Narrow-sized level multi-stage vortex air classifier classification system

An air classifier and classification system technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problems that cannot meet the production needs of high-end products, low added value of products, and particle size distribution range Width and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

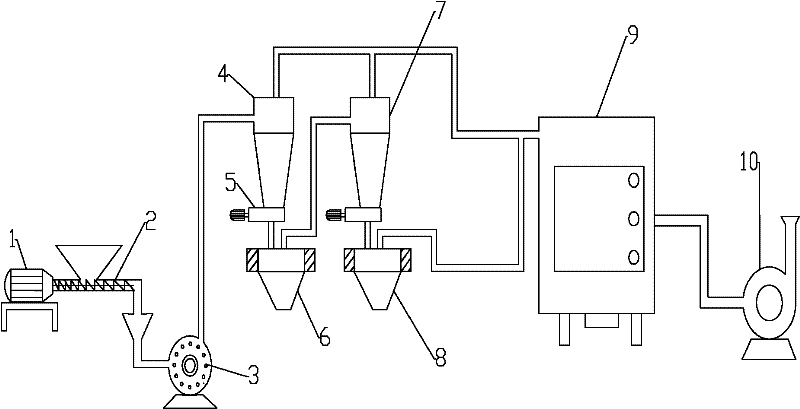

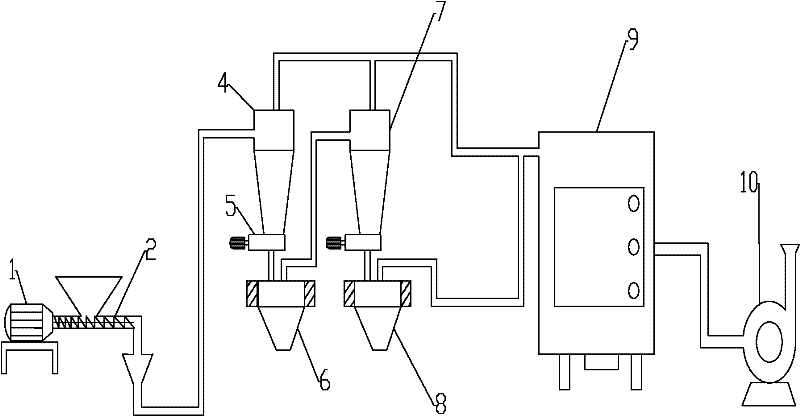

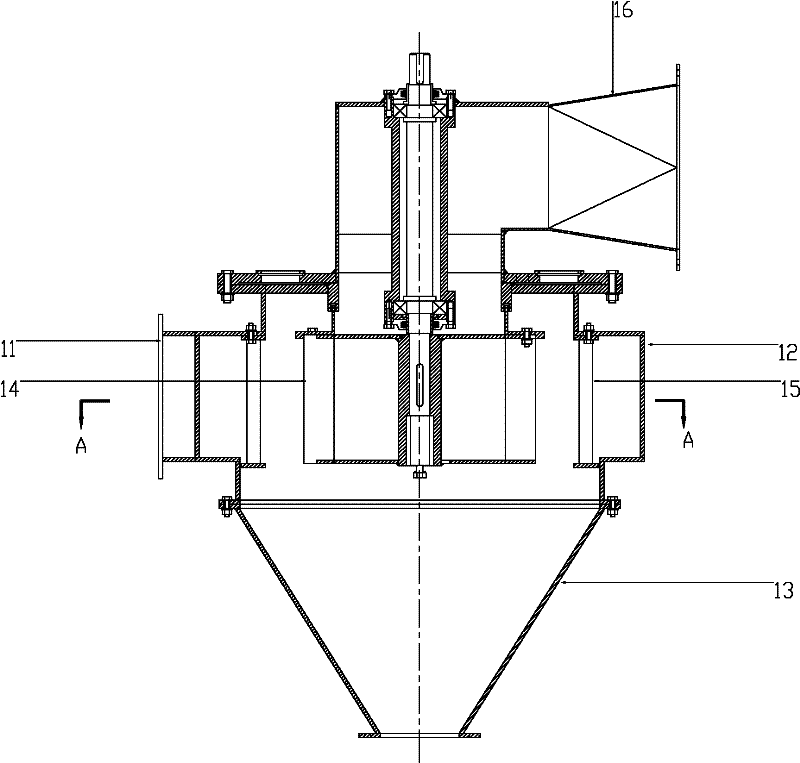

[0023] The present invention is a kind of equipment system that can prepare ultrafine powder of narrow grade, adopts such as figure 1 The schematic diagram of the device shown includes a motor 1, a dispersing device 3 for dispersing the agglomerated materials, or no dispersing device 3, a feeder 2 that can feed at a uniform speed, and can realize pre-separation and a section of vortex air The classifier 6 and the two-stage vortex air classifier 8 are the first-stage cyclone dust collector 4 and the second-stage cyclone dust collector 7 for stable feeding, and the flap valve 5 for stable discharge.

[0024] Classification steps: After the material is sent to the dispersing device 3 by the feeder 2 and dispersed, it is transported to the first-stage cyclone dust collector 4 by the airflow, or the material is directly transported to the first-stage cyclone by the airflow without being dispersed by the dispersing device 3 Dust collector 4, the fine powder separated by the first-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com