High temperature-resistant activated alumina material and preparation method thereof

A technology of activated alumina and high temperature resistance, which is applied in the field of alumina materials and can solve the problem that the specific surface area of alumina materials is not very high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix 69.64g macroporous pseudo-boehmite, 69.64g high-viscosity pseudo-boehmite and 6.76g lanthanum nitrate in water, slowly add 30% nitric acid solution dropwise under stirring at 500r / min to PH= 4.0 is in a peptized state, aged at 90°C for 5 hours with constant stirring, added polyethylene glycol solution (containing 40g of polyethylene glycol) at room temperature, stirred evenly to make a slurry, then sprayed and dried at 90°C.

[0028] (2) Put the powder in a muffle furnace and pass air to decompose at 450°C; form the alumina crystal phase at 600°C; stabilize the alumina structure at 900°C.

[0029] (3) Put the product in a crucible and place it in a high-temperature box furnace and pass it into dry air; calcinate at 1000° C. for 5 hours to obtain the product.

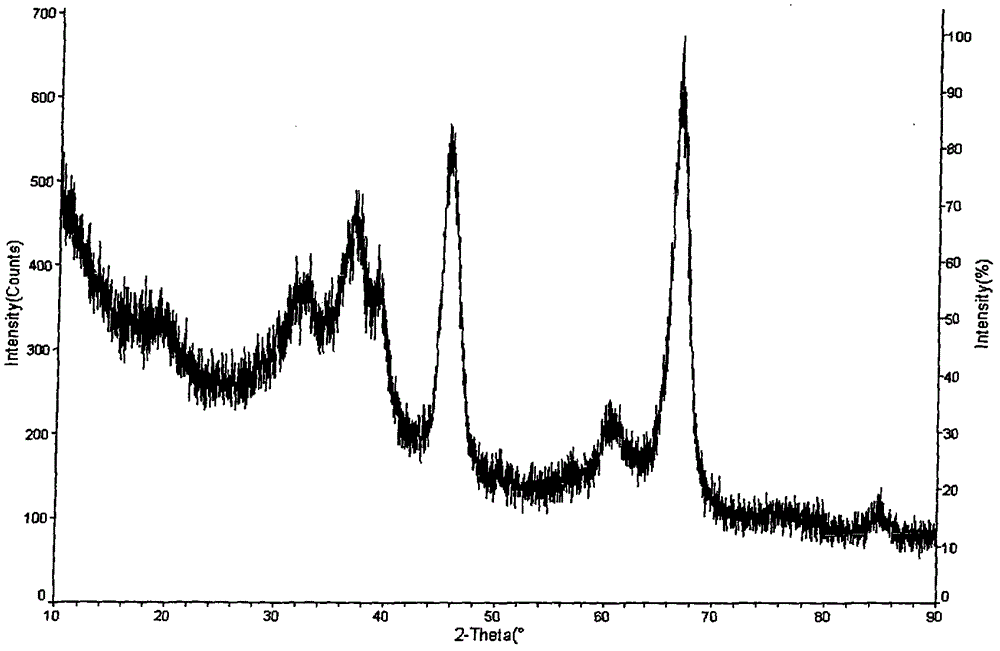

[0030] (4) The XRD analysis of the calcined product is δ phase figure 1 , the specific surface area measured by the surface analyzer is 117.61m 2 / g.

Embodiment 2

[0032] (1) Mix 67.85g macroporous pseudo-boehmite, 67.85g high-viscosity pseudo-boehmite and 12.82g cerium nitrate in water, slowly add 30% nitric acid solution dropwise under stirring at 100r / min to PH= 3.5 In peptized state, aged at 95°C for 4.5 hours with constant stirring, added polyvinyl alcohol solution (containing 20g of polyvinyl alcohol) at room temperature and stirred evenly to make a slurry, then sprayed and dried at 90°C.

[0033] (2) (2) with embodiment 1

[0034] (3) (3) with embodiment 1

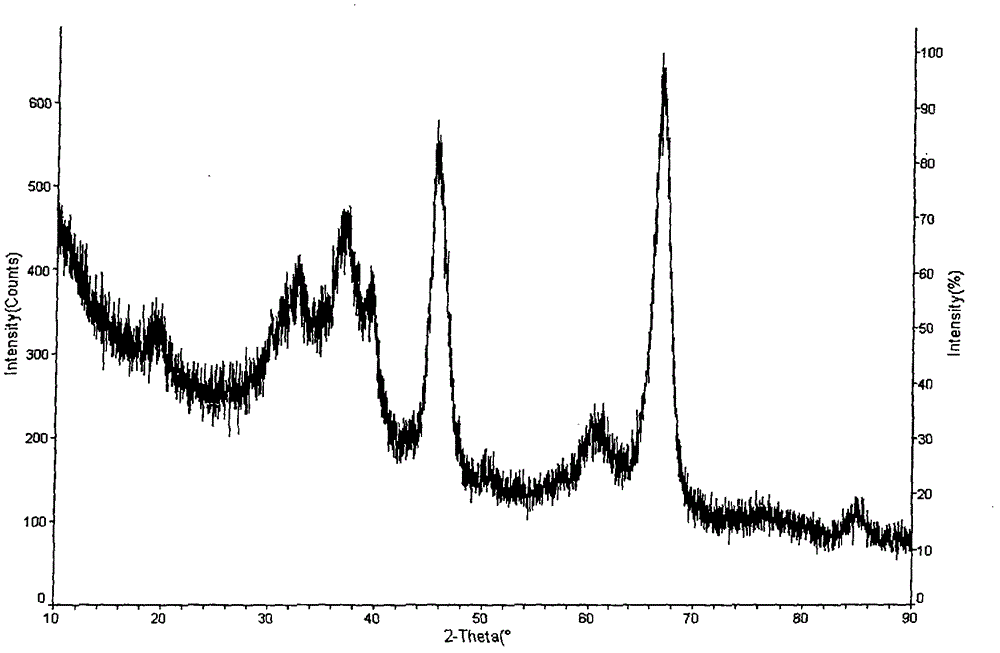

[0035] (4) The XRD analysis of the calcined product is δ phase figure 2 , the specific surface area measured by the surface analyzer is 111.23m 2 / g.

Embodiment 3

[0037] (1) Mix 68.57g macroporous pseudo-boehmite, 68.57g high-viscosity pseudo-boehmite and 13.93g zirconium nitrate in water, slowly add 30% nitric acid solution dropwise under stirring at 650r / min to PH= 3.9 In peptized state, aged at 95°C for 5 hours with constant stirring, added methylcellulose solution (containing 35g of methylcellulose) at room temperature and stirred evenly to make a slurry, then sprayed and dried at 100°C.

[0038] (2) (2) with embodiment 1

[0039] (3) (3) with embodiment 1

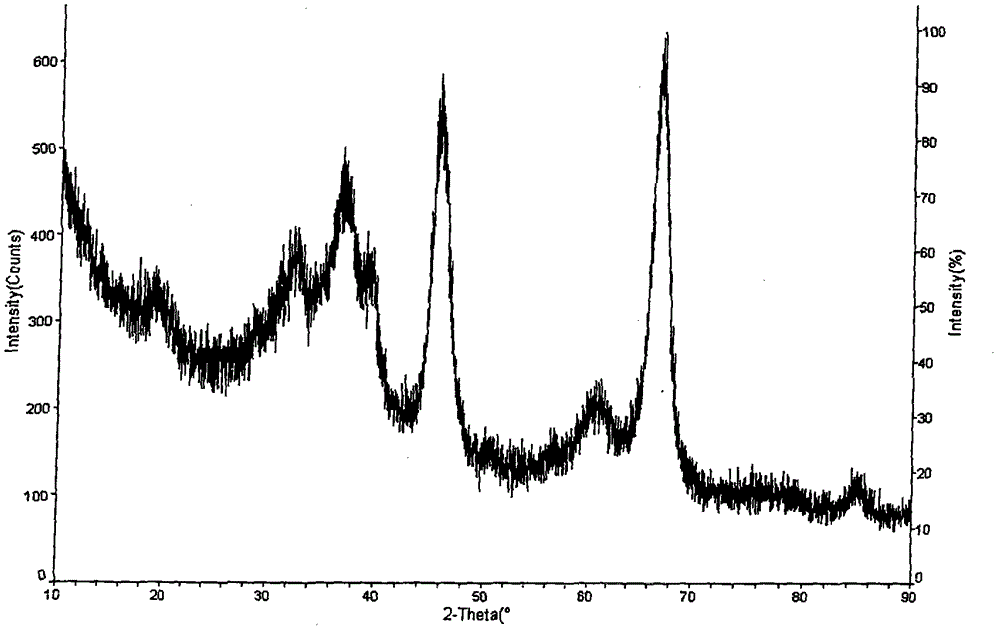

[0040] (4) The XRD analysis of the calcined product is δ phase image 3 , the specific surface area measured by the surface analyzer is 112.55m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com