveCN1884128APromote proliferationWon't happenImmobilised enzymesClimate change adaptationCalcium silicateAdhesive

The invention discloses a microbe composite carrier in the effluent disposal course, which comprises the following parts: 45-60 percent main material, 15-30 percent biological affinity material, 5-15 percent biological hydrophilic material, 18-28 percent adhesive, 2-8 percent foaming agent, wherein the main material is eroded soil, powder coal ash, calcium silicate, kaolin, brown hematite and or zeolite; the biological affinity material is starch and or calcium alginate; the hydrophilic material is diatomaceous soil; the adhesive is soluble silicate and or cement; the forming agent is hydrogen peroxide solution. The making method comprises the following steps: grinding materials at 100-200 order according to proportion; adding water and foaming agent to stir; graining; moulding; gluing at 40-70 deg.c; drying; solidifying; obtaining grain size phi at 20-30mm*60-70mm column state grain with 20-100 mum millipore diameter, 100-300m2 / g specific surface area and 1.18-1.21g / cm3 specific gravity.

Owner:GUOZHONG AIHUA TIANJIN MUNICIPAL ENCIRONMENT ENG

Modified diatom-ooze interior decorative material and production technique thereof

The invention relates to a modified diatom-ooze interior decorative material which is prepared from the following components in percentage by weight: 30-32% of modified kieselguhr, 22-24% of coarse whiting, 5-8% of calcium hydroxide powder, 4-6% of wood fiber, 3-4% of rubber powder, 1-2% of humectant, 22-23% of meerschaum wool and 8-10% of talcum powder. The production technique comprises the following steps: naturally drying and weathering kieselguhr raw ores, detecting the adobe, grading, and transporting to a processing workshop; pulverizing, carrying out air separation, adding a cosolvent, calcining in a high-temperature calcining kiln to remove water and organic impurities, pulverizing, grading repeatedly, carrying out air separation to remove inorganic impurities, and proportionally mixing with calcium hydroxide, coarse whiting, natural rubber and the like. Compared with the existing diatom-ooze product, the modified diatom-ooze interior decorative material provided by the invention has superstrong adsorption capacity, can not shed powder or fade, can be scrubbed with a wet rag, has the advantages of long service life (more than 20 years), no edge tilting, no shedding, no fading and oxidation resistance, and always looks new.

Owner:吉林省临江天元催化剂有限公司 +1

Bentonite modified by surface active agent and preparation method of bentonite

ActiveCN104117342AImprove surface activityGood dispersionOther chemical processesPigment treatment with macromolecular organic compoundsSorbentHexamethylenetetramine

The invention discloses bentonite modified by a surface active agent. The bentonite is characterized by comprising the following materials in parts by weight: 90-95 parts of bentonite, 1-2 parts of tx-10, 2-3 parts of silicon carbide, 3-5 parts of polyacrylamide, 3-4 parts of mineral oil, 4.5-6 parts of vinyl carboxylic ester, 3-5 parts of polyvinyl alcohol, 2-3 parts of konjac glucomannan, 1-2 parts of urotropin and 3-4 parts of modified kieselguhr. The bentonite disclosed by the invention has the advantages that the surface modification is carried out on the bentonite by adding tx-10, urotropin and the like, so that the bentonite has good surface activity; by addition of the high-molecular polymer, the surface can be compatible to multiple substances; and by addition of the modified kieselguhr, polyacrylamide and the like, the dispersing effect is improved, so that the bentonite can be used as a water purifying agent, an absorbing agent or a washing powder additive.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

Building heat preservation material

InactiveCN106588108AReduce weightImprove insulation effectCeramicwareCelluloseEnvironmental resistance

The invention discloses a building heat preservation material. The building heat preservation material is mainly prepared from, by weight, 15-30 parts of bentonite, 15-30 parts of coal ash, 10-20 parts of mica, 2-5 parts of polyacrylamide, 12-27 parts of kaolin, 11-25 parts of expanded perlite, 7-15 parts of phenolic resin, 0.5-2 parts of calcium stearate, 1-3 parts of foaming agent, 6-13 parts of soapstone, 35-55 parts of modified environment-friendly adhesive, 3-6 parts of starch ether, 6-13 parts of centrifugal glass fibers, 2-8 parts of hydroxymethyl propyl cellulose, 15-25 parts of cement, 8-17 parts of ceramsite and 11-23 parts of diatomite. The building heat preservation material is low in weight, can replace a traditional building heat preservation material, and can be used for coating protection of building side walls. The heat conductivity coefficient of the material is tested based on the GB / T10297-1998 standard, the heat conductivity coefficient is only 0.038-0.040, the heat preservation performance is extremely excellent, high acid-base corrosion resistance is achieved, no abnormities exist after the experimental test is carried out for 150 h, superhigh weather fastness is achieved, and no discoloring or pulverization or bubbles or stripping or cracks are generated 420 h later.

Owner:南宁市大江保温材料有限公司

Method for extracting xanthohumol from lupulus

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

Method for preparing catalyst for catalytic hydrogenation of nitro compound and catalyst

ActiveCN101439285AGood dispersionReduce usageOrganic compound preparationAmino compound preparationNitro compoundHydrogen

The invention relates to a preparation method for a catalyst and the prepared catalyst, in particular to a preparation method used for carrying out catalytic hydrogenation on a nitrocompound to prepare the corresponding catalyst of an amino-compound as well as the catalyst. The preparation method for the catalyst is as follows: diatomite is treated at first; nickel is prepared into nitrate and then prepared into water solution; silica sol is added; then a system is heated to the temperature between 50 and 80 DEG C; under a stirring condition, the diatomite is added; then the pH value of the system is regulated between 7.5 and 8.5 and stirring is carried out for 12 to 16 hours under the temperature of 50 and 80 DEG C, then solid and liquid are separated after cooling and treatments of granulating and drying are carried out; under the temperature of 500 and 700 DEG C, the mixture thereof is reduced by hydrogen; then mixed inert gas containing 5 percent of air is used to carry out passivating treatment under a cooling condition.

Owner:甘肃中科药源生物工程股份有限公司

Decoration wall material for purifying indoor air as well as preparation method and use thereof

InactiveCN101439279AImprove adsorption capacityEliminate odorDispersed particle separationDeodrantsHazardous substanceAdhesive

The invention relates to a decoration wall material for purifying indoor air as well as a preparation method and applications thereof. The combination of the invention comprises 50 to 75wt percent of natural porous inorganic materials, 15 to 25wt percent of adhesives, 5 to 15wt percent of dyes and 5 to 10wt percent of addition agent. The natural porous inorganic materials comprise diatomite and natural zeolite; wherein, the diatomite accounts for 70 to 90wt percent and the zeolite accounts for 10 to 30wt percent. The pasty slurry obtained by mixing the combination and water is the wall material of the invention. The invention adopts cheap and natural porous inorganic materials with high surface activity and excellent absorption characteristics as a main base and carries out reaction activity processing on the main base to promote the absorption and degrade the absorbed organic gas matter; finally the base is used for decorating an indoor wall surface by a form of a facing wall material. The decoration wall material has strong absorbability on the organic gases like formaldehyde, benzene, and the like, can remove harmful matters, eliminate peculiar smells, purify the indoor air, is convenient in construction, is low in product cost, and is suitable for large-scale production.

Owner:吉林远通矿业有限公司 +1

Special organic-inorganic composite biological pesticide-fertilizer for tea and preparation method thereof

The invention provides a special organic-inorganic composite biological pesticide-fertilizer for tea. The special organic-inorganic composite biological pesticide-fertilizer for tea is characterized by comprising the following raw materials in parts by weight: 70-90 parts of urban domestic garbage, 10-15 parts of guano, 5-8 parts of bone meal, 4-6 parts of gelatin, 20-25 parts of tree ash, 20-25 parts of modified diatomite, 5-10 parts of monoammonium phosphate, 12-15 parts of urea, 12-15 parts of mineral slag, 5-10 parts of potassium chloride, 3-5 parts of paulownia sawdust, 10-12 parts of animal hair, 3-5 parts of sclerotium mylittae, 3-5 parts of betelnut, 3-5 parts of herba artemisiae scopariae, 5-8 parts of radix sophorae flavescentis, 3-5 parts of radix scutellariae, 10-15 parts of sodium fulvate, 3-5 parts of peat, 0.08-0.12 part of ammonium molybdate, 1.5-2.5 parts of ferrous sulfate, 0.7-1.0 part of copper sulfate, 0.8-1.2 parts of borax and 0.1-0.2 part of EM (effective microorganism) strain. The pesticide-fertilizer disclosed by the invention has the advantages of scientific ratio of nitrogen, phosphorus and potassium, easiness in absorption by crops, obvious yield-increasing benefit and the like. By applying the pesticide-fertilizer, the nutrient absorption of trees can be balanced, the tea quality can be effectively improved and the taste of the tea can become thick.

Owner:东至县神山化肥有限责任公司 +1

Method for improving humidifying capacity of diatomite

InactiveCN102120175AEffectively Regulates HumidityOvercoming the disadvantages of application in the field of humidity controlOther chemical processesDispersed particle separationSaline waterInorganic salts

The invention discloses a method for improving humidifying capacity of diatomite, relating to the technical field of daily chemicals. The method is characterized by comprising the steps of: reacting diatomite with an inorganic salt water solution with mass percent concentration of 10-30 percent in a mass ratio of 1:3-1:5 for 30-90min at a temperature of 50-80 DEG C, and filtering and drying to obtain a diatomite based humidifying material, wherein the diatomite meets the conditions that the content of SiO2 is not less than 89 percent and the specific surface area is not less than 26m<2> / g and the pore volume is not less than 0.05ml / g; and the inorganic salt is one of LiCl, MgCl2, CaCl2 and NaCl. The diatomite needs to reach certain purity, specific surface area and pore volume, is used as a channel enabling to water vapor to pass in and out and a container for storing water, and also has a certain moisture absorption and discharge performance. The modification of the inorganic salt further enhances the moisture absorption performance of the diatomite, and the modified and enhanced humidifying material has a moisture absorption rate of reaching 110 percent. The inorganic salt is mutually fixed with a diatomite porous body. The invention provides a humidifying functional material with high humidifying performance.

Owner:BEIJING UNIV OF TECH

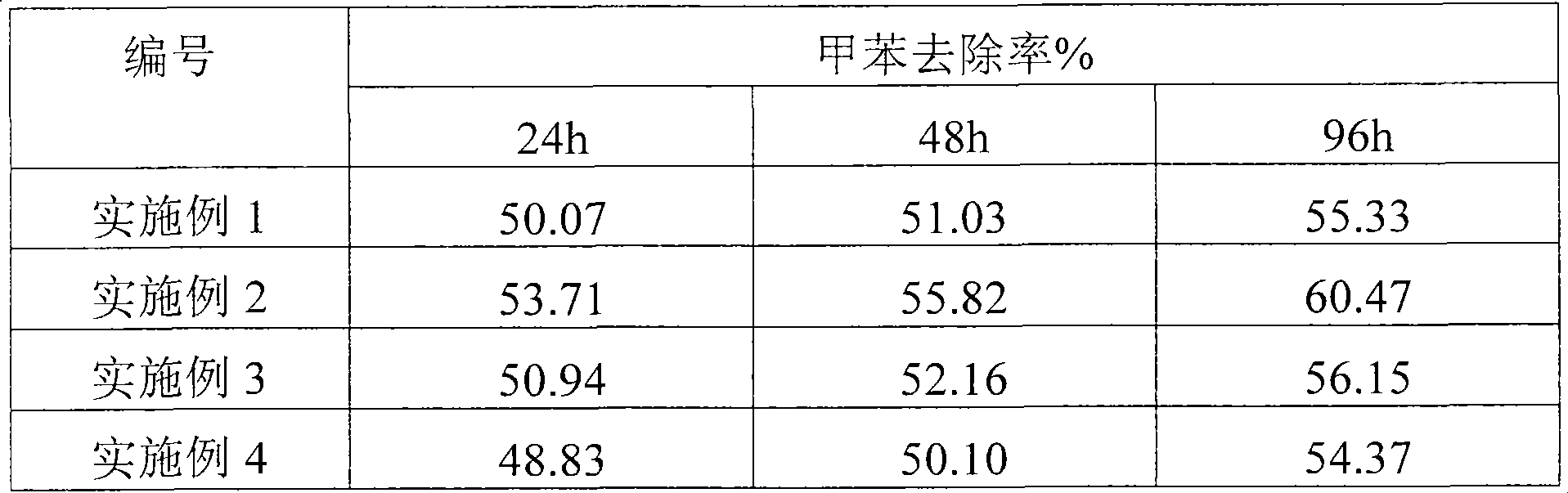

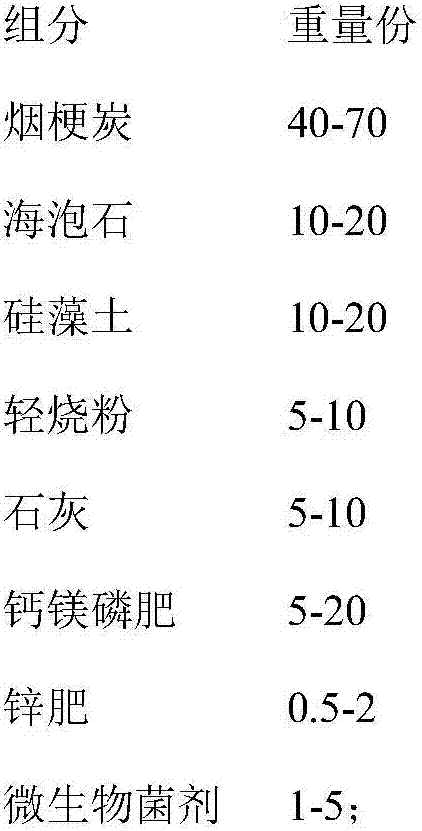

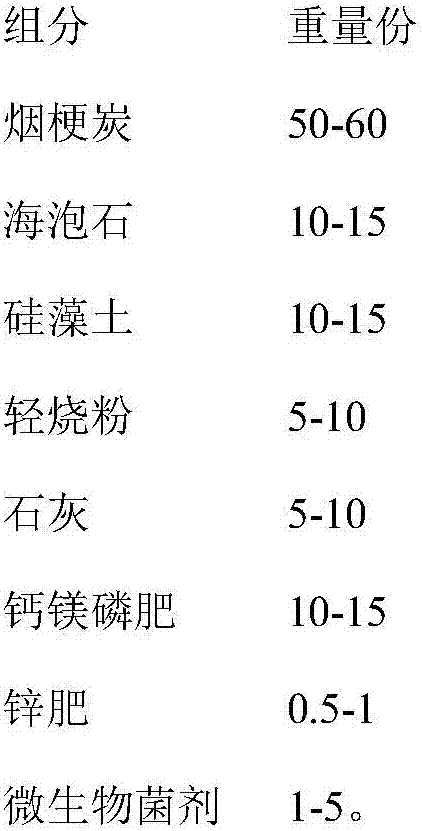

Soil restoring agent for cadmium pollution paddy field and application

InactiveCN106914488ASource of controlHigh ecological valueAgriculture tools and machinesOther chemical processesAdditive ingredientMicrobial agent

The invention belongs to the field of soil heavy metal restoration, and concretely discloses a soil restoring agent for cadmium pollution paddy field and application. The soil restoring agent provided by the invention is prepared from the following ingredients in parts by weight: 40 to 70 parts of tobacco stem charcoal, 10 to 20 parts of sepiolite, 10 to 20 parts of kieselguhr, 5 to 10 parts of light burning powder, 5 to 10 parts of lime, 5 to 20 parts of calcium magnesium phosphate fertilizers, 0.5 to 2 parts of zinc fertilizers and 1 to 5 parts of microbial agents. The soil restoring agent is uniformly spread on the soil surface; then, turning is performed so that the soil restoring agent and the polluted soil are sufficiently mixed; the application quantity is 100 to 300kg / mu. The soil restoring agent belongs to the composite restoration; the application is simple; the cost is low; the efficiency is high; the environment is protected.

Owner:HUNAN SOIL & FERTILIZER INST

Preparation method of undecylene amido propyl betaine modified diatomite

InactiveCN105642237AGood physical and chemical stabilityHigh mechanical strengthOther chemical processesWater/sewage treatment by sorptionAlcoholBetaine

The invention discloses a preparation method of undecylene amido propyl betaine modified diatomite. The method is characterized in that after diatomite is treated with 2 mol / L HCL, pretreated diatomite is obtained; the pretreated diatomite is subjected to organic modification by using absolute ethyl alcohol and (3-chloropropyl)trimethoxysilane; then 45%-55% of deionized water and 8%-18% of undecylene amido propyl betaine are added to a reactor in percentage by mass, the mixture is stirred for dissolution, then 28%-38% of organic diatomite is added, the mixture is evenly mixed, 5%-8% of hydrogen peroxide with the mass percentage concentration of 30% is added, the sum of percentages of all components is 100%, the mixture is stirred at the constant temperature of 65 plus / minus 2 DEG C for a reflux reaction for 4-6 h, solid-liquid separation is performed after cooling, separated solids are washed with deionized water until the filtrate is neutral, filtration and drying are performed, and the undecylene amido propyl betaine modified diatomite is obtained. The adsorbent has very high adsorption capacity for oil, has excellent physical and mechanical properties and high regeneration capacity, and capable of being reused, low in cost and environment-friendly.

Owner:UNIV OF JINAN

Composite material for absorbing harmful substances in water

InactiveCN101905149AReach the hardness requirementMeet strength requirementsAlkali metal oxides/hydroxidesWater/sewage treatment by sorptionHazardous substanceFiltration

The invention provides a high-efficiency environment-friendly composite material which can absorb various harmful substances in water. The invention has the technical scheme that the composite material comprises the following raw materials in weight parts: 6-10 parts of aramid fiber, 12-18 parts of water solution of sodium silicate with 30-35% of mass concentration, 20-30 parts of expanded perlite, 15-25 parts of expanded vermiculite, 10-30 parts of infusorial earth, 8-15 parts of ceramic fiber, 6-12 pars of wollastonite fiber and 5-10 parts of water solution of magnesium chloride as a hardening agent with 30% of mass concentration. The composite material has the characteristic that various organic and inorganic materials with absorption capability are used and can be used for adsorbing different substances, and thus, the composite material has broad-spectrum adsorption filtration property including ion exchange property. The material is prepared with a low-temperature chemical hardening method without high-temperature sintering, so that energy is saved, and the requirements for the hardness and the strength of the material are met. Experimental results show that the hardness and the strength of the material are greater than those of ceramsite and close to those of porcelain sand, and the adsorption property of the material is far better than that of active carbon.

Owner:傅桂云 +1

Preparation method of package-purposed plastic-based film containing modified calcined fluorite powder

ActiveCN103044756AImprove barrier propertiesImprove air tightnessFlexible coversWrappersLow-density polyethylenePolyvinyl chloride

The invention discloses a preparation method of a package-purposed plastic-based film containing modified calcined fluorite powder. The package-purposed plastic-based film is prepared from the following raw materials in parts by weight:10-15 parts of SG-1 type polyvinyl chloride, 3-5 parts of epoxidized linseed oil, 2-3 parts of oxidized polyethlene wax powder, 1-2 parts of distearoyl isopropoxy aluminate, 8-12 parts of kieselguhr, 35-40 parts of mLLDPE (metallocene Linear Low-Density Polyethylene), 38-42 parts of ethylene / alpha olefin copolymer, 8-12 parts of LDPE, 1-2 parts of polyisobutene, 1.2-2.5 parts of poly-4-methyl-1-amylene, 0.8-1.6 parts of nano potassium feldspar powder, 4-6 parts of modified calcined fluorite powder, 1-2 parts of crosslinking agent TAIC (triallyl isocyanurate), 1.5-3 parts of dibutyl maleate, 0.5-1 part of dioctyl maleate, 0.8-1.6 parts of calcium stearate and 1-2 parts of modified sepiolite powder. The package-purposed plastic-based film has good barrier property, gas tightness, pressure resistance and impact resistance and has the characteristics of high heat seal strength and good heat seal property.

Owner:平湖市泓博科技有限公司

Microbial soil remediating agent and preparation method thereof

InactiveCN108795443ARealize processingEasy to handleContaminated soil reclamationOrganic fertilisersBacillus licheniformisTreatment effect

The invention provides a microbial soil remediating agent and a preparation method thereof, and relates to the field of soil remediation. The method comprises the following steps: uniformly mixing pseudomonas, trichoderma, penicillium, alcaligenes, bacillus licheniformis and bacillus subtilis to obtain a microbial agent; and uniformly mixing 20-40 parts by weigh of biomass, 60-75 parts by weight of nutritional agent, 3-5 parts by weight of microbial agent, 20-25 parts by weight of montmorillonite powder, 13-17 parts by weight of attapulgite, 18-32 parts by weight of kieselguhr, 13-20 parts byweight of sulfate filling agent, and 5-10 parts by weight of adsorbing agent to obtain the uniform microbial soil remediating agent. The microbial soil remediating agent is capable of remediating soilsubjected to heavy metal pollution, pesticide residue pollution, etc.; and the microbial soil remediating agent has the advantages of being good in treatment effect, and low in treatment cost.

Owner:GUANGZHOU EP ENVIROMENTAL ENG

Method for preparing novel denitration catalyst

InactiveCN103252230AGood stable mechanical strengthLow costDispersed particle separationCatalyst activation/preparationSodium BentoniteCatalytic effect

The invention discloses a method for preparing a novel denitration catalyst. The method comprises the steps of: mixing 10-40wt% of attapulgite, 0.5-15wt% of bentonite, 10-35wt% of alumina powder, 40-70wt% of 4A molecular sieve, 0.5-10wt% of kieselguhr and 0.5-10wt% of assistant into powder; molding in water mediating and extruding manners and firing a carrier by a high-temperature flame; feeding ammonium metavanadate and metatungstic acid into hot water of which the temperature is not less than 85 DEG C; mixing an ethanol solution with an acid solution to form a mixing solution; adding titanate which is 5-30% of total weight of the mixing solution to the mixing solution, soaking the carrier in steeping liquor; and baking the dried carrier and preparing into the denitration catalyst. The carrier is prepared from a cheap material instead of an expensive titanium dioxide material through reasonable prescription combination; good and stable mechanical strength, 30-70% of water absorption and 20-80 m<2> / g of specific surface area of the catalyst carrier can be ensured by changing the material of the carrier; and the preparation cost can be reduced by 20-50% under the condition of keeping the catalytic effect.

Owner:姚光纯

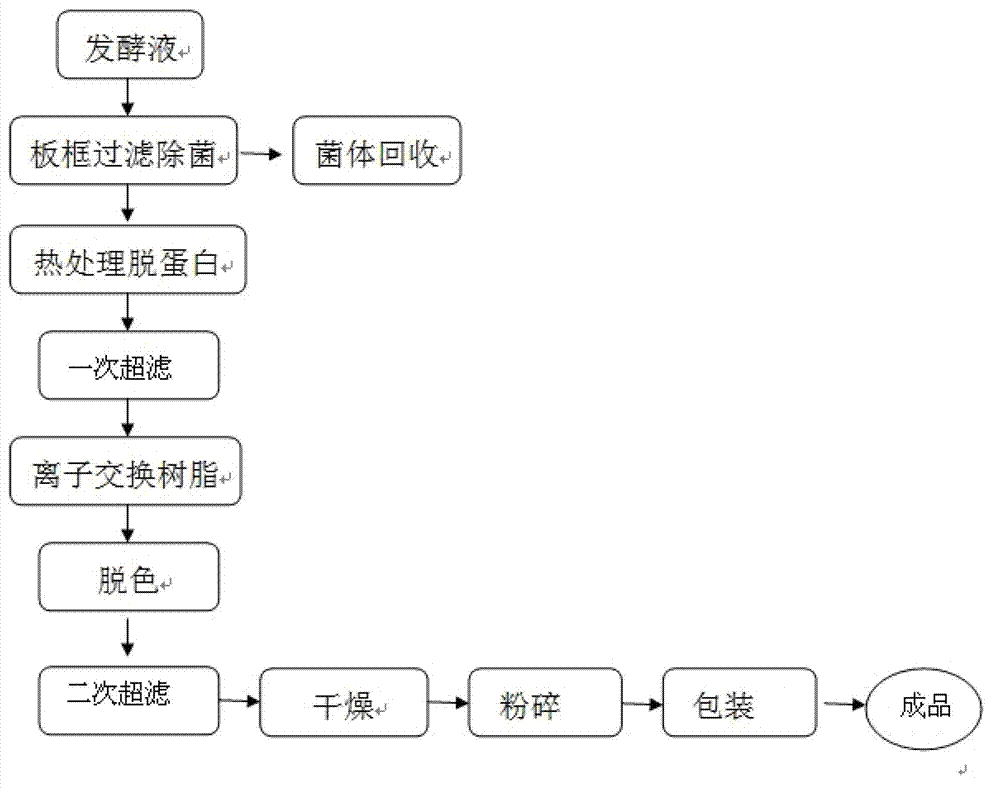

Extracting process of pulullan polysaccharide

The invention discloses an extracting process of pulullan polysaccharide and belongs to the technical field of biology. The extracting process mainly comprises the following steps of: (1), filtering by a plate frame to remove bacteria; (2), performing thermal treatment to remove protein; (3), carrying out primary ultra-filtration; (4), removing ion by use of ion exchange resin; (5), discoloring active carbon; (6), carrying out secondary ultra-filtration; and (7), drying, crushing and packaging. According to the extracting process of the pulullan polysaccharide disclosed by the invention, the bacteria in fermentation liquor are removed by adopting a plate frame filter, so that not only can solvent residue caused by adding an organic flocculating agent and inorganic flocculating agent be effectively avoided, but also the bacteria and diatomite can be recycled to obtain more benefits; meanwhile, potential unsafe factors caused by volatility of solvents (ethanol, methyl alcohol, isopropanol and the like) in the conventional process can be avoided by adopting a microwave drying process or a vacuum drying process; moreover, much steam consumed by recycling and distilling an organic solvent can be saved; the production cost is saved; the product yield can be up to 90%-96%, the purity is as high as 90%-98%, the quality is good, and the production process is safe, continuous and automatic.

Owner:天津慧智百川生物工程有限公司

Composite ionic adsorption material and preparation method thereof

ActiveCN103071453AIncrease swap spaceImprove exchange capacityOther chemical processesAlkali metal oxides/hydroxidesActivated carbonWater baths

The invention discloses a composite ionic adsorption material which is a spherical particle prepared by taking 80-85 parts of zeolitefine powder subjected to water bath modification by 0.8-1.0mol / L NaCl solution, 10-20 parts of medical stone fine powder, and 10-20 parts of kieselguhr fine powder as base materials, and 6 parts of activated carbon powder as a pore former and firing, wherein the diameter of the spherical particle is 2-12mm, and the pore volume of the spherical particle is 0.645-0.650 cm<3> / g. Activated zeolite is added to medical stone and kieselguhr to prepare the novel compound ionic material, and the zeolite, the medical stone and the kieselguhr jointly exert adsorption effects. The salt modified zeolite and medical stone increase an ionic exchange space and internal surface area, so that the adsorption capacity of the prepared composite adsorption material is further improved, and a better adsorption effect is achieved.

Owner:青岛力创星碟环境工程有限公司

Aerated concrete block reinforced by fibers and preparation method thereof

An aerated concrete block reinforced by fibers comprises the components, in parts by weight: 18-22 parts of cement, 15-18 parts of quick lime, 12-15 parts of gypsum, 30-35 parts of fly ash, 0.2-0.3 part of an aluminum powder, 2-3 parts of triethanolamine, 8-10 parts of glass fibers, 2-3 parts of sodium sulfate, 2-3 parts of sodium hydroxide, 10-12 parts of asphalt, 3-5 parts of sodium persulfate, 2-3 parts of foots, 1-2 parts of ferrocene, 8-10 parts of an alum powder, 2-3 parts of trioctyl trimellitate, and 30-40 parts of diatomite. The glass fibers are employed in the raw materials, and thereby significantly increasing the strength of the block; and at the same time, the glass fibers have low cost, and thus can be popularized and promoted.

Owner:TONGLING FENGZE BUILDING MATERIALS TECH

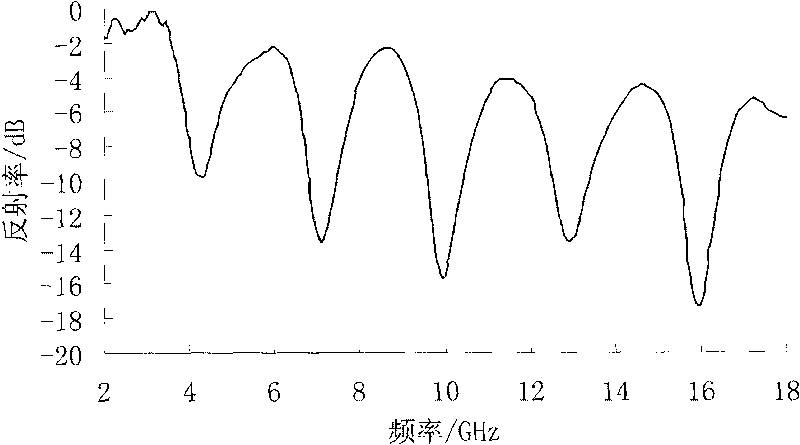

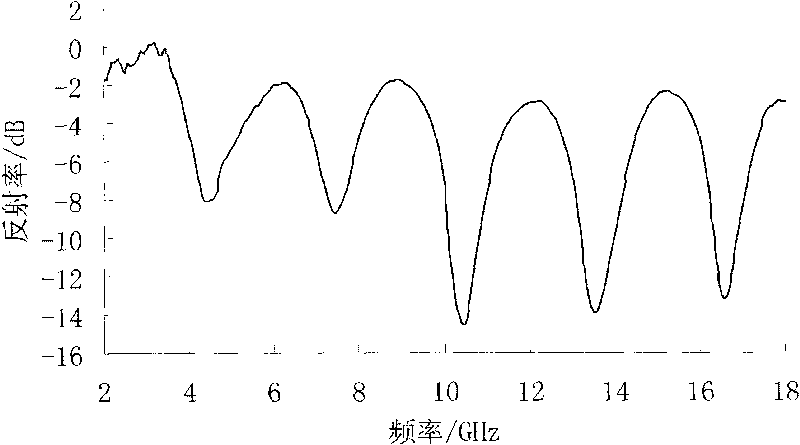

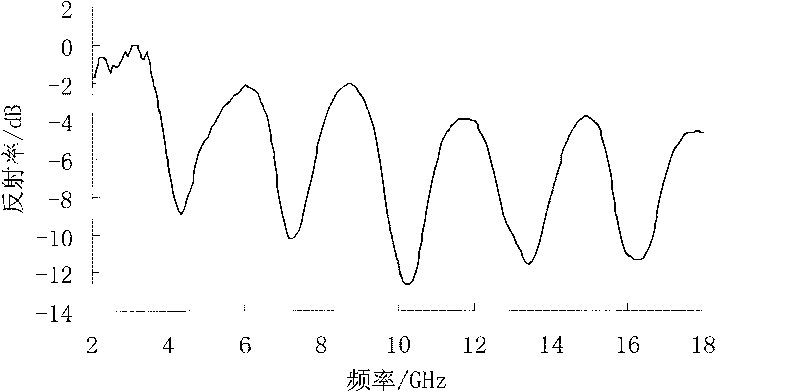

Kieselguhr application in absorbing material preparation, kieselguhr cement-based composite absorbing material and preparation method thereof

InactiveCN101747861AHigh value-added utilizationWide variety of sourcesOther chemical processesCeramic shaping apparatusMaterials preparationMaterials science

The invention discloses a kieselguhr application in electromagnetic wave absorbing material preparation, a low-cost kieselguhr cement-based composite absorbing material and a preparation method thereof. The raw materials of the kieselguhr cement-based composite absorbing material are dry material and water, wherein the dry material is composed of 80-90% cement and 10-20% kieselguhr by weight percent, and the ratio of water to the dry material is 0.30-0.40. The kieselguhr used as absorbing agent has wide material sources and low cost and can realize high value-added utilization of kieselguhr. The kieselguhr can be used as mineral additive of cement concrete material, so that kieselguhr application has no unfavorable influence on the physical mechanics performance of the cement-based material. The preparation method of the kieselguhr cement-based composite absorbing material has the advantages of simple technology, convenient construction, no difference with common cement concrete material, no need of special devices and easy promotion.

Owner:CHONGQING UNIV

Environment-friendly active carbon particle with good absorption degradation effect and method for preparing environment-friendly active carbon particle with good absorption degradation effect

InactiveCN104475020AGood adsorption and dust removal effectNot easy to disintegrateOther chemical processesDispersed particle separationPotassiumZirconium dioxide

The invention discloses an environment-friendly active carbon particle with a good absorption degradation effect. The active carbon particle is characterized by being prepared from the following materials: 100-106 parts of fruit shell active carbon, 36-42 parts of diatomite, 10-13 parts of bamboo charcoal, 7-9 part of medical stone, 3-4 parts of aluminum sulfate, 2-3 parts of sodium silicate, 1-1.5 parts of a silane coupling agent KH-550, 2.5-4 parts of calcium sulfate, 6-8 parts of nanometer zirconium dioxide, 5-7 parts of active aluminum oxide, 2-3 parts of fast dissolved adhesive powder, 2-3 parts of potassium monopersulfate, 4-6 parts of an adsorption additive and a proper amount of water. The environment-friendly active carbon particle is prepared according to a reasonable formula, improves the desulfurization effect due to the addition of aluminum sulfate, sodium silicate, calcium sulfate and nanometer zirconium dioxide, has good adsorption and dedusting effects due to the addition of active carbon, diatomite and bamboo charcoal, is not easily disintegrated due to the adhesive substance, and has a long service life; the environment-friendly active carbon particle disclosed by the invention is made of environment-friendly materials, is biodegradable and environmentally friendly, and is produced according to a simple process and suitable for industrial desulfurization and the like.

Owner:ANHUI TOPTECHSCR ENVIRONMENTAL SCI & TECH

Styrene-acrylic negative ion coating containing formaldehyde catching agent

InactiveCN108395775AImprove elimination effectExcellent capture and elimination effectAntifouling/underwater paintsPaints with biocidesSlurryHydroxyethyl cellulose

The invention provides styrene-acrylic negative ion coating containing a formaldehyde catching agent. Raw materials of the styrene-acrylic negative ion coating comprise the following components in parts by weight: 10 to 20 parts of styrene-acrylic emulsion, 10 to 20 parts of diatomite, 10 to 16 parts of nano titanium dioxide slurry, 4 to 6 parts of antibacterial nano titanium dioxide, 50 to 60 parts of fly ash, 10 to 20 parts of titanium white, 10 to 20 parts of heavy calcium carbonate, 1 to 3 parts of negative ion powder, 1 to 3 parts of hydroxyethyl cellulose solution, 3 to 5 parts of the formaldehyde catching agent, 0.5 to 1.0 part of dispersant, 0.2 to 0.5 part of de-foaming agent, 1.0 to 2.5 parts of film forming auxiliary agent, 0.5 to 0.9 part of thickening agent, 1 to 3 parts of anti-freezing agent and 40 to 60 parts of de-ionized water.

Owner:FOSHAN KANGDONG LIGHTING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com