Fire-resistant panel and method of manufacture

a technology of fire-resistant panels and manufacturing methods, applied in the direction of walls, solid waste management, sustainable waste treatment, etc., can solve the problems of limited fire-resistance, environmental hazards in their manufacture, use and disposal, and excessive weight of non-combustible panel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

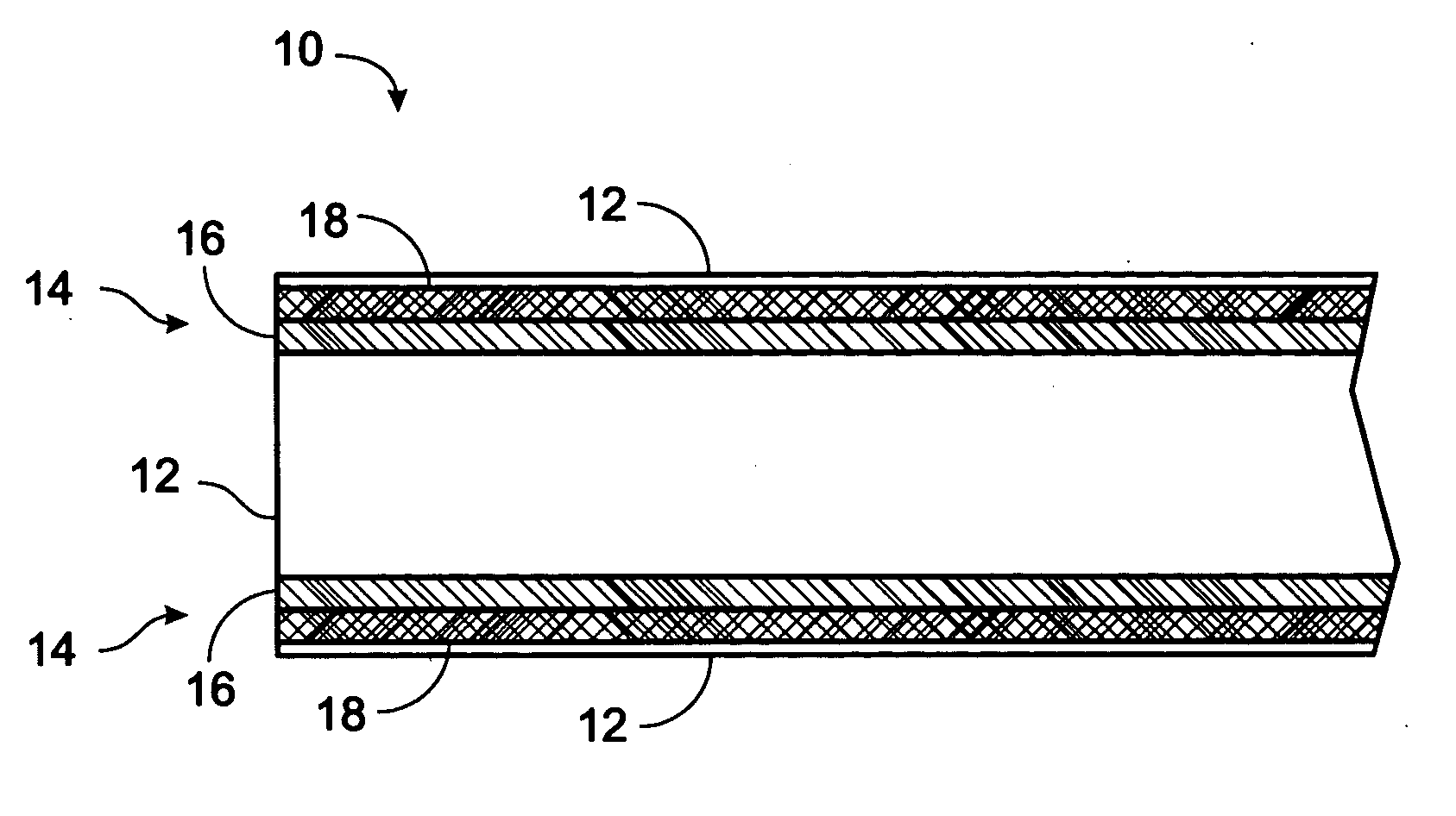

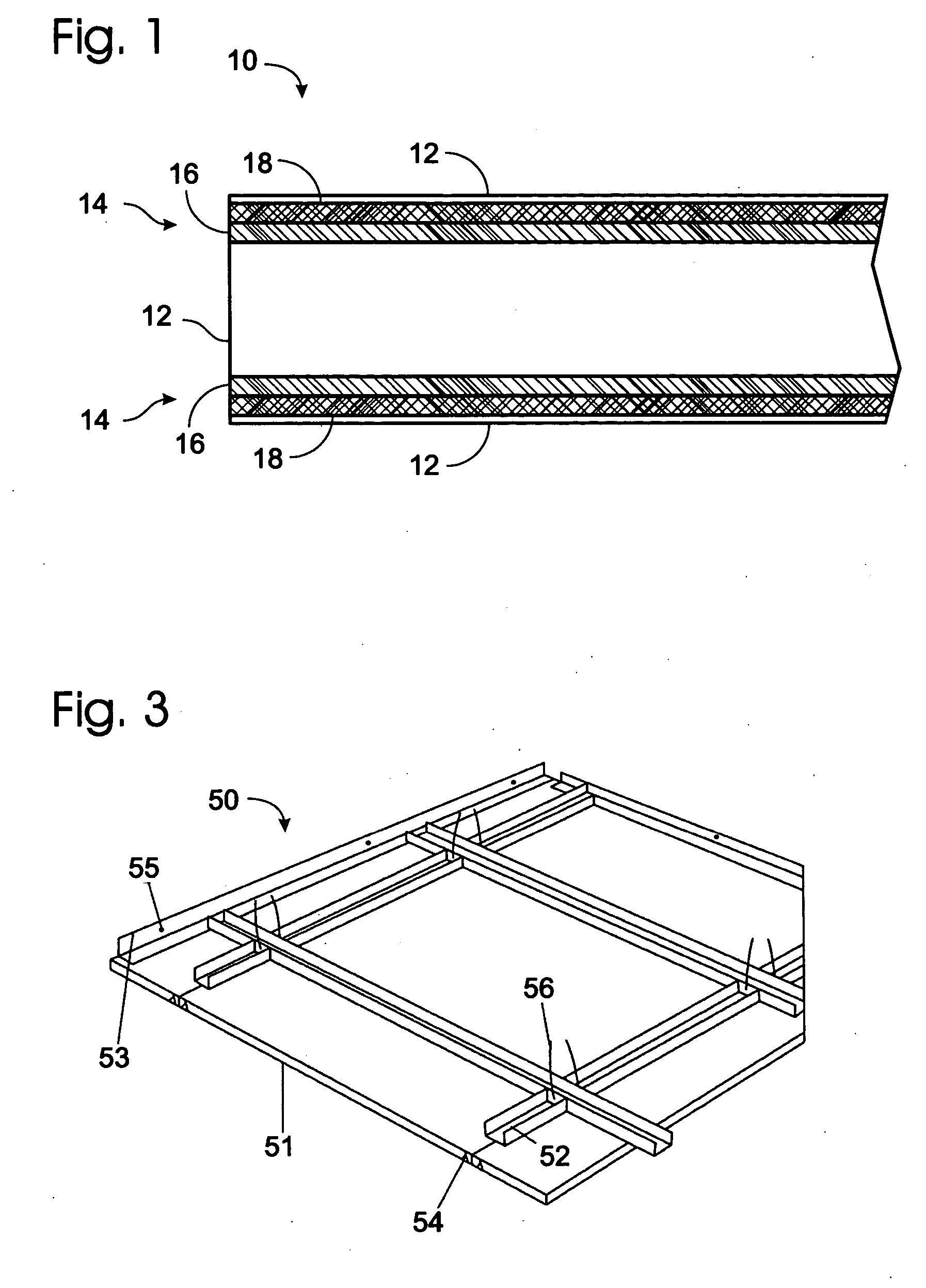

[0014] Referring to FIG. 1, the present invention relates to a fireproof or fire-resistant panel material 10, such as a board, that offers a combination of a high degree of fire resistance, a low density, high flexural strength, and effective water resistance. These advantageous properties may be obtained by the preparation of a panel core 12 that includes magnesium compounds, sodium silicate, and kaolin, and may further include one or more fillers, and hydrophobic agents. The panel may further include one or more fire-resistant layers 14.

[0015] As used herein, the terms “fireproof” and “fire-resistant” refer to a substance that is resistant to the effects of fire, that is, describing a material that is substantially or completely non-combustible and / or substantially insulating. By panel is meant a generally planar construction material. In one aspect of the invention, the panel is a fire-resistant board, dimensioned so as to be compatible with standard construction methods and mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com