Catalyst with meso pore characteristics and application thereof

A catalyst and mesoporous technology, applied in the field of environmental catalysis, can solve the problems of low conversion rate of pollutants, great damage, and affecting the practicality of catalysts, and achieve high catalytic activity and avoid loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

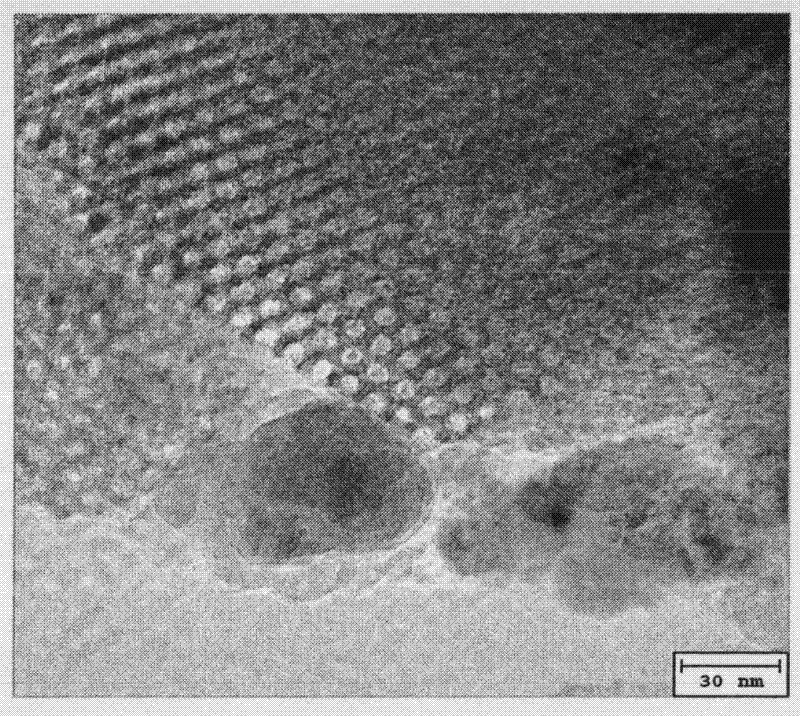

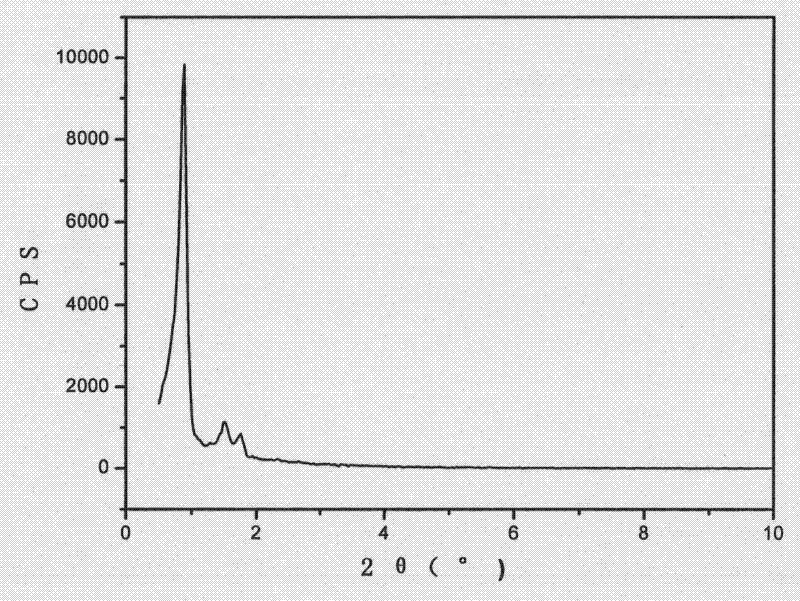

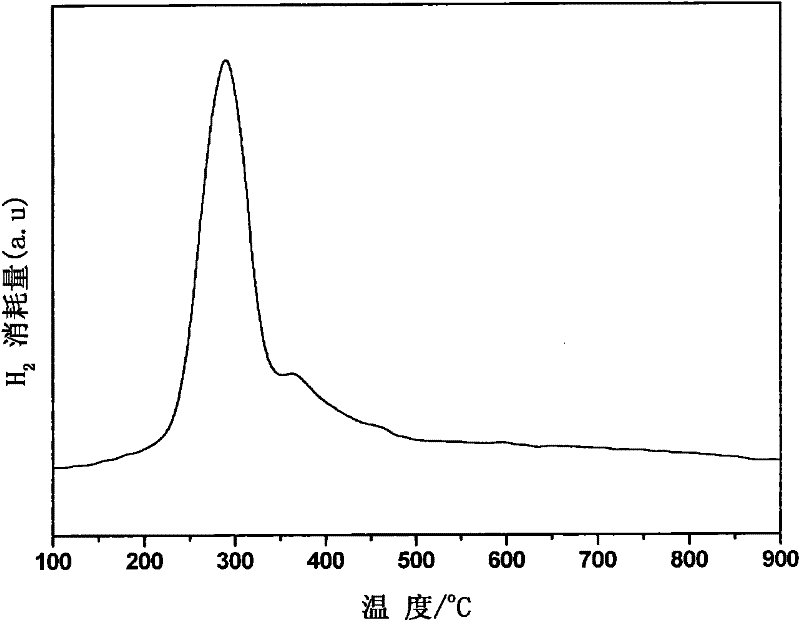

[0026] Under constant temperature conditions of 35°C, 4 grams of P123 (triblock nonionic surfactant polyoxyethylene propylene ether polyoxypropylene ether polyoxyethylene ether) was added to a 250 ml three-necked flask, and 90 ml of deionized water was added as Solvent, after stirring until completely dissolved (about 2 hours), add 60 ml of hydrochloric acid solution (4 mol / liter) dropwise, continue stirring for 1 hour, finally slowly add 9.8 ml of tetraethylsiloxane (TEOS) dropwise, and stir for 22 hours later. Move the solution to a stainless steel reaction bottle with a polytetrafluoroethylene liner, let it stand at 100°C for 24 hours, filter and wash to neutrality after cooling, dry naturally, and roast at 550°C for 6 hours to remove the template agent (heating rate 1°C / min), the mesoporous molecular sieve SBA-15 white powder is obtained. Then, the Cu-Al / SBA-15 mesoporous material catalyst prepared by impregnation method; its transmission electron microscope picture is sh...

example 2

[0030] The SBA-15 raw powder was prepared by hydrothermal crystallization method, and then the Cr / SBA-15 mesoporous material catalyst was obtained by impregnation method, and it was aimed at the removal of nitrogen oxides in automobile exhaust. 3 h 6 , 3000ppm CO, 1% O 2 , and the space velocity is 36,000 / h. The catalytic activity is shown in Table 2: the catalyst exhibits high activity, and the nitrogen oxide conversion rate can reach 79% at 400°C. Further increasing the temperature to 600°C, the conversion rates of nitrogen oxides and hydrocarbons can reach more than 92.4%.

[0031] Table 2

[0032]

example 3

[0034] The V / MCM-41 mesoporous material catalyst prepared by the in-situ synthesis method is aimed at the removal of nitrogen oxides in the tail gas of power plants, at 3000ppm NO, 3000ppm NH 3 , 4% O 2 , and the space velocity is 55,000 / h. The catalytic activity is shown in Table 3. The catalyst exhibits high activity, and the conversion rate of nitrogen oxides can reach 66.4% at 250°C. Further raising the temperature to 300°C, the conversion rates of nitrogen oxides and hydrocarbons can reach more than 99.8%.

[0035] table 3

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com