Low-carbon alkane dehydrogenation catalyst and preparation method thereof

A technology for dehydrogenation catalysts and low-carbon alkanes, which is used in catalyst activation/preparation, hydrocarbons, hydrocarbons, etc., which can solve the problems of limited loading of active components and limited carbon capacity, and achieve enhanced anti-accumulation. The effect of carbon capacity, carbon capacity enhancement, improvement of pore structure and surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

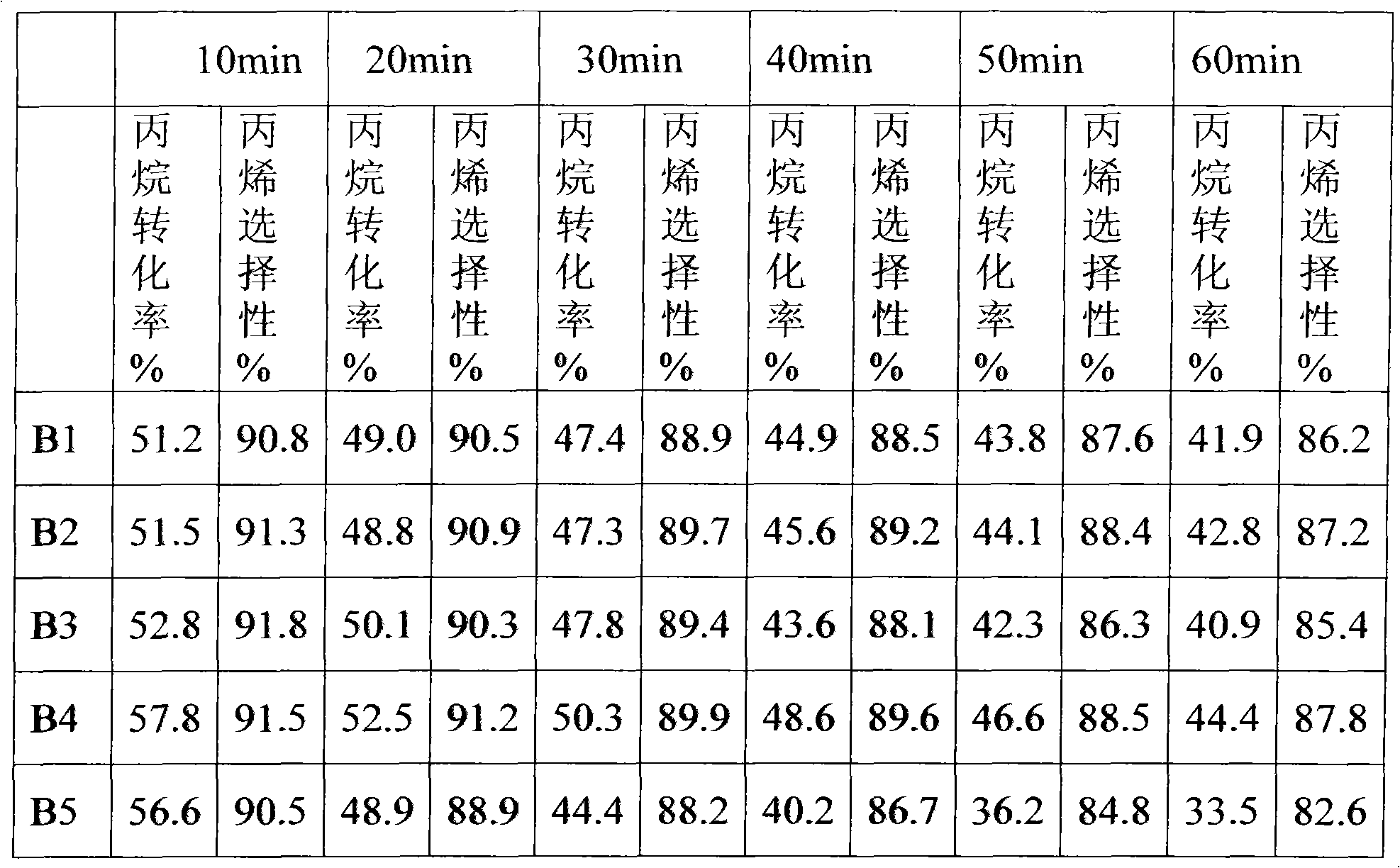

Examples

Embodiment 1

[0024] (1) Weigh 75.03gCr(NO 3 ) 3 ·9H 2 O is dissolved in deionized water and stirred fully to prepare 18.0% (weight concentration) Cr(NO 3 ) 3 Aqueous solution.

[0025] (2) Prepare 3.86% (weight concentration) KNO 3 Aqueous solution.

[0026] (3) Combine 55g pseudo-boehmite, 2.2g bentonite and 28.92g step (1) the prepared Cr(NO 3 ) 3 The aqueous solution is fully mixed and kneaded to form a plastic body and then extruded into a small ball. Then, it was dried at 120°C for 3 hours, and the dried sample was placed in a high-temperature furnace, heated to 280°C at a rate of 2°C / min, and kept at a constant temperature for 1 hour. Then the temperature is increased to 500°C at a rate of 2°C / min, and the temperature is kept constant for 3 hours. Finally, it was raised to 620°C at a rate of 2°C / min, and baked at a constant temperature for 2 hours. Finally, it is calcined at 760°C for 4 hours in an atmosphere of 20% (volume) water and 80% (volume) air to prepare carrier A1, in which Cr ...

Embodiment 2

[0029] (1) Weigh 117.5gCrO 3 (Purity 99.8%) Dissolve in deionized water and stir well to prepare 47.0% (weight concentration) CrO 3 Aqueous solution.

[0030] (2) Prepare 3.86% (weight concentration) KNO 3 Aqueous solution.

[0031] (3) Combine 55g pseudo-boehmite, 2.2g bentonite and 4.19g CrO prepared in step (1) 3 The aqueous solution is fully mixed and kneaded to form a plastic body and then extruded into a small ball. Then, it was dried at 100°C for 5 hours, and the dried sample was placed in a high-temperature furnace, heated to 260°C at a rate of 2°C / min, and kept at a constant temperature for 3 hours. Then the temperature is increased to 530°C at a rate of 2°C / min, and the temperature is kept constant for 3 hours. Finally, it was raised to 640°C at a rate of 2°C / min, and baked at a constant temperature for 2 hours. Finally, it is calcined at 720°C for 3 hours in an atmosphere of 30% water (volume) and 70% (volume) air to prepare carrier A2, in which Cr 2 O 3 The weight con...

Embodiment 3

[0034] (1) Weigh 117.5gCrO 3 (Purity 99.8%) Dissolve in deionized water and stir well to prepare 47% (weight concentration) CrO 3 Aqueous solution.

[0035] (2) Prepare 3.86% (weight concentration) KNO 3 Aqueous solution.

[0036] (3) Combine 55g pseudo-boehmite, 2.2g bentonite and 2.09g step (1) the prepared CrO 3 The aqueous solution is fully mixed and kneaded to form a plastic body and then extruded into a small ball. Then, it was dried at 140°C for 2 hours, and the dried sample was placed in a high-temperature furnace, heated to 300°C at a rate of 2°C / min, and kept at a constant temperature for 1 hour. Then the temperature is increased to 480°C at a rate of 2°C / min, and the temperature is kept constant for 5 hours. Finally, it was raised to 620°C at a rate of 2°C / min, and baked at a constant temperature for 4 hours. Finally, it is calcined at 700°C for 5 hours in an atmosphere of 15% water (volume) and 85% (volume) air to prepare carrier A3, in which Cr 2 O 3 The weight conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com