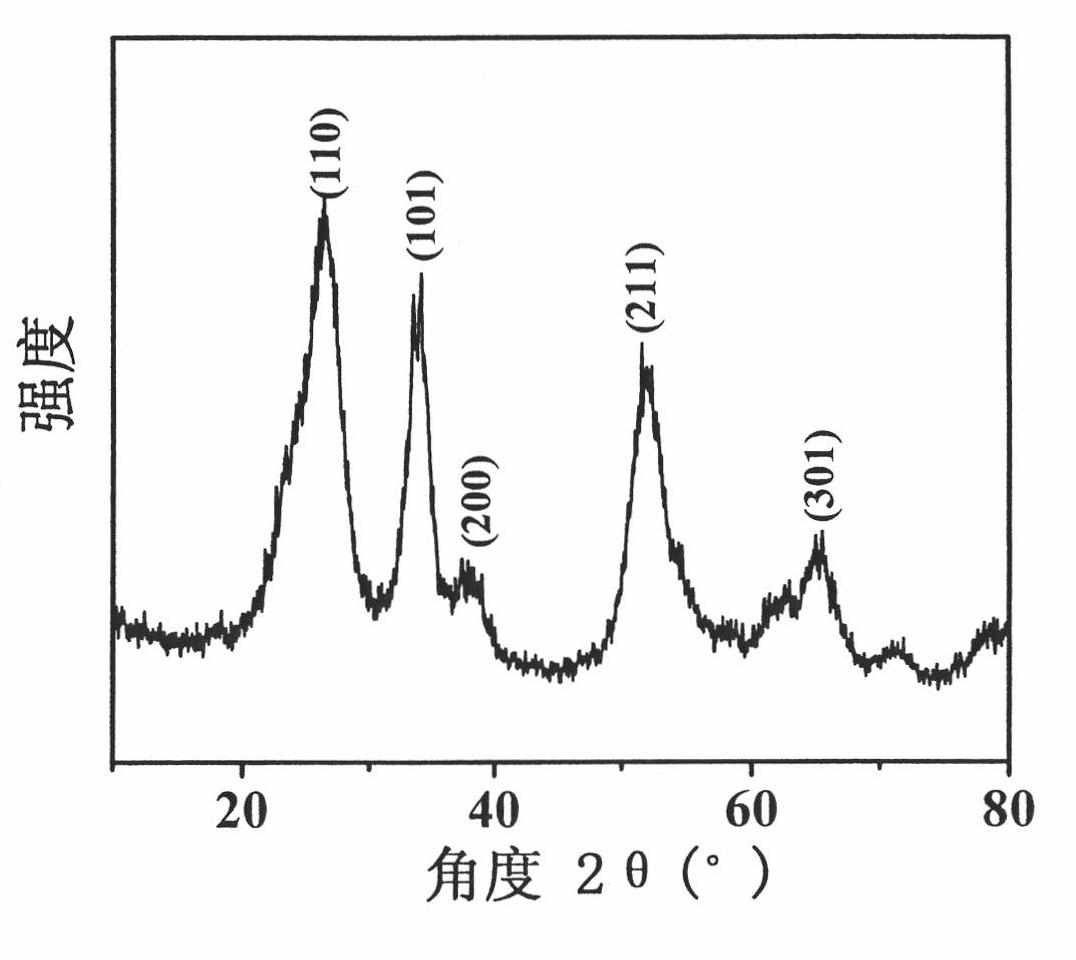

Preparation method of graphene-base tin dioxide composite anode material for lithium ion batteries

A tin dioxide, graphene-based technology, applied in the fields of material science and electrochemistry, can solve the problems of metal oxide negative electrode materials that are difficult to get practical application, loss of electrical contact between ions, electrode cracks and brittleness, etc., and achieve good electrochemical performance. performance, improved electrochemical performance, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] 1. Prepare raw graphite oxide nanosheets according to the prior art (this technical method can refer to the document J.Am.Chem.Soc., 2008, 130(18), 5856-5857).

[0031] A certain amount of K 2 S 2 o 8 and P 2 o 5 Dissolve in concentrated sulfuric acid, add a certain amount of natural graphite after heating to 80°C, keep warm at 80°C for 4.5 hours, and then cool to room temperature; then dilute with deionized water and leave it overnight; then filter and wash, and put the obtained filter residue in Dry in a vacuum oven at 60°C; dissolve the dried filter residue in concentrated H 2 SO 4 , slowly add KMnO in ice bath 4 , stirred at 35°C for 2h; then diluted with deionized water, and slowly added 30% H 2 o 2 After filtering and washing, the washed product is dispersed in deionized water, and ultrasonically stripped to obtain graphite oxide nanosheets, which are centrifuged and dried for use.

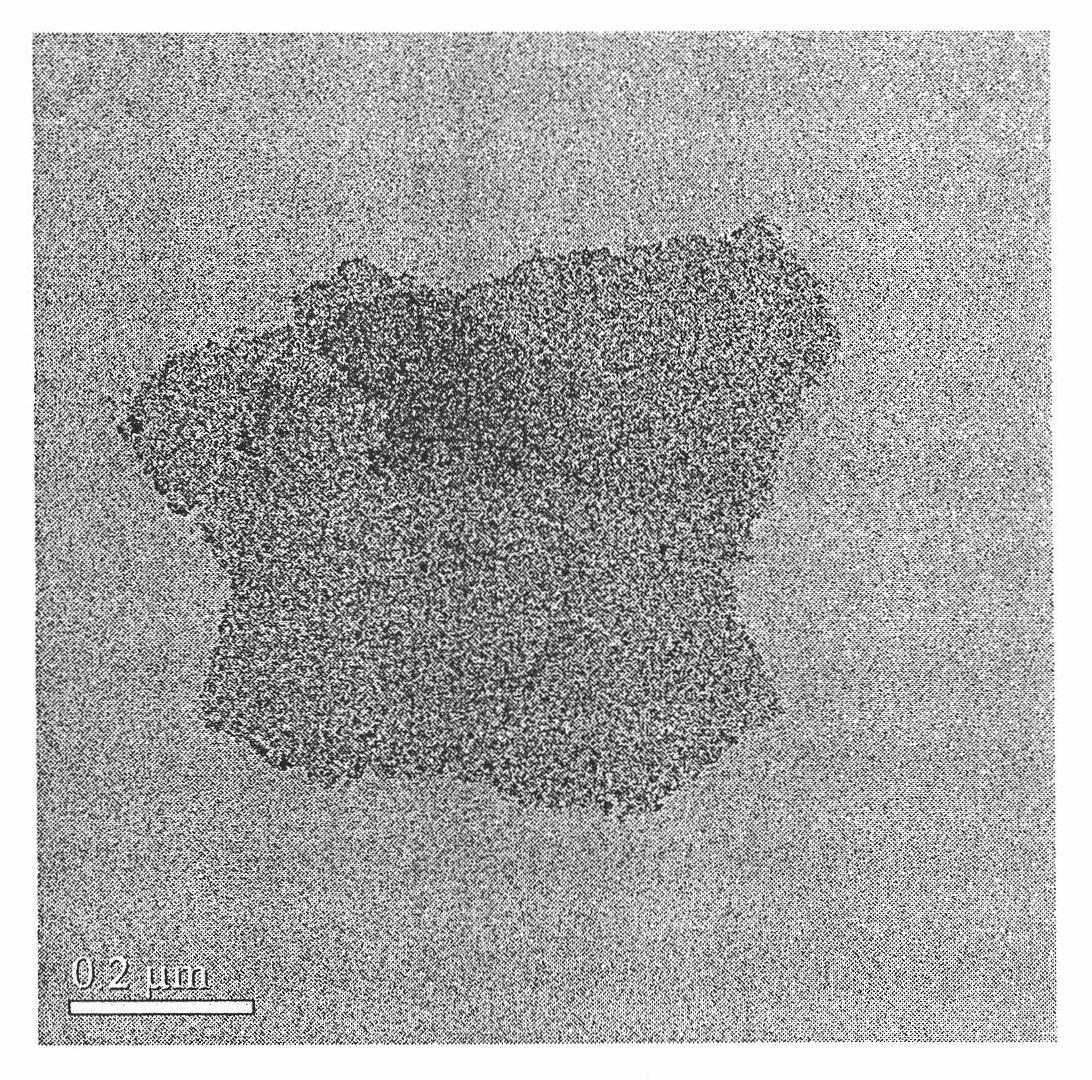

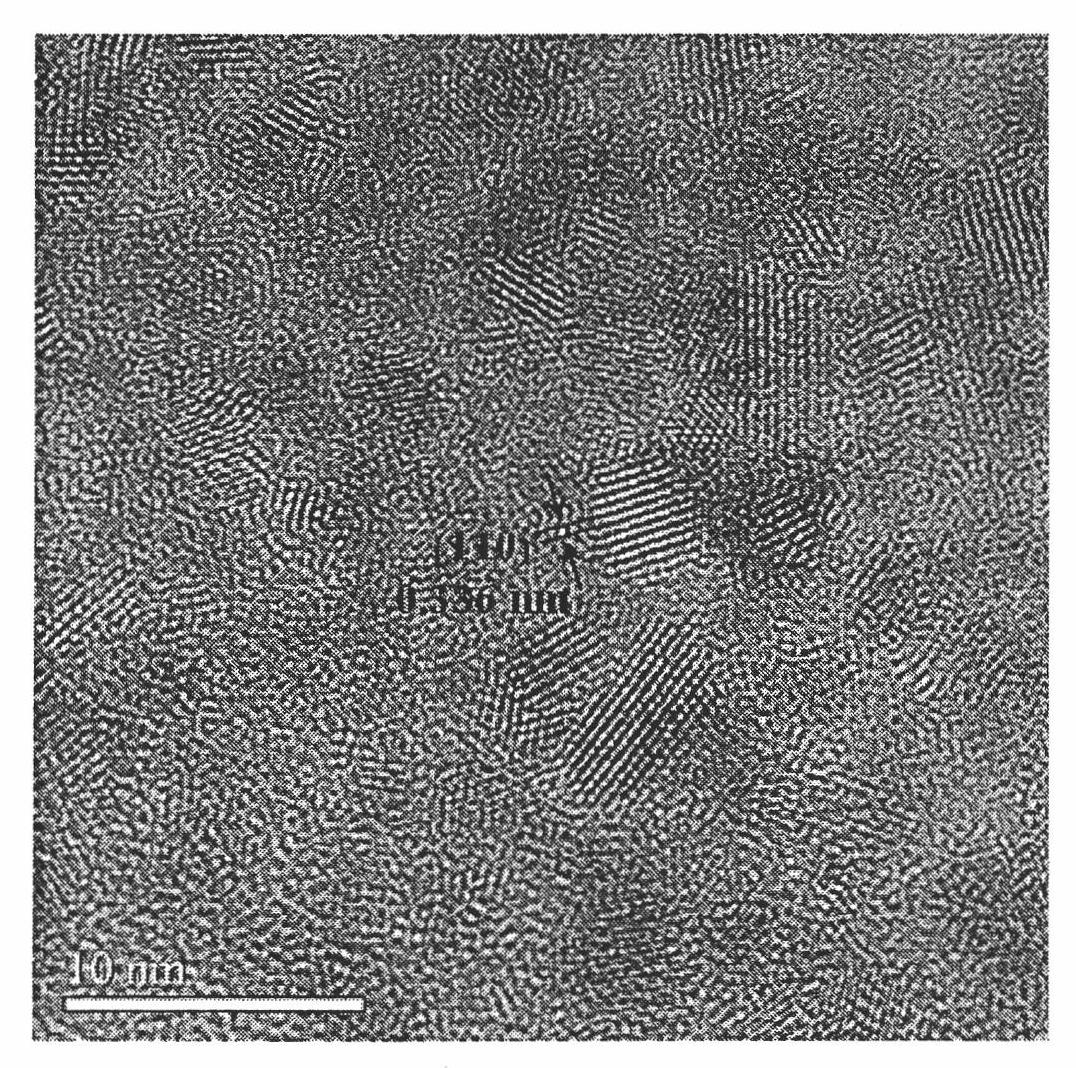

[0032] 2. Preparation of graphene-based tin dioxide composite lithium-io...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com