Steel bar truss and surface layer reinforced type aluminum alloy decoration plate sandwich polyphenyl foaming ceramic composite wallboard and manufacturing method

A foamed ceramic plate and steel truss technology, applied in the direction of walls, building reinforcements, thermal insulation, etc., can solve the problems of poor thermal insulation performance, poor mechanical performance, and self-heavy walls, and achieve good weather resistance, improved Good thermal insulation performance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention will be further described below with reference to specific examples.

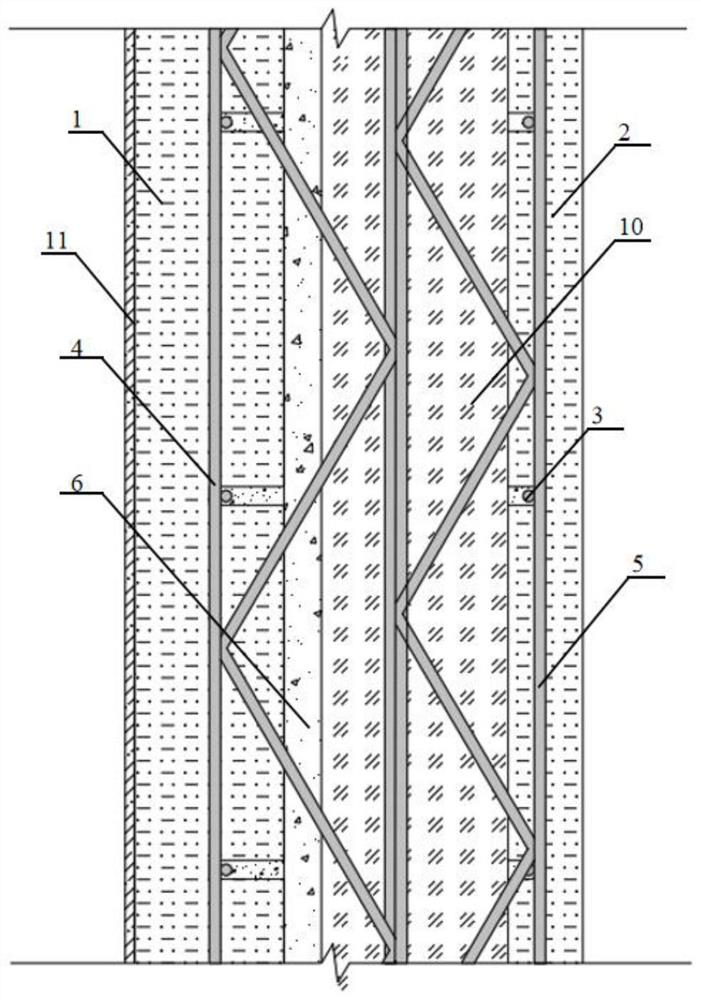

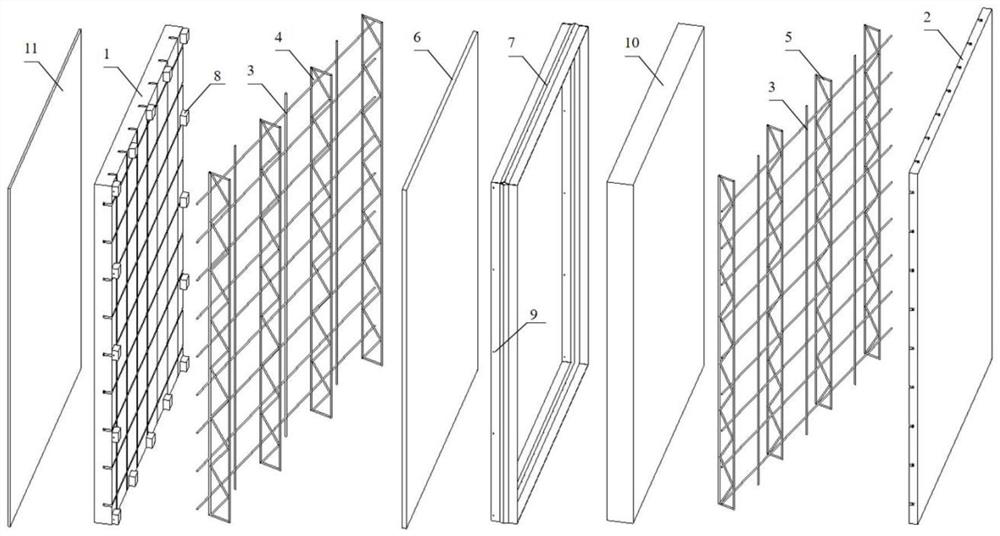

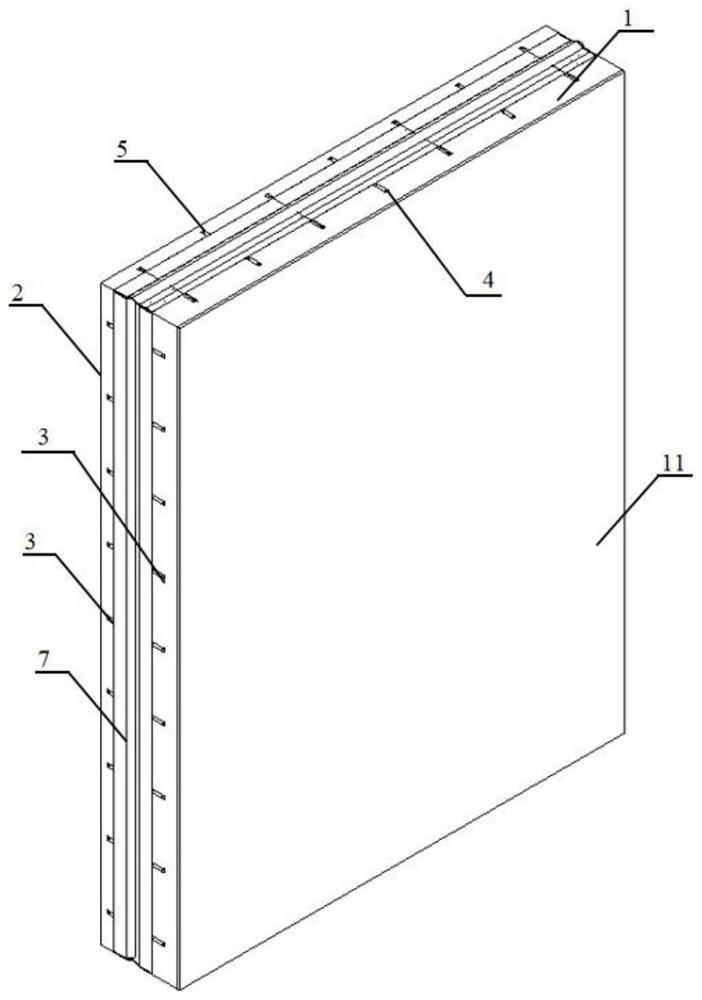

[0035] A reinforced truss and a surface layer reinforced aluminum alloy decorative panel sandwich polyphenyl foam ceramic composite wall panel and method thereof, the wall panel comprises an outer foam ceramic plate (1), an inner foam ceramic plate (2), a steel mesh (3), outer steel truss (4), inner steel truss (5), steel mesh fiber cement mortar reinforced surface (6), light steel keel (7), wood block (8), self-tapping screw (9), A sandwich polystyrene board (10) and a decorative aluminum alloy board (11).

[0036] The surfaces of the outer foamed ceramic plate (1) and the inner foamed ceramic plate (2) are grooved for implanting the reinforcement mesh (3), the outer reinforcement truss (4) and the inner reinforcement truss (5), and are filled with high performance cement slurry to ensure their cooperative work; the outer foamed ceramic board (1) is slotted and planted on one side, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com