Phosphorus modification method of ZSM-5 molecular sieve

A ZSM-5, molecular sieve technology, applied in molecular sieve catalysts, including molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of blocking the pores of molecular sieves, reducing catalytic performance, occupying strong B acid centers, etc., and achieving hydrothermal activity. The effect of improved stability, superior catalytic performance and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weigh 5.40g of diammonium hydrogen phosphate and add 50g of deionized water to make a solution, add 56.0g of ZSM-5 molecular sieve Z1, dip and stir for a period of time, dry and roast, then add ammonium nitrate with 0.02g / ml ammonium ion concentration 500g of aqueous solution was stirred at 50°C for 1h, and then sodium was eluted with 500g of deionized water. After drying, it was hydrothermally aged at 800°C in 100% water vapor for 17h. The product sample was designated as P2-Z1.

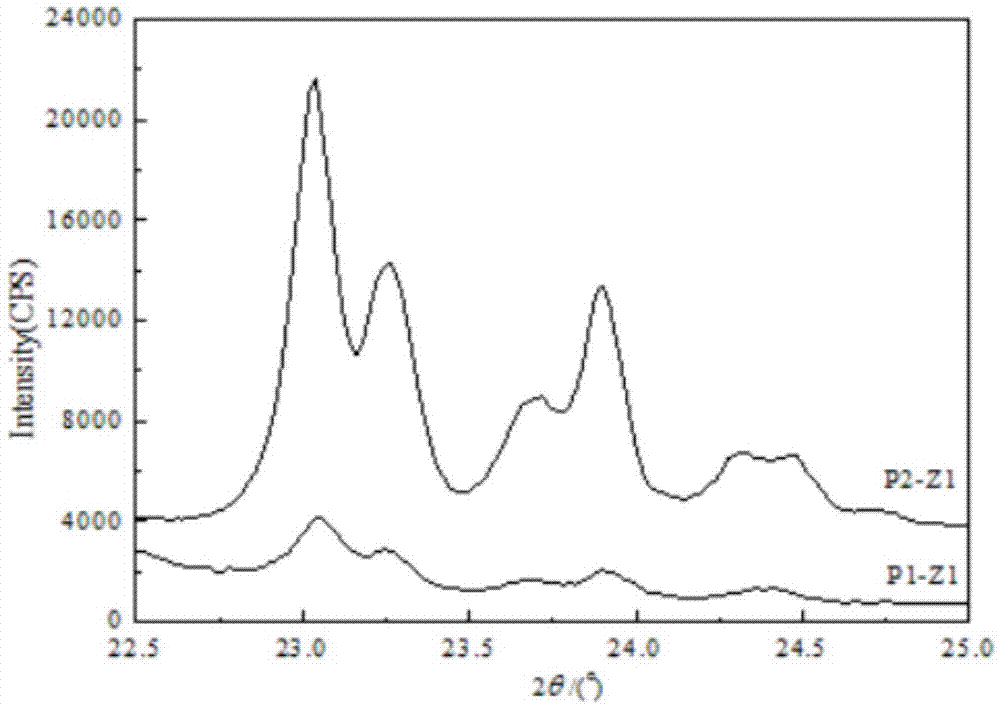

[0043] The crystallinity of sample P2-Z1 is 86.0, Na in molecular sieve 2 O mass fraction is 0.03wt%.

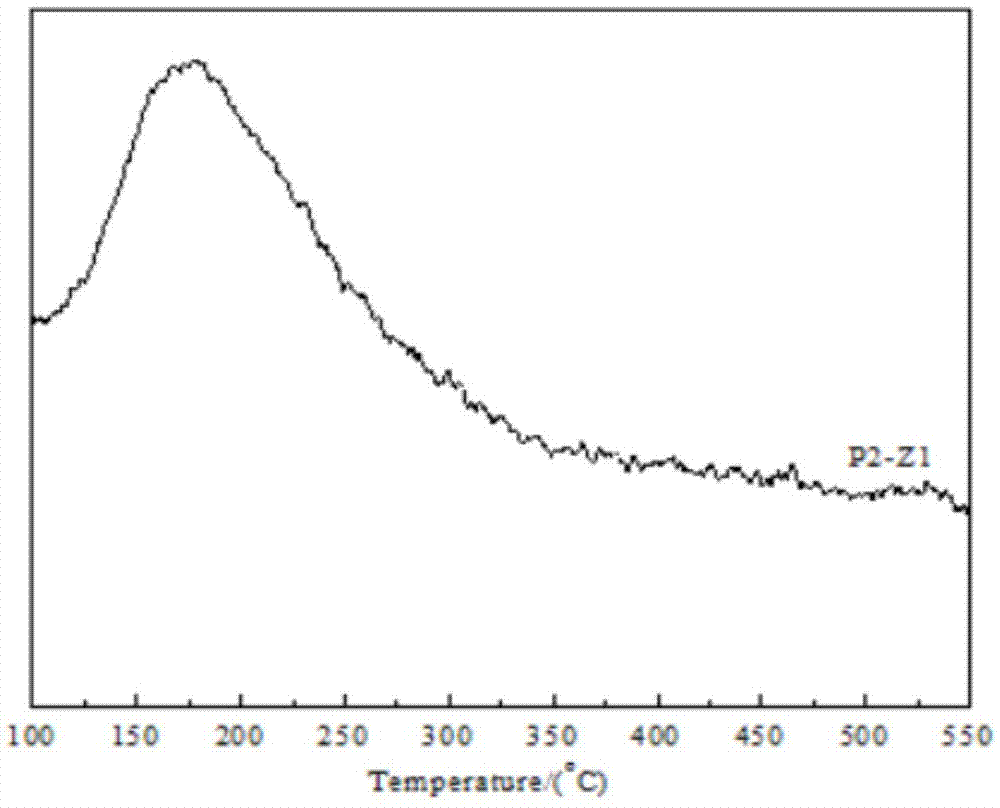

[0044] The XRD spectrum of sample P2-Z1 is shown in figure 1 , the total acid content measured by the temperature-programmed desorption method and the pore structure data measured by the nitrogen adsorption-desorption curve are shown in Table 1, and the NH 3 -TPD see figure 2 .

[0045] Table 1

[0046]

[0047] From figure 1 As can be seen from the XRD spectrum of the comparative...

Embodiment 2

[0055] Take by weighing 3.40g diammonium hydrogen phosphate (Tianjin Standard Technology Co., Ltd., analytically pure, P 2 o 5 The mass fraction is 3.5wt%), add 48g of deionized and stir evenly, add 54.0g of ZSM-5 molecular sieve Z1, impregnate and stir for a period of time, after drying and roasting, add 500g of ammonium nitrate aqueous solution with 0.04g / mL ammonium ion concentration, 40 Stir at ℃ for 1 hour, then wash off the sodium with 500g of deionized water, dry it, and record it as P4-Z1.

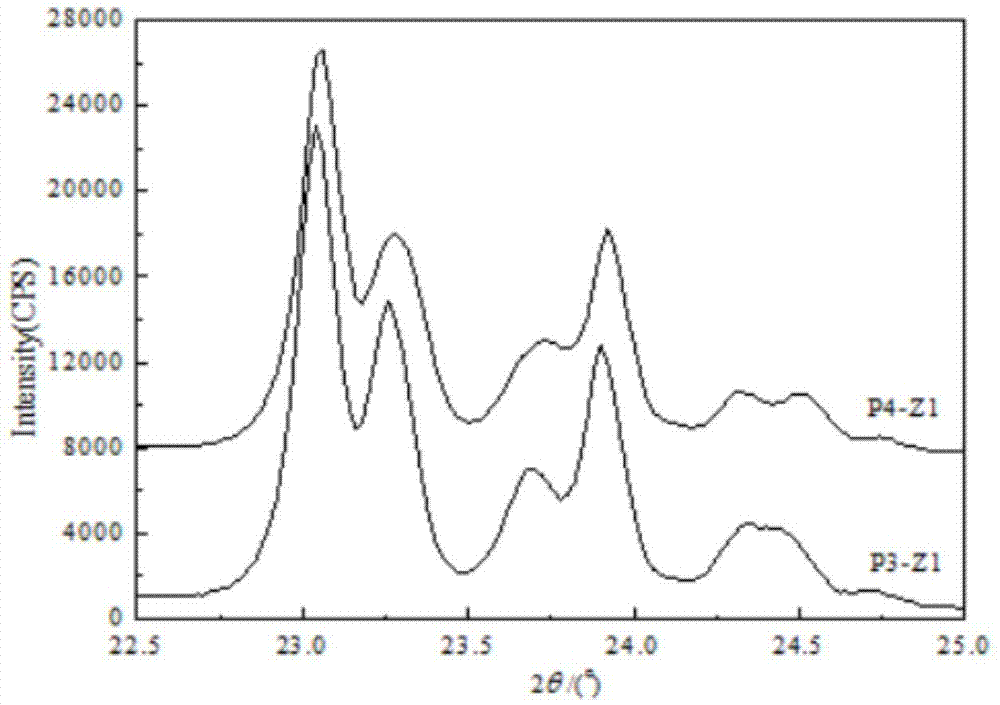

[0056] Under 100% water vapor, hydrothermal aging at 800 °C for 17 h, the obtained product is labeled as P4-Z1, with a crystallinity of 86.3, Na 2 The mass fraction of O is 0.02wt%.

[0057] The XRD spectrum of P4-Z1 is shown in image 3 , the total acid content measured by the temperature-programmed desorption method and the pore structure data measured by the nitrogen adsorption-desorption curve are shown in Table 2, and the NH 3 -TPD curve see Figure 4 . Table 2 shows the...

Embodiment 3

[0067] Take by weighing 4.40g diammonium hydrogen phosphate (Tianjin Standard Technology Co., Ltd., analytically pure, P 2 o 5The mass fraction is 5.5wt%), add 42g of deionized and stir evenly, add 44.0g of ZSM-5 molecular sieve Z2, after dipping and stirring for a period of time, after drying and roasting, add 500g of aqueous solution with 0.05g / mL ammonium ion concentration, 60°C After stirring for 1 h, the sodium was eluted with 500 g of deionized water, dried, and recorded as P2-Z2.

[0068] In 100% water vapor, the crystallinity of P2-Z2 hydrothermally aged at 800°C for 17h was 83.1, and Na in molecular sieve 2 O mass fraction is 0.01wt%.

[0069] The XRD spectrum of P1-Z2 and P2-Z2 after hydrothermal treatment is shown in Figure 5 , NH measured by temperature programmed desorption 3 -TPD curve see Figure 6 , the total acid content measured by the temperature-programmed desorption method and the pore structure data measured by the nitrogen adsorption-desorption cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com