Waterborne ceramic coated membrane for lithium ion battery and preparation method thereof

A lithium-ion battery, water-based technology, applied to battery components, coatings, circuits, etc., can solve the problems of lithium-ion battery performance impact, high water content, etc., to improve the battery cycle life and use safety, infiltration Good performance and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

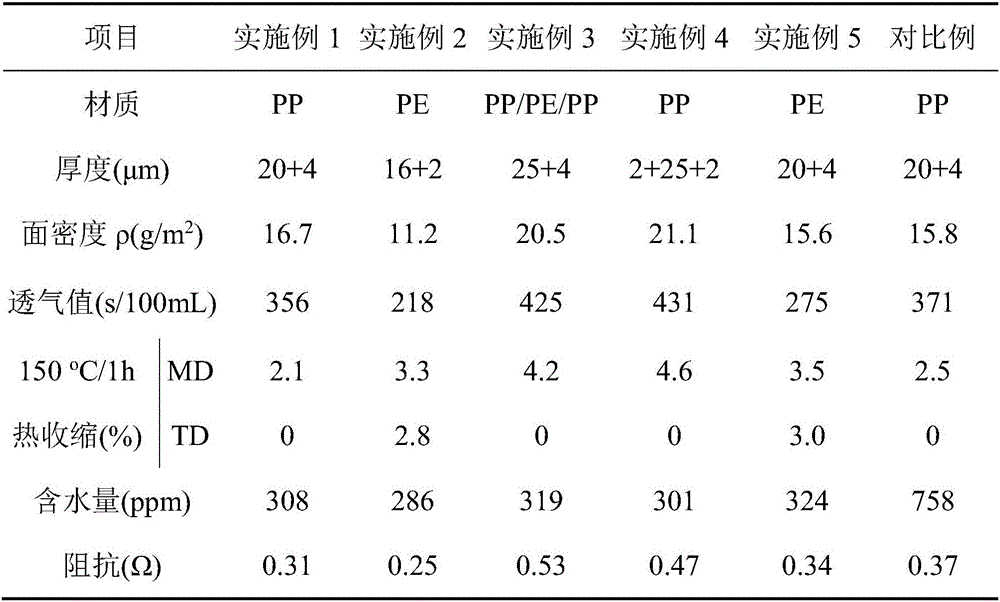

Embodiment 1

[0022] The present invention uses a polypropylene microporous membrane with a thickness of 20 μm and a porosity of 45%. One side of the polypropylene microporous membrane is coated with a water-based ceramic coating with a thickness of 4 μm, wherein the water-based ceramic coating slurry contains The base material of 40wt% and the water of 60wt%; Said base material comprises boehmite powder 80g, D 50 0.4 μm, water-based wetting agent sodium dodecylbenzene sulfonate 10g, water-based adhesive polymethyl methacrylate 8g, water-based dispersant polyacrylic acid 2g, the total mass of the base material is 100g.

[0023] Its preparation method comprises the following steps:

[0024] (1). After stirring and mixing the boehmite powder and deionized water, use a high-speed disperser to disperse at a speed of 13000 rpm to obtain a boehmite dispersion solution;

[0025] (2). Mix the above-mentioned boehmite dispersion solution with water-based dispersant polyacrylic acid, water-based adh...

Embodiment 2

[0028] The present invention uses a polyethylene microporous membrane with a thickness of 16 μm and a porosity of 55%. One side of the polyethylene microporous membrane is coated with a water-based ceramic coating with a thickness of 2 μm, wherein the water-based ceramic coating slurry contains The base material of 30wt% and the water of 70wt%; Said base material comprises boehmite powder 98g, D 50 1 μm, water-based wetting agent sodium isopropyl naphthalene sulfonate 1g, water-based adhesive styrene-butadiene latex 1g, water-based dispersant sodium polyacrylate 1g, the total mass of the base material is 100g.

[0029] The preparation method is the same as in Example 1, wherein the speed of the disperser is 15000 rpm, the speed of the mixer is 600 rpm, the stirring time is 30 minutes, the coating method is spray coating, and the coating thickness is 2 μm.

Embodiment 3

[0031] The present invention uses a polypropylene / polyethylene / polypropylene microporous membrane with a thickness of 25 μm and a porosity of 49%. One side of the polyethylene microporous membrane is coated with a water-based ceramic coating with a thickness of 4 μm, wherein the water-based ceramic coating slurry The material contains 50wt% base material and 50wt% water by mass percent; the base material includes 75g of boehmite powder, D 50 0.7μm, water-based wetting agent butylnaphthalene sodium sulfonate 10g, water-based adhesive polymethyl methacrylate and polybutyl methacrylate mixture 10g, water-based dispersant polyacrylamide 5g, the total mass of the base material 100g.

[0032] The preparation method is the same as in Example 1, wherein the rotational speed of the disperser is 10000 rpm, the rotational speed of the mixer is 650 rpm, the stirring time is 25 minutes, the coating method is dip coating, and the coating thickness is 4 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com