Extracting process of pulullan polysaccharide

A technology of pullulan polysaccharide and extraction process, which is applied in the field of industrialized production of pullulan polysaccharide, can solve problems such as high cost, flocculant, organic solvent residue, and immature industrial extraction process route, and achieve good quality and safe production process Reliable, effective in reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

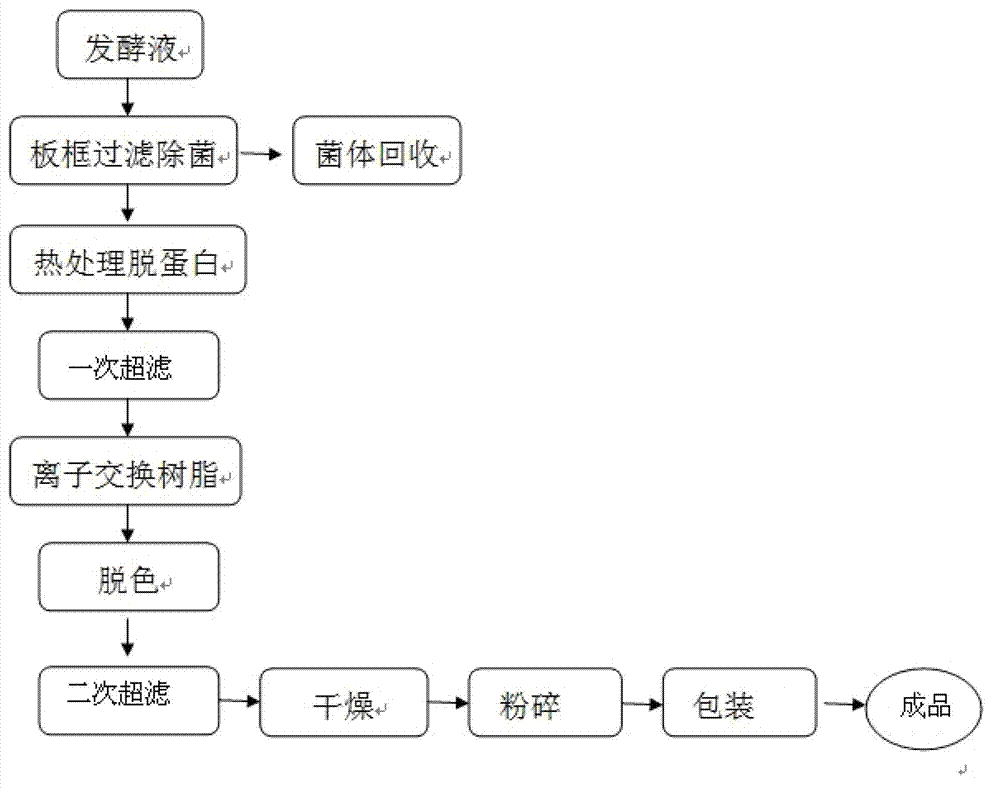

Method used

Image

Examples

Embodiment 1

[0037] (1) Removal of bacteria: make the viscosity 900mm 2 / s fermentation broth is diluted with deionized water twice, every 100mL of diluted fermentation broth is added with 0.7g of 100-mesh diatomaceous earth, pre-coated with 300-mesh diatomite with a 500-mesh filter cloth, and filtered with a plate-and-frame filter. To 0.22Mpa, remove the bacteria.

[0038] (2) Removal of protein: adjust the pH value of the fermented broth after removing the bacteria to 6.7 with a NaOH solution with a concentration of 5mol / L, keep it at 80°C for 20min, cool to room temperature, add 0.5g of 60 per 100mL of fermented broth Mesh powder activated carbon, carry out static adsorption for 1h, then use 700 mesh filter cloth to pre-coat 300 mesh diatomite, filter with plate and frame filter, the operating pressure is 0.20Mpa, remove the added activated carbon or the mixture of diatomite and activated carbon and Denatured protein flocs.

[0039] (3) One-time ultrafiltration desalination and concen...

Embodiment 2

[0046] (1) Removal of bacteria: make the viscosity 900mm 2 / s fermented liquid is diluted with deionized water twice, every 100mL of diluted fermented liquid is added with 100 mesh diatomite 1g, 600 mesh filter cloth is used to pre-coat 300 mesh diatomite, and a plate and frame filter is used for filtration. The operating pressure is 0.22Mpa, remove bacteria.

[0047] (2) Removal of protein: adjust the pH value of the fermented broth after removing the bacteria to 6.7 with a NaOH solution with a concentration of 5mol / L, keep it at 130°C for 20min, cool to room temperature, add 0.5g of 60 per 100mL of fermented broth Mesh powder activated carbon, carry out static adsorption for 1h, then use 700 mesh filter cloth to pre-coat 300 mesh diatomite, filter with plate and frame filter, the operating pressure is 0.20Mpa, remove the added activated carbon or the mixture of diatomite and activated carbon and Denatured protein flocs.

[0048] (3) One-time ultrafiltration desalination an...

Embodiment 3

[0055] (1) Removal of bacteria: make the viscosity 300mm 2 / s fermentation broth was diluted 0.5 times with deionized water, 1g of 100 mesh diatomite was added to every 100mL diluted fermentation broth, 600 mesh filter cloth was used to pre-coat 300 mesh diatomite, and a plate and frame filter was used for filtration. The operating pressure was 0.24Mpa, remove bacteria.

[0056] (2) Removal of protein: adjust the pH value of the fermented broth after removing the bacteria to 6.7 with a NaOH solution with a concentration of 5mol / L, keep it at 130°C for 20min, cool to room temperature, add 0.5g of 250 per 100mL of fermented broth Mesh powdered activated carbon and 0.5g of 100 mesh diatomite, conduct static adsorption for 1h, then use 700 mesh filter cloth to pre-coat 300 mesh diatomite, filter with plate and frame filter, operating pressure is 0.20Mpa, remove the added silicon A mixture of algal earth and activated carbon and denatured protein flocs.

[0057] (3) One-time ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com