Zinc-free aluminum alloy sacrificial anode

A sacrificial anode, aluminum alloy technology, applied in the field of anti-corrosion, can solve the problems of reducing the quality of aquatic products in the mariculture industry, hindering the growth and maturity of individuals, hindering the movement of biological breathing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

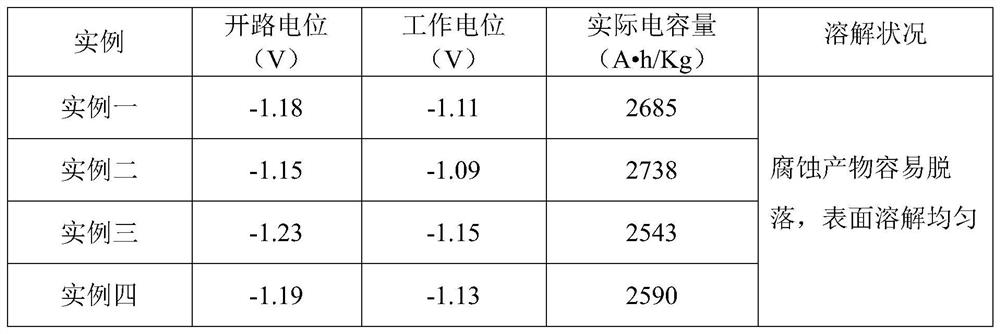

Examples

example 1

[0042] The formula of the zinc-free aluminum alloy sacrificial anode is (mass percentage): Sn 0.01%, In 0.005%, wherein impurity elements Fe 0.058%, Si 0.056%, Cu 0.004%, and the balance is Al.

[0043] Put the aluminum ingot into a heating device (melting furnace, crucible or heating furnace, etc.) and heat the aluminum ingot to 720 ° C ~ 750 ° C to completely melt the aluminum ingot to obtain aluminum liquid (no solid aluminum ingot visually); then use a small Scoop aluminum liquid from the crucible, wrap the tin block and indium block with aluminum foil, add them to the aluminum liquid in the small crucible, stir them with a graphite rod to dissolve them, and then pour them into a high-temperature heating device to obtain a mixture of aluminum tin and indium liquid; continue to heat the aluminum-tin-indium mixture, and stir it to make it fully melt, and remove the dross in the aluminum-tin-indium mixture; stop heating after the aluminum-tin-indium mixture is fully melted, an...

example 2

[0046] The formula of the zinc-free aluminum alloy sacrificial anode is (mass percentage): Sn 0.01%, In 0.03%, wherein impurity elements Fe 0.058%, Si 0.062%, Cu 0.004%, and the balance is Al.

[0047] Put the aluminum ingot into a heating device (melting furnace, crucible or heating furnace, etc.) and heat the aluminum ingot to 720 ° C ~ 750 ° C to completely melt the aluminum ingot to obtain aluminum liquid (no solid aluminum ingot visually); then use a small Scoop aluminum liquid from the crucible, wrap the tin block and indium block with aluminum foil, add them to the aluminum liquid in the small crucible, stir them with a graphite rod to dissolve them, and then pour them into a high-temperature heating device to obtain a mixture of aluminum tin and indium liquid; continue to heat the aluminum-tin-indium mixture, and stir it to make it fully melt, and remove the dross in the aluminum-tin-indium mixture; stop heating after the aluminum-tin-indium mixture is fully melted, and...

example 3

[0050] The formula of the zinc-free aluminum alloy sacrificial anode is (mass percentage): Sn 0.04%, In 0.005%, wherein impurity elements Fe 0.058%, Si 0.062%, Cu 0.004%, and the balance is Al.

[0051] Put the aluminum ingot into a heating device (melting furnace, crucible or heating furnace, etc.) and heat the aluminum ingot to 720 ° C ~ 750 ° C to completely melt the aluminum ingot to obtain aluminum liquid (no solid aluminum ingot visually); then use a small Scoop aluminum liquid from the crucible, wrap the tin block and indium block with aluminum foil, add them to the aluminum liquid in the small crucible, stir them with a graphite rod to dissolve them, and then pour them into a high-temperature heating device to obtain a mixture of aluminum tin and indium liquid; continue to heat the aluminum-tin-indium mixture, and stir it to make it fully melt, and remove the dross in the aluminum-tin-indium mixture; stop heating after the aluminum-tin-indium mixture is fully melted, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com