Economical high-strength binding strip steel with tensile strength more than or equal to 1,000 MPa, and manufacturing method thereof

A technology of tensile strength and manufacturing method, which is applied in the design and manufacture of economical high-strength strapping steel, can solve the problems of low production efficiency, serious environmental pollution and high cost, and achieves low cost, low environmental pollution, and improved plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

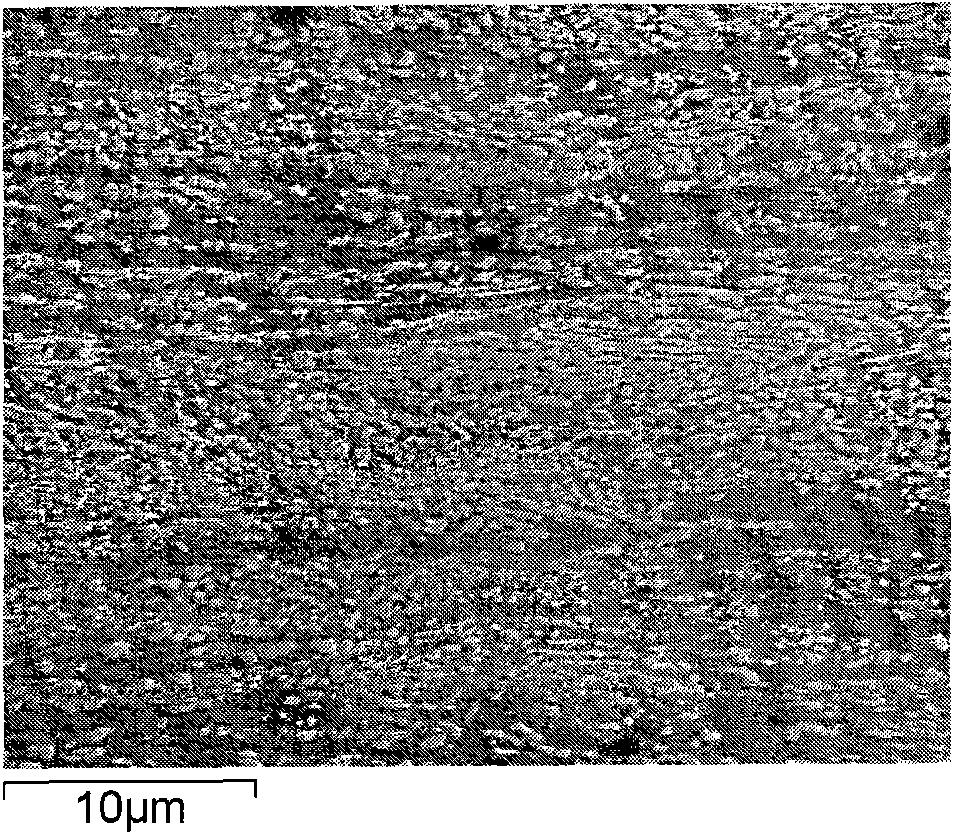

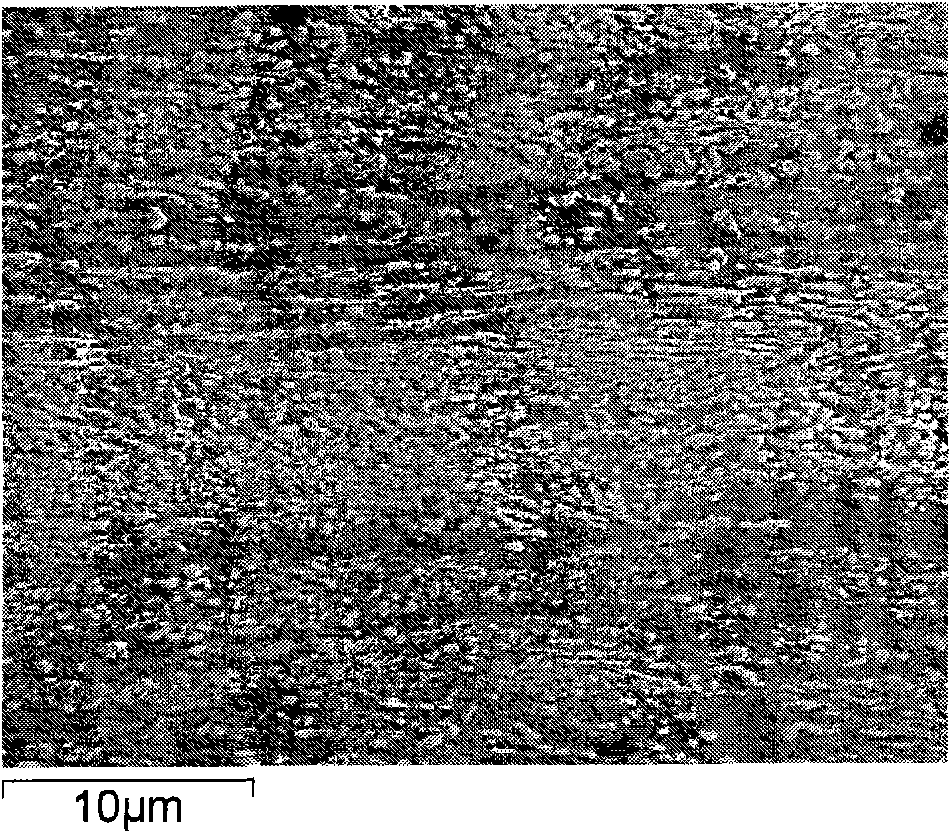

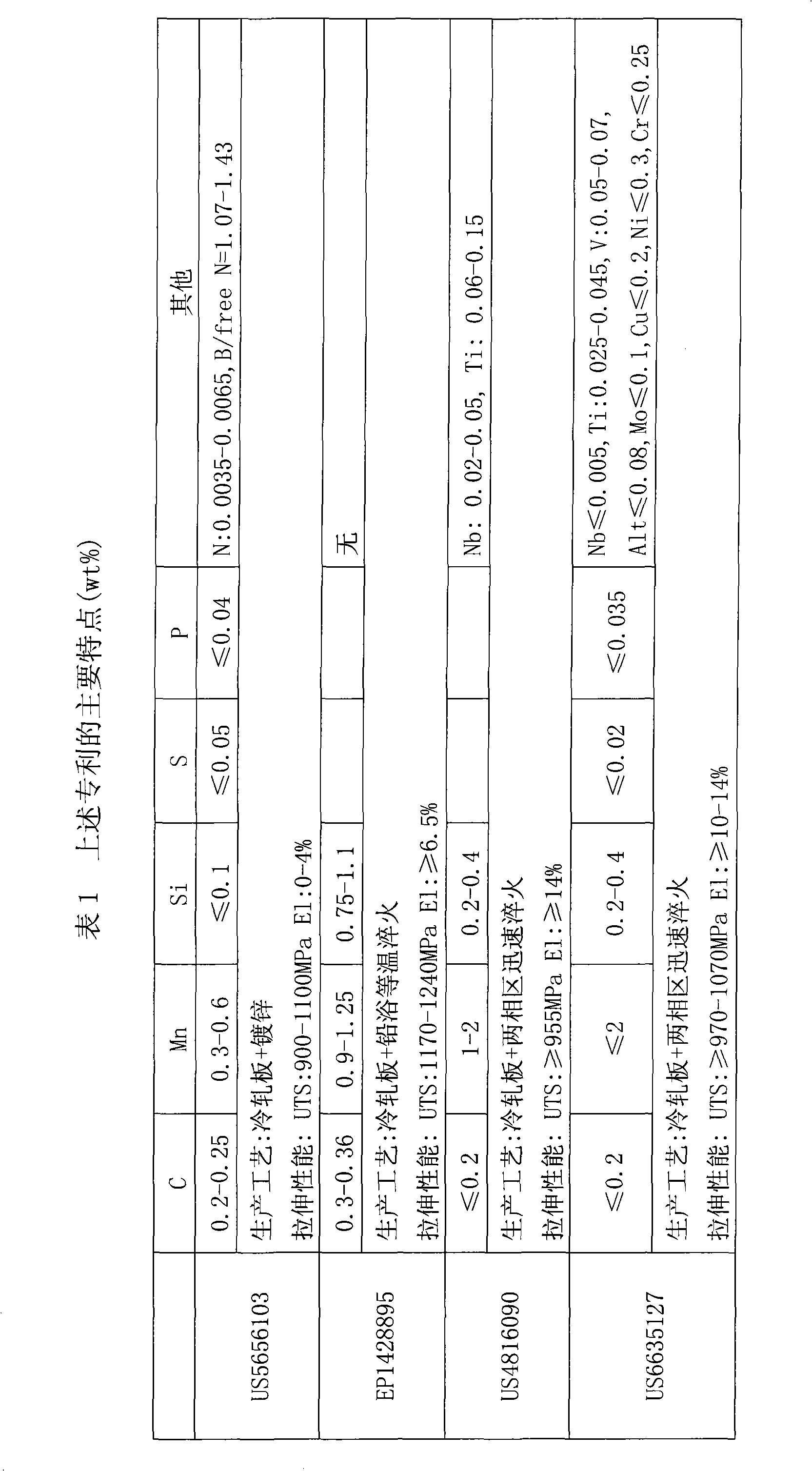

[0042] The following tables are specific embodiments of the present invention, wherein Table 2 is the chemical composition of the high-strength strap steel produced by the present invention, Table 3 is the process parameters adopted, and Table 4 is the performance of the tensile test under room temperature conditions Test Results. another example figure 1 As shown, it can be clearly seen from the metallographic structure that the structure of recovered ferrite + granular pearlite is finer.

[0043] The chemical composition (wt%) of the embodiment of table 2

[0044] Example

C

mn

Si

S

P

Al

1

0.25

1.01

0.05

0.004

0.012

0.037

2

0.31

1.39

0.069

0.033

0.012

0.051

3

0.31

1.43

0.37

0.01

0.033

0.001

4

0.36

1.40

0.039

0.036

0.038

0.026

5

0.39

1.74

0.42

0.017

0.015

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com