Method for preparing high dielectric constant polymer-based nano composite material

A technology of nanocomposite materials and polymers, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of uniform dispersion of filler particles, and achieve the goals of improving uniform dispersion, reducing agglomeration, excellent thermal stability and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

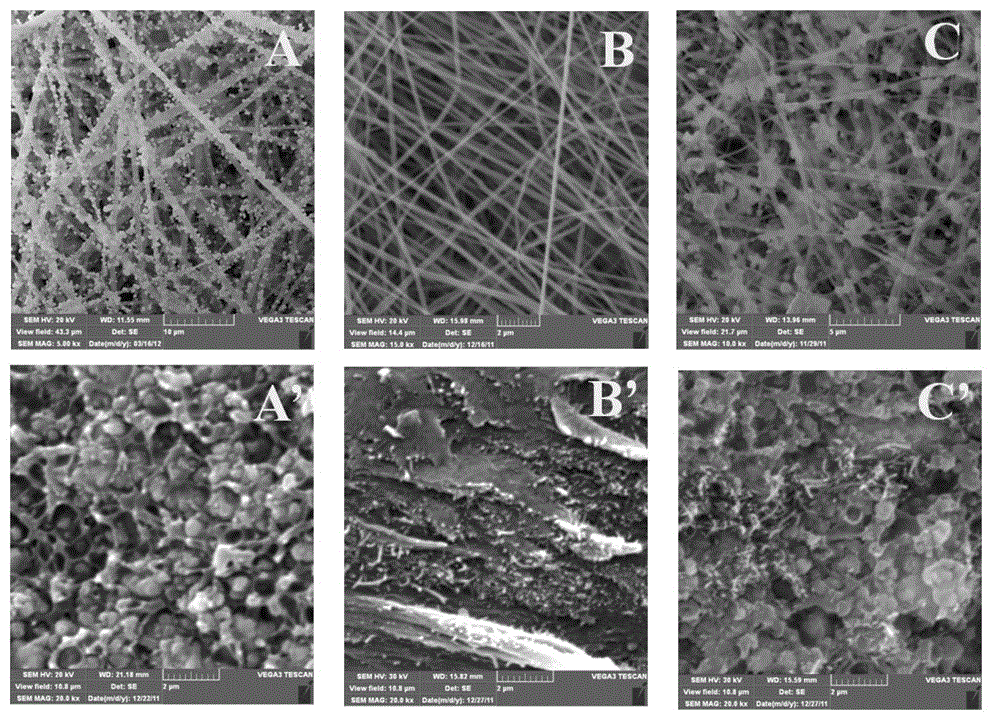

[0030] Embodiment one: polyimide / barium titanate (PI / BaTiO 3 ) Preparation of high dielectric nanocomposites

[0031] The synthetic polyimide monomers selected in this example are 4,4'-terephthalic dioxydiphthalic anhydride (HQDA) and 4,4'-diphenyl ether diamine (ODA). In fact, polyimides with different structures can be selected as the matrix of composite materials according to specific needs.

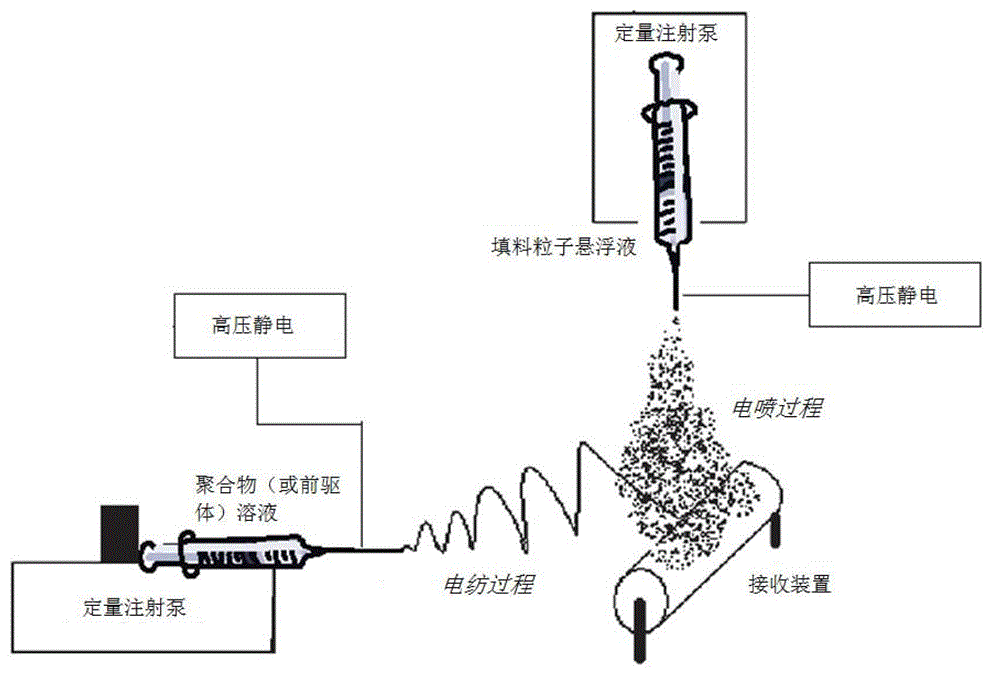

[0032] Follow the steps below to prepare polyimide / barium titanate (PI / BaTiO 3 ) high dielectric nanocomposites:

[0033]1) Prepare polyamic acid solution by low-temperature polymerization: weigh 4.0046g (0.02mol) 4,4'-diphenyl ether diamine (ODA), 8.0462g (0.02mol) 4,4'-terephthalic dioxydiamine Add phthalic anhydride (HQDA) into a three-necked flask, add 60mL DMAc, stir vigorously, first react at -5°C for 6h, then raise the temperature to 10°C for 6h to obtain a polyamic acid (PAA) solution.

[0034] 2) Add 10g BaTiO 3 Add the powder into 40g of absolute ethanol, and disperse w...

Embodiment 2

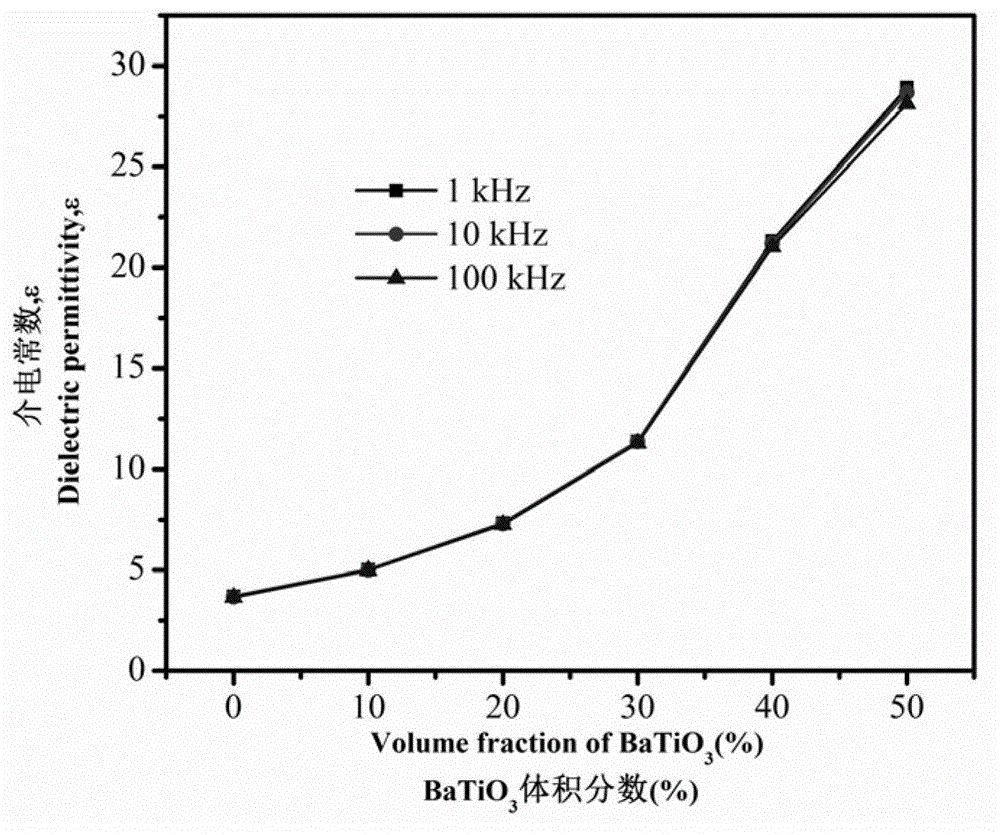

[0039] Example two: polyvinylidene fluoride / barium titanate (PVDF / BaTiO 3 ) Preparation of high dielectric nanocomposites:

[0040] 1) Add 18g PVDF and 82g DMF into a three-necked flask, stir and dissolve at room temperature to obtain a solution suitable for electrospinning.

[0041] 2) Prepare BaTiO according to the method of step 2) of Example 1 3 suspension;

[0042] 3) Electrospinning the PVDF solution obtained in step 1), the electrospinning conditions are: voltage 17kV, the distance between the needle tip and the receiving device is 25cm; at the same time, the BaTiO obtained in step 2) 3 The suspension was electrostatically sprayed, and the electrospray conditions were as follows: the voltage was 28kV, the distance between the needle tip and the receiving device was 15cm; a continuously rotating drum was used as the receiving device; the BaTiO 3 The content is 0-50vol%; PVDF / BaTiO is finally obtained on the receiving device 3 nanofibrous membrane.

[0043] 4) The na...

Embodiment 3

[0045] Example 3: Preparation of polyimide / carbon nanotube (PI / CNTs) high dielectric nanocomposite

[0046] 1) PAA solution obtained by step 1) in Example 1;

[0047] 2) The carboxylated carbon nanotubes were added to a mixed solvent of DMAc and acetone (5:5 volume ratio), and dispersed by ultrasonic stirring to obtain a stable suspension.

[0048] 3) Electrospinning the PAA solution obtained in step 1), the electrospinning conditions are: voltage 25kV, the distance between the needle tip and the receiving device is 20cm; at the same time, the carbon nanotube suspension obtained in step 2) is electrostatically sprayed; The spraying conditions are: the voltage is 18kV, the distance between the needle tip and the receiving device is 25cm; the continuously rotating drum is used as the receiving device; the content of CNTs is adjusted to 0-18vol%; the PAA / CNTs nanofiber film is finally obtained on the receiving device.

[0049] 4) Treat the fiber membrane obtained in step 3) acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com