Preparation method of nano-particle reinforcement magnesium-based biocomposite material

A composite material and nanoparticle technology is applied in the field of preparation of nanoparticle reinforced magnesium-based biocomposite materials, which can solve the problems of high corrosion rate and poor plasticity of composite materials, improve comprehensive performance, refine magnesium alloy matrix grains, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

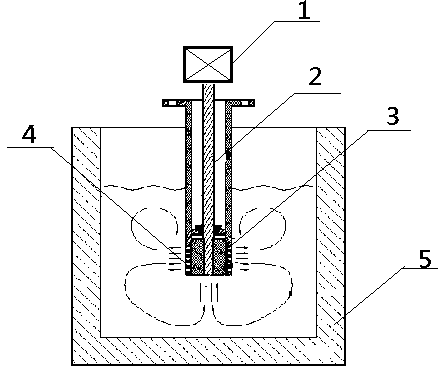

[0025] A method for preparing a nanoparticle-reinforced magnesium-based biocomposite material, which uses a combination of melt shear stirring and equal-channel angular extrusion deformation to prepare a particle-reinforced metal-based composite material, and the steps are as follows:

[0026] 1) at 10 -3 Under the condition of Pa vacuum and argon protection, the matrix alloy raw material is kept at a temperature of 720°C until it is completely melted to obtain a melt. The matrix alloy raw material is a magnesium alloy, and the alloying elements in the magnesium alloy are Zn and Ca. Each group The mass of sub-elements is: 958.89g of pure magnesium particles, 20g of zinc particles, and 11.11 g of Ca particles;

[0027] 2) Pre-heat-treat Ca-P ceramic particle powder with a particle size of 400-500nm at a temperature of 200°C for 2 hours, then mix and grind 10g of Ca-P ceramic particle powder and 10g of pure magnesium particle powder, and the grinding time is 120min ;

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com