Method for separating zinc-containing substance of blast furnace dry method dust separation ash

A dry dust removal and blast furnace technology, which is applied in the separation method, solid separation, dispersed particle separation, etc., can solve the problems of reducing the dezincification processing capacity of high zinc ash, post-processing requirements for products, and complex equipment systems. Novel and flexible, wide application range of processing capabilities, and high grading accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

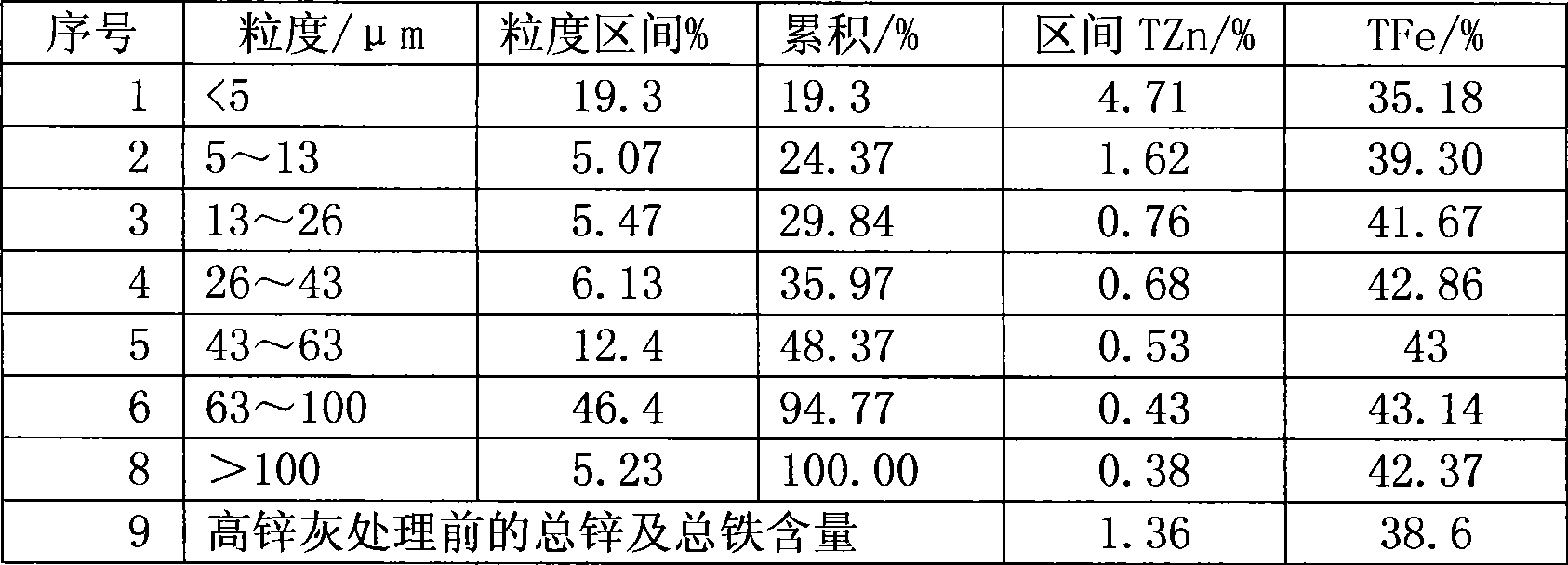

[0019] Taking the high zinc ash actually produced by a certain enterprise as an example:

[0020] The geometric particle size distribution and the corresponding total zinc content of the high-zinc ash to be treated were measured by the experimental device. As shown in Table 1, the ash with a particle size of less than 5 μm accounted for 19.3% of the total ash, and the total zinc content reached 4.71%. , the total iron content is only 35.18%; the high-zinc ash with a particle size of 5-13 μm accounts for 5.07% of the total ash, and its total zinc content has dropped significantly to 1.62%. Correspondingly, the total iron content has increased to 39.30%, obviously The distribution law of such total zinc content provides a strong basis for dry separation of high-zinc ash. By analyzing the measured data, it is advisable to use 5 μm as the target cutting particle size for separation in production. During the implementation process, the high zinc ash with a total zinc content of 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com