Continuous dry ball milling device

A ball milling and dry-type technology, applied in grain processing, etc., can solve the problems of uncontrollable product particles, complicated operation procedures, high production costs, etc., and achieve the effects of stable product quality, reasonable particle size distribution, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

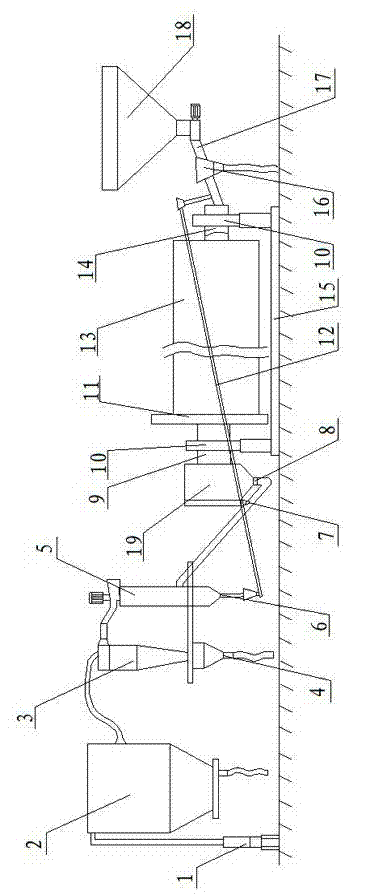

[0015] Embodiment 1, with reference to accompanying drawing, a kind of continuous dry ball milling device comprises ball mill, air classifier 5, cyclone collector 3 and dust collector 2, and air classifier 5 is provided with raw material inlet, fine powder outlet and coarse powder outlet. Powder outlet 6; the bottom of the cyclone collector 3 is provided with a finished powder outlet 4, and the upper part of the cyclone collector 3 is provided with a dust outlet and a powder inlet; the lower part of the dust collector 2 is provided with a dust outlet, and the upper part is provided with a dust inlet. An induced draft fan 1 is connected to the bottom of the side of the collector 2 to help discharge dust;

[0016] The ball mill includes a frame 15 and a cylinder body 13, the two ends of the cylinder body 13 are respectively fixedly connected with a feed pipe 14 and a discharge pipe 9 through end caps, and the feed pipe 14 and the discharge pipe 9 are installed on the machine thro...

Embodiment 2

[0019] Example 2: In the continuous dry ball milling device described in Example 1, an impurity filter 16 is provided in the middle of the automatic conveying pipeline 17 , and an impurity collection device is provided below the impurity filter 16 . When the quartz sand raw material passes through the automatic conveying pipeline 17, impurities such as small stones in the raw material will fall from the impurity filter screen 16 and enter the impurity collection device, thus eliminating the manual process of picking impurities and improving work efficiency.

Embodiment 3

[0020] Embodiment 3, in the continuous dry ball milling device described in Embodiment 1, the feed pipe 14 is provided with a material propulsion thread, and the thread in the feed pipe 14 can spirally push the material into the barrel 13 of the ball mill , to improve the feeding effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com