Nucleocapsid energizing agent for propelling agent and method for preparing same

A core-shell catalyst and propellant technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor compatibility of composite particles, poor coating effect, complex process, etc. To achieve the effect of stable product quality, low price and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

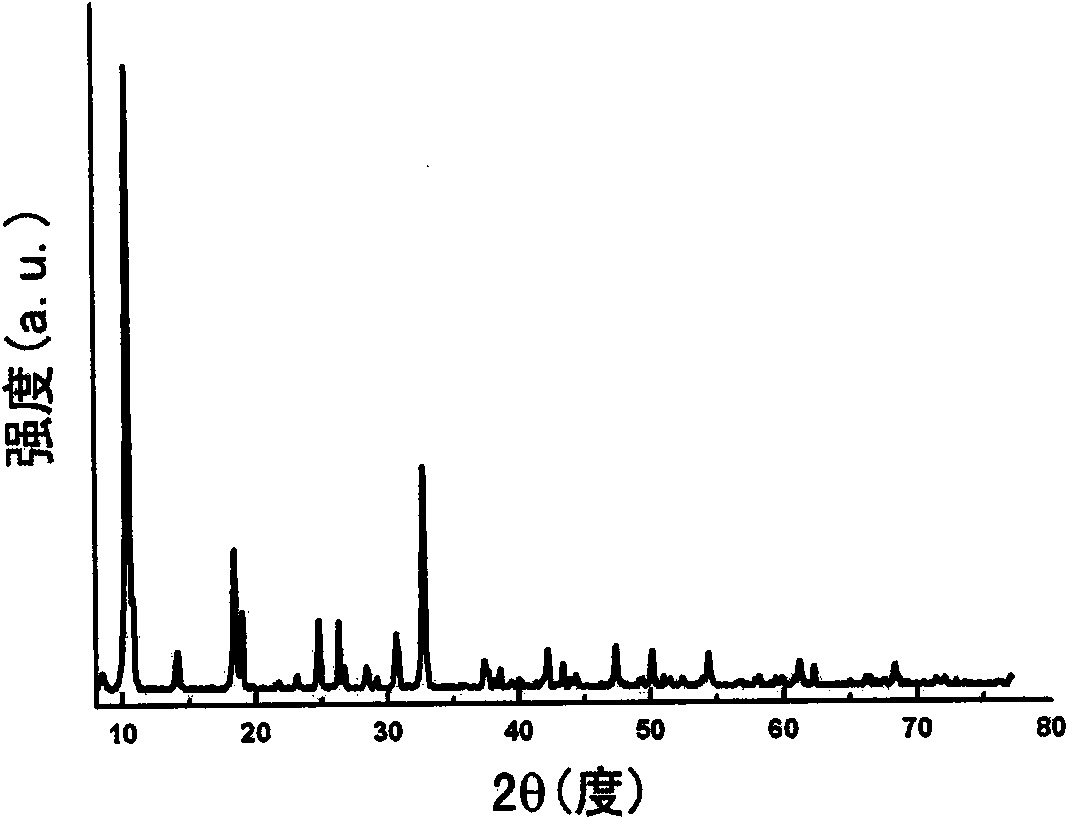

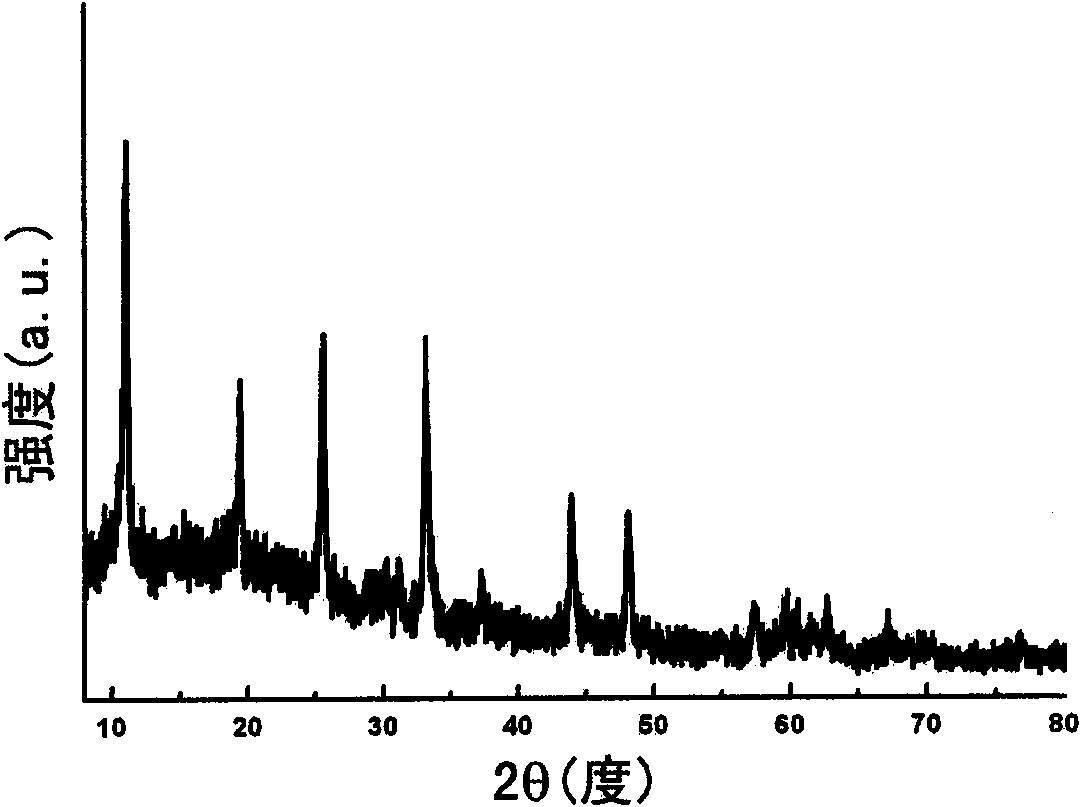

[0032] Add mannose to 50 mL of deionized water to prepare a 100 g / L solution. Then add vanadium oxide powder to the solution to make it account for 30% of the mass of mannose, ultrasonically disperse the vanadium oxide powder for 0.5 h, transfer to an autoclave, and react at 160° C. for 6 h. After the reaction is finished, the material is naturally cooled and discharged, washed with deionized water, centrifuged, and the water-soluble impurities are removed several times, so that the upper layer solution after centrifugation can be clarified, and then the precipitate obtained by centrifugation is vacuum-dried to obtain Vanadium oxide@C core-shell structure materials. The product was identified as a core-shell structure by TEM electron microscopy, see figure 1 . Vanadium oxide was characterized by XRD before being coated with carbon layer as V 3 o 7 ·H 2 O, such as figure 2 The crystallinity of the vanadium oxide@C core-shell structure becomes worse after being covered by...

Embodiment 2

[0034] According to the same method as in Example 1, keeping other conditions unchanged, changing the types of different soluble sugars, and their concentrations were varied within the range of 50-1500 g / L. The characterization was carried out in the same manner as in Example 1, and it was confirmed that the vanadium oxide@C core-shell structure material was also obtained after the reaction.

Embodiment 3

[0036] By the same method as in Example 1, keeping other conditions unchanged, the quality of vanadium oxide was changed so that its quality varied within the range of 1-60% of the raw material quality. The characterization was carried out in the same manner as in Example 1, and it was confirmed that the vanadium oxide@C core-shell structure material was also obtained after the reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com