Manganese dioxide nanorod/graphene composite electrode material and preparation method thereof

A graphene composite and electrode material technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of electrochemical performance impact, poor conductivity of MnO2, etc., achieve low raw material cost, easy graphene composite, highly reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1). Graphite oxide (GO) was prepared by the modified Hummers method.

[0022] 2). Disperse the prepared GO in deionized water and ultrasonically treat it for 60min to obtain a dispersion solution of GO (0.5mg mL -1 ).

[0023] 3). Add 30wt% glucose and 25wt% ammonia water to the above solution and stir for 15min. Then the mixed solution was stirred in a 95 °C water bath for 1 h.

[0024] 4). After cooling, the black uniform suspension was centrifuged, filtered and washed, and dried at 50° C. for 12 hours to obtain pure graphene. GO, glucose, and ammonia can be scaled proportionally. The specific volume ratio is GO dispersion liquid: glucose solution: ammonia water = 100:10:1.

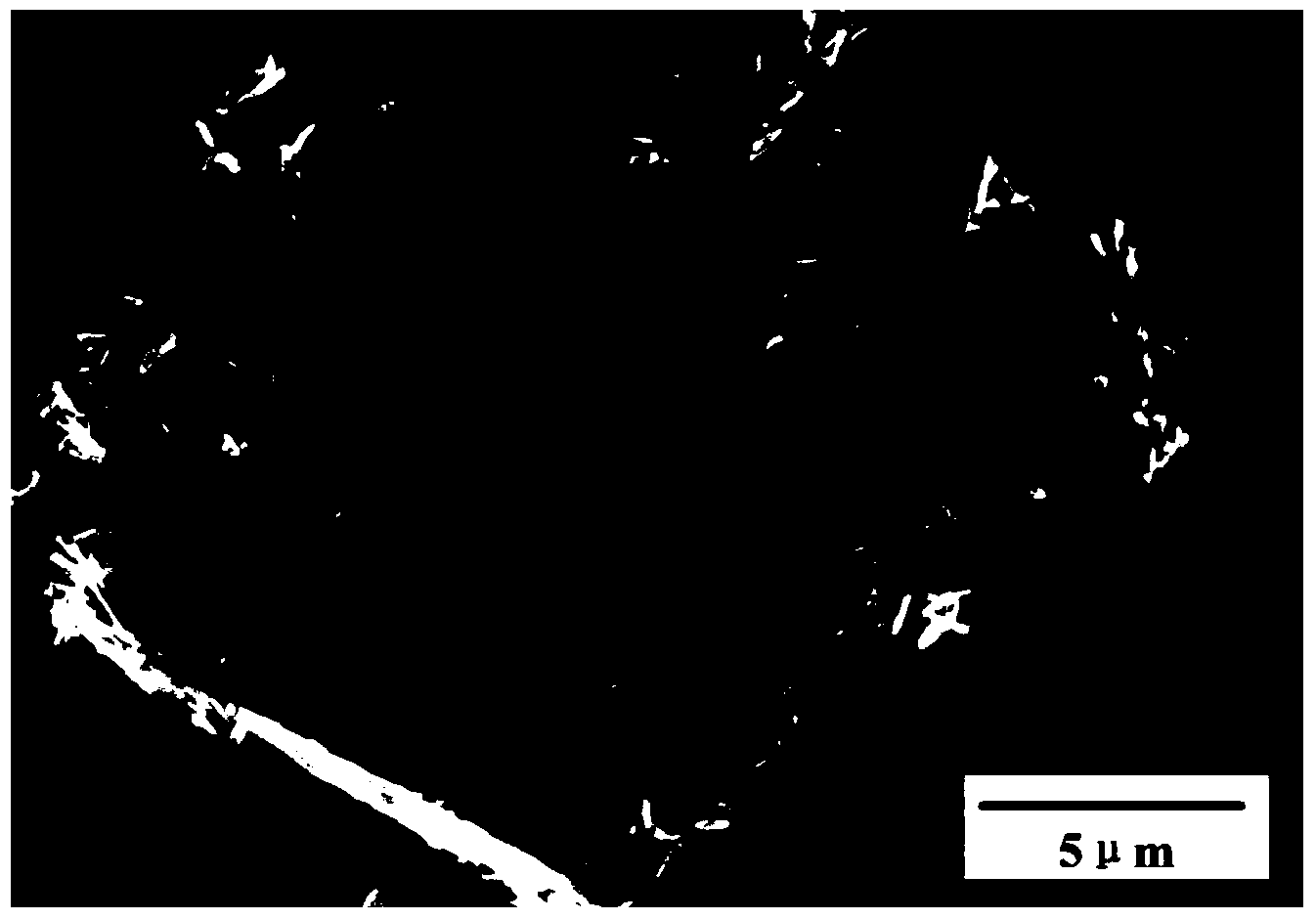

[0025] 5). Disperse 0.05g graphene in 80mL deionized water and sonicate for 20min.

[0026] 6). The equimolar concentration of MnSO 4 and KMnO 4 (0.03M) was added to the above solution and stirred for 1 h to obtain a precursor solution. Graphene, MnSO 4 , KMnO 4 All three can be scaled ...

Embodiment 2

[0030] 1). Graphite oxide (GO) was prepared by the modified Hummers method.

[0031] 2). Disperse the prepared GO in deionized water and ultrasonically treat it for 60min to obtain a dispersion solution of GO (0.5mg mL -1 ).

[0032] 3). Add 30wt% glucose and 25wt% ammonia water to the above solution and stir for 15min. Then the mixed solution was stirred in a 95 °C water bath for 1 h.

[0033] 4). After cooling, the black uniform suspension was centrifuged, filtered and washed, and dried at 50° C. for 12 hours to obtain pure graphene. GO, glucose, and ammonia can be scaled proportionally. The specific volume ratio is GO dispersion liquid: glucose solution: ammonia water = 100:10:1.

[0034] 5). Disperse 0.05g graphene in 80mL deionized water and sonicate for 20min.

[0035] 6). The equimolar concentration of MnSO 4 and KMnO 4 (0.06M) was added to the above solution and stirred for 1 h to obtain a precursor solution. Graphene, MnSO 4 , KMnO 4 All three can be scaled ...

Embodiment 3

[0039] 1). Graphite oxide (GO) was prepared by the modified Hummers method.

[0040]2). Disperse the prepared GO in deionized water and ultrasonically treat it for 60min to obtain a dispersion solution of GO (0.5mg mL -1 ).

[0041] 3). Add 30wt% glucose and 25wt% ammonia water to the above solution and stir for 15min. Then the mixed solution was stirred in a 95 °C water bath for 1 h.

[0042] 4). After cooling, the black uniform suspension was centrifuged, filtered and washed, and dried at 50° C. for 12 hours to obtain pure graphene. GO, glucose, and ammonia can be scaled proportionally. The specific volume ratio is GO dispersion liquid: glucose solution: ammonia water = 100:10:1.

[0043] 5). Disperse 0.05g graphene in 80mL deionized water and sonicate for 20min.

[0044] 6). The equimolar concentration of MnSO 4 and KMnO 4 (0.03M) was added to the above solution and stirred for 1 h to obtain a precursor solution. Graphene, MnSO 4 , KMnO 4 All three can be scaled p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com